化工学报 ›› 2024, Vol. 75 ›› Issue (8): 2960-2969.DOI: 10.11949/0438-1157.20240231

收稿日期:2024-03-01

修回日期:2024-06-29

出版日期:2024-08-25

发布日期:2024-08-21

通讯作者:

白博峰

作者简介:赵帅琪(1997—),男,博士研究生,shuaiqizhao@stu.xjtu.edu.cn

基金资助:

Shuaiqi ZHAO( ), Rui ZHANG, Han HUANG, Kunpeng ZHAO, Bofeng BAI(

), Rui ZHANG, Han HUANG, Kunpeng ZHAO, Bofeng BAI( )

)

Received:2024-03-01

Revised:2024-06-29

Online:2024-08-25

Published:2024-08-21

Contact:

Bofeng BAI

摘要:

水气转化是煤炭超临界水气化技术中关键的均相化学反应。然而,水气转化反应对煤颗粒孔隙内非均相气化反应的影响尚不清楚。通过三维数值模拟,研究了颗粒孔隙内部水气转化反应对不规则煤颗粒超临界水气化过程的作用机理。研究结果表明,孔隙内的水气转化反应掉了大量用于煤的非均相气化反应的超临界水,降低了颗粒的气化反应速率,同时大量生成二氧化碳并富集于颗粒孔隙中,减小了孔隙中超临界水的扩散系数。定义了有效气化因子以定量表征水气转化反应对颗粒气化的抑制程度,发现了该抑制作用随颗粒粒径的增大而增强,且由于该抑制作用而增加的颗粒气化反应时间与有效气化因子呈简单对数关系。

中图分类号:

赵帅琪, 张瑞, 黄瀚, 赵昆鹏, 白博峰. 水气转化对超临界水煤气化的抑制特性[J]. 化工学报, 2024, 75(8): 2960-2969.

Shuaiqi ZHAO, Rui ZHANG, Han HUANG, Kunpeng ZHAO, Bofeng BAI. Inhibition of water-gas shift reaction on coal gasification in supercritical water[J]. CIESC Journal, 2024, 75(8): 2960-2969.

| 算例 | 颗粒当量 直径/mm | 水气转化反应 | 算例 | 颗粒当量 直径/mm | 水气转化反应 |

|---|---|---|---|---|---|

| Case1 | 0.2 | 考虑 | Case10 | 0.2 | 忽略 |

| Case2 | 0.4 | 考虑 | Case11 | 0.4 | 忽略 |

| Case3 | 0.6 | 考虑 | Case12 | 0.6 | 忽略 |

| Case4 | 0.8 | 考虑 | Case13 | 0.8 | 忽略 |

| Case5 | 1.0 | 考虑 | Case14 | 1.0 | 忽略 |

| Case6 | 1.4 | 考虑 | Case15 | 1.4 | 忽略 |

| Case7 | 1.8 | 考虑 | Case16 | 1.8 | 忽略 |

| Case8 | 2.0 | 考虑 | Case17 | 2.0 | 忽略 |

| Case9 | 2.4 | 考虑 | Case18 | 2.4 | 忽略 |

表1 数值模拟算例设置

Table 1 Simulation case set-up

| 算例 | 颗粒当量 直径/mm | 水气转化反应 | 算例 | 颗粒当量 直径/mm | 水气转化反应 |

|---|---|---|---|---|---|

| Case1 | 0.2 | 考虑 | Case10 | 0.2 | 忽略 |

| Case2 | 0.4 | 考虑 | Case11 | 0.4 | 忽略 |

| Case3 | 0.6 | 考虑 | Case12 | 0.6 | 忽略 |

| Case4 | 0.8 | 考虑 | Case13 | 0.8 | 忽略 |

| Case5 | 1.0 | 考虑 | Case14 | 1.0 | 忽略 |

| Case6 | 1.4 | 考虑 | Case15 | 1.4 | 忽略 |

| Case7 | 1.8 | 考虑 | Case16 | 1.8 | 忽略 |

| Case8 | 2.0 | 考虑 | Case17 | 2.0 | 忽略 |

| Case9 | 2.4 | 考虑 | Case18 | 2.4 | 忽略 |

图1 超临界水气化过程中煤颗粒内部非均相反应锋面形貌、流体组分分布、温度分布和孔隙率分布随颗粒转化率的演化

Fig.1 Evolution of heterogeneous reaction front morphology, fluid species distributions, temperature distribution and porosity distribution inside the coal particle during the SCWG

