化工学报 ›› 2019, Vol. 70 ›› Issue (6): 2252-2258.DOI: 10.11949/j.issn.0438-1157.20181522

收稿日期:2018-12-27

修回日期:2019-02-17

出版日期:2019-06-05

发布日期:2019-06-05

通讯作者:

胡大鹏

作者简介:<named-content content-type="corresp-name">刘培启</named-content>(1981—),男,博士,副教授,<email>lpq21cn@dlut.edu.cn</email>

基金资助:

Peiqi LIU( ),Xinchen HE,Jia CHEN,Jiangtao GUO,Jianyu XI,Dapeng HU(

),Xinchen HE,Jia CHEN,Jiangtao GUO,Jianyu XI,Dapeng HU( )

)

Received:2018-12-27

Revised:2019-02-17

Online:2019-06-05

Published:2019-06-05

Contact:

Dapeng HU

摘要:

随着天然气井开发时间的推移,井口压力逐渐降低,低压井口的增压集输成为研究热点。目前,常用的天然气引射技术由于结构尺寸固定,对气井的压力和流量的变化适应性差,使其运行效率普遍较低。据此,设计加工了一台锥芯可调型引射器装置,并对其变工况性能进行了实验研究。结果表明随着可调锥的深入,高压口流量减小,可实现70%左右的流量调节,而且调节过程中低压口流量几乎保持不变,从而使得装置引射率ξ提高,可见该引射技术具有很强的抗流量波动能力。随着可调锥的深入,装置对应的最佳膨胀比增大,从而提高了装置对大膨胀比工况的适应性。同样压缩比下,装置引射效率会随着可调锥的深入而提高,但会降低装置有效引射的压缩比范围。

中图分类号:

刘培启, 何昕琛, 陈佳, 郭江涛, 席建宇, 胡大鹏. 锥芯可调型引射技术变工况适应性实验研究[J]. 化工学报, 2019, 70(6): 2252-2258.

Peiqi LIU, Xinchen HE, Jia CHEN, Jiangtao GUO, Jianyu XI, Dapeng HU. Variable working condition adaptability of cone core adjustable ejector[J]. CIESC Journal, 2019, 70(6): 2252-2258.

