化工学报 ›› 2024, Vol. 75 ›› Issue (2): 715-726.DOI: 10.11949/0438-1157.20231213

• 材料化学工程与纳米技术 • 上一篇

张兆想1( ), 蔡茂坤1, 任志英1, 贾晓红2, 郭飞2(

), 蔡茂坤1, 任志英1, 贾晓红2, 郭飞2( )

)

收稿日期:2023-11-21

修回日期:2024-01-09

出版日期:2024-02-25

发布日期:2024-04-10

通讯作者:

郭飞

作者简介:张兆想(1991—),男,博士,副教授,zhangzxpro@126.com

基金资助:

Zhaoxiang ZHANG1( ), Maokun CAI1, Zhiying REN1, Xiaohong JIA2, Fei GUO2(

), Maokun CAI1, Zhiying REN1, Xiaohong JIA2, Fei GUO2( )

)

Received:2023-11-21

Revised:2024-01-09

Online:2024-02-25

Published:2024-04-10

Contact:

Fei GUO

摘要:

硫化是橡胶密封成型过程的关键工艺,对橡胶密封产品性能有决定性影响。目前橡胶行业多采用经验式硫化成型方法,对橡胶密封硫化演变过程缺乏理解,难以理论指导橡胶密封实际生产过程。针对这一制约橡胶密封质量提升的薄弱环节,开展了橡胶密封硫化成型过程数值仿真研究。基于胶料的积分型反应动力学模型与变物性参数传热控制方程,建立了橡胶制品热-化学耦合的瞬态仿真模型,实现了橡胶制品成型过程时变温度场及硫化程度场的实时预测,并通过试验验证了模型及求解方法的正确性。进而,仿真分析了典型结构密封件的硫化过程,探讨了模具温度、胶料预热温度和温度波动行为对橡胶密封硫化成型过程的影响规律,最后为橡胶密封实际硫化生产提供了参考。

中图分类号:

张兆想, 蔡茂坤, 任志英, 贾晓红, 郭飞. 温度及其波动对橡胶密封硫化过程影响的仿真分析[J]. 化工学报, 2024, 75(2): 715-726.

Zhaoxiang ZHANG, Maokun CAI, Zhiying REN, Xiaohong JIA, Fei GUO. Numerical analysis of the effect of temperature and its fluctuations on the vulcanization process of rubber seals[J]. CIESC Journal, 2024, 75(2): 715-726.

| 参数 | 数值/公式(160~185℃) |

|---|---|

| Ea /R | 16606.73 |

| h(α) | |

| h′(α) |

表1 EPDM-60橡胶热硫化期反应动力学模型参数

Table 1 Parameters of the reaction kinetics model for EPDM-60 rubber during vulcanization period

| 参数 | 数值/公式(160~185℃) |

|---|---|

| Ea /R | 16606.73 |

| h(α) | |

| h′(α) |

| 参数 | 关系式 |

|---|---|

| 比定压热容/(J/(kg·K)) | |

| 热导率/(W/(m·K)) |

表2 EPDM-60热物性参数与硫化程度及温度间关系式

Table 2 Relationship between EPDM-60 thermophysical parameters and degree of vulcanization and temperature

