化工学报 ›› 2025, Vol. 76 ›› Issue (12): 6179-6195.DOI: 10.11949/0438-1157.20250329

陈欣妍( ), 陈依玲, 彭馨博, 胡靖杰, 江学良, 游峰(

), 陈依玲, 彭馨博, 胡靖杰, 江学良, 游峰( )

)

收稿日期:2025-04-01

修回日期:2025-04-19

出版日期:2025-12-31

发布日期:2026-01-23

通讯作者:

游峰

作者简介:陈欣妍(2004—),女,本科生,1980215892@qq.com

Xinyan CHEN( ), Yiling CHEN, Xinbo PENG, Jingjie HU, Xueliang JIANG, Feng YOU(

), Yiling CHEN, Xinbo PENG, Jingjie HU, Xueliang JIANG, Feng YOU( )

)

Received:2025-04-01

Revised:2025-04-19

Online:2025-12-31

Published:2026-01-23

Contact:

Feng YOU

摘要:

随着全球能源消耗和温室气体排放问题日益严峻,开发高效、环保的隔热材料已成为材料科学与工程领域的重要课题。隔热材料在建筑、工业、航空航天等领域应用广泛,尤其在减少能量损失和提高能源效率方面起着关键作用。综述了近年来隔热材料的制备、结构研究进展,重点介绍了有机、无机及其复合气凝胶和泡沫的结构特性及其隔热性能,通过对比分析各类材料的热导率及耐温性能,系统梳理了不同材料体系的适用场景与应用现状。最后,展望了隔热材料未来的发展趋势,认为多尺度结构设计、仿生结构和可持续材料的结合将成为提高隔热性能的关键路径。

中图分类号:

陈欣妍, 陈依玲, 彭馨博, 胡靖杰, 江学良, 游峰. 隔热材料的制备、结构及应用研究进展[J]. 化工学报, 2025, 76(12): 6179-6195.

Xinyan CHEN, Yiling CHEN, Xinbo PENG, Jingjie HU, Xueliang JIANG, Feng YOU. Recent progress in the preparation, structure, and application of thermal insulation materials[J]. CIESC Journal, 2025, 76(12): 6179-6195.

| 分类 | 典型材料 | 形态 | 热导率/ (W/(m·K)) | 性能特点 | 制备方法 | 文献 |

|---|---|---|---|---|---|---|

| 有机高分子材料 | 聚苯乙烯泡沫板(EPS) | 泡沫 | 40.0 | 轻质易切割,吸水性较高,需阻燃处理;广泛用于建筑墙体保温 | 挤出法、泡沫塑料加工法 | — |

| 聚苯乙烯泡沫挤塑板(XPS) | 泡沫 | 30.0 | 闭孔结构,抗压强度高,防潮性好;适用于地暖、冷库 | 挤出成型法 | — | |

| 聚氨酯泡沫(PUR) | 泡沫 | 20.0~30.0 | 高黏结性,无缝填充,阻燃性优于EPS;用于冷链、管道保温 | 发泡法、喷涂法 | [ | |

| 聚酰亚胺 | 泡沫 | 100.0~50.0 | 耐温性较好,低烟无毒,脆性较高 | 热固化法、发泡法 | [ | |

| 生物质材料 | 纤维素 | 颗粒 | 40.0~60.0 | 天然可再生,弹性好,但易受潮霉变;用于红酒塞、装饰保温 | — | [ |

| 壳聚糖 | 松散填充 | 50.0~200.0 | 高孔隙率,吸声性强,防虫蛀;适用于热带地区建筑隔热 | — | [ | |

| 木质素 | 板材 | 50.0~70.0 | 农业废弃物再生利用,成本低,但耐火性差;用于临时建筑夹层 | — | [ | |

| 无机材料 | 硅酸铝纤维 | 纤维棉 | 30.0~40.0 | 耐高温,抗热震,但对皮肤有刺激性;用于窑炉内衬 | 纤维化法、吹气法 | [ |

| 碳纳米线圈 | — | 20.0~40.0 | 超弹性,电磁屏蔽效能高,表面活性位点多;用于催化载体,柔性传感器 | — | [ | |

| 石墨烯 | — | 10.0~20.0 | 超高导电性,超轻,力学强度可调;应用于超级电容器电极,高效散热片 | — | [ | |

| 二氧化硅 | 气凝胶 | 10.0~20.0 | 超轻,憎水性强,柔性可裁剪;用于航天服、管道包裹 | 超临界干燥法、溶胶-凝胶法 | [ | |

| 碳 | 气凝胶 | 10.0~20.0 | 导电性可控,耐高温,纳米多孔结构;用于电池隔热、电子器件 | — | [ | |

| 玻璃棉 | 纤维卷材 | 30.0~40.0 | 成本低,吸声性能好,但易碎裂;广泛用于建筑吊顶、管道保温 | 纤维化法、吹气法 | [ | |

| 有机-无机杂化材料 | 二氧化硅气凝胶/聚酰亚胺泡沫 | 泡沫 | 24.0 | 高温稳定性强,良好的隔热性能 | 液氮气化法 | [ |

| 聚酰亚胺气凝胶/二氧化硅复合材料 | 气凝胶 | 7.4 | 卓越的低热导率和结构稳定性 | 3D打印与氢键网络调控 | [ | |

| 间位芳纶纤维/氟化空心玻璃微球 | 气凝胶 | 21.6 | 高的隔热性能及耐热性 | 溶胶-凝胶法 | [ |

表1 常见隔热材料及其相关性能

Table 1 Common thermal insulation materials and their properties

| 分类 | 典型材料 | 形态 | 热导率/ (W/(m·K)) | 性能特点 | 制备方法 | 文献 |

|---|---|---|---|---|---|---|

| 有机高分子材料 | 聚苯乙烯泡沫板(EPS) | 泡沫 | 40.0 | 轻质易切割,吸水性较高,需阻燃处理;广泛用于建筑墙体保温 | 挤出法、泡沫塑料加工法 | — |