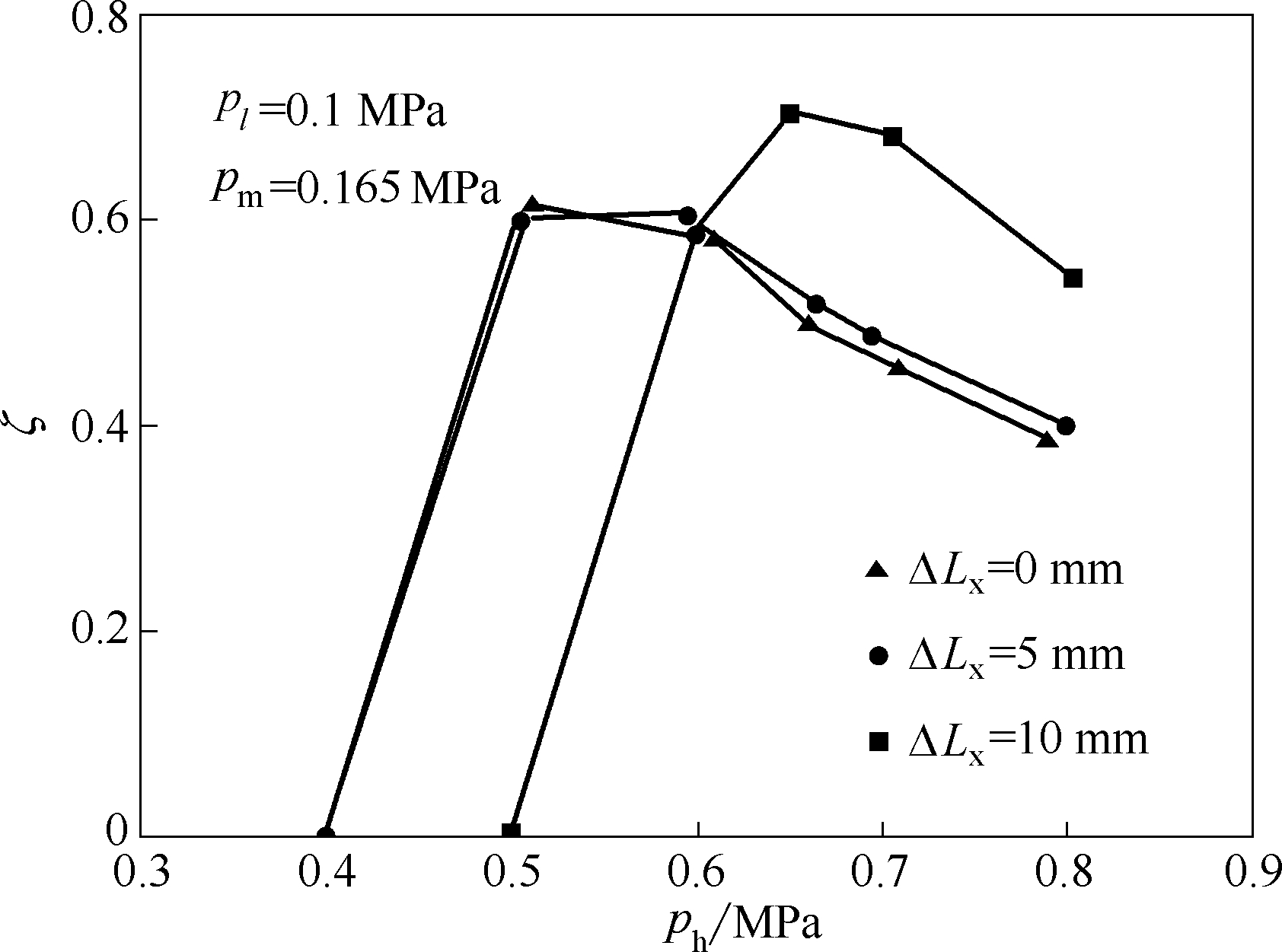

图10 P m =0.165 MPa、Pl = 0.1 MPa 时,具有可调锥结构的引射器性能曲线

Fig.10 Ejector performance curves with adjustable cone structure when P m =0.165 MPa and Pl = 0.1 MPa