| 参数 | 关系式 |

|---|---|

| 比定压热容/(J/(kg·K)) | |

| 热导率/(W/(m·K)) |

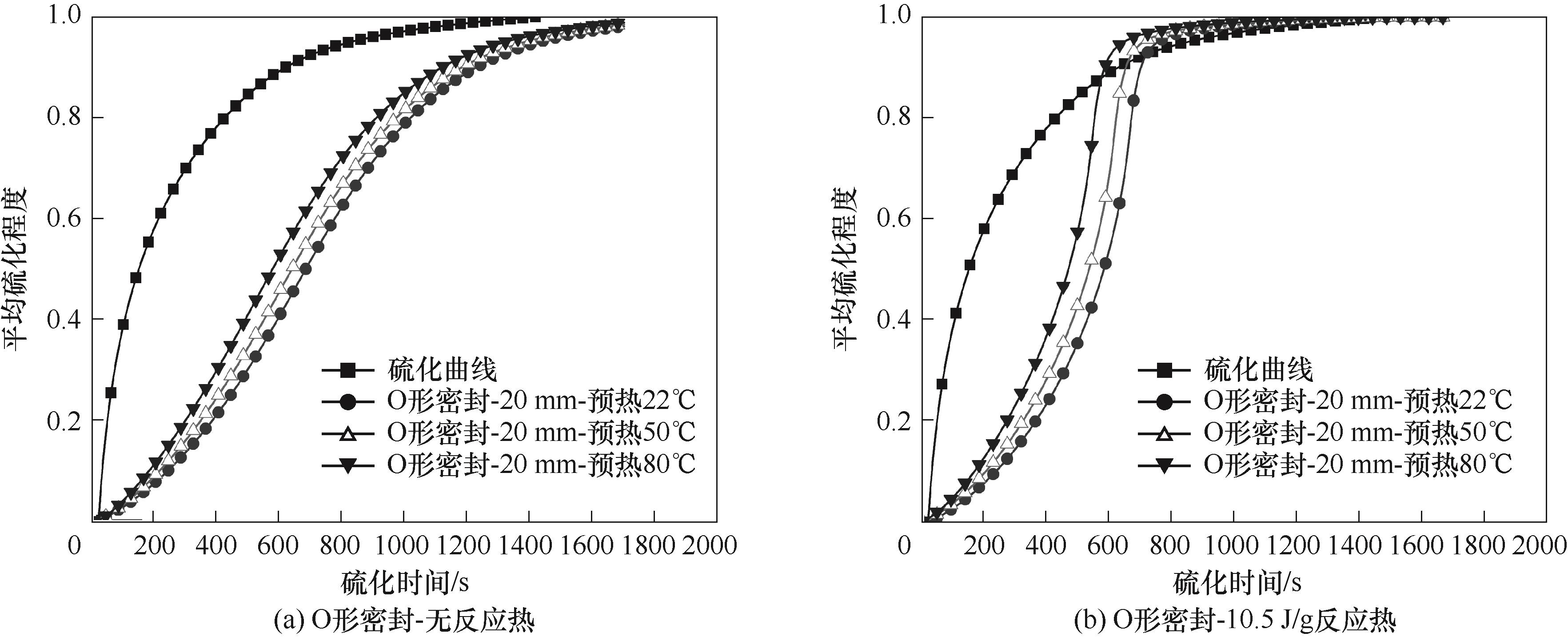

图11 不同预热温度下尺寸20 mm的密封件在175℃下硫化过程对比

Fig.11 Comparison of vulcanization process of seals with a size of 20 mm at 175℃ with different preheating temperatures

