化工学报 ›› 2024, Vol. 75 ›› Issue (4): 1485-1496.DOI: 10.11949/0438-1157.20231197

王成秀( ), 宋大山, 李之辉, 杨潇, 蓝兴英(

), 宋大山, 李之辉, 杨潇, 蓝兴英( ), 高金森, 徐春明

), 高金森, 徐春明

收稿日期:2023-11-20

修回日期:2024-01-03

出版日期:2024-04-25

发布日期:2024-06-06

通讯作者:

蓝兴英

作者简介:王成秀(1983—),女,博士,副教授,cwang1277@cup.edu.cn

基金资助:

Chengxiu WANG( ), Dashan SONG, Zhihui LI, Xiao YANG, Xingying LAN(

), Dashan SONG, Zhihui LI, Xiao YANG, Xingying LAN( ), Jinsen GAO, Chunming XU

), Jinsen GAO, Chunming XU

Received:2023-11-20

Revised:2024-01-03

Online:2024-04-25

Published:2024-06-06

Contact:

Xingying LAN

摘要:

我国CO2的排放中70%来自工业领域,故工业过程的碳捕集对实现“双碳目标”十分关键。工业烟气中往往含有的硫氧化物会腐蚀设备并使后续脱碳等过程使用的催化剂中毒。因此,工业烟气的深度脱硫技术对后续的CO2捕集或提纯过程至关重要。循环流化床半干法烟气脱硫因具有脱硫效率高、无污染、停留时间可控等优点受到广泛关注。循环流化床脱硫工艺中作为脱硫剂的脱硫灰颗粒为典型Geldart C类颗粒。由于C类颗粒的强黏附性,其在循环流化床操作中容易结块,从而影响装置稳定运行。为了强化脱硫灰颗粒在循环流化床内的流动稳定性,提出了环流强化的耦合提升管反应器的概念,并自行设计搭建了一套导流筒内径100 mm、高度300 mm,外筒内径160 mm、高度760 mm,输送段内径75 mm、总高度12.6 m的环流耦合提升管。在Ug = 4 m/s、Gs = 45 kg/(m2·s), Ug = 7 m/s、Gs = 25 kg/(m2·s)的操作条件下,考察了环流段的压力分布、标准差以及功率谱密度。当环隙区气速为0.4 m/s时,环流流动能够实现稳定、连续的密相环流流动。在C类颗粒形成稳定流动基础上,讨论了环流耦合提升管内的流动特性分布规律,包括固含率和颗粒速度。实验发现,环流流动的设计可以强化C类颗粒的流动特性,大幅提高耦合反应器内C类颗粒脱硫灰固含率,并实现了C类颗粒循环流态化装置的稳定运行。同时,这些研究结果可以为C类颗粒新型循环流态化反应器设计提供参考。

中图分类号:

王成秀, 宋大山, 李之辉, 杨潇, 蓝兴英, 高金森, 徐春明. Geldart C类脱硫灰颗粒在环流耦合提升管内稳定流动特性[J]. 化工学报, 2024, 75(4): 1485-1496.

Chengxiu WANG, Dashan SONG, Zhihui LI, Xiao YANG, Xingying LAN, Jinsen GAO, Chunming XU. Stable flow characteristics of Geldart C particles of desulfurization ash in a loop-coupled riser[J]. CIESC Journal, 2024, 75(4): 1485-1496.

| Dimensionless radial position | Draft tube region | Annulus region | Transition region | Transmission region |

|---|---|---|---|---|

| R0/R | 0 | — | 0 | 0 |

| R1/R | 0.158 | — | 0.158 | 0.158 |

| R2/R | 0.382 | — | 0.382 | 0.382 |

| R3/R | 0.497 | — | 0.497 | 0.497 |

| R4/R | 0.590 | — | 0.590 | 0.590 |

| R5/R | — | 0.669 | 0.669 | 0.669 |

| R6/R | — | 0.741 | 0.741 | 0.741 |

| R7/R | — | 0.805 | 0.805 | 0.805 |

| R8/R | — | 0.866 | 0.866 | 0.866 |

| R9/R | — | 0.922 | 0.922 | 0.922 |

| R10/R | — | 0.974 | 0.974 | 0.974 |

表1 环流耦合反应器各区域无量纲径向位置

Table 1 Dimensionless radial position for each region of the loop-coupled reactor

