化工学报 ›› 2024, Vol. 75 ›› Issue (11): 4264-4273.DOI: 10.11949/0438-1157.20241148

收稿日期:2024-10-17

修回日期:2024-11-19

出版日期:2024-11-25

发布日期:2024-12-26

通讯作者:

赵玉军

作者简介:周琳(2001—),女,硕士研究生,zhou_linlin518@tju.edu.cn

Lin ZHOU( ), Bin YE, Xinyi SUN, Lingxin KONG, Yan XU, Yujun ZHAO(

), Bin YE, Xinyi SUN, Lingxin KONG, Yan XU, Yujun ZHAO( )

)

Received:2024-10-17

Revised:2024-11-19

Online:2024-11-25

Published:2024-12-26

Contact:

Yujun ZHAO

摘要:

丁二酸酐(SA)是合成可降解塑料聚丁二酸丁二醇酯(PBS)的原料,开展顺酐(MA)加氢制备SA催化剂的研究具有重要的应用价值。为解决MA低温加氢转化率低且容易失活的问题,本文以介孔碳为载体制备了系列不同镍含量的yNi/MC催化剂并进行表征和催化性能评价。由于介孔碳具有较大的比表面积和孔容,故适量提高金属Ni负载量[40%(质量)]可以增加金属Ni位点,有利于提高MA催化加氢反应的活性。在低负载量情况下,适当增加氢气的弱吸附位点有利于提高MA催化加氢的活性;而Ni的负载量高于20%(质量)之后,H2吸附解离能力相对较强,而C=C键的桥式吸附成为反应活性的提升关键。研究表明,40%(质量)镍负载量的40Ni/MC催化剂经500℃还原后,在较低的温度(60℃)和较高的质量空速(8.3 h-1)条件下可实现100%的SA选择性和80.1%的MA转化率,并在5次循环套用中表现出较佳的稳定性。而且,当反应温度提高至90℃时,MA转化率和SA选择性均接近100%。当采用固定床反应体系评价时,可达到150 h后依旧保持100%的MA转化率和SA选择性。因此,所制备的介孔碳负载镍催化剂在MA加氢领域显示了良好的工业应用前景。

中图分类号:

周琳, 叶斌, 孙心怡, 孔令鑫, 徐艳, 赵玉军. 介孔碳负载Ni催化剂催化顺酐加氢反应研究[J]. 化工学报, 2024, 75(11): 4264-4273.

Lin ZHOU, Bin YE, Xinyi SUN, Lingxin KONG, Yan XU, Yujun ZHAO. Study on the catalytic hydrogenation of maleic anhydride by mesoporous carbon-supported Ni catalyst[J]. CIESC Journal, 2024, 75(11): 4264-4273.

| 催化剂 | 反应 温度/℃ | 氢气 压力/MPa | MA 转化率/% | SA 选择性/% |

|---|---|---|---|---|

| 40Ni/MC | 30 | 1 | 20.8 | 100.0 |

| 60 | 1 | 80.1 | 100.0 | |

| 90 | 1 | 100.0 | 100.0 | |

| 60 | 2 | 86.9 | 100.0 | |

| 60 | 3 | 89.1 | 100.0 | |

| 60 | 4 | 96.5 | 100.0 |

表1 反应温度和氢气压力对MA加氢性能的影响

Table 1 Effect of reaction temperature and hydrogen pressure on the hydrogenation performance of maleic anhydride