| 聚苯乙烯泡沫挤塑板(XPS) | 泡沫 | 30.0 | 闭孔结构,抗压强度高,防潮性好;适用于地暖、冷库 | 挤出成型法 | — | |

| 聚氨酯泡沫(PUR) | 泡沫 | 20.0~30.0 | 高黏结性,无缝填充,阻燃性优于EPS;用于冷链、管道保温 | 发泡法、喷涂法 | [ | |

| 聚酰亚胺 | 泡沫 | 100.0~50.0 | 耐温性较好,低烟无毒,脆性较高 | 热固化法、发泡法 | [ | |

| 生物质材料 | 纤维素 | 颗粒 | 40.0~60.0 | 天然可再生,弹性好,但易受潮霉变;用于红酒塞、装饰保温 | — | [ |

| 壳聚糖 | 松散填充 | 50.0~200.0 | 高孔隙率,吸声性强,防虫蛀;适用于热带地区建筑隔热 | — | [ | |

| 木质素 | 板材 | 50.0~70.0 | 农业废弃物再生利用,成本低,但耐火性差;用于临时建筑夹层 | — | [ | |

| 无机材料 | 硅酸铝纤维 | 纤维棉 | 30.0~40.0 | 耐高温,抗热震,但对皮肤有刺激性;用于窑炉内衬 | 纤维化法、吹气法 | [ |

| 碳纳米线圈 | — | 20.0~40.0 | 超弹性,电磁屏蔽效能高,表面活性位点多;用于催化载体,柔性传感器 | — | [ | |

| 石墨烯 | — | 10.0~20.0 | 超高导电性,超轻,力学强度可调;应用于超级电容器电极,高效散热片 | — | [ | |

| 二氧化硅 | 气凝胶 | 10.0~20.0 | 超轻,憎水性强,柔性可裁剪;用于航天服、管道包裹 | 超临界干燥法、溶胶-凝胶法 | [ | |

| 碳 | 气凝胶 | 10.0~20.0 | 导电性可控,耐高温,纳米多孔结构;用于电池隔热、电子器件 | — | [ | |

| 玻璃棉 | 纤维卷材 | 30.0~40.0 | 成本低,吸声性能好,但易碎裂;广泛用于建筑吊顶、管道保温 | 纤维化法、吹气法 | [ | |

| 有机-无机杂化材料 | 二氧化硅气凝胶/聚酰亚胺泡沫 | 泡沫 | 24.0 | 高温稳定性强,良好的隔热性能 | 液氮气化法 | [ |

| 聚酰亚胺气凝胶/二氧化硅复合材料 | 气凝胶 | 7.4 | 卓越的低热导率和结构稳定性 | 3D打印与氢键网络调控 | [ | |

| 间位芳纶纤维/氟化空心玻璃微球 | 气凝胶 | 21.6 | 高的隔热性能及耐热性 | 溶胶-凝胶法 | [ |

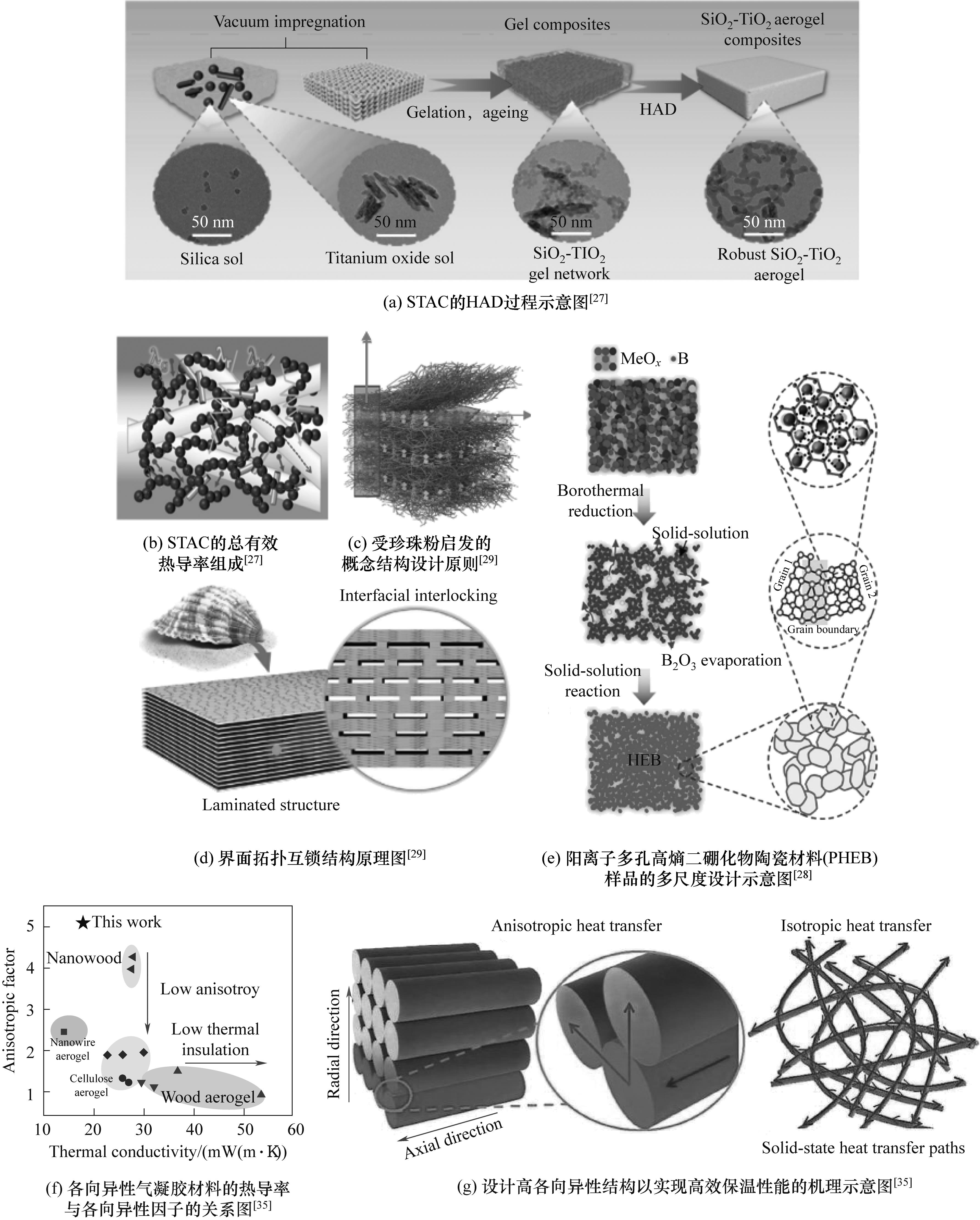

图2 陶瓷隔热材料制备方法、微观形貌以及隔热机理分析

Fig.2 The preparation methods, microstructures and thermal insulation mechanism analysis of ceramic thermal insulation materials