| Dimensionless radial position | Draft tube region | Annulus region | Transition region | Transmission region |

|---|---|---|---|---|

| R0/R | 0 | — | 0 | 0 |

| R1/R | 0.158 | — | 0.158 | 0.158 |

| R2/R | 0.382 | — | 0.382 | 0.382 |

| R3/R | 0.497 | — | 0.497 | 0.497 |

| R4/R | 0.590 | — | 0.590 | 0.590 |

| R5/R | — | 0.669 | 0.669 | 0.669 |

| R6/R | — | 0.741 | 0.741 | 0.741 |

| R7/R | — | 0.805 | 0.805 | 0.805 |

| R8/R | — | 0.866 | 0.866 | 0.866 |

| R9/R | — | 0.922 | 0.922 | 0.922 |

| R10/R | — | 0.974 | 0.974 | 0.974 |

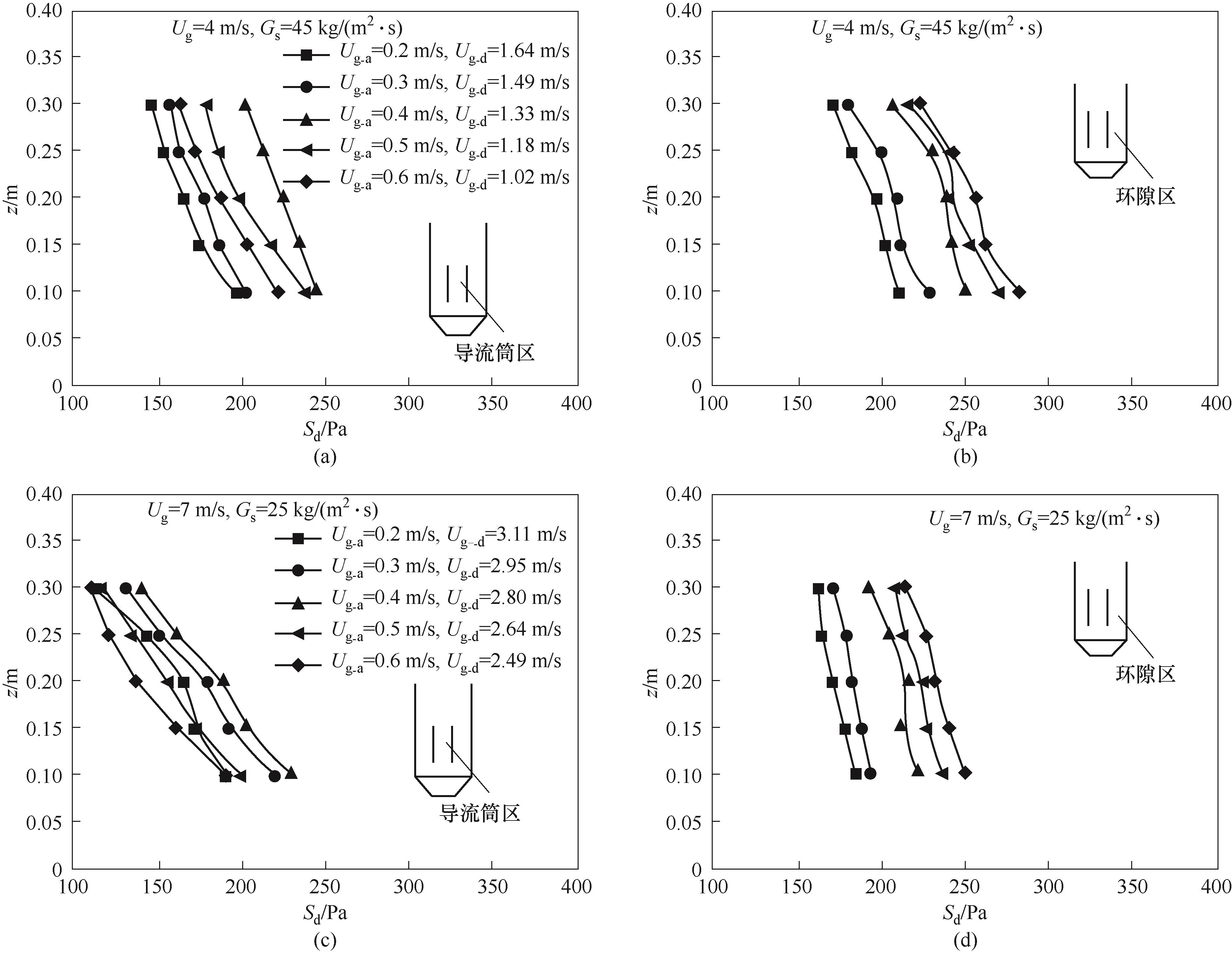

图4 导流筒区和环隙区的压力标准偏差随环隙区表观气速变化的情况

Fig.4 The variation of the pressure standard deviation in the loop section with the apparent gas velocity in the draft tube region and annulus region