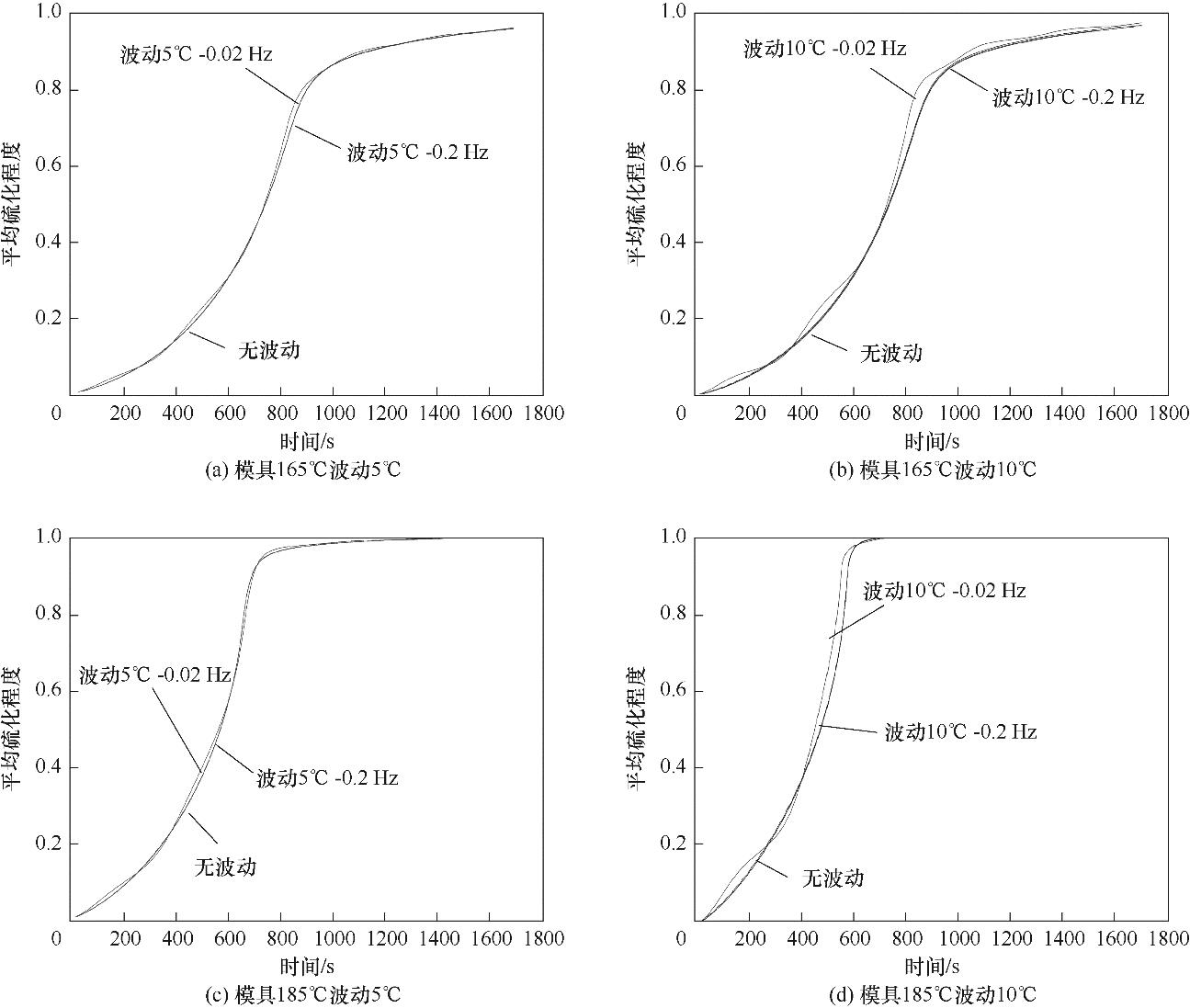

图14 截面直径5 mm的O形密封件在不同温度波动情况下的硫化情况

Fig.14 Vulcanization of O-ring seals with a cross-sectional diameter of 5 mm under different temperature fluctuations

图15 截面直径20 mm的O形密封件在不同温度波动情况下的硫化情况

Fig.15 Vulcanization of O-ring seals with a cross-sectional diameter of 20 mm under different temperature fluctuations

| 1 | 彭旭东, 王玉明, 黄兴, 等. 密封技术的现状与发展趋势[J]. 液压气动与密封, 2009, 29(4): 4-11. |

| Peng X D, Wang Y M, Huang X, et al. State-of-the-art and future development of sealing technology[J]. Hydraulics Pneumatics & Seals, 2009, 29(4): 4-11. | |

| 2 | 黄兴, 郭飞, 叶素娟, 等. 橡塑密封技术发展现状与趋势[J]. 润滑与密封, 2020, 45(6): 1-6, 21. |

| Huang X, Guo F, Ye S J, et al. Research status and development trend of rubber and plastic sealing technology[J]. Lubrication Engineering, 2020, 45(6): 1-6, 21. | |

| 3 | 张妙恬, 李德才, 索双富. 橡塑往复密封技术的研究现状与发展趋势[J]. 液压气动与密封, 2021, 41(3): 1-5. |

| Zhang M T, Li D C, Suo S F. Research and development trend of rubber reciprocating sealing technology[J]. Hydraulics Pneumatics & Seals, 2021, 41(3): 1-5. | |

| 4 | Limrungruengrat S, Chaikittiratana A, Pornpeerakeat S, et al. Thermo-mechanical finite element simulation and validation of rubber curing process[J]. Journal of Mechanical Science and Technology, 2022, 36(6): 3039-3046. |

| 5 | Zhang Z X, Jia X H, Guo F, et al. Effect of vulcanization on the tribological behavior and sealing performance of EPDM seals: experimentation and simulation[J]. Tribology International, 2021, 164: 107219. |

| 6 | Zhang Z X, Guo F, Ke Y C, et al. Effect of vulcanization on deformation behavior of rubber seals: thermal-mechanical-chemical coupling model, numerical studies, and experimental validation[J]. Materials & Design, 2022, 224: 111314. |

| 7 | Milani G, Milani F. A new simple numerical model based on experimental scorch curve data fitting for the interpretation of sulphur vulcanization[J]. Journal of Mathematical Chemistry, 2010, 48(3): 530-557. |