| 催化剂 | 反应 温度/℃ | 氢气 压力/MPa | MA 转化率/% | SA 选择性/% |

|---|---|---|---|---|

| 40Ni/MC | 30 | 1 | 20.8 | 100.0 |

| 60 | 1 | 80.1 | 100.0 | |

| 90 | 1 | 100.0 | 100.0 | |

| 60 | 2 | 86.9 | 100.0 | |

| 60 | 3 | 89.1 | 100.0 | |

| 60 | 4 | 96.5 | 100.0 |

| 理论镍负载量/%(质量) | ICP-OES测定镍负载量/%(质量) |

|---|---|

| 10 | 9.9 |

| 20 | 20.4 |

| 30 | 29.8 |

| 40 | 39.4 |

| 50 | 50.2 |

表 2 ICP-OES测得不同镍负载量催化剂的实际镍含量

Table 2 The real Ni loadings of the catalysts from the results of ICP-OES

| 理论镍负载量/%(质量) | ICP-OES测定镍负载量/%(质量) |

|---|---|

| 10 | 9.9 |

| 20 | 20.4 |

| 30 | 29.8 |

| 40 | 39.4 |

| 50 | 50.2 |

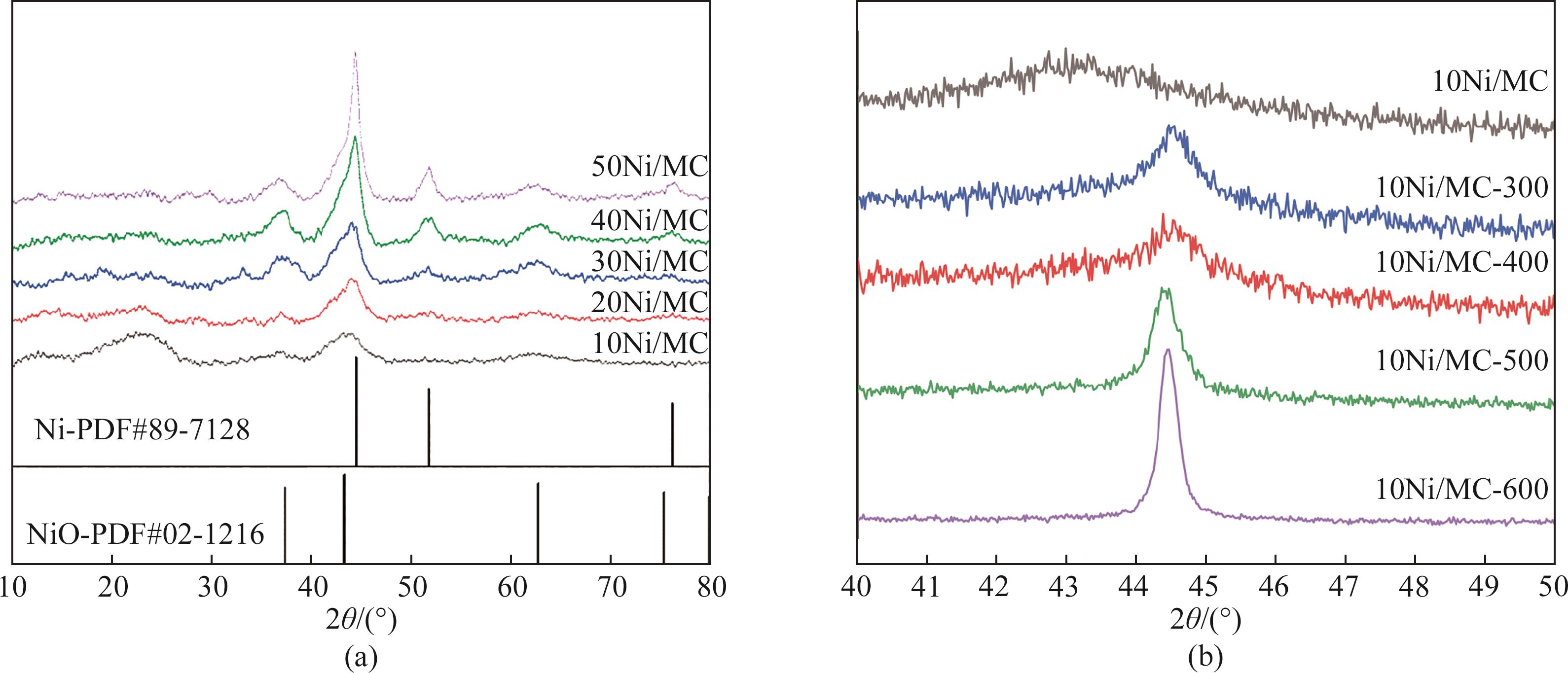

图 5 (a)还原前催化剂的XRD谱图;(b)不同还原温度下的10Ni/MC催化剂的XRD谱图

Fig.5 (a) XRD pattern of the catalyst before reduction; (b) XRD pattern of the 10Ni/MC catalyst at different reduction temperatures