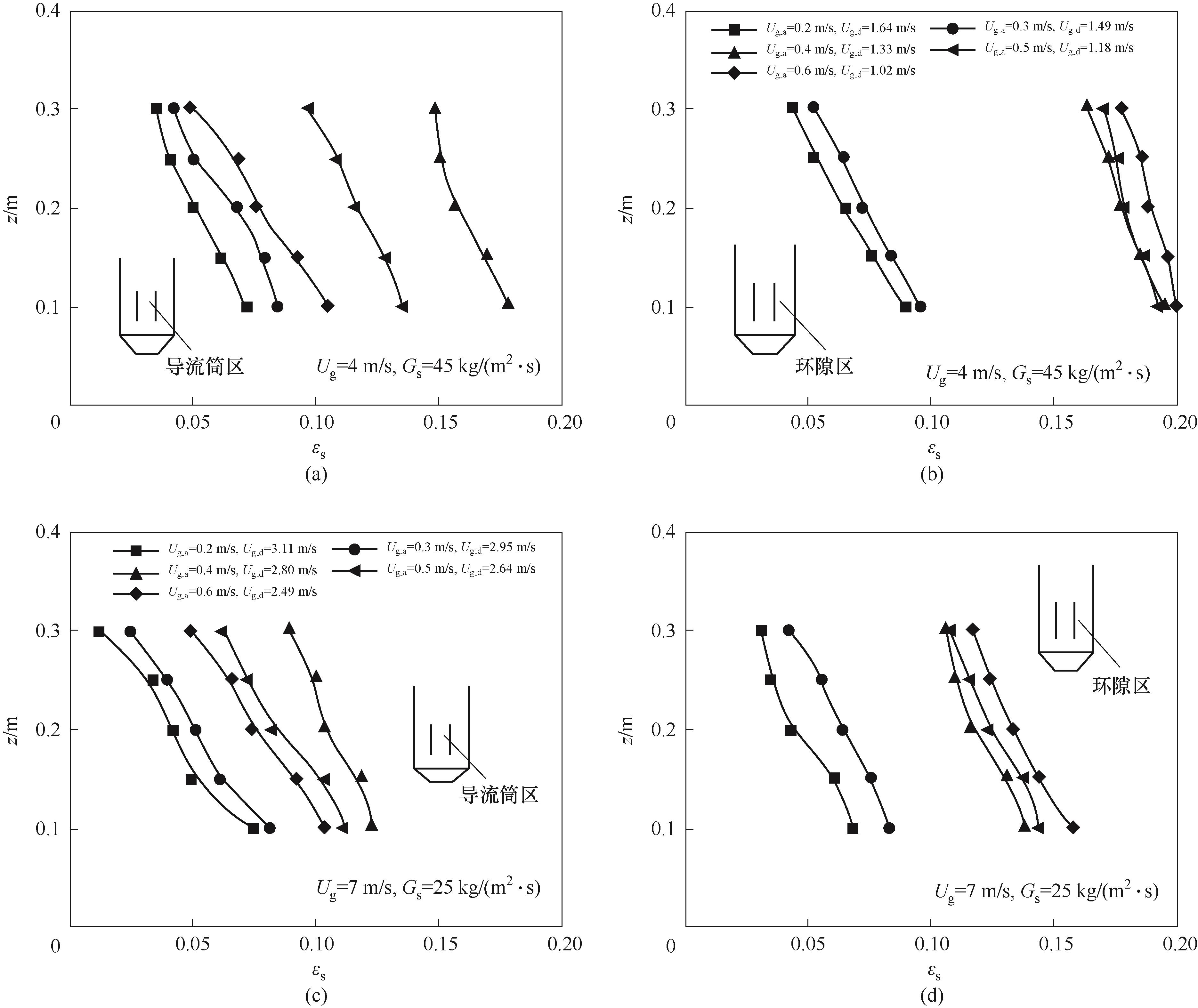

图6 各轴向位置导流筒区与环隙区脱硫灰颗粒固含率的分布

Fig.6 Distribution of solid holdup of desulphurized ash particles in the draft tube region and annulus region at each axial position of loop zone

