化工学报 ›› 2019, Vol. 70 ›› Issue (8): 2991-2999.DOI: 10.11949/0438-1157.20190269

收稿日期:2019-03-21

修回日期:2019-06-03

出版日期:2019-08-05

发布日期:2019-08-05

通讯作者:

俞海淼

作者简介:刘阳(1994—),男,硕士研究生,基金资助:

Yang LIU( ),Jiecheng LIU,Haimiao YU(

),Jiecheng LIU,Haimiao YU( ),Dezhen CHEN

),Dezhen CHEN

Received:2019-03-21

Revised:2019-06-03

Online:2019-08-05

Published:2019-08-05

Contact:

Haimiao YU

摘要:

采用过量浸渍法制备了镍基镁渣催化剂,并在小型气流床气化炉上开展了松木热解挥发分的催化重整研究。评估了煅烧/催化温度、镍含量和水碳比对焦油组分的影响,同时在不同煅烧/催化温度下与Ni/γ-Al2O3催化剂进行了裂解焦油性能的对比。采用比表面积测试(BET)、X射线衍射(XRD)、扫描电镜(SEM)和透射电镜(TEM)对催化剂进行了表征。结果表明,当镍含量为3%,煅烧/催化温度为800℃,水碳比为0.5时,镍基镁渣催化剂表现出最优异的催化裂解焦油能力:大幅度降低了重质多环芳烃的相对含量,并且焦油转化率达到95.69%,同时焦油露点温度降至40.2℃。XRD结果表明,Ni、Fe、Ca、Mg相互作用可以形成多种活性中心,进而协同提高催化剂活性。

中图分类号:

刘阳, 刘捷成, 俞海淼, 陈德珍. 新型镍基镁渣催化重整松木热解挥发分焦油析出特性研究[J]. 化工学报, 2019, 70(8): 2991-2999.

Yang LIU, Jiecheng LIU, Haimiao YU, Dezhen CHEN. Characteristics of tar formation during catalytic reforming of pyrolysis volatile from pine saw dust over novel Ni-based magnesium slag catalyst[J]. CIESC Journal, 2019, 70(8): 2991-2999.

| 生物质原料 | 工业分析(质量分数 )/% | 元素分析(质量分数 )/% | Q LHV/(MJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vad | Aad | FCad | Mad | Cad | Had | Nad | Oad | Sad | ||

| 松木锯屑 | 76.16 | 0.26 | 14.07 | 9.51 | 46.42 | 4.38 | 0.30 | 38.97 | 0.16 | 17.91 |

表1 松木锯屑的工业分析与元素分析

Table 1 Component analysis of pine sawdust

| 生物质原料 | 工业分析(质量分数 )/% | 元素分析(质量分数 )/% | Q LHV/(MJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vad | Aad | FCad | Mad | Cad | Had | Nad | Oad | Sad | ||

| 松木锯屑 | 76.16 | 0.26 | 14.07 | 9.51 | 46.42 | 4.38 | 0.30 | 38.97 | 0.16 | 17.91 |

| Ca | Fe | Mg | Si | Al | Mn | Ti | S |

|---|---|---|---|---|---|---|---|

| 43.62 | 4.27 | 3.77 | 11.28 | 0.59 | 0.56 | 0.34 | 0.02 |

表2 镁渣的元素组成(质量分数)

