化工学报 ›› 2024, Vol. 75 ›› Issue (10): 3610-3622.DOI: 10.11949/0438-1157.20240406

李泓宇( ), 刘祥坤, 施尧, 曹约强, 钱刚(

), 刘祥坤, 施尧, 曹约强, 钱刚( ), 段学志

), 段学志

收稿日期:2024-04-12

修回日期:2024-06-07

出版日期:2024-10-25

发布日期:2024-11-04

通讯作者:

钱刚

作者简介:李泓宇(1998—),男,硕士研究生,18795907997@163.com

基金资助:

Hongyu LI( ), Xiangkun LIU, Yao SHI, Yueqiang CAO, Gang QIAN(

), Xiangkun LIU, Yao SHI, Yueqiang CAO, Gang QIAN( ), Xuezhi DUAN

), Xuezhi DUAN

Received:2024-04-12

Revised:2024-06-07

Online:2024-10-25

Published:2024-11-04

Contact:

Gang QIAN

摘要:

乙烯产量是反映国家石油化工发展水平的关键指标。构建了颗粒分辨的乙炔选择性加氢固定床反应器模型,分析圆柱形颗粒堆积结构对传递过程以及操作条件对其反应性能的影响。结果表明,床层压降主要集中在反应器入口段,该段乙炔加氢反应速率最高,但在后半段催化剂颗粒未被充分利用,而且反应器内存在明显的径向温度梯度。入口压力的增加和空速的降低均有利于提升乙炔转化率,但同时会降低乙烯选择性,其中乙烯选择性对压力更敏感,而乙炔转化率对空速更敏感;反应温度和氢炔比的提高均有利于促进乙炔生成乙烯的速率,但会导致乙烯富集在催化剂颗粒的外表面,其进一步向颗粒内部扩散时过度加氢生成乙烷,使乙烯选择性降低。

中图分类号:

李泓宇, 刘祥坤, 施尧, 曹约强, 钱刚, 段学志. 颗粒分辨的乙炔选择性加氢固定床反应器数值模拟[J]. 化工学报, 2024, 75(10): 3610-3622.

Hongyu LI, Xiangkun LIU, Yao SHI, Yueqiang CAO, Gang QIAN, Xuezhi DUAN. Numerical simulation of particle-resolved fixed-bed reactor for selective acetylene hydrogenation process[J]. CIESC Journal, 2024, 75(10): 3610-3622.

| 分子 | 扩散体积 |

|---|---|

| C2H2 | 36.42 |

| H2 | 6.12 |

| C2H4 | 41.01 |

| C2H6 | 45.66 |

| C3H8 | 65.34 |

| C4H8 | 82.08 |

| Ar | 16.10 |

表1 模拟中所用的扩散体积[35]

Table 1 Diffusion volumes used in simulation[35]

| 分子 | 扩散体积 |

|---|---|

| C2H2 | 36.42 |

| H2 | 6.12 |

| C2H4 | 41.01 |

| C2H6 | 45.66 |

| C3H8 | 65.34 |

| C4H8 | 82.08 |

| Ar | 16.10 |

| 物性 | 经验公式 | 文献 |

|---|---|---|

| 催化剂粉末热导率 | [ | |

| 气体混合物热导率 | [ | |

| 物质i和物质j的二元黏度 | [ | |

| 气体混合物比热容 | [ | |

| 气体混合物密度 | [ | |

| 气体混合物平均摩尔质量 | [ | |

| 反应热 | [ |

表2 模型中所用的计算经验方程式

Table 2 Empirical equations used in simulation

| 物性 | 经验公式 | 文献 |

|---|---|---|

| 催化剂粉末热导率 | [ | |

| 气体混合物热导率 | [ | |

| 物质i和物质j的二元黏度 | [ | |

| 气体混合物比热容 | [ | |

| 气体混合物密度 | [ | |

| 气体混合物平均摩尔质量 | [ | |

| 反应热 | [ |

| 位置 | 动量方程 | 质量方程 | 能量方程 |

|---|---|---|---|

| 反应器入口 ( | |||

| 反应器出口 ( | |||

| 反应器管壁( | |||

| 颗粒与流体交界面 | — |

表3 求解式(12)~式(14)、式(16)和式(17)使用的边界条件

Table 3 Boundary conditions for solving Eqs.(12)—(14), Eq.(16) and Eq.(17)

| 位置 | 动量方程 | 质量方程 | 能量方程 |

|---|---|---|---|

| 反应器入口 ( | |||

| 反应器出口 ( | |||

| 反应器管壁( | |||

| 颗粒与流体交界面 | — |

图5 反应器中心纵截面和横截面(30 mm处)的乙炔浓度分布和反应器轴向乙炔浓度分布

Fig.5 Central longitudinal and cross-sectional (30 mm) C2H2 concentration distribution and C2H2 concentration along axial direction of reactor