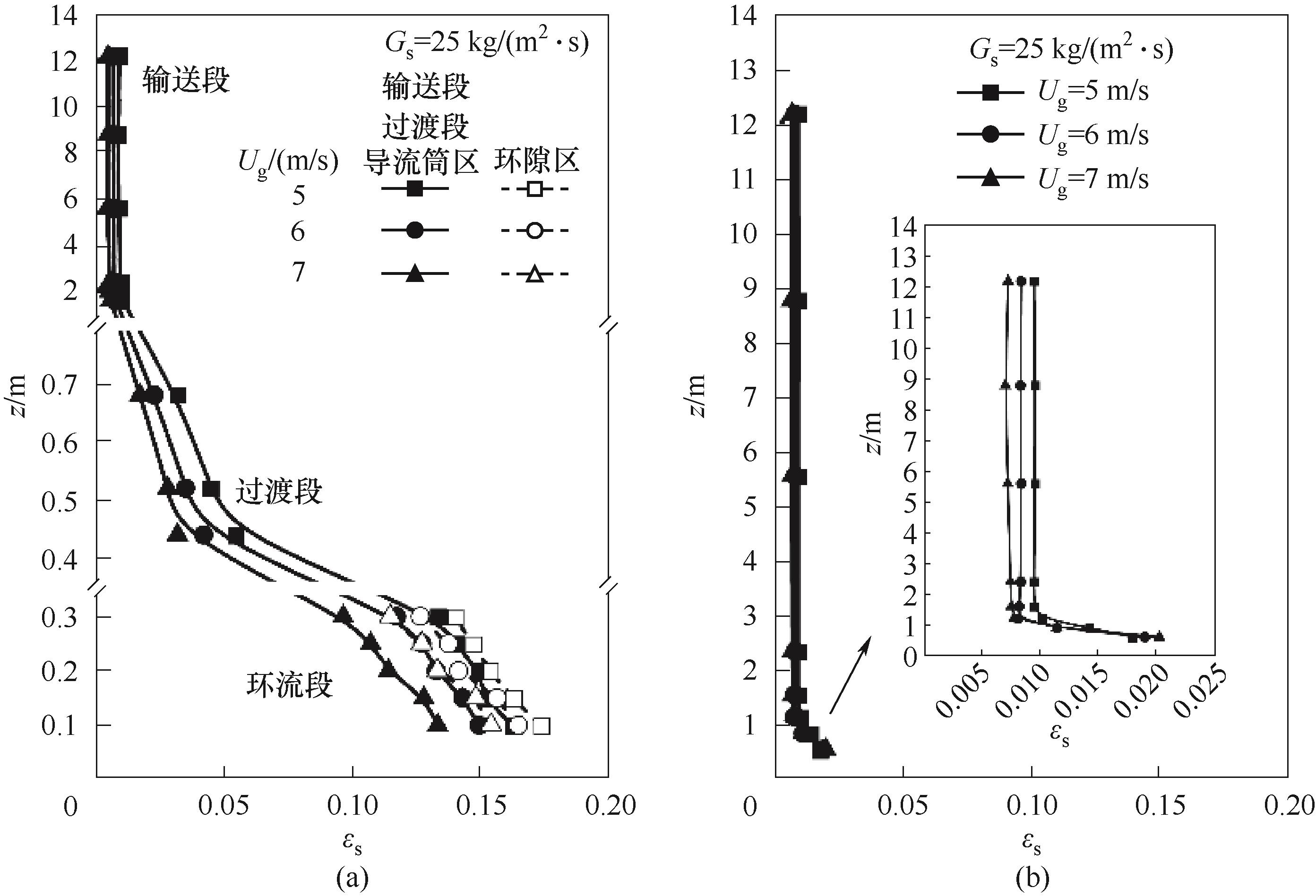

图7 环流耦合提升管(a)与常规提升管(b)脱硫灰颗粒固含率的分布特性对比

Fig.7 Distribution of solids holdup of desulphurized ash particles in the loop-coupled reactor (a) and riser (b)

