化工学报 ›› 2024, Vol. 75 ›› Issue (11): 4254-4263.DOI: 10.11949/0438-1157.20240808

收稿日期:2024-07-17

修回日期:2024-09-25

出版日期:2024-11-25

发布日期:2024-12-26

通讯作者:

侯宝林,王晓东

作者简介:侯宝林(1979—),男,博士,研究员,blhou@dicp.ac.cn

基金资助:

Baolin HOU1( ), Ruoxi HAN1,2, Xiaodong WANG1(

), Ruoxi HAN1,2, Xiaodong WANG1( )

)

Received:2024-07-17

Revised:2024-09-25

Online:2024-11-25

Published:2024-12-26

Contact:

Baolin HOU, Xiaodong WANG

摘要:

单组元能源属于燃气能源,不同于依赖氧气燃烧释能的常规能源,它是无须空气条件下通过催化分解含能液体化学品生成高温高压气体,流经拉瓦尔喷管产生推力或吹动涡轮输出轴功率。特点是高可靠,快响应,低成本,飞行高度不受限,常被用于为航空航天装备提供轨道维持和应急保障的动力。该类能源动力系统启动时,液体推进剂进入到反应催化床内与催化剂接触,并在毛细管力作用下,浸入载体微-纳孔道内被贵金属纳米粒子活化,发生催化分解反应生成高温高压小分子气相。受催化剂孔道结构、尺寸及表面活性影响,孔道内催化分解产气速率大于流体向外运动速度时,内部气相压力会急剧升高,甚至破坏载体毛细孔道结构导致失活。本文采用Poiseuille流描述催化剂孔道内的气相产物流动、毛细管力驱动牛顿第二定律解析气-液界面移动、反应物扩散-反应模型预测产气速率,揭示肼推进剂催化分解反应启动时在催化剂微纳孔道内的流动,催化反应以及气相压力形成过程,解析了启动过程中孔道内压过大导致催化剂破坏失活的物理现象,为单组元推进剂分解用催化剂孔道结构设计开发提供理论基础。

中图分类号:

侯宝林, 韩若曦, 王晓东. 催化剂微纳孔道内液体推进剂流动与分解反应过程研究[J]. 化工学报, 2024, 75(11): 4254-4263.

Baolin HOU, Ruoxi HAN, Xiaodong WANG. Process of monopropellant flow and catalytic decomposition reaction in micro/nano pores of catalyst[J]. CIESC Journal, 2024, 75(11): 4254-4263.