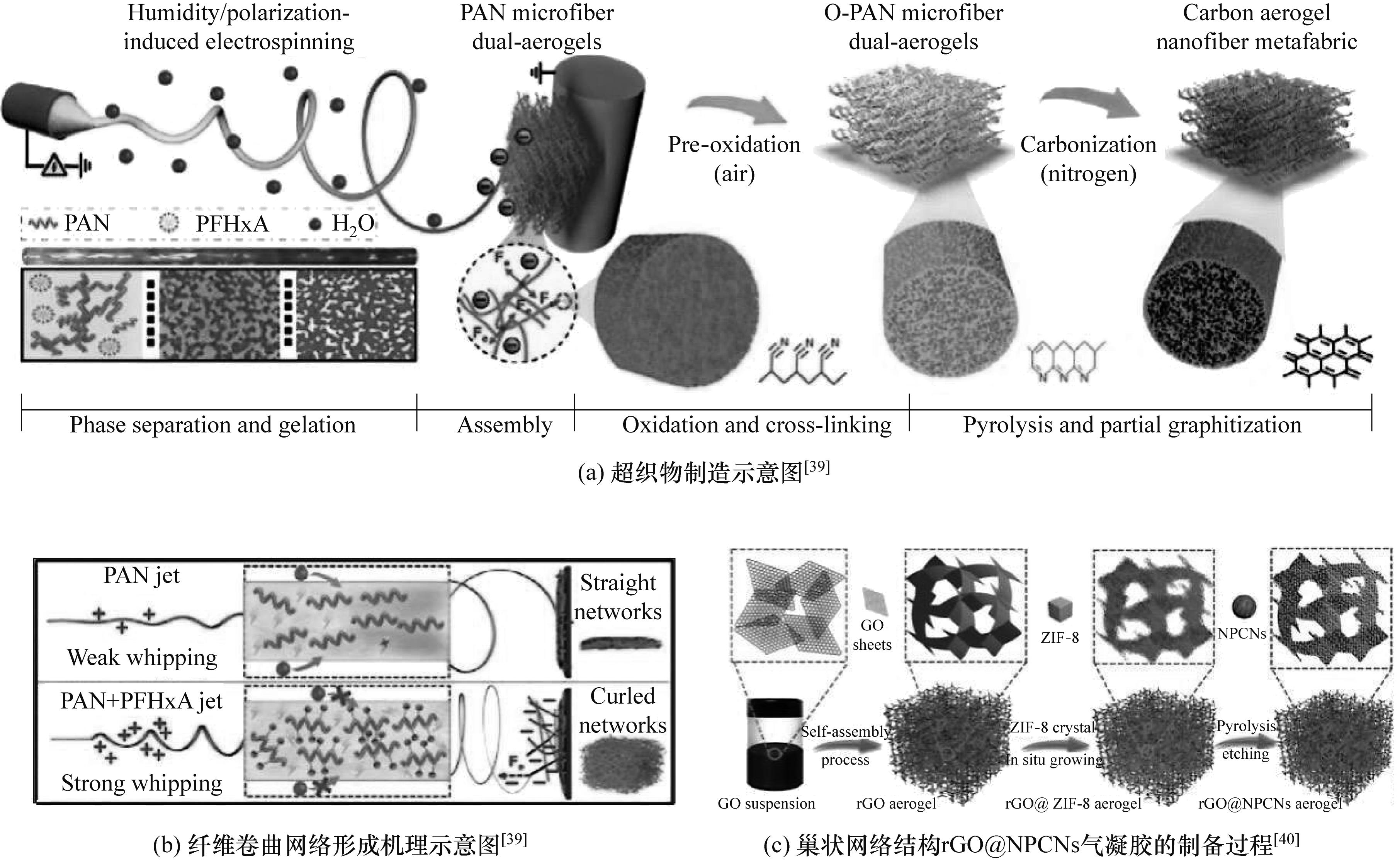

图3 碳基隔热材料制备方法、热导率比较及隔热机理分析

Fig.3 Preparation methods of carbon-based thermal insulation materials, comparison of thermal conductivity, and analysis of insulation mechanisms

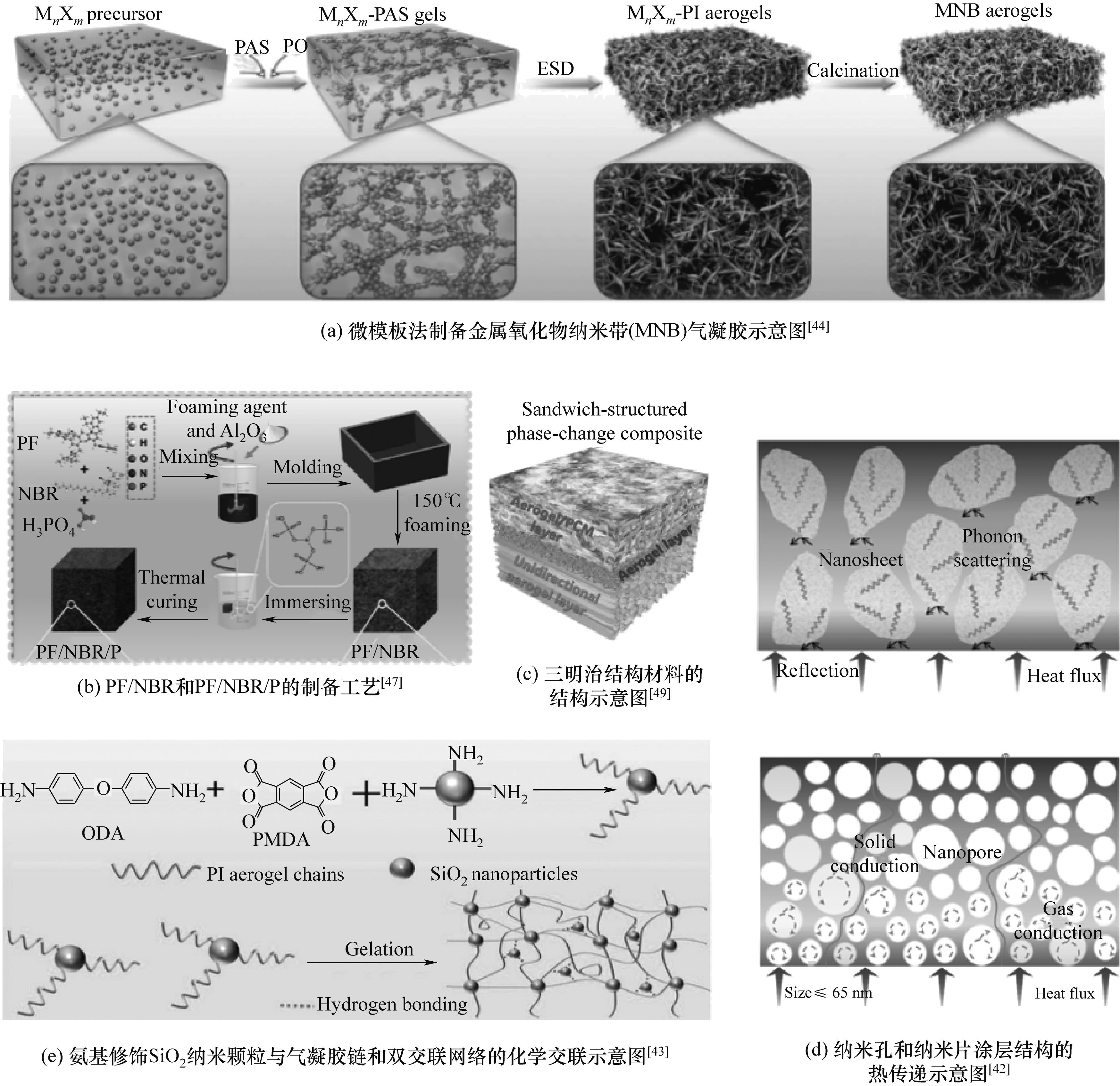

图4 有机高分子隔热材料制备工艺、结构设计以及传热机理分析

Fig.4 The preparation process, structural design, and heat transfer mechanism analysis of organic polymer thermal insulation materials