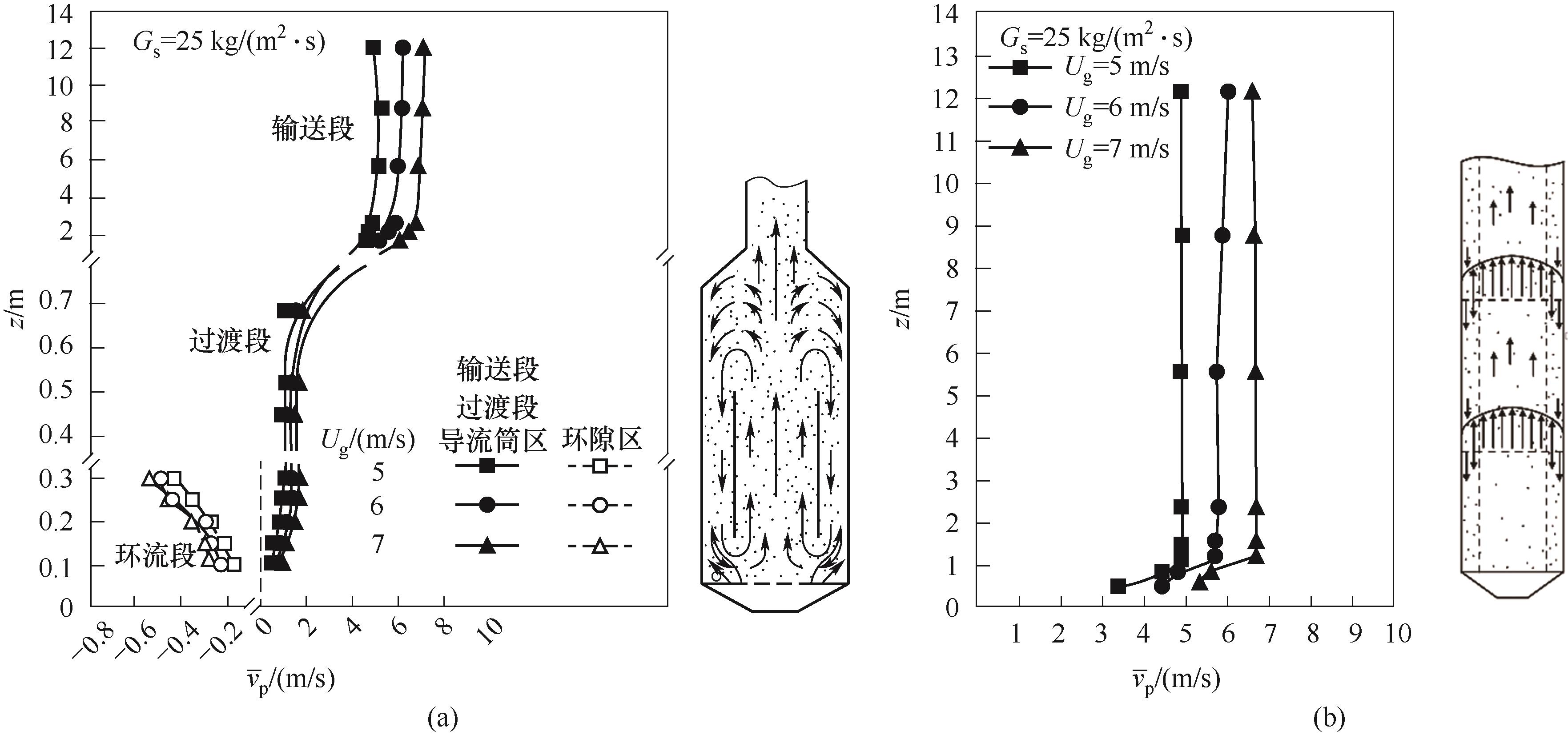

图8 环流耦合提升管(a)与常规提升管(b)脱硫灰颗粒速度的分布特性对比

Fig.8 Distribution of particle velocity of desulphurized ash particles in the loop-coupled reactor (a) and riser (b)