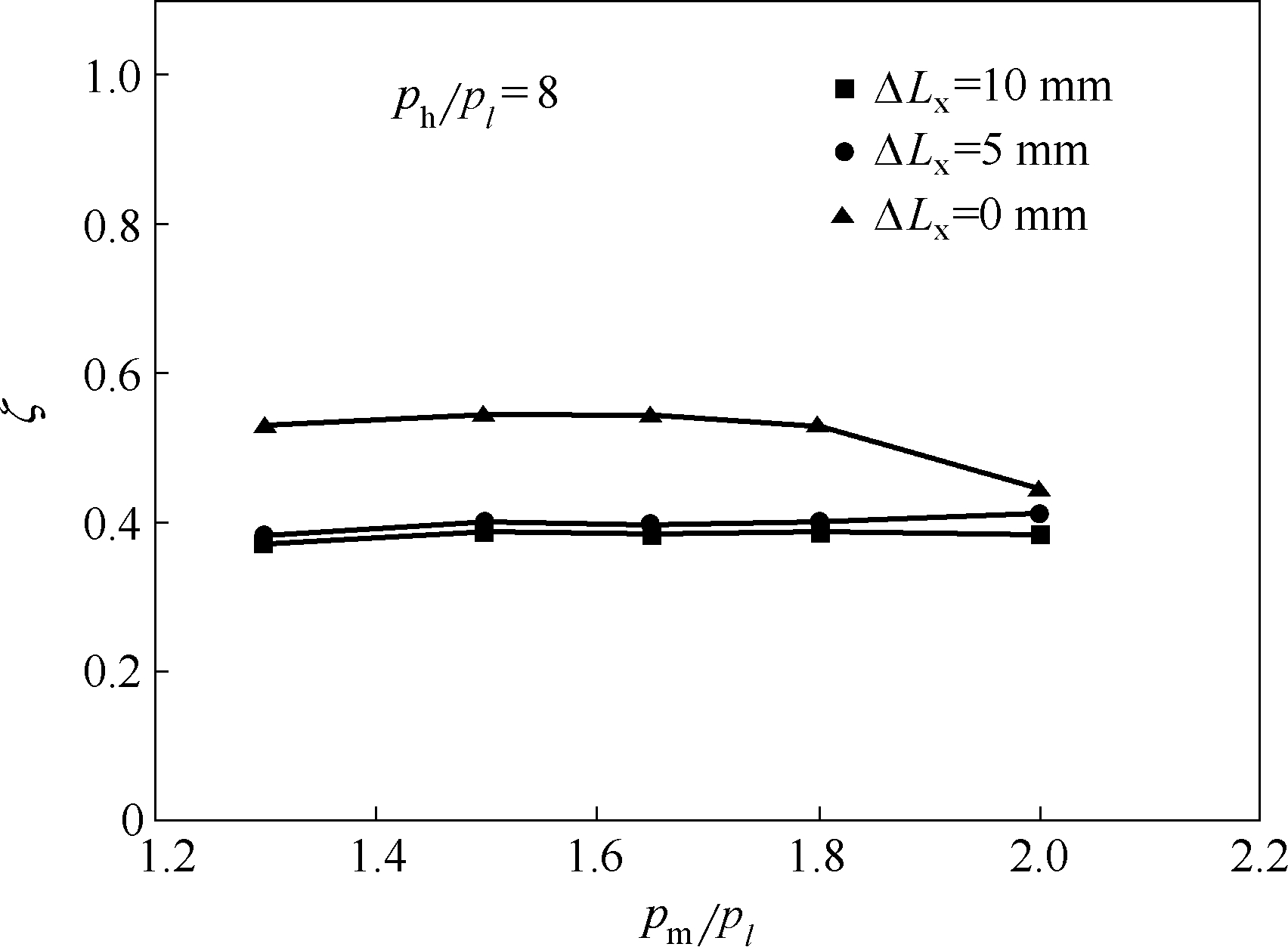

图12 膨胀比为8.0时,不同调节锥位置下引射率随压缩比的变化曲线

Fig.12 Curves of ejector rate with compression ratio at different adjustment cone positions when expansion ratio is 8.0