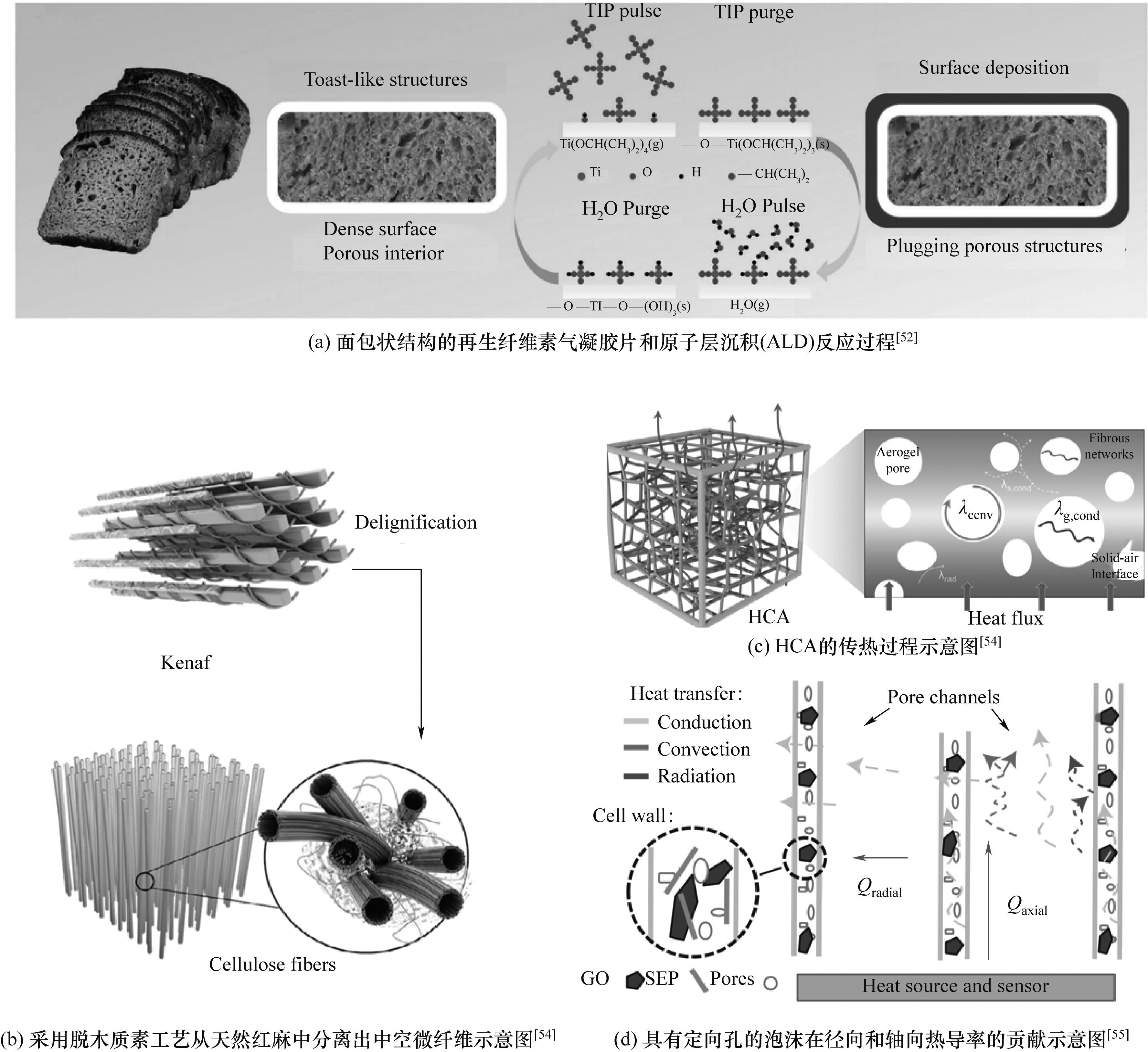

图5 生物质隔热材料结构设计、多孔调控及热传导路径优化研究

Fig.5 Research on structural design, porosity regulation, and thermal conduction path optimization of biomass insulation materials

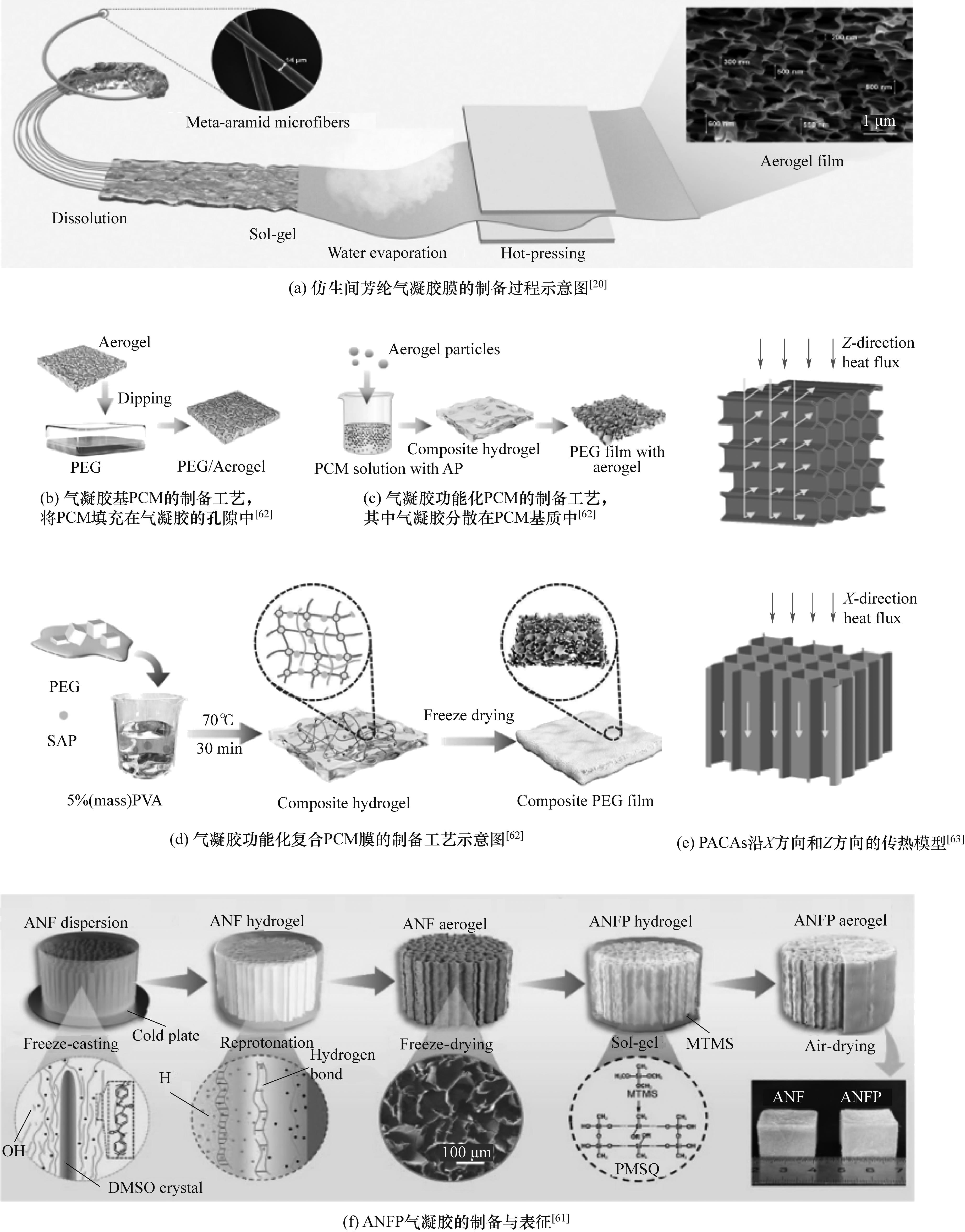

图7 有机-无机杂化隔热材料的制备工艺以及传热机理分析

Fig.7 The preparation process of organic-inorganic hybrid thermal insulation materials and the analysis of heat transfer mechanisms