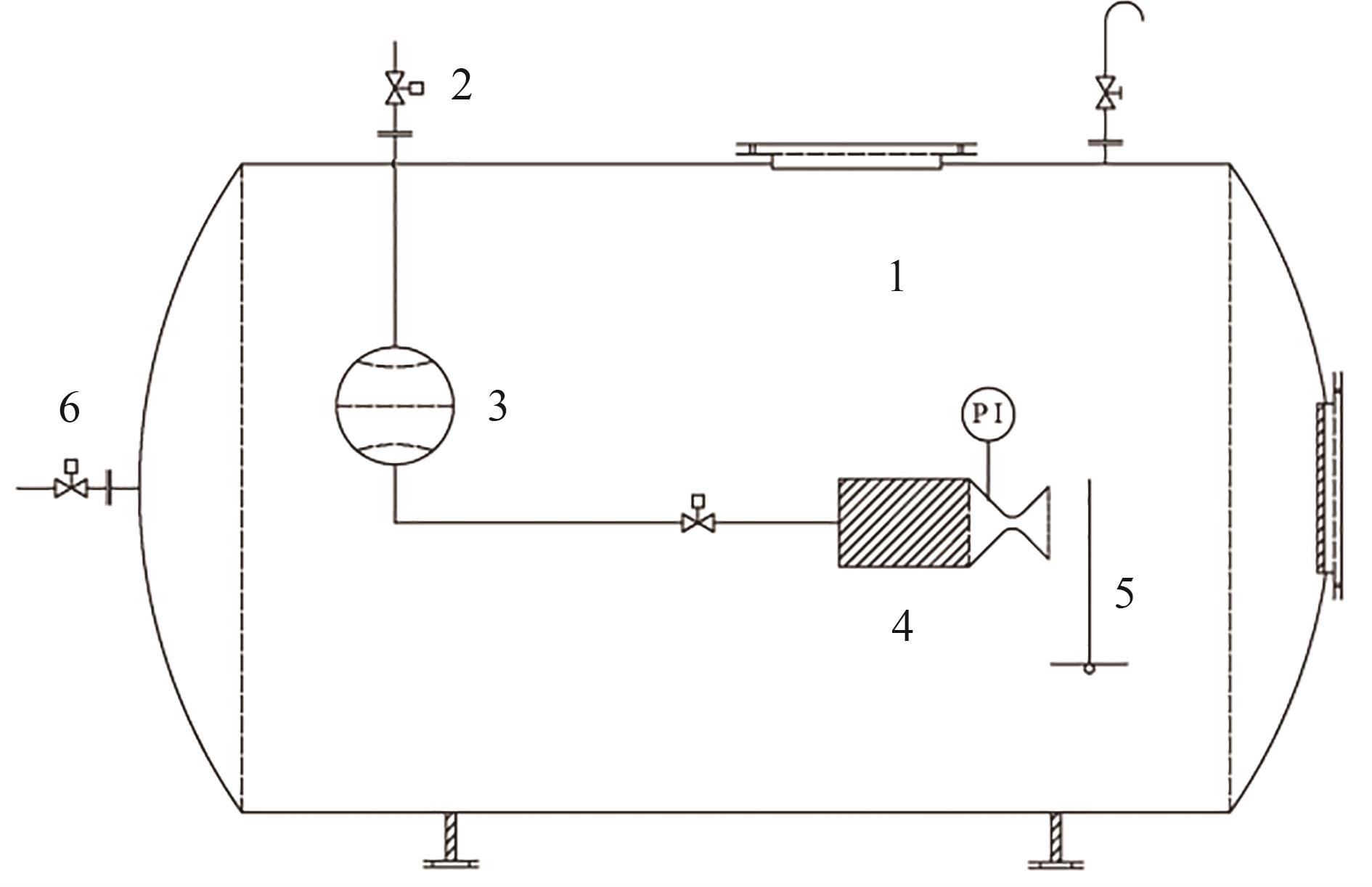

图4 单组元发动机点火实验舱示意图1—真空舱;2—高压氮气阀门;3—推进剂储箱;4—单组元发动机;5—推力架;6—真空泵入口

Fig.4 Schematic diagram of monopropellant thruster ignition test chamber1—vacuum chamber; 2—high pressure nitrogen valve; 3—propellant storage tank; 4—monopropellant; 5—thrust force test; 6—vacuum pump inlet

| 1 | Hwang C H, Lee S N, Baek S W, et al. Effects of catalyst bed failure on thermochemical phenomena for a hydrazine monopropellant thruster using Ir/Al2O3 catalysts[J]. Industrial & Engineering Chemistry Research, 2012, 51(15): 5382-5393. |

| 2 | Hou B L, Wang X D, Li T, et al. Steady-state behavior of liquid fuel hydrazine decomposition in packed bed[J]. AIChE Journal, 2015, 61(3): 1064-1080. |

| 3 | Spores R, Masse R, Kimbrel S, et al. GPIM AF-M315E propulsion system[C]//51st AIAA/SAE/ASEE Joint Propulsion Conference. Reston, Virginia: AIAA, 2015: 3753. |

| 4 | Chambreau S D, Popolan-Vaida D M, Kostko O, et al. Thermal and catalytic decomposition of 2-hydroxyethylhydrazine and 2-hydroxyethylhydrazinium nitrate ionic liquid[J]. The Journal of Physical Chemistry A, 2022, 126(3): 373-394. |

| 5 | Koerner M. Recent developments in aircraft emergency power[C]//35th Intersociety Energy Conversion Engineering Conference and Exhibit. Reston, Virginia: AIAA, 2000: 2802. |

| 6 | Masse R K, Glassy B A, Spores R A, et al. Hydrazine-based green monopropellant blends[C]//AIAA SCITECH 2024 Forum. Reston, Virginia: AIAA, 2024: 1619. |

| 7 | Thomas J C, Rodriguez F A, Teitge D S, et al. Lab-scale ballistic and safety property investigations of LMP-103S[J]. Combustion and Flame, 2023, 253: 112810. |