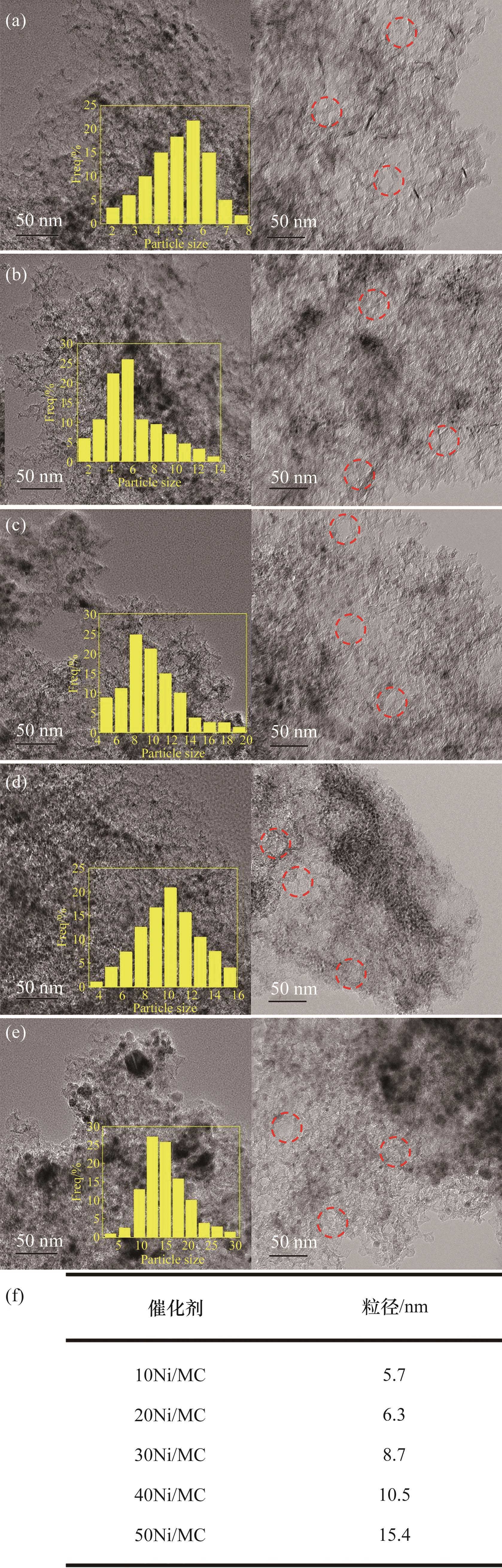

图6 不同负载量Ni/MC催化剂TEM图像

Fig.6 TEM images of catalysts with different nickel loadings (a) 10Ni/MC; (b) 20Ni/MC; (c) 30Ni/MC; (d) 40Ni/MC; (e) 50Ni/MC; (f) average particle size of yNi/MC catalysts