图6 反应器中心纵截面和横截面(40 mm处)的温度分布和反应器轴向温度分布

Fig.6 Central longitudinal and cross-sectional (40 mm) temperature distribution and temperature distribution along axial direction of reactor

图7 反应器中心纵截面温度分布、轴向温度分布、中心纵截面乙炔浓度分布、轴向乙炔浓度分布以及乙炔转化率和乙烯选择性随压力的变化

Fig.7 Central longitudinal temperature distribution, temperature along axial direction, central longitudinal C2H2 concentration distribution, C2H2 concentration along axial direction and C2H2 conversion and C2H4 selectivity with respect to pressure

图8 反应器中心纵截面温度分布、轴向温度分布、中心纵截面乙炔浓度分布、轴向乙炔浓度分布以及乙炔转化率和乙烯选择性随空速的变化

Fig.8 Central longitudinal temperature distribution, temperature along axial direction, central longitudinal C2H2 concentration distribution, C2H2 concentration along axial direction and C2H2 conversion and C2H4 selectivity with respect to GHSV

图9 反应器中心纵截面温度分布、轴向温度分布、中心纵截面乙炔浓度分布、轴向乙炔浓度分布以及乙炔转化率和乙烯选择性随入口温度的变化

Fig.9 Central longitudinal temperature distribution, temperature along axial direction, central longitudinal C2H2 concentration distribution, C2H2 concentration along axial direction and C2H2 conversion and C2H4 selectivity with respect to inlet temperature