图2 分别考虑与忽略颗粒孔隙内部水气转化反应时,气化反应的对比和组分扩散的对比

Fig.2 Comparison of heterogeneous reaction as well as comparison of species diffusion in the SCWG with or without the intrapore WGSR

图3 超临界水气化过程中不同粒径颗粒的传热速率、传质速率、气化反应速率和有效因子随颗粒转化率的变化

Fig.3 Variation of heat transport rate, species diffusion rate, heterogeneous reaction rate and effectiveness factor with particle conversion of particles with different sizes

图4 分别考虑与忽略颗粒孔隙内部水气转化反应时,不同粒径颗粒到达85%转化率时的气化时间(tc1—考虑, tc2—忽略),不同粒径颗粒的有效气化因子

Fig.4 Gasification time (when particle conversion X = 85%) of particles with different sizes in the SCWG with or without intrapore WGSR (tc1—with, tc2—without), effective gasification factor of particles with different sizes

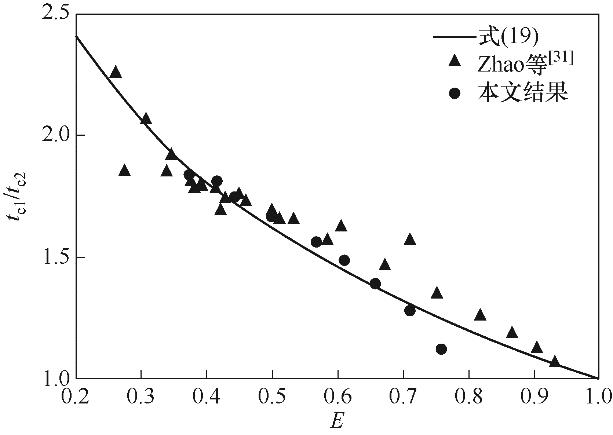

图5 分别考虑与忽略颗粒孔隙内部水气转化反应时,颗粒转化率到达85%时的气化时间之比随颗粒有效气化因子的变化(tc1—考虑, tc2—忽略)

Fig.5 Ratio of gasification time (when particle conversion X = 85%) of the SCWG with and without intrapore WGSR versus effective gasification factor of particles (tc1—with, tc2—without)

| 1 | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902, 3980. |

| Chen Z W, Wei J J, Zhang Y M. System integration and energy conversion mechanism of the power technology with integrated supercritical water gasification of coal and SOFC[J]. CIESC Journal, 2023, 74(9): 3888-3902, 3980. | |

| 2 | Jin H, Zhang B W, Fan C, et al. A perspective on multi-component resistance analogy analysis for process intensification: taking supercritical water gasification of coal as an example[J]. Chemical Engineering and Processing - Process Intensification, 2022, 174: 108859. |

| 3 | Guo L J, Ou Z S, Liu Y, et al. Technological innovations on direct carbon mitigation by ordered energy conversion and full resource utilization[J]. Carbon Neutrality, 2022, 1(1): 4. |

| 4 | Zhang R, Zhao S Q, Sun C Z, et al. Particle morphology evolution and its enhancement for lignite gasification in supercritical water[J]. Industrial & Engineering Chemistry Research, 2023, 62(40): 16268-16279. |

| 5 | Jin H, Fan C, Wei W W, et al. Evolution of pore structure and produced gases of Zhundong coal particle during gasification in supercritical water[J]. The Journal of Supercritical Fluids, 2018, 136: 102-109. |

| 6 | Fan C, Jin H, Shang F, et al. Study on the surface structure development of porous char particles in catalytic supercritical water gasification process[J]. Fuel Processing Technology, 2019, 193: 73-81. |

| 7 | Ge Z W, Guo L J, Jin H. Hydrogen production by non-catalytic partial oxidation of coal in supercritical water: the study on reaction kinetics[J]. International Journal of Hydrogen Energy, 2017, 42(15): 9660-9666. |

| 8 | 葛庆仁. 气固反应动力学[M]. 北京: 原子能出版社, 1991. |

| Ge Q R. Gas-Solid Reaction Kinetics[M]. Beijing: Atomic Press, 1991. | |

| 9 | 孙康. 宏观反应动力学及其解析方法[M]. 北京: 冶金工业出版社, 1998. |

| Sun K. Macroscopic Reaction Kinetics and its Analytical Method[M]. Beijing: Metallurgical Industry Press, 1998. | |

| 10 | Yagi T, Ono Y. A method of analysis for reduction of iron oxide in mixed-control kinetics[J]. Transactions of the Iron and Steel Institute of Japan, 1968, 8(6): 377-381. |