| Catalyst | SBET①/ (m2/g) | Vpore①/ (cm3/g) | Dpore①/nm | Metal dispersion②/% |

|---|---|---|---|---|

| MC | 974 | 3.4 | 11.8 | — |

| 10Ni/MC | 905 | 1.8 | 8.2 | 7.5 |

| 20Ni/MC | 825 | 1.6 | 8.3 | 6.8 |

| 30Ni/MC | 718 | 1.5 | 8.5 | 5.5 |

| 40Ni/MC | 654 | 1.4 | 8.8 | 4.3 |

| 50Ni/MC | 560 | 1.2 | 8.9 | 3.7 |

表 3 不同镍负载量的介孔碳催化剂物理结构特征

Table 3 Textural properties of Ni/MC catalysts with different content of Ni

| Catalyst | SBET①/ (m2/g) | Vpore①/ (cm3/g) | Dpore①/nm | Metal dispersion②/% |

|---|---|---|---|---|

| MC | 974 | 3.4 | 11.8 | — |

| 10Ni/MC | 905 | 1.8 | 8.2 | 7.5 |

| 20Ni/MC | 825 | 1.6 | 8.3 | 6.8 |

| 30Ni/MC | 718 | 1.5 | 8.5 | 5.5 |

| 40Ni/MC | 654 | 1.4 | 8.8 | 4.3 |

| 50Ni/MC | 560 | 1.2 | 8.9 | 3.7 |

| Catalyst | Temperature/℃ | Peak area×103 | ||

|---|---|---|---|---|

| α | β | α | β | |

| MC | — | 491.9 | — | 102.9 |

| 10Ni/MC | 246.2 | 492.7 | 3.5 | 134.1 |

| 20Ni/MC | 234.3 | 500.9 | 10.5 | 158.4 |

| 30Ni/MC | 243.0 | 495.6 | 19.7 | 196.2 |

| 40Ni/MC | 223.7 | 492.3 | 23.0 | 228.7 |

| 50Ni/MC | 213.4 | 494.0 | 17.9 | 254.7 |

表4 不同镍负载量催化剂的H2-TPR曲线拟合结果

Table 4 H2-TPR curve fitting results of catalysts with different nickel loads

| Catalyst | Temperature/℃ | Peak area×103 | ||

|---|---|---|---|---|

| α | β | α | β | |

| MC | — | 491.9 | — | 102.9 |

| 10Ni/MC | 246.2 | 492.7 | 3.5 | 134.1 |

| 20Ni/MC | 234.3 | 500.9 | 10.5 | 158.4 |

| 30Ni/MC | 243.0 | 495.6 | 19.7 | 196.2 |

| 40Ni/MC | 223.7 | 492.3 | 23.0 | 228.7 |

| 50Ni/MC | 213.4 | 494.0 | 17.9 | 254.7 |

| Catalyst | Temperature/℃ | Peak area | ||||

|---|---|---|---|---|---|---|

| α | β | γ | α | β | γ | |

| 20Ni/MC | 112.6 | 259.1 | 377.8 | 8.5 | 13.5 | 15.5 |

| 30Ni/MC | 114.3 | 263.1 | 378.0 | 14.4 | 27.8 | 34.3 |

| 40Ni/MC | 114.4 | 263.2 | 382.2 | 21.6 | 26.8 | 30.9 |

| 50Ni/MC | 116.7 | 271.8 | 378.5 | 20.3 | 41.3 | 63.4 |

表 5 不同镍负载量催化剂的C2H4-TPD曲线拟合结果

Table 5 C2H4-TPD curve fitting results of catalysts with different nickel loads

| Catalyst | Temperature/℃ | Peak area | ||||

|---|---|---|---|---|---|---|

| α | β | γ | α | β | γ | |

| 20Ni/MC | 112.6 | 259.1 | 377.8 | 8.5 | 13.5 | 15.5 |

| 30Ni/MC | 114.3 | 263.1 | 378.0 | 14.4 | 27.8 | 34.3 |

| 40Ni/MC | 114.4 | 263.2 | 382.2 | 21.6 | 26.8 | 30.9 |

| 50Ni/MC | 116.7 | 271.8 | 378.5 | 20.3 | 41.3 | 63.4 |

| Catalyst | Temperature/℃ | Peak area | ||

|---|---|---|---|---|

| α | β | α | β | |

| MC | 111.8 | 472.6 | — | — |

| 10Ni/MC | 93.3 | 475.0 | 240.8 | 2694.5 |

| 20Ni/MC | 127.7 | 484.2 | 489.6 | 2502.6 |

| 30Ni/MC | 126.4 | 504.4 | 509.1 | 3090.5 |

| 40Ni/MC | 114.9 | 494.6 | 534.8 | 3701.3 |

| 50Ni/MC | 114.2 | 521.1 | 519.8 | 3852.4 |

表 6 不同镍负载量催化剂的H2-TPD曲线拟合结果