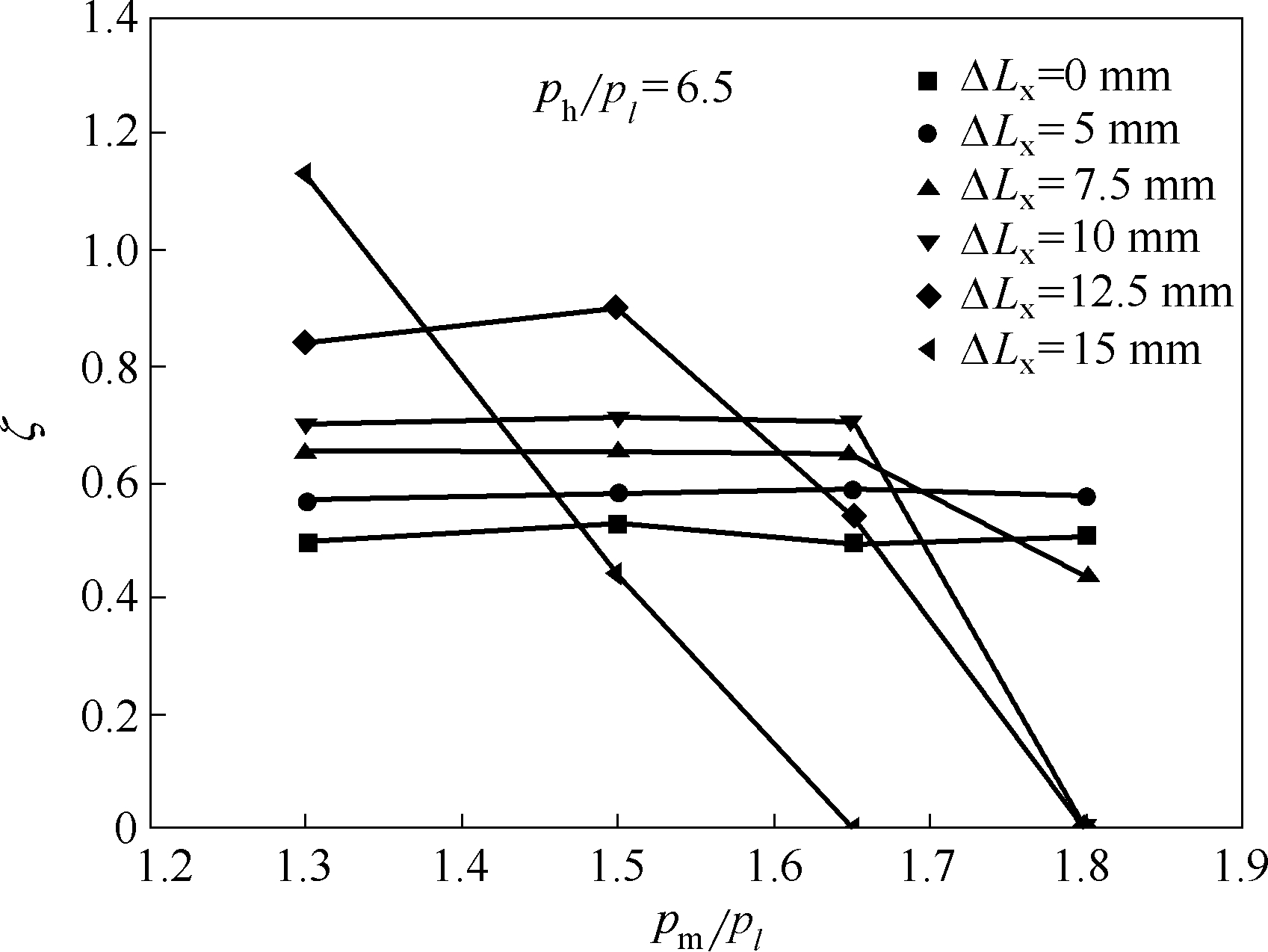

图13 膨胀比为6.5时,不同调节锥位置下引射率随压缩比的变化曲线

Fig.13 Curves of ejector rate with compression ratio at different adjustment cone positions when expansion ratio is 6.5