| 8 | Esparza A A, Chambreau S D, Vaghjiani G L, et al. Two-stage decomposition of 2-hydroxyethylhydrazinium nitrate (HEHN)[J]. Combustion and Flame, 2020, 220: 1-6. |

| 9 | 杨敏, 曹炳阳. 微纳通道中牛顿流体毛细流动的研究进展[J]. 科学通报, 2016, 61(14): 1574-1584. |

| Yang M, Cao B Y. Advances of capillary filling of Newtonian fluids in micro- and nanochannels[J]. Chinese Science Bulletin, 2016, 61(14): 1574-1584. | |

| 10 | Ye G H, Wang H Z, Zhou X G, et al. Optimizing catalyst pore network structure in the presence of deactivation by coking[J]. AIChE Journal, 2019, 65(10): e16687. |

| 11 | Kerr D H, Karagozian A R, Bilyeu D, et al. Nondeterministic analysis of monopropellant catalyst bed model[J]. Journal of Propulsion and Power, 2021, 37(1): 126-138. |

| 12 | Sun D C, Liu J, Xiang W B. Numerical simulation of the transient process of monopropellant rocket engines[J]. Aerospace Science and Technology, 2020, 103: 105921. |

| 13 | Hwang C H, Baek S W, Cho S J. Experimental investigation of decomposition and evaporation characteristics of HAN-based monopropellants[J]. Combustion and Flame, 2014, 161(4): 1109-1116. |

| 14 | Walls P L L, Dequidt G, Bird J C. Capillary displacement of viscous liquids[J]. Langmuir, 2016, 32(13): 3186-3190. |

| 15 | Fries N, Dreyer M. An analytic solution of capillary rise restrained by gravity[J]. Journal of Colloid and Interface Science, 2008, 320(1): 259-263. |

| 16 | Bird B R, Stewart W E, Lightfoot E N. Transport Phenomena[M]. 2nd ed. New York: John Wiley & Sons, Inc., 2002:46. |

| 17 | Levenspiel O. Chemical Reaction Engineering [M]. 3rd ed. New York: John Wiley & Sons, Inc., 1999:105. |

| 18 | Washburn E W. The dynamics of capillary flow[J]. Physical Review, 1921, 17(3): 273-283. |

| 19 | Figliuzzi B, Buie C R. Rise in optimized capillary channels[J]. Journal of Fluid Mechanics, 2013, 731: 142-161. |

| 20 | Han A P, Mondin G, Hegelbach N G, et al. Filling kinetics of liquids in nanochannels as narrow as 27 nm by capillary force[J]. Journal of Colloid and Interface Science, 2006, 293(1): 151-157. |

| 21 | Wu P K, Ramakrishnan T S, Zhang H, et al. Closed-end capillary rise—an experimental study[J]. AIChE Journal, 2020, 66(6): e16964. |

| 22 | Wood J, Gladden L F. Modelling diffusion and reaction accompanied by capillary condensation using three-dimensional pore networks (Part 1): Fickian diffusion and pseudo-first-order reaction kinetics[J]. Chemical Engineering Science, 2002, 57(15): 3033-3045. |

| 23 | Wood J, Gladden L F, Keil F J. Modelling diffusion and reaction accompanied by capillary condensation using three-dimensional pore networks (Part 2): Dusty gas model and general reaction kinetics[J]. Chemical Engineering Science, 2002, 57(15): 3047-3059. |

| 24 | 吕同富, 康兆敏, 方秀男. 数值计算方法[M]. 北京: 清华大学出版社, 2008: 281. |

| Lyu T F, Kang Z M, Fang X N. Numerical Computation Method[M]. Beijing: Tsinghua University Press, 2008: 281. | |

| 25 | Soares Neto T G, Dias F F, Cobo A J G, et al. Evolution of textural properties and performance of Ir/Al2O3 catalysts during hydrazine catalytic decomposition in a 2N satellite thruster[J]. Chemical Engineering Journal, 2011, 173(1): 220-225. |

| 26 | Heo S, Jo S, Yun Y, et al. Effect of dual-catalytic bed using two different catalyst sizes for hydrogen peroxide thruster[J]. Aerospace Science and Technology, 2018, 78: 26-32. |

| 27 | Wilhelm M, Negri M, Ciezki H, et al. Preliminary tests on thermal ignition of ADN-based liquid monopropellants[J]. Acta Astronautica, 2019, 158: 388-396. |