Table 6 H2-TPD curve fitting results of catalysts with different nickel loads

| Catalyst | Temperature/℃ | Peak area | ||

|---|---|---|---|---|

| α | β | α | β | |

| MC | 111.8 | 472.6 | — | — |

| 10Ni/MC | 93.3 | 475.0 | 240.8 | 2694.5 |

| 20Ni/MC | 127.7 | 484.2 | 489.6 | 2502.6 |

| 30Ni/MC | 126.4 | 504.4 | 509.1 | 3090.5 |

| 40Ni/MC | 114.9 | 494.6 | 534.8 | 3701.3 |

| 50Ni/MC | 114.2 | 521.1 | 519.8 | 3852.4 |

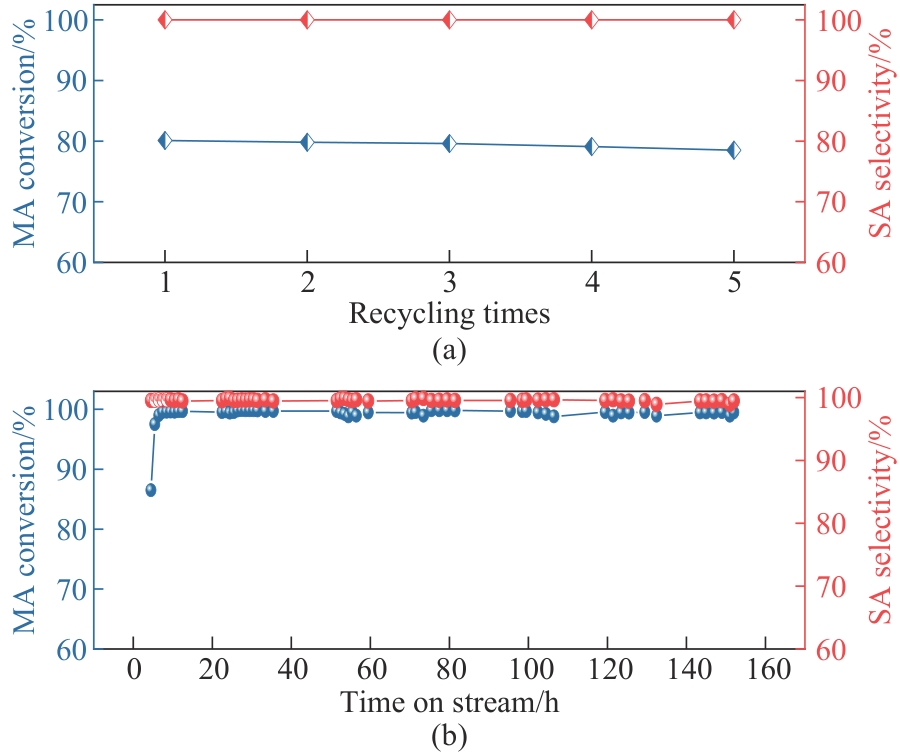

图 11 (a)40Ni/MC催化剂在间歇反应釜中的循环套用性能;(b)40Ni/MC催化剂在固定床反应器中的性能

Fig.11 (a) Performances of 40Ni/MC catalyst in batch kettle reactor (reaction conditions: 60℃, 1 MPa, WHSV 8.3 h-1); (b) Performances of 40Ni/MC catalyst in fixed bed reactor (reaction conditions: 60℃, 1 MPa, WHSV 2 h-1, H2/MA=20)

| 1 | 安思源, 朱晶莹, 卢滇楠, 等. 酶催化合成高分子量聚丁二酸丁二醇酯(PBS)及其材料特性[J]. 化工学报, 2013, 64(5): 1855-1861. |

| An S Y, Zhu J Y, Lu D N, et al. Lipase-catalyzed synthesis and characterization of high-molecular-weight PBS[J]. CIESC Journal, 2013, 64(5): 1855-1861. | |

| 2 | Cukalovic A, Stevens C V. Feasibility of production methods for succinic acid derivatives: a marriage of renewable resources and chemical technology[J]. Biofuels, Bioproducts and Biorefining, 2008, 2(6): 505-529. |

| 3 | 陈建兵, 廖克俭, 佟明友, 等. 顺酐加氢制备丁二酸酐的研究[J]. 石油化工高等学校学报, 2010, 23(4): 29-32. |

| Chen J B, Liao K J, Tong M Y, et al. Maleic anhydride hydrogenated to succinic anhydride[J]. Journal of Petrochemical Universities, 2010, 23(4): 29-32. | |

| 4 | 钟驭涛, 尚长宇, 王言东, 等. 利用酵母细胞工厂合成丁二酸的研究进展[J]. 生物工程学报, 2024, 40(8): 2644-2665. |

| Zhong Y T, Shang C Y, Wang Y D, et al. Advances in synthesis of succinic acid using yeast cell factories[J]. Chinese Journal of Biotechnology, 2024, 40(8): 2644-2665. | |

| 5 | Pallassana V, Neurock M. First-principles periodic density functional study of the hydrogenation of maleic anhydride to succinic anhydride over palladium(111)[J]. The Journal of Physical Chemistry B, 2000, 104(40): 9449-9459. |

| 6 | Wang C L, Zhang Y, Li H T, et al. Ni@C nanocatalysts for the highly efficient hydrogenation of maleic anhydride to γ-butyrolactone[J]. Molecular Catalysis, 2024, 556: 113866. |

| 7 | 房畅, 吕清林, 韩冰, 等. 顺酐加氢催化剂的研究进展[J]. 石油化工, 2023, 52(5): 720-727. |

| Fang C, Lyu Q L, Han B, et al. Research progress of maleic anhydride hydrogenation catalyst[J]. Petrochemical Technology, 2023, 52(5): 720-727. | |

| 8 | 黄国强. 负载型镍基催化剂的制备及加氢性能研究[D]. 西安: 西安石油大学, 2021. |

| Huang G Q. Preparation and hydrogenation performance of supported nickel-based catalyst[D]. Xi'an: Xi'an Shiyou University, 2021. | |

| 9 | Chen M R, Meng X, Liu N W, et al. Low supported nickel-cobalt catalyst for hydrogenation of maleic anhydride[J]. Fuel, 2023, 331: 125520. |