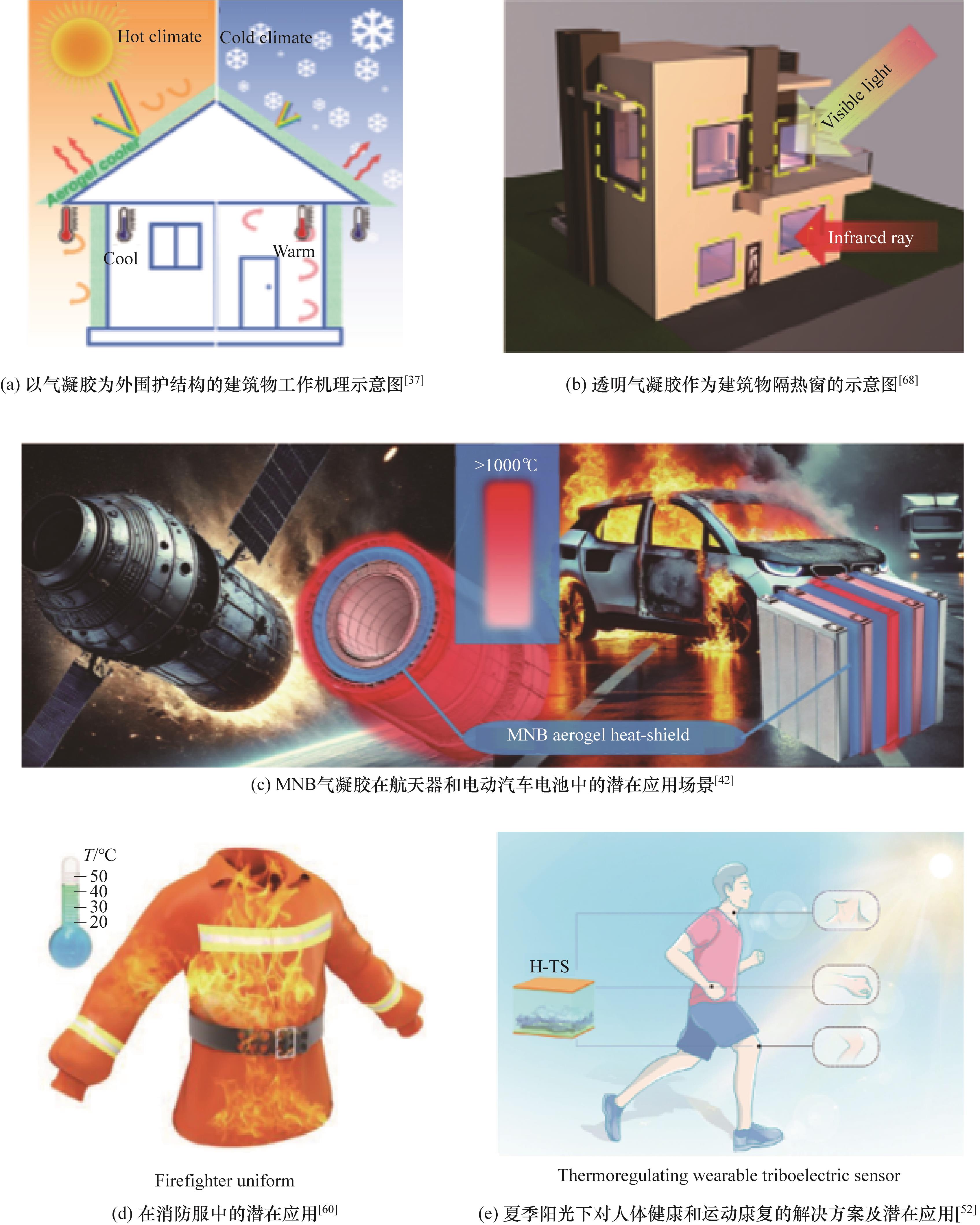

图8 隔热材料在建筑、航天、电池、防护衣物等领域的多功能应用研究

Fig.8 Research on the multifunctional applications of thermal insulation materials in the fields of construction, aerospace, batteries, and protective clothing

| [1] | Feng J B, Ma Z W, Wu J P, et al. Fire-safe aerogels and foams for thermal insulation: from materials to properties[J]. Advanced Materials, 2025, 37(3): 2411856. |

| [2] | 章婷, 赵春林, 乐弦, 等. 气凝胶研究进展[J]. 现代技术陶瓷, 2018, 39(1): 1-39. |

| Zhang T, Zhao C L, Le X, et al. Research progress of aerogels[J]. Advanced Ceramics, 2018, 39(1): 1-39. | |

| [3] | 李德富, 杨炜平, 刘小旭. 多层隔热材料传热特性研究现状及展望[J]. 航天器环境工程, 2013, 30(3): 302-309. |

| Li D F, Yang W P, Liu X X. Heat transfer characteristics of multilayer insulation materials[J]. Spacecraft Environment Engineering, 2013, 30(3): 302-309. | |

| [4] | 柳凤琦, 王鲁凯, 门静, 等. 气凝胶隔热材料制备及航天热防护应用研究进展[J]. 宇航材料工艺, 2022, 52(2): 26-47. |

| Liu F Q, Wang L K, Men J, et al. Progress on the preparation of aerogel thermal insulations and their applications in aerospace thermal protection system[J]. Aerospace Materials & Technology, 2022, 52(2): 26-47. | |

| [5] | 施伟, 谭毅, 曹作暄. 隔热材料研究现状及发展趋势[J]. 材料导报, 2012, 26(S1): 344-347. |

| Shi W, Tan Y, Cao Z X. Research status and development trend of thermal insulating materials[J]. Materials Reports, 2012, 26(S1): 344-347. | |

| [6] | 门静, 王鲁凯, 冯军宗, 等. 炭气凝胶隔热材料研究进展[J]. 材料工程, 2024, 52(6): 78-91. |

| Men J, Wang L K, Feng J Z, et al. Research progress in carbon aerogels for thermal insulations[J]. Journal of Materials Engineering, 2024, 52(6): 78-91. | |

| [7] | Zhang Y, Wu Y Y, Liu Z J, et al. Preparation and properties of waterborne polyurethane/nanocellulose/sepiolite composite aerogel for sound absorption and heat insulation[J]. International Journal of Biological Macromolecules, 2025, 298: 140015. |