| 28 | Negri M, Lauck F. Hot firing tests of a novel green hypergolic propellant in a thruster[J]. Journal of Propulsion and Power, 2022, 38(3): 467-477. |

| 29 | 吴越. 应用催化基础[M]. 北京: 化学工业出版社, 2009: 243. |

| Wu Y. Basis of Applied Catalysis[M]. Beijing: Chemical Industry Press, 2009: 243. | |

| 30 | Gugulothu R, Macharla A K, Chatragadda K, et al. Catalytic decomposition mechanism of aqueous ammonium dinitramide solution elucidated by thermal and spectroscopic methods[J]. Thermochimica Acta, 2020, 686: 178544. |

| [1] | 赵振刚, 周梦瑶, 金典, 张大骋. 基于泡沫碳扩散层的直接甲醇燃料电池改性研究[J]. 化工学报, 2024, 75(S1): 259-266. |

| [2] | 赵昂然, 韩永强, 王志鹏, 李鹏飞, 许亚伟, 佟会玲. 常温条件下赤泥同时脱硫脱硝实验研究[J]. 化工学报, 2024, 75(S1): 276-282. |

| [3] | 赵焕娟, 包颖昕, 于康, 刘婧, 钱新明. 多元组分爆轰不稳定性定量实验研究[J]. 化工学报, 2024, 75(S1): 339-348. |

| [4] | 李焱, 郑利军, 张恩勇, 王云飞. 深水海底管道软管内部流体渗透特性模型与试验研究[J]. 化工学报, 2024, 75(S1): 118-125. |

| [5] | 杨勇, 祖子轩, 李煜坤, 王东亮, 范宗良, 周怀荣. T型圆柱形微通道内CO2碱液吸收数值模拟[J]. 化工学报, 2024, 75(S1): 135-142. |

| [6] | 王冉, 王焕, 熊晓云, 关慧敏, 郑云锋, 陈彩琳, 秦玉才, 宋丽娟. FCC催化剂传质强化活性位利用效率的可视化分析[J]. 化工学报, 2024, 75(9): 3198-3209. |

| [7] | 杨子驰, 谢冰琪, 石瑞莘, 雷虹, 陈晨, 周才金, 张吉松. 套管膜式微反应器内高效安全的气液传质-反应过程研究进展[J]. 化工学报, 2024, 75(9): 3011-3027. |

| [8] | 罗欣怡, 徐强, 佘永璐, 聂腾飞, 郭烈锦. 光电分解水制氢气泡动力学特性及其传质机理研究[J]. 化工学报, 2024, 75(9): 3083-3093. |

| [9] | 刘亚超, 谭晓杰, 李旭东, 王瑞, 王慧, 韩璇, 赵青山. DES合成高活性CoCO3纳米片及析氧反应性能研究[J]. 化工学报, 2024, 75(9): 3320-3328. |

| [10] | 张梦婷, 王书林, 桑熙, 元兴昊, 徐刚. 人工Cu-TM1459金属酶催化不对称迈克尔加成反应[J]. 化工学报, 2024, 75(9): 3255-3265. |

| [11] | 丁家琦, 刘海涛, 赵普, 朱香凝, 王晓放, 谢蓉. 煤炭超临界水制氢反应器内多相流场智能滚动预测研究[J]. 化工学报, 2024, 75(8): 2886-2896. |

| [12] | 吕方明, 包志铭, 王博文, 焦魁. 气体扩散层侵入流道对燃料电池水管理影响研究[J]. 化工学报, 2024, 75(8): 2929-2938. |

| [13] | 赵帅琪, 张瑞, 黄瀚, 赵昆鹏, 白博峰. 水气转化对超临界水煤气化的抑制特性[J]. 化工学报, 2024, 75(8): 2960-2969. |

| [14] | 姚宏哲, 黄飞宇, 杨松, 钟梅, 代正华. 重质油高温快速热解自动反应网络的动力学建模[J]. 化工学报, 2024, 75(7): 2644-2655. |

| [15] | 黄静茹, 陈佳轩, 张群锋, 阮晋, 朱来, 叶光华, 周兴贵. ZSM-5分子筛结构对苯烷基化反应性能影响的数值模拟研究[J]. 化工学报, 2024, 75(7): 2544-2555. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号