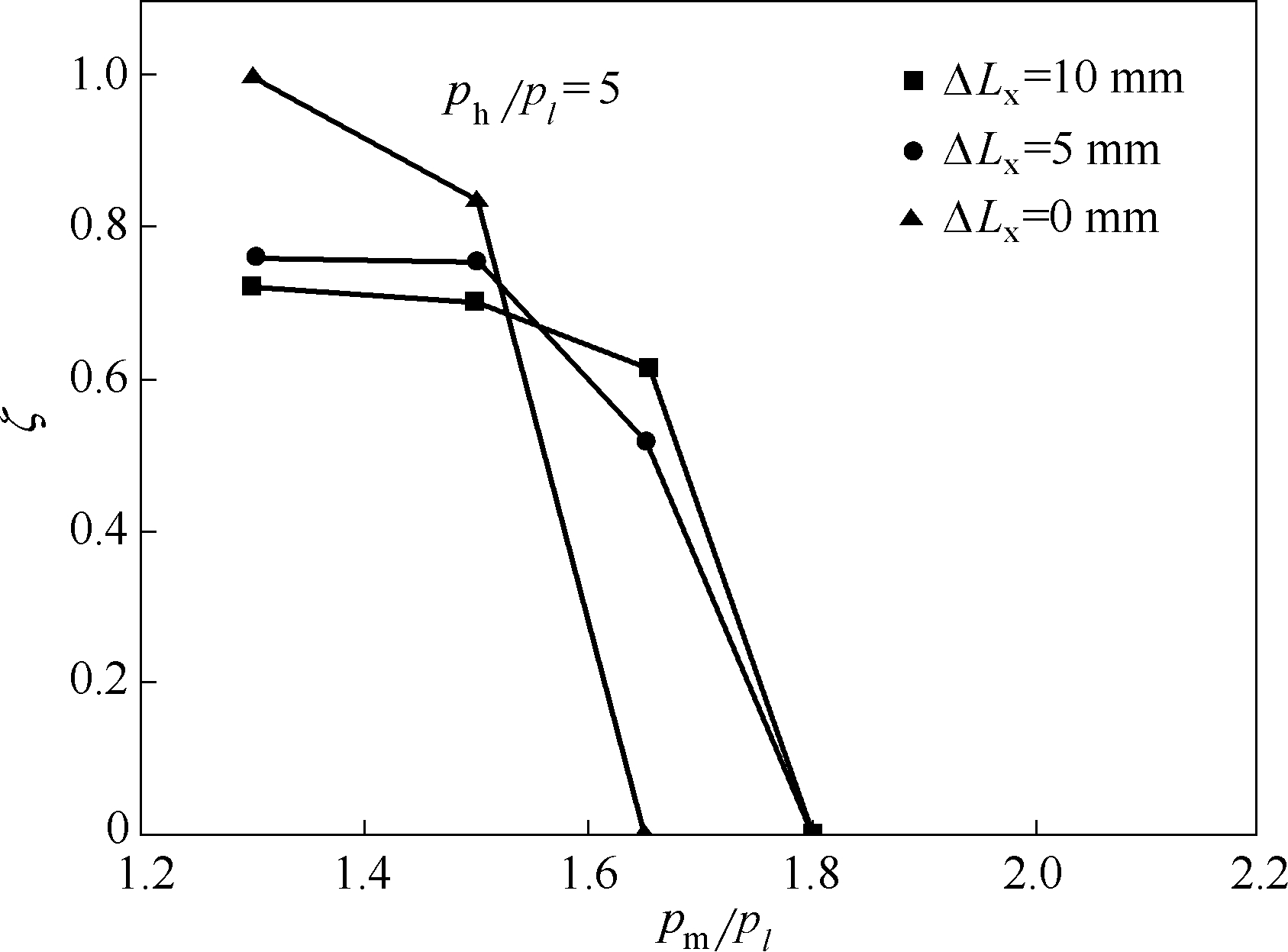

图14 膨胀比为5.0时,不同调节锥位置下引射率随压缩比的变化曲线

Fig.14 Curves of ejector rate with compression ratio at different adjustment cone positions when expansion ratio is 5.0

| 1 | 嵇国华, 索美娟 . 高压气井井下节流工艺[J]. 石油机械, 2010, 38(4): 87-88. |

| Ji G H , Suo M J . Downhole throttling process for high pressure gas wells[J]. Petroleum Machinery, 2010, 38(4): 87-88. | |

| 2 | 张洪杰, 朱琳, 解永海, 等 . 天然气引射技术在低压积液气井中的试验与应用[J]. 新疆石油天然气, 2014, 10(2): 76-80+8. |

| Zhang H J , Zhu L , Xie Y H , et al . Experiment and application of natural gas ejection technology in low pressure liquid-liquid gas well[J]. Xinjiang Oil and Gas, 2014, 10(2): 76-80+8. | |

| 3 | 文昌玉, 苏鹏, 王磊, 等 . 低压气井井口增压开采技术[J]. 石油钻采工艺, 2015, 37(5): 124-125. |

| Wen C Y , Su P , Wang L , et al . Pressurized mining technology of low pressure gas well head [J]. Oil Drilling Technology, 2015, 37(5): 124-125. | |

| 4 | 沈坚, 胡国新 . 引射器及引射循环在工程中的应用[J]. 煤气与热力, 2005, (1): 34-38. |

| Shen J , Hu G X . Application of ejector and ejection cycle in engineering[J]. Gas & Heat, 2005, (1): 34-38. | |

| 5 | 胡述明 . 喷射泵在低压天然气采输中的应用[J]. 石油矿厂机械, 2011, 40(8): 62-64. |

| Hu S M . Application of jet pumps in low pressure gas production and transportation[J]. Machinery for Petroleum Mines, 2011, 40(8): 62-64. | |

| 6 | 杨德伟, 林日亿, 王弥康, 等 . 利用喷射器技术输送低压气层天然气[J]. 油气田地面工程, 2005, 24(4): 10-12. |

| Yang D W , Lin R Y , Wang M K , et al . Injector technology is used to transport gas in low pressure gas layer[J]. Oil-Gasfield Surface Engineering, 2005, 24(4): 10-12. | |