| 1 | 熊波, 陈健, 李克兵, 等. 工业排放气二氧化碳捕集与利用技术进展[J]. 低碳化学与化工, 2023, 48(1): 9-18. |

| Xiong B, Chen J, Li K B, et al. Technical progress in carbon dioxide capture and utilization of industrial vent gas[J]. Low-Carbon Chemistry and Chemical Engineering, 2023, 48(1): 9-18. | |

| 2 | 窦立荣, 孙龙德, 吕伟峰, 等. 全球二氧化碳捕集、利用与封存产业发展趋势及中国面临的挑战与对策[J]. 石油勘探与开发, 2023, 50(5): 1083-1096. |

| Dou L R, Sun L D, Lyu W F, et al. Trend of global carbon dioxide capture, utilization and storage industry and challenges and countermeasures in China[J]. Petroleum Exploration and Development, 2023, 50(5): 1083-1096. | |

| 3 | Khoma М S, Vasyliv K B, Chuchman М R. Influence of the hydrogen sulfide concentration on the corrosion and hydrogenation of pipe steels (a survey)[J]. Materials Science, 2021, 57(3): 308-318. |

| 4 | Guo K, Ji J W, Song W, et al. Conquering ammonium bisulfate poison over low-temperature NH3-SCR catalysts: a critical review[J]. Applied Catalysis B: Environmental, 2021, 297: 120388. |

| 5 | 贠莹, 高峰, 高鲜会. 催化裂化装置再生烟气醇胺法回收CO2技术模拟研究[J]. 炼油技术与工程, 2023, 53(2): 10-14. |

| Yun Y, Gao F, Gao X H. Simulation study of CO2 recovery from regenerated flue gas of FCC unit by alcohol amine method[J]. Petroleum Refinery Engineering, 2023, 53(2): 10-14. | |

| 6 | 刘忠生, 王学海, 齐慧敏, 等. 催化裂化烟气脱硝脱硫除尘新技术[J]. 石油炼制与化工, 2018, 49(1): 103-108. |

| Liu Z S, Wang X H, Qi H M, et al. New technologies of denitration, desulfurization and dust removal for FCC flue gas[J]. Petroleum Processing and Petrochemicals, 2018, 49(1): 103-108. | |

| 7 | Matsushima N, Li Y, Nishioka M, et al. Novel dry-desulfurization process using Ca(OH)2/fly ash sorbent in a circulating fluidized bed[J]. Environmental Science & Technology, 2004, 38(24): 6867-6874. |

| 8 | Zhou Y G, Wang D F, Zhang M C. Study on multiphase flow and mixing in semidry flue gas desulfurization with a multifluid alkaline spray generator using particle image velocimetry[J]. Industrial & Engineering Chemistry Research, 2009, 48(12): 5808-5815. |

| 9 | Hansen B B, Kiil S. Investigation of parameters affecting gypsum dewatering properties in a wet flue gas desulphurization pilot plant[J]. Industrial & Engineering Chemistry Research, 2012, 51(30): 10100-10107. |

| 10 | Jin Y. The influence of exit structures on the axial distribution of voidage in fast fluidized bed [C]//Fluidization 88 Science and Technology. Beijing: Science Press, 1988: 165-173. |

| 11 | 金涌. 流态化工程原理[M]. 北京: 清华大学出版社, 2001. |

| Jin Y. Fluidization Engineering Principles[M]. Beijing: Tsinghua University Press, 2001. | |

| 12 | Montagnaro F, Salatino P, Scala F, et al. A population balance model on sorbent in CFB combustors: the influence of particle attrition[J]. Industrial & Engineering Chemistry Research, 2011, 50(16): 9704-9711. |

| 13 | Figueroa I, Li H M, McCarthy J. Predicting the impact of adhesive forces on particle mixing and segregation[J]. Powder Technology, 2009, 195(3): 203-212. |