| 8 | Milani G, Milani F. A numerical model for the optimal vulcanization of 2D polar rubber compounds using microwaves[J]. Macromolecular Theory and Simulations, 2009, 18(6): 336-354. |

| 9 | Khimi S R, Pickering K L. A new method to predict optimum cure time of rubber compound using dynamic mechanical analysis[J]. Journal of Applied Polymer Science, 2014, 131(6): 40008. |

| 10 | Traintinger M, Kerschbaumer R C, Hornbachner M, et al. Investigation on strategies for optimizing process definition in rubber processing: a study on mechanical and chemical properties of vulcanizates as basis for the development of a new calculation model for quality prediction[J]. Journal of Applied Polymer Science, 2024, 141(6): e54901. |

| 11 | 张建, 唐文献, 王国林, 等. 一种橡胶硫化有限元分析方法[J]. 橡胶工业, 2012, 59(7): 401-407. |

| Zhang J, Tang W X, Wang G L, et al. Finite element modeling of rubber curing process[J]. China Rubber Industry, 2012, 59(7): 401-407. | |

| 12 | 文将儒, 李凡珠, 杨海波, 等. 圆柱形橡胶试样硫化过程的有限元分析与实验研究[J]. 中国塑料, 2020, 34(3): 40-47. |

| Wen J R, Li F Z, Yang H B, et al. Finite element simulation and experimental study of vulcanization process for cylindrical rubber specimens[J]. China Plastics, 2020, 34(3): 40-47. | |

| 13 | 张梦飞, 张玲, 李晓闯, 等. 厚壁橡胶制品非等温硫化过程模拟与实验研究[J]. 化工学报, 2021, 72(4): 2065-2075. |

| Zhang M F, Zhang L, Li X C, et al. Simulation and experimental study on non-isothermal vulcanization process of thick-walled rubber products[J]. CIESC Journal, 2021, 72(4): 2065-2075. | |

| 14 | Abhilash P M, Kannan K, Varkey B. Simulation of curing of a slab of rubber[J]. Materials Science and Engineering: B, 2010, 168(1/2/3): 237-241. |

| 15 | 赵树高, 张萍, 邓涛, 等. 轮胎硫化过程的数值模拟[J]. 轮胎工业, 2001, 21(10): 617-622. |

| Zhao S G, Zhang P, Deng T, et al. Numerical model of tire vulcanization process[J]. Tire Industry, 2001, 21(10): 617-622. | |

| 16 | Su B L, Wu J, Cui Z B, et al. Modeling of truck tire curing process by an experimental and numerical method[J]. Iranian Polymer Journal, 2015, 24(7): 583-593. |

| 17 | Zreid I, Behnke R, Kaliske M. ALE formulation for thermomechanical inelastic material models applied to tire forming and curing simulations[J]. Computational Mechanics, 2021, 67(6): 1543-1557. |

| 18 | Shi F, Dong X H. Three-dimension numerical simulation for vulcanization process based on unstructured tetrahedron mesh[J]. Journal of Manufacturing Processes, 2016, 22: 1-6. |

| 19 | Chen M M, Zhou Y, Shen Z X, et al. A crosslinking kinetic model considering reversion effect with verification and its application in thick rubber vulcanization process[J]. Polymer, 2023, 287: 126443. |

| 20 | Lubura J, Kojić P, Pavličević J, et al. A novel approach for simulation and optimization of rubber vulcanization[J]. Polymers, 2023, 15(7): 1750. |

| 21 | Likozar B, Krajnc M. A study of heat transfer during molding of elastomers[J]. Chemical Engineering Science, 2008, 63(12): 3181-3192. |

| 22 | Cheheb Z, Mousseau P, Sarda A, et al. Thermal conductivity of rubber compounds versus the state of cure[J]. Macromolecular Materials and Engineering, 2012, 297(3): 228-236. |

| 23 | Shao Y R, Wang G F, Han Z J, et al. Vulcanization and stress analysis of heat vulcanizing bonding joints in fabric rubber seals[J]. Composite Structures, 2023, 319: 117180. |

| 24 | 郭飞, 张兆想, 宋炜, 等. 橡胶硫化过程数值模拟研究进展[J]. 化工学报, 2020, 71(8): 3393-3402. |

| Guo F, Zhang Z X, Song W, et al. Research progress in numerical simulation of rubber vulcanization[J]. CIESC Journal, 2020, 71(8): 3393-3402. | |