| [8] | Wu H, Ren X H, Hu W X, et al. Permittivity controllable CNTs/PI composite aerogels with oriented microchannels for advanced microwave absorption and thermal isolation[J]. Carbon, 2025, 233: 119883. |

| [9] | Zhou Q Q, Hong W J, Sheng K X, et al. Direct ink writing 3D printed graphene oxide nanocomposite aerogel for intelligent fire-warning and exceptional fire-shielding[J]. Chemical Engineering Journal, 2024, 499: 156325. |

| [10] | Wang H C, Cao L Y, Liu Y, et al. Preparation of sustainable kapok fiber/chitosan composite aerogels with amphiphilic and mechanical properties for thermal insulation and packaging applications[J]. Fibers and Polymers, 2024, 25(6): 2081-2091. |

| [11] | Zhang M R, Jeong S, Cho W, et al. Green co-solvent-assisted one-pot synthesis of high-performance flexible lignin polyurethane foam[J]. Chemical Engineering Journal, 2024, 499: 156142. |

| [12] | Deng T, Li Y F, Jiang C W, et al. A facile and green preparation of aluminum silicate fiber reinforced silica aerogel composites for thermal insulation[J]. Journal of Porous Materials, 2025, 32: 1237-1251. |

| [13] | Guo Y, Duan Y P, Gu S D, et al. Carbon nanocoils-assisted formation of tunable pore graphene aerogels for lightweight broadband microwave absorption, thermal insulation, and antifreeze devices[J]. Small, 2025, 21(10): 2412270. |

| [14] | Cho J, Jang E, Kim J, et al. Development of boron nitride hydroxide/aluminum oxide/epoxy resin spheres and graphene oxide-loaded L-ascorbic acid aerogel for enhanced thermal conductivity and insulation via hot-pressing[J]. Polymers for Advanced Technologies, 2025, 36(2): e70120. |

| [15] | Wang J H, Liu L P, Dong W L, et al. Ultra-high radial elastic aerogel fibers for thermal insulation textile[J]. Advanced Functional Materials, 2025, 35(13): 2417873. |

| [16] | Sha R Y, Wang B Z, Dai J X, et al. Novel ultralight carbon foam reinforced carbon aerogel composites with low volume shrinkage and excellent thermal insulation performance[J]. Carbon, 2025, 232: 119826. |

| [17] | Tariq I, Hu J H, Chen W J, et al. Summer and winter performance evaluation of double layered PTFE dome with aerogel-glass wool thermal insulation—field experiments and numerical simulation[J]. Energy and Buildings, 2024, 319: 114538. |

| [18] | Wang Y Y, Pang N, Yin X Q, et al. Rapid preparation of stretchable, compressible and flexible nanofiber foams by one-step expansion for thermal insulation and adsorption of sound and oil[J]. Chemical Engineering Journal, 2025, 506: 159916. |

| [19] | Li M M, Wu T T, Zhao Z Y, et al. Multiscale manufacturing of recyclable polyimide composite aerogels[J]. Advanced Materials, 2025, 37(5): 2411599. |

| [35] | Zhang Z, Liu C, Li N, et al. Highly oriented SiC@SiO2 ceramic fiber aerogels with good anisotropy of the thermal conductivity and high-temperature resistance[J]. Advanced Science, 2025, 12(17): 2416740. |

| [36] | Zhou J T, Wu E J, Hu Y H, et al. Structurally resilient carbon nanofiber aerogels from aramid nanofibers for thermal insulation under extreme conditions[J]. Chemical Engineering Journal, 2025, 505: 159507. |

| [37] | Wu F S, Hu P Y, Hu F Y, et al. Multifunctional MXene/C aerogels for enhanced microwave absorption and thermal insulation[J]. Nano-Micro Letters, 2023, 15(1): 194. |

| [38] | Ma Y J, Hu Y H, Wang Y, et al. Seasonal thermal management and fire-resistant aramid nanofiber/MXene-NH2 aerogel for enhanced safety and year-round energy saving[J]. ACS Applied Nano Materials, 2024, 7(20): 23485-23493. |

| [39] | Tian Y C, Chen Y X, Wang S, et al. Energy-harvesting carbon aerogel nanofiber metafabric for high-efficiency thermoregulation[J]. Advanced Functional Materials, 2025, 35(4): 2414229. |

| [40] | Gai L X, Zhao H H, Li X A, et al. Shell engineering afforded dielectric polarization prevails and impedance amelioration toward electromagnetic wave absorption enhancement in nested-network carbon architecture[J]. Chemical Engineering Journal, 2024, 501: 157556. |

| [41] | Cheng Y J, Cheng H L, Gao J, et al. Air-drying for rapid manufacture of flexible aramid nanofiber aerogel fibers with robust mechanical properties and thermal insulation in harsh environments[J]. Small, 2025, 21(7): 2409408. |

| [42] | Luo W, Wang T, Gou X, et al. In situ assembly of nanostructured polyelectrolyte coatings by aqueous phase separation toward outstanding thermal insulation and fire resistance[J]. ACS Materials Letters, 2024, 6(12): 5418-5428. |

| [43] | Chen J, Hou X B, Chen Z L, et al. Double-crosslinked organic-inorganic hybrid polyimide aerogel composites with ultra-robust toughness for foldable mechanical-thermal-coupled protection[J]. Advanced Functional Materials, 2025, 35(23): 2420717. |

| [44] | Wang X D, Wang Y J, Zhang Z, et al. Strong and ultrahigh temperature-resistant metal oxide nanobelt aerogels[J]. Advanced Functional Materials, 2025, 35(5): 2414592. |

| [45] | Yang C G, Xu Y K, Liu H Y, et al. Multiscale porous heat insulation polypropylene foam with high infrared absorption performance[J]. Langmuir, 2025, 41(8): 5546-5556. |

| [46] | Hu L K, Luo L, Zhang F H, et al. Self-Sensing shape memory boron phenolic-formaldehyde aerogels with tunable heat insulation for smart thermal protection systems[J]. Chemical Engineering Journal, 2025, 505: 159558. |

| [20] | Yang R, Yu K X, Yu X, et al. Penguin feather-inspired flexible aerogel composite films featuring ultra-low thermal conductivity and dielectric constant[J]. Materials Horizons, 2025, 12(8): 2629-2640. |

| [21] | Niu Z Q, Qu F J, Chen F, et al. Multifunctional integrated organic-inorganic-metal hybrid aerogel for excellent thermal insulation and electromagnetic shielding performance[J]. Nano-Micro Letters, 2024, 16(1): 200. |

| [22] | Wang Z Y, Li Z C, Li B, et al. Functional carbon springs enabled dynamic tunable microwave absorption and thermal insulation[J]. Advanced Materials, 2024, 36(49): 2412605. |

| [23] | Zhang W, Liang G Q, Wang S, et al. Loofah-inspired ultralight and superelastic micro/nanofibrous aerogels for highly efficient thermal insulation[J]. Advanced Functional Materials, 2025, 35(2): 2412424. |