| 14 | Katoh K, Song S, Wakimoto T, et al. A study on the removal of infinitesimal particles on a wall by high-speed air jet―measurements of adhesive force and particle removal rate[J]. Journal of Fluid Science and Technology, 2014, 9(3): JFST0032. |

| 15 | Barletta D, Poletto M. Aggregation phenomena in fluidization of cohesive powders assisted by mechanical vibrations[J]. Powder Technology, 2012, 225: 93-100. |

| 16 | Montz K W, Beddow J K, Butler P B. Adhesion and removal of particulate contaminants in a high-decibel acoustic field[J]. Powder Technology, 1988, 55(2): 133-140. |

| 17 | Lepek D, Valverde J M, Pfeffer R, et al. Enhanced nanofluidization by alternating electric fields[J]. AIChE Journal, 2010, 56(1): 54-65. |

| 18 | Zhou T, Li H Z. Effects of adding different size particles on fluidization of cohesive particles[J]. Powder Technology, 1999, 102(3): 215-220. |

| 19 | Xu C C, Zhang H, Zhu J. Improving flowability of cohesive particles by partial coating on the surfaces[J]. The Canadian Journal of Chemical Engineering, 2009, 87(3): 403-414. |

| 20 | Mori S, Yamamoto A, Iwata S. Vibro-fluidization of group-C particles and its industrial applications[J]. AIChE Symposium Series, 1990, 86(276): 88-94. |

| 21 | Brekken R A, Lancaster E B, Wheellock T D. Fluidization of flour in a stirred aerated bed(Ⅰ): General fluidization characteristics[C]// Chemical Engineering Progress, Symposium Series. 1970, 66(101): 81-90. |

| 22 | Zhu Q S, Li H Z. Study on magnetic fluidization of group C powders[J]. Powder Technology, 1996, 86(2): 179-185. |

| 23 | Lu X S, Li H Z. Fluidization of CaCO3 and Fe2O3 particle mixtures in a transverse rotating magnetic field[J]. Powder Technology, 2000, 107(1/2): 66-78. |

| 24 | Kato K, Takarada T, Matsuo N, et al. Residence time distribution of fine particles in a powder-particle fluidized bed[J]. International Chemical Engineering, 1994, 34(4): 605-610. |

| 25 | Krupp H. Particle adhesion theory and experiment[J]. Advances in Colloid and Interface Science, 1967, 1(2): 111-239. |

| 26 | Nowakw W, Hasatani M. Fluidization and heat transfer of fine particles in an acoustic field[J]. AIChE Symposium Series, 1993, 89(296): 137-149. |

| 27 | Chirone R, Massimilla L, Russo S. Bubble-free fluidization of a cohesive powder in an acoustic field[J]. Chemical Engineering Science, 1993, 48(1): 41-52. |

| 28 | Milne B J, Berruti F, Behie L A, et al. The internally circulating fluidized bed (ICFB): a novel solution to gas bypassing in spouted beds[J]. The Canadian Journal of Chemical Engineering, 1992, 70(5): 910-915. |

| 29 | 沈志远, 杨利军, 刘梦溪, 等. 中心气升式环流反应器内压力脉动特性的研究[J]. 中国粉体技术, 2014, 20(6): 1-8. |

| Shen Z Y, Yang L J, Liu M X, et al. Investigation of pressure fluctuation in draft tube-lifted gas-solid air loop reactor[J]. China Powder Science and Technology, 2014, 20(6): 1-8. | |

| 30 | 卢春喜, 范怡平, 刘梦溪, 等. 催化裂化反应系统关键装备技术研究进展[J]. 石油学报(石油加工), 2018, 34(3): 441-454. |

| Lu C X, Fan Y P, Liu M X, et al. Advances in key equipment technologies of reaction system in RFCC unit[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2018, 34(3): 441-454. | |

| 31 | Wang F F, Ma S H, Wen J J, et al. Gas hydrodynamics of a novel MTO high-speed loop reactor: the bypassing and backmixing along with average residence time[J]. Powder Technology, 2020, 364: 1062-1075. |

| 32 | 卢春喜, 徐桂明, 卢水根, 等. 用于催化裂化的预汽提式提升管末端快分系统的研究及工业应用[J]. 石油炼制与化工, 2002, 33(1): 33-37. |