| 7 | 胡均志, 王雅萍, 刘慧, 等 . 可调式喷射引流装置在榆林气田的应用[J]. 石油化工应用, 2012, 31(12): 60-61+68. |

| Hu J Z , Wang Y P , Liu H , et al . Application of adjustable jet drainage device in Yulin gas field[J]. Petrochemical Industry Application, 2012, 31(12): 60-61+68. | |

| 8 | 张书平, 刘双全, 陈德见 . 天然气喷射引流技术在靖边气田的应用试验[J]. 新疆石油天然气, 2008, 10(2): 113-119. |

| Zhang S P , Liu S Q , Chen D J . Application test of jet drainage technology of natural gas in Jingbian gas field[J]. Xinjiang Oil & Gas, 2008, 10(2): 113-119. | |

| 9 | 王晓荣, 王惠, 宋汉华, 等 . 实现低压气井增压开采的喷射引流技术[J]. 石油化工应用, 2009, 28(6): 25-27. |

| Wang X R , Wang H , Song H H , et al . Jet drainage technology for pressurized exploitation of low pressure gas wells is realized[J]. Petrochemical Industry Application, 2009, 28(6): 25-27. | |

| 10 | Elrod H G . The theory of ejectors[J]. ASME Journal of Applied Mechanics, 1945. 67: 170-174. |

| 11 | 索科洛夫 . 喷射泵[M]. 北京: 科学出版社, 1977. |

| Sokolow . Ejector[M]. Beijing: Science Press, 1977. | |

| 12 | Sun D W , Eames I W . Recent developments in the design theories and application of ejectors—a review[J]. Journal of the Institute of Energy, 1995. 68: 65-79. |

| 13 | 宓亢琪 . 天然气引射器特性方程与工况的研究[J]. 煤气与热力, 2006, (6): 1-5. |

| Fu K Q . Study on characteristic equation and working condition of natural gas ejector[J]. Gas & Heat, 2006, (6): 1-5. | |

| 14 | Pereira P R , Varga S , Soares J , et al . Experimental results with a variable geometry ejector using R600a as working fluid[J]. International Journal of Refrigeration, 2014, 46: 77-85. |

| 15 | Keenan J H , Neumann E P , Lustwerk F . An investigation of ejector design by analysis and experiment[J]. ASME Journal of Applied Mechanics, 1950, 72: 299-309. |

| 16 | Zheng L X , Deng J Q , Zhang Z X . Dynamic simulation of an improved transcritical CO2 ejector expansion refrigeration cycle[J]. Energy Conversion and Management, 2016, 114: 278-289. |

| 17 | Liu F , Groll E A , Ren J . Comprehensive experimental performance analyses of an ejector expansion transcritical CO2 system[J]. Applied Thermal Engineering, 2016, 98: 1061-1069 |

| 18 | 李熠桥 . 可调式蒸汽喷射器性能计算分析[D]. 大连: 大连理工大学, 2015. |

| Li Y Q . Calculation and analysis of adjustable steam ejector performance [D]. Dalian: Dalian University of Technology, 2015. | |

| 19 | 浦晖 . 可调式引射器的流动特性研究[D]. 福州: 福州大学, 2005. |

| Pu H . Study on flow characteristics of adjustable ejector [D]. Fuzhou : Fuzhou University, 2005. | |

| 20 | 蒋小丽 . 高压气井针形节流阀结构性能分析与优化[D]. 南充: 西南石油大学, 2014. |

| Jiang X L . Structural performance analysis and optimization of high pressure gas well needle throttle valve [D]. Nanchong: Southwest Petroleum University, 2014. | |

| 21 | 曾伟, 吴巍巍 . 基于Fluent的高压针形节流阀冲蚀磨损分析[J]. 内江科技, 2013, 34(6): 74-79. |

| Zeng W , Wu W W . Analysis of erosion wear of high pressure needle throttle valve based on Fluent[J]. NEI JIANG KE JI, 2013, 34(6): 74-79. | |

| 22 | 张奕, 陈丹丹, 石嵩 . 花瓣喷嘴引射器引射系数的数值分析[J]. 南京师范大学学报(工程技术版), 2012, 12(1): 29-32. |

| Zhang W , Chen D D , Shi S . Numerical analysis of the injecting coefficient of petal nozzle ejector[J]. Journal of Nanjing Normal University(Engineering & Technology Edition), 2012, 12(1): 29-32. | |