| [24] | Yu N, Wang T, Xu C X, et al. In-situ packing self-intumescent aerogel particles in rigid polyurethane foam towards thermal insulation, flame retardance and smoke suppression[J]. Chemical Engineering Journal, 2025, 503: 158514. |

| [25] | Cai S H, Deng X P, Beiyuan J Z, et al. Review of synthetic polymer-based thermal insulation materials in construction and building[J]. Journal of Building Engineering, 2024, 97: 110846. |

| [26] | Zhang P, Zhao S, Li K F, et al. Large-scale production of elastic SiC/SiO2 nanofibrous composite aerogels with a labyrinth structure for high-temperature insulation, fire prevention, and noise absorption[J]. Chemical Engineering Journal, 2025, 505: 159166. |

| [27] | Xie Z Q, Jiang Y G, Feng J Z, et al. Thermally insulating fiber-reinforced SiO2-TiO2 aerogel composites via a novel hydrothermal-assisted drying process[J]. Ceramics International, 2025, 51(11): 14834-14841. |

| [28] | Wen Z H, Tang Z Y, Liu Y W, et al. Ultrastrong and high thermal insulating porous high-entropy ceramics up to 2000℃[J]. Advanced Materials, 2024, 36(14): 2311870. |

| [29] | Zhang X, Huang W B, Yu J Y, et al. Nacre-mimetic multi-mechanical synergistic ceramic aerogels with interfacial bridging and stress delocalization[J]. Advanced Functional Materials, 2025, 35(10): 2416857. |

| [30] | Yu P H, Gao Y, Zhang G D, et al. 3D self-supportive structures of micro/nanofiber assemblies constructed in situ in air turbulent flow fields for thermal protection at extreme conditions[J]. Chemical Engineering Journal, 2025, 511: 161536. |

| [31] | Li L F, Yin Y G, Mi C Y, et al. Phase stability, flexibility and thermal insulation of DyTaO4 fibers[J]. Chemical Engineering Journal, 2025, 505: 159590. |

| [47] | Song L M, Wu Y Z, Xue J L, et al. A high-temperature resistant phosphate-phenolic composite foam with low density, high strength, flame retardant and thermal insulating properties[J]. Composites Part B: Engineering, 2025, 297: 112294. |

| [48] | Zhang X, Wang Z Q, Ding S, et al. Improved thermal insulation, mechanical properties, energy absorption and flame retardancy of bio-based rigid polyurethane foam modified with calcium hydroxystannate[J]. Construction and Building Materials, 2024, 456: 139251. |

| [49] | Shi T, Jing J W, Qian Z Q, et al. Sandwich-structured fluorinated polyimide aerogel/paraffin phase-change composites simultaneously enables gradient thermal protection and electromagnetic wave transmission[J]. Advanced Science, 2025, 12(5): 2411758. |

| [50] | Fu X T, Si L M, Zhang Z X, et al. Gradient all-nanostructured aerogel fibers for enhanced thermal insulation and mechanical properties[J]. Nature Communications, 2025, 16(1): 2357. |

| [51] | Chen Z L, Hou X B, Chen J, et al. Two-step phase-separated ANF/polyimide aerogel fibers with tunable in situ core-sheath structure for wearable heat-insulated fabrics[J]. Composites Part A: Applied Science and Manufacturing, 2025, 192: 108801. |

| [52] | Huang Z Y, Tong A X, Xing T H, et al. Regenerated cellulose/lignin composite aerogel with unique toast-like structure and their potential applications in thermal camouflage[J]. Advanced Functional Materials, 2025, 35(6): 2414696. |

| [53] | Liu Y M, Bu X H, Feng M X, et al. Spectrally selective and thermally insulating hybrid nanofiber aerogel coolers for building energy conservation[J]. Journal of Colloid and Interface Science, 2025, 680: 345-354. |

| [54] | Zhong S J, Lu B H, Wang D C, et al. Passive isothermal flexible sensor enabled by smart thermal-regulating aerogels[J]. Advanced Materials, 2025, 37(8): 2415386. |

| [55] | Wicklein B, Kocjan A, Salazar-Alvarez G, et al. Thermally insulating and fire-retardant lightweight anisotropic foams based on nanocellulose and graphene oxide[J]. Nature Nanotechnology, 2015, 10(3): 277-283. |

| [56] | Gao C Q, Gou D M, Huang G, et al. Spiderweb-structured aerogels with high-efficiency microwave absorption and multifunctionality[J]. Nano Energy, 2025, 138: 110863. |

| [57] | Le D T, Carbonnier B, Hamadi S, et al. Toward the development of graphene/chitosan biocomposite aerogels with enhanced mechanical and thermal insulation performance[J]. ACS Applied Polymer Materials, 2024, 6(21): 13132-13146. |

| [58] | Liu Z Y, Liu T, Dong H P, et al. Diatom-inspired nanoscale heterogeneous assembly strategy for constructing thermal insulating wood-based aerogels with exceptional strength, resilience, degradability, and flame retardancy[J]. ACS Nano, 2025, 19(7): 6826-6839. |

| [59] | Zhang J Y, Zheng J J, Gao M Y, et al. Nacre-mimetic nanocomposite aerogels with exceptional mechanical performance for thermal superinsulation at extreme conditions[J]. Advanced Materials, 2023, 35(29): 2300813. |

| [60] | Men J, He C B, Wang L K, et al. Synthesis of structure controllable carbon aerogel with low drying shrinkage and scalable size as high-temperature thermal insulator[J]. Chemical Engineering Journal, 2025, 503: 157989. |

| [61] | Hu Z H, Wang S, Wu J P, et al. Robust multi-scale bionic ANF/PMSQ aerogel featuring impact protection, thermal insulation and anti-icing functions[J]. Composites Part B: Engineering, 2025, 297: 112304. |

| [62] | Wang G L, Liu L, Hu X Y, et al. Aerogel-functionalized phase change materials toward lightweight and robust thermal management[J]. Small Methods, 2025, 9(8): 2500127. |

| [63] | Wang L Y, Li W J, Wang C, et al. “Cocktail-like” double-layered polyimide/alumina composite aerogels via side-direction freezing method as designable high-temperature thermal insulations[J]. Chemical Engineering Journal, 2024, 500: 157052. |

| [64] | Kang Y F, Tang J L, Song M, et al. Electrostatic encapsulation of cobalt ions into crystalline framework derived polymer aerogel: ultra-light, pressure resistant, hydrophobic, photothermal conversion, heat insulation and infrared stealth[J]. Chinese Journal of Polymer Science, 2024, 42(7): 946-957. |

| [65] | Liu X, Zhu Q Z, Qian Y P, et al. Enhanced photothermal interface evaporation via coupling of Ag-GO aerogel with thermal insulation substrate[J]. Separation and Purification Technology, 2025, 360: 131080. |

| [66] | Ma Y L, Xing D M, Tian M W, et al. Multiwalled hollow polyurethane and graphene oxide/polyurethane fibers in Janus textiles for thermal management and sensors[J]. ACS Applied Nano Materials, 2024, 7(19): 22884-22894. |