| 10 | 梁旭, 李丰, 魏灵朝, 等. 顺酐加氢连续生产丁二酸酐中试工艺研究[J]. 化学与生物工程, 2018, 35(10): 56-59. |

| Liang X, Li F, Wei L C, et al. Pilot process of continuous production of succinic anhydride by hydrogenation of maleic anhydride[J]. Chemistry & Bioengineering, 2018, 35(10): 56-59. | |

| 11 | Cai J X, Zhu J X, Zuo L, et al. Effect of surface acidity/basicity on the selective hydrogenation of maleic anhydride to succinic anhydride over supported nickel catalysts[J]. Catalysis Communications, 2018, 110: 93-96. |

| 12 | Zhao Y X, Qin X Q, Hou X C, et al. Preparation, characterization and properties of selective hydrogenation on Ni-based catalysts[J]. Acta Physico-Chimica Sinica, 2003, 19(5): 450-454. |

| 13 | Tian F P, Zhang M J, Zhang X C, et al. Porous carbon-encapsulated Ni nanocatalysts for selective catalytic hydrogenation of cinnamaldehyde to hydrocinnamaldehyde[J]. Journal of Materials Science, 2022, 57(5): 3168-3182. |

| 14 | Zhou Y F, Chen Q L, Wang Q, et al. Selective hydrogenation of maleic anhydride to succinic anhydride over nickel catalyst supported on carbon microspheres[J]. China Petroleum Processing & Petrochemical Technology, 2021, 23(4): 75-82. |

| 15 | Wang Y, Sang S Y, Zhu W, et al. CuNi@C catalysts with high activity derived from metal-organic frameworks precursor for conversion of furfural to cyclopentanone[J]. Chemical Engineering Journal, 2016, 299: 104-111. |

| 16 | 姚雅琪. 凝聚相脂肪酸酯加氢铜基催化剂的制备与调控[D]. 天津: 天津大学, 2020. |

| Yao Y Q. Preparation and regulation of copper-based catalyst for hydrogenation of fatty acid esters in condensed phase[D]. Tianjin: Tianjin University, 2020. | |

| 17 | 曹萌. 草酸酯加氢制乙醇负载型铁基催化剂的研究[D]. 天津: 天津大学, 2022. |

| Cao M. Study on supported iron-based catalyst for hydrogenation of oxalate to ethanol[D]. Tianjin: Tianjin University, 2022. | |

| 18 | 杨文龙, 赵玉军, 王胜平, 等. 铜硅催化剂中层状硅酸铜的形成过程[J]. 化学工业与工程, 2016, 33(1): 1-5. |

| Yang W L, Zhao Y J, Wang S P, et al. Formation of copper phyllosilicate in silica supported copper catalyst[J]. Chemical Industry and Engineering, 2016, 33(1): 1-5. | |

| 19 | Tan J J, Xia X L, Cui J L, et al. Efficient tuning of surface nickel species of the Ni-phyllosilicate catalyst for the hydrogenation of maleic anhydride[J]. The Journal of Physical Chemistry C, 2019, 123(15): 9779-9787. |

| 20 | Sheng Q, Wang Y Y, Zhang P F, et al. Highly dispersed Ni on defective carbon with metal-support interaction for efficient and selective cinnamaldehyde hydrogenation[J]. Applied Surface Science, 2024, 666: 160369. |

| 21 | Campisi S, Chan-Thaw C E, Villa A. Understanding heteroatom-mediated metal-support interactions in functionalized carbons: a perspective review[J]. Applied Sciences, 2018, 8(7): 1159. |

| 22 | Zhuang J G, Yan S Y, Zhang P, et al. Regulating the states of Ni species by controlling the silanols of MCM-41 support to promote the hydrogenation of maleic anhydride[J]. Fuel, 2023, 335: 127030. |

| 23 | 张因, 赵丽丽, 张鸿喜, 等. 载体对镍基催化剂顺酐液相加氢性能的影响[J]. 化工学报, 2015, 66(7): 2505-2513. |

| Zhang Y, Zhao L L, Zhang H X, et al. Effect of support on catalytic performance of nickel-based catalysts used for liquid phase hydrogenation of maleic anhydride[J]. CIESC Journal, 2015, 66(7): 2505-2513. | |

| 24 | Li P F, Huang H J, Wang Z, et al. Reductive amination of n-hexanol to n-hexylamine over Ni-Ce/γ-Al2O3 catalysts[J]. Frontiers of Chemical Science and Engineering, 2023, 17(1): 82-92. |

| 25 | Feng Y H, Yin H B, Wang A L, et al. Selective hydrogenation of maleic anhydride to succinic anhydride catalyzed by metallic nickel catalysts[J]. Applied Catalysis A: General, 2012, 425: 205-212. |