| 23 | 陆宏圻 . 射流泵技术的理论及应用[M]. 沈阳: 水利电力出版社, 1989. |

| Lu H Q . Theory and Application of Jet Pump Technology [M]. Shenyang: Water Conservancy and Electric Power Press, 1989. | |

| 24 | Cattadoti G , Galbiati L , Mazzocchi L , et al . A single-stage high-pressure steam injector for next generation reactors test results and analysis[J]. International Journal of Multiphase Flow, 1995, 21(4): 591-606. |

| 25 | Liu F , Groll E . Study of ejector efficiencies in refrigeration cycles[J]. Applied Thermal Engineering, 2013, 52(2): 360-370. |

| 26 | Chen J Y , Havtun H , Palm B . Parametric analysis of ejector working characteristics in the refrigeration system[J]. Applied Thermal Engineering, August 2014, 69(1/2): 130-142. |

| 27 | Zhu Y H , Huang Y L , Li C H . Experimental investigation on the performance of transcritical CO2 ejector–expansion heat pump water heater system[J]. Energy Conversion and Management, 2018, 167: 147–155 |

| 28 | Zheng L X , Deng J Q , Zhang Z X . Dynamic simulation of an improved transcritical CO2 ejector expansion refrigeration cycle[J]. Energy Conversion and Management, 2016, 114: 278–289. |

| 29 | Banasiak K , Hafner A . 1D Computational model of a two-phase R744 ejector for expansion work recovery [J]. International Journal of Thermal Sciences, 2011, 50: 2235-2247. |

| 30 | Ameur K , Aidoun Z , Ouzzane M . Modeling and numerical approach for the design and operation of two-phase ejectors [J]. Applied Thermal Engineering, 2016, 109: 809-818. |

| 31 | Chen J Y , Jarall S , Havtun H , et al . A review on versatile ejector applications in refrigeration systems[J]. Renewable and Sustainable Energy Reviews, 2015, 49: 67-90. |

| [1] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [2] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [3] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [4] | 闫琳琦, 王振雷. 基于STA-BiLSTM-LightGBM组合模型的多步预测软测量建模[J]. 化工学报, 2023, 74(8): 3407-3418. |

| [5] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [6] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [7] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| [8] | 刘尚豪, 贾胜坤, 罗祎青, 袁希钢. 基于梯度提升决策树的三组元精馏流程结构最优化[J]. 化工学报, 2023, 74(5): 2075-2087. |

| [9] | 周必茂, 许世森, 王肖肖, 刘刚, 李小宇, 任永强, 谭厚章. 烧嘴偏转角度对气化炉渣层分布特性的影响[J]. 化工学报, 2023, 74(5): 1939-1949. |

| [10] | 王泽栋, 石至平, 刘丽艳. 考虑气泡非均匀耗散的矩形反应器声流场数值模拟及结构优化[J]. 化工学报, 2023, 74(5): 1965-1973. |

| [11] | 李明川, 樊栓狮, 徐赋海, 卢惠东, 李晓军. 水合物热分解Stefan相变模型解的存在性及Laplace变换求解[J]. 化工学报, 2023, 74(4): 1746-1754. |

| [12] | 许文烜, 江锦波, 彭新, 门日秀, 刘畅, 彭旭东. 宽速域三种典型型槽油气密封泄漏与成膜特性对比研究[J]. 化工学报, 2023, 74(4): 1660-1679. |

| [13] | 罗来明, 张劲, 郭志斌, 王海宁, 卢善富, 相艳. 1~5 kW高温聚合物电解质膜燃料电池堆的理论模拟与组装测试[J]. 化工学报, 2023, 74(4): 1724-1734. |

| [14] | 李纪元, 李金旺, 周刘伟. 不同扰流结构冷板传热性能研究[J]. 化工学报, 2023, 74(4): 1474-1488. |

| [15] | 陈俊先, 姬忠礼, 赵瑜, 张倩, 周岩, 刘猛, 刘震. 基于微波技术的天然气管道内颗粒物在线检测方法研究[J]. 化工学报, 2023, 74(3): 1042-1053. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号