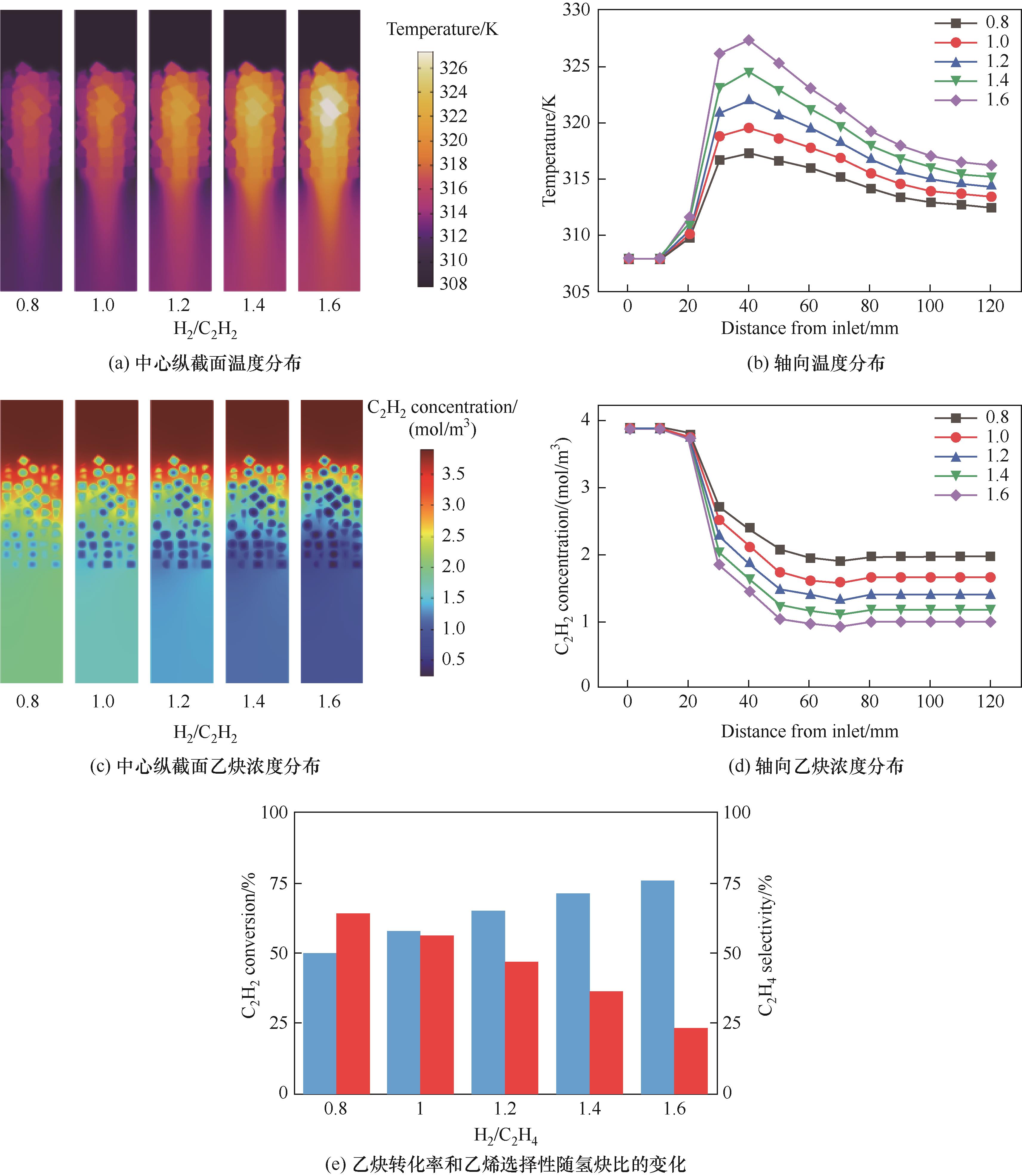

图10 反应器中心纵截面温度分布、轴向温度分布、中心纵截面乙炔浓度分布、轴向乙炔浓度分布以及乙炔转化率和乙烯选择性随氢炔比的变化

Fig.10 Central longitudinal temperature distribution, temperature along axial direction, central longitudinal C2H2 concentration distribution, C2H2 concentration along axial direction and C2H2 conversion and C2H4 selectivity with respect to hydrogen-acetylene ratio

| 1 | Borodziński A, Bond G C. Selective hydrogenation of ethyne in ethene-rich streams on palladium catalysts. Part 1. Effect of changes to the catalyst during reaction[J]. Catalysis Reviews, 2006, 48(2): 91-144. |

| 2 | Dehghani O, Rahimpour M R, Shariati A. An experimental approach on industrial Pd-Ag supported α-Al2O3 catalyst used in acetylene hydrogenation process: mechanism, kinetic and catalyst decay[J]. Processes, 2019, 7(3): 136. |

| 3 | 张谦温, 刘新香, 朱起明. 炔烃和二烯烃选择加氢现状与发展[J]. 石油化工, 1998, 27(1): 53-58. |

| Zhang Q W, Liu X X, Zhu Q M. Present situation and development of selective hydrogenation of alkynes and dienes[J]. Petrochemical Technology, 1998, 27(1): 53-58. | |

| 4 | Takht Ravanchi M, Sahebdelfar S. Pd-Ag/Al2O3 catalyst: stages of deactivation in tail-end acetylene selective hydrogenation[J]. Applied Catalysis A: General, 2016, 525: 197-203. |

| 5 | Aeowjaroenlap H, Chotiwiriyakun K, Tiensai N, et al. Model-based optimization of an acetylene hydrogenation reactor to improve overall ethylene plant economics[J]. Industrial & Engineering Chemistry Research, 2018, 57(30): 9943-9951. |

| 6 | Dehghani O, Bolhasani A, Hosseini S, et al. Process intensification of selective acetylene hydrogenation reactor by bed configuration change: a case study of an ethylene plant[J]. Case Studies in Chemical and Environmental Engineering, 2023, 7: 100321. |

| 7 | Dehghani Khold O, Parhoudeh M, Rahimpour M R, et al. A new configuration in the tail-end acetylene hydrogenation reactor to enhance catalyst lifetime and performance[J]. Journal of the Taiwan Institute of Chemical Engineers, 2016, 65: 8-21. |

| 8 | Szukiewicz M, Kaczmarski K, Petrus R. Modelling of fixed-bed reactor: two models of industrial reactor for selective hydrogenation of acetylene[J]. Chemical Engineering Science, 1998, 53(1): 149-155. |

| 9 | Ge X H, Cao Y Q, Yan K L, et al. Increasing the distance of adjacent palladium atoms for configuration matching in selective hydrogenation[J]. Angewandte Chemie International Edition, 2022, 61(51): e202215225. |

| 10 | Ge X H, Dou M Y, Cao Y Q, et al. Mechanism driven design of trimer Ni1Sb2 site delivering superior hydrogenation selectivity to ethylene[J]. Nature Communications, 2022, 13: 5534. |

| 11 | Cao Y Q, Zhang H, Ji S F, et al. Adsorption site regulation to guide atomic design of Ni-Ga catalysts for acetylene[J]. Angewandte Chemie International Edition, 2020, 59(28): 11647-11652. |