| 26 | Regenhardt S A, Meyer C I, Garetto T F, et al. Selective gas phase hydrogenation of maleic anhydride over Ni-supported catalysts: effect of support on the catalytic performance[J]. Applied Catalysis A: General, 2012, 449: 81-87. |

| 27 | Choy J H, Yoon J B, Jung H, et al. Structural evolution of SiO2-ZrO2 nano-sol intercalated clays upon pillaring reaction[J]. Journal of Materials Chemistry, 2003, 13(3): 557-562. |

| 28 | Baldovino-Medrano V G, Niño-Celis V, Isaacs Giraldo R. Systematic analysis of the nitrogen adsorption-desorption isotherms recorded for a series of materials based on microporous-mesoporous amorphous aluminosilicates using classical methods[J]. Journal of Chemical & Engineering Data, 2023, 68(9): 2512-2528. |

| 29 | Meyer C I, Regenhardt S A, Bertone M E, et al. Gas-phase maleic anhydride hydrogenation over Ni/SiO2-Al2O3 catalysts: effect of metal loading[J]. Catalysis Letters, 2013, 143(10): 1067-1073. |

| 30 | Molina-Sabio M, Rodrı́guez-Reinoso F. Role of chemical activation in the development of carbon porosity[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2004, 241(1/2/3): 15-25. |

| 31 | Gao B Y, Huang H J, Rehman M U, et al. Amination of n-hexanol to n-hexylamine over Ru-Ni bimetallic catalyst [J]. Journal of Chemical Technology & Biotechnology, 2024. doi: 10.1002/jctb.7751 . |

| 32 | Pham-Huu C, Ledoux M J. Carbon nanomaterials with controlled macroscopic shapes as new catalytic materials[J]. Topics in Catalysis, 2006, 40(1): 49-63. |

| 33 | Fúnez A, De Lucas A, Sánchez P, et al. Hydroisomerization in liquid phase of a refinery naphtha stream over Pt-Ni/H-beta zeolite catalysts[J]. Chemical Engineering Journal, 2008, 136(2/3): 267-275. |

| 34 | Byun M Y, Lee M S. Pt supported on hierarchical porous carbon for furfural hydrogenation[J]. Journal of Industrial and Engineering Chemistry, 2021, 104: 406-415. |

| 35 | Fu Y, Devred F, Eloy P, et al. The effect of Ni particle size and carbon support on catalytic activity for glucose hydrogenation reaction[J]. Applied Catalysis A: General, 2022, 644: 118833. |

| 36 | Dasari M A, Kiatsimkul P P, Sutterlin W R, et al. Low-pressure hydrogenolysis of glycerol to propylene glycol[J]. Applied Catalysis A: General, 2005, 281(1/2): 225-231. |

| 37 | 李波, 鲍世宁, 曹培林. 乙烯和乙炔基在Ni(110)表面上吸附结构的研究[J]. 物理学报, 2005, 54(12): 5784. |

| Li B, Bao S N, Cao P L. Adsorption geometry of C2H4 and C2H on Ni(110) surface[J]. Acta Physica Sinica, 2005, 54(12): 5784. | |

| 38 | Li B, Bao S N, Zhuang Y Y, et al. The adsorption geometry of ethylene on the Ni (110) surface[J]. Acta Physica Sinica, 2003, 52(1): 202. |

| 39 | Lv S S, Liu X J, Shen X J. A simulated-TPD study of H2 desorption on metal surfaces[J]. Surface Science, 2022, 718: 122015. |

| 40 | Lueking A D, Yang R T. Hydrogen spillover to enhance hydrogen storage—study of the effect of carbon physicochemical properties[J]. Applied Catalysis A: General, 2004, 265(2): 259-268. |

| 41 | Zea H, Lester K, Datye A K, et al. The influence of Pd-Ag catalyst restructuring on the activation energy for ethylene hydrogenation in ethylene-acetylene mixtures[J]. Applied Catalysis A: General, 2005, 282(1/2): 237-245. |

| 42 | Neurock M, Pallassana V, van Santen R A. The importance of transient states at higher coverages in catalytic reactions[J]. Journal of the American Chemical Society, 2000, 122(6): 1150-1153. |

| 43 | Filhol J S, Simon D, Sautet P. Ethylene adsorption and coadsorption with H on Pd(110) from first principles[J]. The Journal of Physical Chemistry B, 2003, 107(7): 1604-1615. |