| Lu C X, Xu G M, Lu S G, et al. Study and industry application of a pre-stripping separation system for riser termination of FCCU[J]. Petroleum Processing and Petrochemicals, 2002, 33(1): 33-37. | |

| 33 | 刘显成,卢春喜,时铭显. 两段气升式气固环流取热器导流筒壁与床层间的传热特性研究[J]. 过程工程学报, 2004, 4(z1): 611-618. |

| Liu X C, Lu C X, Shi M X. Study on heat transfer between gas solids suspension and the surfaces of two draft tubes in an airlift loop heat exchanger[J]. The Chinese Journal of Process Engineering, 2004, 4(z1): 611-618. | |

| 34 | Zhu L Y, Fan Y P, Wang Z B, et al. Comparative study of hydrodynamic and mixing behaviors in different pre-lifting schemes for an FCC riser[J]. Powder Technology, 2016, 301: 557-567. |

| 35 | 严超宇. 新型组合流化床石油焦燃烧器内气固流动行为研究[D]. 北京: 中国石油大学(北京), 2007. |

| Yan C Y. Gas-solid flow behavior in a new combined fluidized bed petroleum coke combustor[D]. Beijing: China University of Petroleum, 2007. | |

| 36 | Liu M X, Lu C X, Zhu X M, et al. Bed density and circulation mass flowrate in a novel annulus-lifted gas-solid air loop reactor[J]. Chemical Engineering Science, 2010, 65(22): 5830-5840. |

| 37 | Jaiboon O A, Chalermsinsuwan B, Mekasut L, et al. Effect of flow pattern on power spectral density of pressure fluctuation in various fluidization regimes[J]. Powder Technology, 2013, 233: 215-226. |

| 38 | 丁睿, 王德武, 刘燕, 等. 提升管加床层反应器不同操作模式下的压力脉动特性[J]. 过程工程学报, 2016, 16(5): 721-729. |

| Ding R, Wang D W, Liu Y, et al. Pressure fluctuation characteristics of riser-fluidized bed reactor under different operating modes[J]. The Chinese Journal of Process Engineering, 2016, 16(5): 721-729. |

| [1] | 成文凯, 颜金钰, 王嘉骏, 冯连芳. 卧式捏合反应器及其在聚合工业中的研究进展[J]. 化工学报, 2024, 75(3): 768-781. |

| [2] | 谭耀文, 姜攀星, 杜青, 余婉秋, 温小飞, 詹志刚. 工作电压对PEMFC膜电极衰退影响模拟研究[J]. 化工学报, 2024, 75(3): 974-986. |

| [3] | 谷世良, 谭博仁, 程全中, 姚玮洁, 董志鹏, 许峰, 王勇. 轴流泵式混合室内水力学特征的数值模拟[J]. 化工学报, 2024, 75(3): 815-822. |

| [4] | 李文俊, 赵中阳, 倪震, 周灿, 郑成航, 高翔. 基于气-液传质强化的湿法烟气脱硫CFD模拟研究[J]. 化工学报, 2024, 75(2): 505-519. |

| [5] | 詹小斌, 王会彬, 蒋亚龙, 史铁林. 声共振混合器高黏度流体混合的功耗特性研究[J]. 化工学报, 2024, 75(2): 531-542. |

| [6] | 麻雪怡, 刘克勤, 胡激江, 姚臻. POE溶液聚合反应器内混合与反应过程的CFD研究[J]. 化工学报, 2024, 75(1): 322-337. |

| [7] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [8] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [9] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [10] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [11] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [12] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [13] | 何晓崐, 刘锐, 薛园, 左然. MOCVD生长AlN单晶薄膜的气相和表面化学反应综述[J]. 化工学报, 2023, 74(7): 2800-2813. |

| [14] | 牛超, 沈胜强, 杨艳, 潘泊年, 李熠桥. 甲烷BOG喷射器流动过程计算与性能分析[J]. 化工学报, 2023, 74(7): 2858-2868. |

| [15] | 于源, 陈薇薇, 付俊杰, 刘家祥, 焦志伟. 几何相似涡流空气分级机环形区流场变化规律研究及预测[J]. 化工学报, 2023, 74(6): 2363-2373. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号