| 12 | Takht Ravanchi M, Sahebdelfar S, Komeili S. Acetylene selective hydrogenation: a technical review on catalytic aspects[J]. Reviews in Chemical Engineering, 2018, 34(2): 215-237. |

| 13 | McCue A J, Anderson J A. Recent advances in selective acetylene hydrogenation using palladium containing catalysts[J]. Frontiers of Chemical Science and Engineering, 2015, 9(2): 142-153. |

| 14 | Zhang L L, Zhou M X, Wang A Q, et al. Selective hydrogenation over supported metal catalysts: from nanoparticles to single atoms[J]. Chemical Reviews, 2020, 120(2): 683-733. |

| 15 | Wang Z, Luo Q, Mao S J, et al. Fundamental aspects of alkyne semi-hydrogenation over heterogeneous catalysts[J]. Nano Research, 2022, 15(12): 10044-10062. |

| 16 | Asplund S. Coke formation and its effect on internal mass transfer and selectivity in Pd-catalysed acetylene hydrogenation[J]. Journal of Catalysis, 1996, 158(1): 267-278. |

| 17 | Jurtz N, Kraume M, Wehinger G D. Advances in fixed-bed reactor modeling using particle-resolved computational fluid dynamics (CFD)[J]. Reviews in Chemical Engineering, 2019, 35(2): 139-190. |

| 18 | Partopour B, Dixon A G. 110th anniversary: commentary: CFD as a modeling tool for fixed bed reactors[J]. Industrial & Engineering Chemistry Research, 2019, 58(14): 5733-5736. |

| 19 | Dixon A G, Partopour B. Computational fluid dynamics for fixed bed reactor design[J]. Annual Review of Chemical and Biomolecular Engineering, 2020, 11: 109-130. |

| 20 | Wehinger G D, Ambrosetti M, Cheula R, et al. Quo vadis multiscale modeling in reaction engineering? — A perspective[J]. Chemical Engineering Research and Design, 2022, 184: 39-58. |

| 21 | Partopour B, Dixon A G. An integrated workflow for resolved-particle packed bed models with complex particle shapes[J]. Powder Technology, 2017, 322: 258-272. |

| 22 | Moghaddam E M, Foumeny E A, Stankiewicz A I, et al. Rigid body dynamics algorithm for modeling random packing structures of nonspherical and nonconvex pellets[J]. Industrial & Engineering Chemistry Research, 2018, 57(44): 14988-15007. |

| 23 | Chen H, Shi Y, Li Z, et al. Structure-resolved CFD simulations to guide catalyst packing of selective NO reduction[J]. Chemical Engineering Science, 2022, 446: 136888. |

| 24 | Partopour B, Dixon A G. Effect of particle shape on methanol partial oxidation in a fixed bed using CFD reactor modeling[J]. AIChE Journal, 2020, 66(5): e16904. |

| 25 | Wehinger G D, Eppinger T, Kraume M. Detailed numerical simulations of catalytic fixed-bed reactors: heterogeneous dry reforming of methane[J]. Chemical Engineering Science, 2015, 122: 197-209. |

| 26 | Karthik G M, Buwa V V. Particle-resolved simulations of methane steam reforming in multilayered packed beds[J]. AIChE Journal, 2018, 64(11): 4162-4176. |

| 27 | Liu X L, Qin B, Zhang Q F, et al. Optimizing catalyst supports at single catalyst pellet and packed bed reactor levels: a comparison study[J]. AIChE Journal, 2021, 67(8): e17163. |

| 28 | Dixon A G. General correlation for pressure drop through randomly-packed beds of spheres with negligible wall effects[J]. AIChE Journal, 2023, 69(6): e18035. |

| 29 | Dixon A G. Are there wall effects on pressure drop through randomly packed beds of spherical catalyst particles?[J]. AIChE Journal, 2024, 70(1): e18272. |

| 30 | Shi Y, Chen H, Chen W Y, et al. Effects of particle shape and packing style on ethylene oxidation reaction using particle-resolved CFD simulation[J]. Particuology, 2023, 82: 87-97. |

| 31 | Dixon A G. Local transport and reaction rates in a fixed bed reactor tube: endothermic steam methane reforming[J]. Chemical Engineering Science, 2017, 168: 156-177. |

| 32 | Dong Y, Geske M, Korup O, et al. What happens in a catalytic fixed-bed reactor for n-butane oxidation to maleic anhydride? Insights from spatial profile measurements and particle resolved CFD simulations[J]. Chemical Engineering Journal, 2018, 350: 799-811. |