| 11 | Jin H, Zhao X, Guo S M, et al. Investigation on linear description of the char conversion for the process of supercritical water gasification of Yimin lignite[J]. International Journal of Hydrogen Energy, 2016, 41(36): 16070-16076. |

| 12 | Zhang X S, Zhu Z M, Wen G C, et al. Study on gas desorption and diffusion kinetic behavior in coal matrix using a modified shrinking core model[J]. Journal of Petroleum Science and Engineering, 2021, 204: 108701. |

| 13 | Bhatia S K, Perlmutter D D. A random pore model for fluid-solid reactions(Ⅰ): Isothermal, kinetic control[J]. AIChE Journal, 1980, 26(3): 379-386. |

| 14 | Iwaszenko S, Howaniec N, Smoliński A. Determination of random pore model parameters for underground coal gasification simulation[J]. Energy, 2019, 166: 972-978. |

| 15 | Szekely J, Evans J W. A structural model for gas-solid reactions with a moving boundary[J]. Chemical Engineering Science, 1970, 25(6): 1091-1107. |

| 16 | Siddiqui H, Gupta A, Mahajani S M. Non-equimolar transient grain model for CO2-gasification of single biomass char pellet[J]. Fuel, 2021, 293: 120389. |

| 17 | Prasannan P C, Doraiswamy L K. Gas-solid reactions: experimental evaluation of the zone model[J]. Chemical Engineering Science, 1982, 37(6): 925-937. |

| 18 | Szekely J, Evans J W. A structural model for gas-solid reactions with a moving boundary(Ⅱ): The effect of grain size, porosity and temperature on the reaction of porous pellets[J]. Chemical Engineering Science, 1971, 26(11): 1901-1913. |

| 19 | Wang J J, Hu S W, Liu X H. Kinetic modelling and experimental validation of single large particle combustion of coal char[J]. Chemical Engineering Journal, 2022, 450: 138227. |

| 20 | Ishida M, Wen C Y. Comparison of zone-reaction model and unreacted-core shrinking model in solid-gas reactions(Ⅰ): Isothermal analysis[J]. Chemical Engineering Science, 1971, 26(7): 1031-1041. |

| 21 | Gil M V, Riaza J, Álvarez L, et al. Kinetic models for the oxy-fuel combustion of coal and coal/biomass blend chars obtained in N2 and CO2 atmospheres[J]. Energy, 2012, 48(1): 510-518. |

| 22 | Chen L, Kang Q J, Carey B, et al. Pore-scale study of diffusion-reaction processes involving dissolution and precipitation using the lattice Boltzmann method[J]. International Journal of Heat and Mass Transfer, 2014, 75: 483-496. |

| 23 | Kang Q J, Lichtner P C, Viswanathan H S, et al. Pore scale modeling of reactive transport involved in geologic CO2 sequestration[J]. Transport in Porous Media, 2010, 82(1): 197-213. |

| 24 | Chen L, Kang Q J, Tang Q, et al. Pore-scale simulation of multicomponent multiphase reactive transport with dissolution and precipitation[J]. International Journal of Heat and Mass Transfer, 2015, 85: 935-949. |

| 25 | Alhashmi Z, Blunt M J, Bijeljic B. The impact of pore structure heterogeneity, transport, and reaction conditions on fluid-fluid reaction rate studied on images of pore space[J]. Transport in Porous Media, 2016, 115(2): 215-237. |

| 26 | Liu M, Mostaghimi P. Numerical simulation of fluid-fluid-solid reactions in porous media[J]. International Journal of Heat and Mass Transfer, 2018, 120: 194-201. |

| 27 | Feng H F, Sun J L, Jin H, et al. Char suppression mechanism using recycled intermediate phenol in supercritical water gasification of coal[J]. Fuel, 2021, 305: 121441. |

| 28 | Ge Z W, Guo L J, Jin H. Catalytic supercritical water gasification mechanism of coal[J]. International Journal of Hydrogen Energy, 2020, 45(16): 9504-9511. |

| 29 | Sun J L, Feng H F, Xu J L, et al. Investigation of the conversion mechanism for hydrogen production by coal gasification in supercritical water[J]. International Journal of Hydrogen Energy, 2021, 46(17): 10205-10215. |

| 30 | Ou Z S, Guo L J, Chi C, et al. Fully resolved direct numerical simulation of single coal particle gasification in supercritical water[J]. Fuel, 2022, 329: 125474. |