| 44 | Tan Y C, Abu Bakar N H H, Tan W L, et al. Hydrogenation of liquid styrene by alumina supported nickel catalysts: comparison between classical and non-classical methods[J]. IOP Conference Series: Materials Science and Engineering, 2016, 133: 012017. |

| 45 | Chen S, Miao C X, Luo Y, et al. Study of catalytic hydrodeoxygenation performance of Ni catalysts: effects of prepared method[J]. Renewable Energy, 2018, 115: 1109-1117. |

| [1] | 陈彦霖, 周爱国, 郑家乐, 杨川箬, 葛天舒. 载体对于胺浸渍类DAC吸附剂性能的影响[J]. 化工学报, 2024, 75(S1): 217-222. |

| [2] | 石美琳, 赵连达, 邓行健, 王静松, 左海滨, 薛庆国. 催化甲烷重整工艺的研究进展[J]. 化工学报, 2024, 75(S1): 25-39. |

| [3] | 王树振, 王玉婷, 马梦茜, 张巍, 向江南, 鲁海莹, 王琰, 范彬彬, 郑家军, 代卫炯, 李瑞丰. 两步晶化合成ZSM-22分子筛及其临氢异构反应性能[J]. 化工学报, 2024, 75(9): 3176-3187. |

| [4] | 王冉, 王焕, 熊晓云, 关慧敏, 郑云锋, 陈彩琳, 秦玉才, 宋丽娟. FCC催化剂传质强化活性位利用效率的可视化分析[J]. 化工学报, 2024, 75(9): 3198-3209. |

| [5] | 胡德政, 王榕, 王世栋, 杨文菲, 张宏伟, 袁珮. 兼具加氢和脱硫活性的富含Ni δ+非晶态NiP@γ-Al2O3催化剂的构筑及其用于石油树脂加氢的性能研究[J]. 化工学报, 2024, 75(9): 3152-3162. |

| [6] | 刘亚超, 谭晓杰, 李旭东, 王瑞, 王慧, 韩璇, 赵青山. DES合成高活性CoCO3纳米片及析氧反应性能研究[J]. 化工学报, 2024, 75(9): 3320-3328. |

| [7] | 张梦婷, 王书林, 桑熙, 元兴昊, 徐刚. 人工Cu-TM1459金属酶催化不对称迈克尔加成反应[J]. 化工学报, 2024, 75(9): 3255-3265. |

| [8] | 刘旭升, 李泽洋, 杨宇森, 卫敏. 电催化二氧化碳还原制备气态产物的研究进展[J]. 化工学报, 2024, 75(7): 2385-2408. |

| [9] | 王寅, 初鹏飞, 刘虎, 吕静, 黄守莹, 王胜平, 马新宾. 不同pH铝溶胶对二甲醚羰基化成型丝光沸石催化剂性能的影响[J]. 化工学报, 2024, 75(7): 2533-2543. |

| [10] | 杨露, 刘聪聪, 孟彤彤, 张博远, 杨腾飞, 邓文安, 王晓斌. 分散型催化剂在煤/重油共炼体系中的加氢抑焦作用[J]. 化工学报, 2024, 75(7): 2556-2564. |

| [11] | 罗莉, 陈文尧, 张晶, 钱刚, 周兴贵, 段学志. 氧化铝结构与表面性质调控及其催化甲醇脱水制二甲醚性能研究[J]. 化工学报, 2024, 75(7): 2522-2532. |

| [12] | 王天闻, 闫肃, 赵梦园, 杨天让, 刘建国. 固体氧化物电池空气电极铬中毒机理及抗铬性能研究进展[J]. 化工学报, 2024, 75(6): 2091-2108. |

| [13] | 丁禹, 杨昌泽, 李军, 孙会东, 商辉. 原子尺度钼系加氢脱硫催化剂的研究进展与展望[J]. 化工学报, 2024, 75(5): 1735-1749. |

| [14] | 赵亭亭, 鄢立祥, 唐福利, 肖敏之, 谭烨, 宋刘斌, 肖忠良, 李灵均. 光辅助锂-二氧化碳电池催化剂的设计策略与反应机理研究进展[J]. 化工学报, 2024, 75(5): 1750-1764. |

| [15] | 莫锦洪, 韩雪, 朱毅翔, 李菁, 王旭裕, 纪红兵. Pt-Ga/CeO2-ZrO2-Al2O3脱氢裂解双功能催化剂用于正丁烷催化制烯烃研究[J]. 化工学报, 2024, 75(5): 1855-1869. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号