| 25 | Wang D H, Dong Q, Jia Y X. Mathematical modelling and numerical simulation of the non-isothermal in-mold vulcanization of natural rubber[J]. Chinese Journal of Polymer Science, 2015, 33(3): 395-403. |

| 26 | Rafei M, Ghoreishy M H R, Naderi G. Development of an advanced computer simulation technique for the modeling of rubber curing process[J]. Computational Materials Science, 2009, 47(2): 539-547. |

| 27 | Gong L H, Yang H, Ke Y C, et al. Investigation on vulcanization degree and residual stress on fabric rubber composites[J]. Composite Structures, 2019, 209: 472-480. |

| 28 | Zhang Z X, Guo F, Song W, et al. Empirical correction of kinetic model for polymer thermal reaction process based on first order reaction kinetics[J]. Chinese Journal of Chemical Engineering, 2021, 38: 132-144. |

| 29 | Zhang Z X, Jia X H, Guo F, et al. Numerical analysis of heat transfer and chemical reaction coupling in the rubber seal vulcanization process[J]. Rubber Chemistry and Technology, 2022, 95(2): 342-358. |

| 30 | ABAQUS Inc. ABAQUS Analysis User's Manual[M]. USA: Dassault Systemes Simulia Corp., 2011. |

| [1] | 王学云, 郁肖兵, 彭万旺, 沈岩松. 熔渣气化炉喷嘴燃烧区行为的数值模拟研究[J]. 化工学报, 2024, 75(2): 659-674. |

| [2] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [3] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [4] | 张蒙蒙, 颜冬, 沈永峰, 李文翠. 电解液类型对双离子电池阴阳离子储存行为的影响[J]. 化工学报, 2023, 74(7): 3116-3126. |

| [5] | 邵远哲, 赵忠盖, 刘飞. 基于共同趋势模型的非平稳过程质量相关故障检测方法[J]. 化工学报, 2023, 74(6): 2522-2537. |

| [6] | 李正涛, 袁志杰, 贺高红, 姜晓滨. 疏水界面上的NaCl液滴蒸发过程内环流调控机制研究[J]. 化工学报, 2023, 74(5): 1904-1913. |

| [7] | 禹进, 余彬彬, 蒋新生. 一种基于虚拟组分的燃烧调控化学作用量化及分析方法研究[J]. 化工学报, 2023, 74(3): 1303-1312. |

| [8] | 刘世君, 郑安庆, 陈晓丽, 付娟, 苏秋成. 纤维素增强环氧树脂复合材料热解特性研究[J]. 化工学报, 2023, 74(12): 4968-4978. |

| [9] | 刘宗鹏, 胡少剑, 张宇宁, 马玲, 李磊, 武本成, 朱建华. 复合型多元醇酯合成反应的热力学分析及动力学研究[J]. 化工学报, 2023, 74(11): 4475-4486. |

| [10] | 章蕾, 宋孝辉, 张建庭, 屠美玲, 杨阿三. 氨甲环酸异构化过程的反应动力学研究[J]. 化工学报, 2023, 74(10): 4173-4181. |

| [11] | 陈睿哲, 刘永峰, 殷晨阳, 王龙, 张璐, 宋金瓯. 1-硝基丙烷引发正己烷热解的机理研究[J]. 化工学报, 2023, 74(10): 4319-4329. |

| [12] | 魏进家, 刘蕾, 杨小平. 面向高热流电子器件散热的环路热管研究进展[J]. 化工学报, 2023, 74(1): 60-73. |

| [13] | 陈晨, 杨倩, 陈云, 张睿, 刘冬. 不同氧浓度下煤挥发分燃烧的化学动力学研究[J]. 化工学报, 2022, 73(9): 4133-4146. |

| [14] | 陈玉弓, 陈昊, 黄耀松. 基于分子反应动力学模拟的六甲基二硅氧烷热解机理研究[J]. 化工学报, 2022, 73(7): 2844-2857. |

| [15] | 魏琳, 郭剑, 廖梓豪, Dafalla Ahmed Mohmed, 蒋方明. 空气流量对空冷燃料电池电堆性能的影响研究[J]. 化工学报, 2022, 73(7): 3222-3231. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号