| 31 | Zhao S Q, Zhang R, Huang H, et al. Intrapore water-gas shift reaction inhibits coal gasification in supercritical water[J]. Chemical Engineering Science, 2024, 289: 119843. |

| 32 | Wang H, Li Z S, Fan X X, et al. Rate-equation-based grain model for the carbonation of CaO with CO2 [J]. Energy & Fuels, 2017, 31(12): 14018-14032. |

| 33 | Wesenauer F, Jordan C, Pichler M, et al. An unreacted shrinking core model serves for predicting combustion rates of organic additives in clay bricks[J]. Energy & Fuels, 2020, 34(12): 16679-16692. |

| 34 | Kay W. Gases and vapors at high temperature and pressure-density of hydrocarbon[J]. Industrial & Engineering Chemistry, 1936, 28(9): 1014-1019. |

| [1] | 王成秀, 宋大山, 李之辉, 杨潇, 蓝兴英, 高金森, 徐春明. Geldart C类脱硫灰颗粒在环流耦合提升管内稳定流动特性[J]. 化工学报, 2024, 75(4): 1485-1496. |

| [2] | 徐安冉, 刘凯, 王娜, 赵振宇, 李洪, 高鑫. 强吸波催化剂协同微波能强化果糖脱水制5-羟甲基糠醛[J]. 化工学报, 2024, 75(4): 1565-1577. |

| [3] | 张家琳, 徐大为, 高越, 李新刚. 泡沫镍负载CeO2改性CuO催化剂的碳烟燃烧性能研究[J]. 化工学报, 2024, 75(1): 312-321. |

| [4] | 朱风, 陈凯琳, 黄小凤, 鲍银珠, 李文斌, 刘嘉鑫, 吴玮强, 高王伟. KOH改性电石渣脱除羰基硫的性能研究[J]. 化工学报, 2023, 74(6): 2668-2679. |

| [5] | 张梦波, 楼琳瑾, 冯艺荣, 郑雨婷, 张浩淼, 王靖岱, 阳永荣. 烷基铝氧烷合成技术研究进展[J]. 化工学报, 2023, 74(2): 525-534. |

| [6] | 蔡骁, 张龙凯, 王金华, 黄佐华. 单颗粒铁粉燃烧特性及产物形貌分析[J]. 化工学报, 2023, 74(11): 4702-4709. |

| [7] | 李晨亚, 刘捷, 王建芝, 刘艳萍, 林笑, 喻发全. 螺旋微通道反应器贝克曼重排制备己内酰胺[J]. 化工学报, 2023, 74(10): 4182-4190. |

| [8] | 陈余, 郑晓妍, 赵辉, 王二强, 李杰, 李春山. Pickering乳液催化非均相羟醛缩合反应研究[J]. 化工学报, 2023, 74(1): 449-458. |

| [9] | 周桓, 张梦丽, 郝晴, 吴思, 李杰, 徐存兵. 硫酸镁型光卤石转化钾盐镁矾的过程机制与动态规律[J]. 化工学报, 2022, 73(9): 3841-3850. |

| [10] | 陈昇, 王梦钶, 鲁波娜, 李秀峰, 刘岑凡, 刘梦溪, 范怡平, 卢春喜. 原料油汽化特性对催化裂化反应结焦过程影响的CFD模拟[J]. 化工学报, 2022, 73(7): 2982-2995. |

| [11] | 戚子豪, 钟文琪, 陈曦, 周冠文, 赵小亮, 辛美静, 陈翼, 朱永长. 基于混合建模的水泥生料分解过程动态特性研究[J]. 化工学报, 2022, 73(5): 2039-2051. |

| [12] | 王佳怡, 范垂钢, 李松庚. 碳氧官能团对煤焦低温还原NO的影响[J]. 化工学报, 2022, 73(5): 2140-2148. |

| [13] | 戴琼斌, 刘宏斌, 夏启斌, 周欣, 李忠. 一种新的颗粒炭材料的制备及其高效分离甲烷氮气性能[J]. 化工学报, 2021, 72(8): 4196-4203. |

| [14] | 李宇明, 刘梓烨, 张启扬, 王雅君, 崔国庆, 姜桂元, 贺德华. 氮掺杂碳材料的制备及其在催化领域中的应用[J]. 化工学报, 2021, 72(8): 3919-3932. |

| [15] | 娄锋炎, 尹佳滨, 段笑南, 王祁宁, 艾宁, 张吉松. 连续微反应加氢技术在脱保护反应中的应用[J]. 化工学报, 2021, 72(2): 761-771. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号