| 33 | Pachulski A, Schödel R, Claus P. Kinetics and reactor modeling of a Pd-Ag/Al2O3 catalyst during selective hydrogenation of ethyne[J]. Applied Catalysis A: General, 2012, 445: 107-120. |

| 34 | Hite R H, Jackson R. Pressure gradients in porous catalyst pellets in the intermediate diffusion regime[J]. Chemical Engineering Science, 1977, 32(7): 703-709. |

| 35 | Faghri A, Zhang Y W. Transport Phenomena in Multiphase Systems[M]. Burlington, MA: Elsevier Academic Press, 2006. |

| 36 | Yaws C L. Chemical Properties Handbook: Physical, Thermodynamic, Environmental, Transport, Safety, and Health Related Properties for Organic and Inorganic Chemicals[M]. New York: McGraw-Hill, 1999. |

| 37 | Bird R B, Stewart W E, Lightfoot E N. Transport Phenomena [M]. New York: John Wiley & Sons Inc, 2002. |

| [1] | 陈巨辉, 苏潼, 李丹, 陈立伟, 吕文生, 孟凡奇. 翅形扰流片作用下的微通道换热特性[J]. 化工学报, 2024, 75(9): 3122-3132. |

| [2] | 王冉, 王焕, 熊晓云, 关慧敏, 郑云锋, 陈彩琳, 秦玉才, 宋丽娟. FCC催化剂传质强化活性位利用效率的可视化分析[J]. 化工学报, 2024, 75(9): 3198-3209. |

| [3] | 李舒月, 王欢, 周少强, 毛志宏, 张永民, 王军武, 吴秀花. 基于CPFD方法的U3O8氢还原流化床反应器数值模拟[J]. 化工学报, 2024, 75(9): 3133-3151. |

| [4] | 陈超伟, 柳洋, 杜文静, 李金波, 史大阔, 辛公明. 局部热点下微肋通道流动传热特性[J]. 化工学报, 2024, 75(9): 3113-3121. |

| [5] | 杨子驰, 谢冰琪, 石瑞莘, 雷虹, 陈晨, 周才金, 张吉松. 套管膜式微反应器内高效安全的气液传质-反应过程研究进展[J]. 化工学报, 2024, 75(9): 3011-3027. |

| [6] | 罗欣怡, 徐强, 佘永璐, 聂腾飞, 郭烈锦. 光电分解水制氢气泡动力学特性及其传质机理研究[J]. 化工学报, 2024, 75(9): 3083-3093. |

| [7] | 钱啸宇, 阮璇, 李水清. 外加电场下电介质颗粒层结构重构与悬浮[J]. 化工学报, 2024, 75(8): 2756-2762. |

| [8] | 朱子良, 王爽, 姜宇昂, 林梅, 王秋旺. 欧拉-拉格朗日迭代固-液相变算法[J]. 化工学报, 2024, 75(8): 2763-2776. |

| [9] | 邓爱明, 何玉荣, 唐天琪, 胡彦伟. 导流板对喷雾流化床内颗粒生长过程影响的模拟[J]. 化工学报, 2024, 75(8): 2787-2799. |

| [10] | 王倩倩, 李冰, 郑伟波, 崔国民, 赵兵涛, 明平文. 氢燃料电池局部动态特征三维模型[J]. 化工学报, 2024, 75(8): 2812-2820. |

| [11] | 毛宇飞, 曹飞, 上官燕琴. 超临界压力流体管内湍流对流传热的计算方法[J]. 化工学报, 2024, 75(8): 2821-2830. |

| [12] | 李倩, 张蓉民, 林子杰, 战琪, 蔡伟华. 基于机器学习的印刷电路板式换热器流动换热预测与仿真[J]. 化工学报, 2024, 75(8): 2852-2864. |

| [13] | 金虎, 杨帆, 戴梦瑶. 基于格子Boltzmann方法的液滴在圆柱壁面上运动过程研究[J]. 化工学报, 2024, 75(8): 2897-2908. |

| [14] | 豆少军, 郝亮. PEMFC催化层耦合气体电荷传输过程的介观模拟[J]. 化工学报, 2024, 75(8): 3002-3010. |

| [15] | 韩志敏, 李江, 陈则齐, 刘威, 徐志明. 脉动流通道内不同纵向涡发生器的颗粒污垢特性[J]. 化工学报, 2024, 75(7): 2486-2496. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号