| [67] | Jiang S, Jiang S Q, Yan J T, et al. Large-scale continuous production of cellulose/hollow SiO2 composite aerogel fibers for outdoor all-day radiation cooling[J]. Nano Energy, 2025, 136: 110688. |

| [68] | Li Y H, Zhang X, Zhang T, et al. Radiative cooling materials prepared by SiO2 aerogel microspheres@PVDF-HFP nanofilm for building cooling and thermal insulation[J]. Ceramics International, 2024, 50(22): 48031-48040. |

| [69] | Zhu T Y, Wang D B, Wang Y S, et al. Gelation-constrained freeze-casting fabrication of ultra-homogeneous nanocomposite aerogels with superelasticity and harsh environment tolerance[J]. Advanced Functional Materials, 2025, 35(12): 2503693. |

| [70] | Yu D Y, Xue T T, Ma Z C, et al. 3D printed polyimide/silica composite aerogels for customizable thermal insulation from -50℃ to 1300℃[J]. Chinese Journal of Polymer Science, 2024, 42(7): 936-945. |

| [32] | Miao J H, Song X L, Xu J X, et al. Ultralight, elastic, thermally insulating, and high-temperature resistant Al2O3-SiO2-B2O3 nanofibrous aerogels prepared via the direct foaming method[J]. ACS Applied Materials & Interfaces, 2025, 17(8): 12402-12414. |

| [33] | Dang S X, Guo J R, Deng Y P, et al. Highly-buckled nanofibrous ceramic aerogels with ultra-large stretchability and tensile-insensitive thermal insulation[J]. Advanced Materials, 2025, 37(4): 2415159. |

| [34] | Zhang X, Yu J Y, Si Y. Programmable shape-morphing enables ceramic meta-aerogel highly stretchable for thermal protection[J]. Advanced Materials, 2025, 37(3): 2412962. |

| [71] | Xue T T, Yuan S J, Yang Y, et al. Freezing-assisted direct ink writing of customized polyimide aerogels with controllable micro- and macro- structures for thermal insulation[J]. Advanced Functional Materials, 2025, 35(13): 2417734. |

| [72] | Chen Z Y, Wu Y Y, Liu S C, et al. Pottery-inspired flexible fire-shielding ceramifiable silicone foams for exceptional long-term thermal protection[J]. Advanced Functional Materials, 2025, 35(3): 2413362. |

| [73] | Zhou T P, He L B, Zhen Y, et al. Superstrong lightweight aerogel with supercontinuous layer by surface reaction[J]. Advanced Materials, 2025, 37(10): 2418083. |

| [74] | Wang G, Feng J B, Zhou Z Z, et al. Low-cost hyperelastic fuller-dome-structured nanocellulose aerogels by dual templates for personal thermal management[J]. Advanced Materials, 2024, 37(22): 2414896. |

| [75] | Yu Y, Xu C J, Hu Z X, et al. Industrial scale sea-island melt-spun continuous ultrafine fibers for highly comfortable insulated aerogel felt clothing[J]. Advanced Materials, 2024, 36(52): 2414731. |

| [76] | Hu Z Y, Zhang X Y, Sun Q, et al. Biomimetic transparent layered tough aerogels for thermal superinsulation and triboelectric nanogenerator[J]. Small, 2024, 20(24): 2307602. |

| [1] | 赵维, 邢文乐, 韩朝旭, 袁兴中, 蒋龙波. g-C3N4基非金属异质结光催化降解水中有机污染物的研究进展[J]. 化工学报, 2025, 76(9): 4752-4769. |

| [2] | 孙传付, 胡桂林, 曹俊杰, 左启斌, 陈媚, 夏玉珍. 梯度孔分布ZnO-GA锂离子电池负极材料研究[J]. 化工学报, 2025, 76(7): 3710-3718. |

| [3] | 郭铮铮, 赵一丹, 王辅强, 裴璐, 靳彦岭, 任芳, 任鹏刚. 异质结构MoS2/RGO/NiFe2O4复合材料的构筑及电磁波吸收性能研究[J]. 化工学报, 2025, 76(7): 3719-3732. |

| [4] | 陆学瑞, 周帼彦, 方琦, 俞孟正, 张秀成, 涂善东. 固体氧化物燃料电池外重整器积炭效应数值模拟研究[J]. 化工学报, 2025, 76(7): 3295-3304. |

| [5] | 唐银香, 朱风, 范莹莹, 龙雨欣, 代雍, 邓春玲, 黄小凤. 制备条件对改性电石渣低温共脱除COS和CS2的影响[J]. 化工学报, 2025, 76(7): 3639-3650. |

| [6] | 郭乃胜, 朱小波, 王双, 陈平, 褚召阳, 王志臣. 聚氨酯改性沥青高低温性能及影响因素的研究进展[J]. 化工学报, 2025, 76(6): 2505-2523. |

| [7] | 彭健, 沈鲁恺, 王立坤, 忻利宏, 刘涌, 赵高凌, 马赛男, 韩高荣. 钨酸盐纳米材料的制备及其在电致变色领域的研究进展[J]. 化工学报, 2025, 76(6): 2451-2468. |

| [8] | 杨盛华, 孙阳杰, 薛晓君, 米杰, 王建成, 冯宇. 缺陷型金属氧化物脱除气体污染物研究进展[J]. 化工学报, 2025, 76(6): 2469-2482. |

| [9] | 朱迪, 高守建, 方望熹, 靳健. 水蒸气诱导相分离构筑海绵孔结构超亲水聚醚砜膜及其油/水乳液分离性能研究[J]. 化工学报, 2025, 76(5): 2397-2409. |

| [10] | 王金月, 谢恩泽, 马翰泽, 袁晟, 何光伟, 姜忠义. 单原子层分离膜:进展与展望[J]. 化工学报, 2025, 76(5): 1943-1959. |

| [11] | 安昊天, 韩章烨, 陆慕瑶, 周阿武, 李建荣. 推进MOF产业化应用:宏量制备与成型[J]. 化工学报, 2025, 76(5): 2011-2025. |

| [12] | 李家顺, 李旺, 秦祖赠, 苏通明, 谢新玲, 纪红兵. 聚酰亚胺增强木质纤维素纳米纤丝气凝胶制备及其油水分离性能研究[J]. 化工学报, 2025, 76(5): 2169-2185. |

| [13] | 石孟琪, 王欢, 王守娟, 席跃宾, 孔凡功. 木质素基炭材料的制备及其在锂硫电池中的研究进展[J]. 化工学报, 2025, 76(4): 1463-1483. |

| [14] | 肖俊兵, 钟湘宇, 任建地, 钟芳芳, 刘昌会, 贾传坤. 基于生物碳材料强化的硬脂酸相变材料储热性能研究[J]. 化工学报, 2025, 76(3): 1312-1322. |

| [15] | 刘彦贝, 王若名, 刘娟, Raza Taimoor, 陆玉正, Raza Rizwan, 朱斌, 李松波, 安胜利, 云斯宁. CeO2@La0.6Sr0.4Co0.2Fe0.8O3-δ 电解质的制备及半导体离子燃料电池性能研究[J]. 化工学报, 2025, 76(3): 1353-1362. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号