Table 2 Main chemical composition of magnesium

| Ca | Fe | Mg | Si | Al | Mn | Ti | S |

|---|---|---|---|---|---|---|---|

| 43.62 | 4.27 | 3.77 | 11.28 | 0.59 | 0.56 | 0.34 | 0.02 |

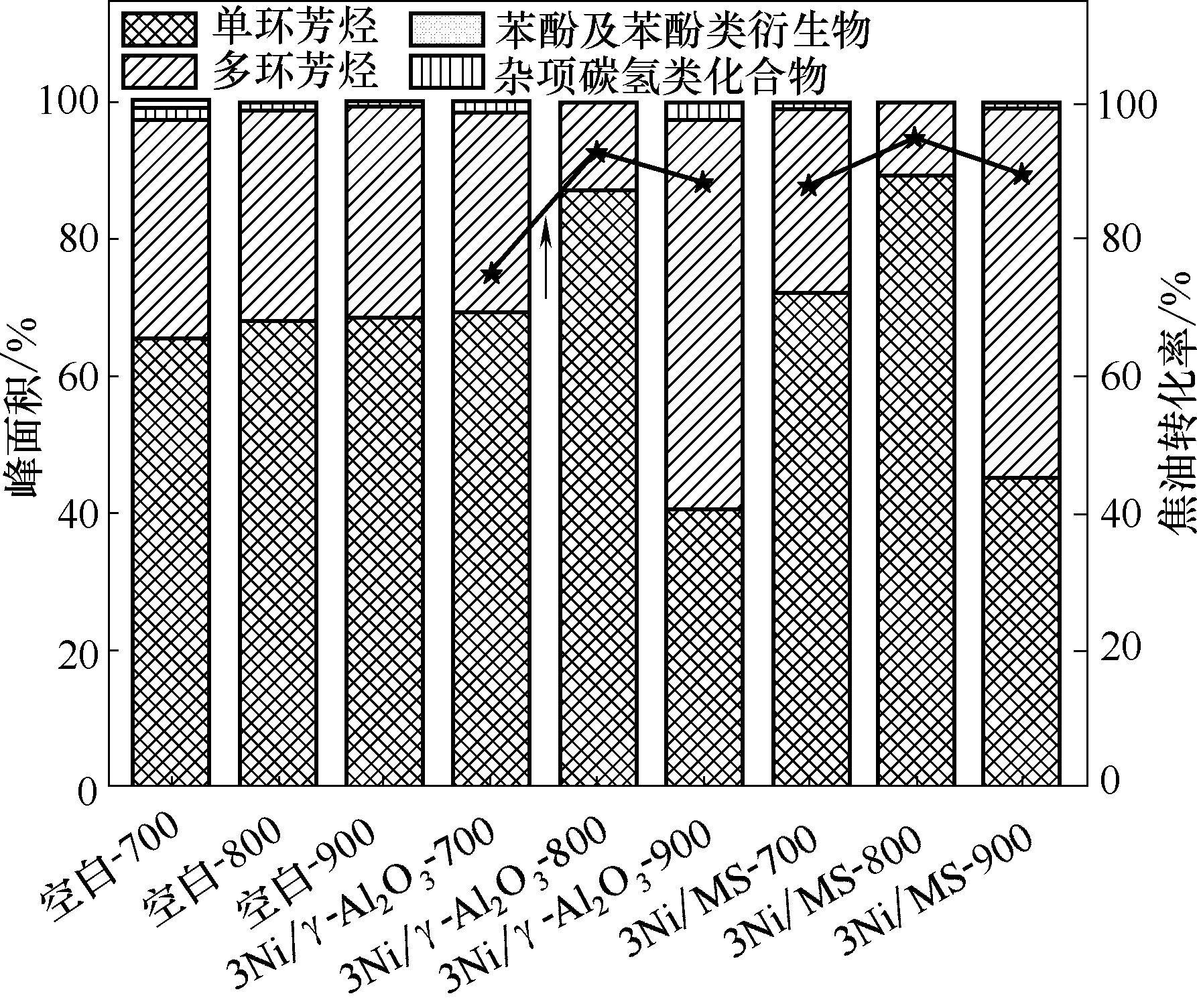

图2 煅烧/催化温度对焦油组分和焦油转化率的影响(镍含量为3%,水碳比为0)

Fig.2 Effect of calcination/catalytic temperature on tar composition and tar conversion (Ni content 3%, S/C = 0)

| 催化剂 | 轻质多环芳烃(area)/% | 重质多环芳烃(area)/% | 焦油露点温度 ① /℃ |

|---|---|---|---|

| 空白-700 | 29.88 | 2.03 | 110.1 |

| 空白-800 | 29.08 | 1.88 | 98.2 |

| 空白-900 | 28.41 | 2.66 | 111.1 |

| 3Ni/γ-Al2O3-700 | 27.14 | 2.22 | 109.2 |

| 3Ni/γ-Al2O3-800 | 12.26 | 0.29 | 51.3 |

| 3Ni/γ-Al2O3-900 | 53.76 | 3.02 | 85.1 |

| 3Ni/MS-700 | 25.63 | 0.92 | 78.4 |

| 3Ni/MS-800 | 10.58 | 0.12 | 42.4 |

| 3Ni/MS-900 | 52.53 | 1.32 | 72.6 |

表3 不同煅烧/催化温度下的多环芳烃组成及焦油露点温度

Table 3 Effect of temperature on PAH composition categorized by molecular weight and tar dew point

| 催化剂 | 轻质多环芳烃(area)/% | 重质多环芳烃(area)/% | 焦油露点温度 ① /℃ |

|---|---|---|---|

| 空白-700 | 29.88 | 2.03 | 110.1 |

| 空白-800 | 29.08 | 1.88 | 98.2 |

| 空白-900 | 28.41 | 2.66 | 111.1 |

| 3Ni/γ-Al2O3-700 | 27.14 | 2.22 | 109.2 |

| 3Ni/γ-Al2O3-800 | 12.26 | 0.29 | 51.3 |

| 3Ni/γ-Al2O3-900 | 53.76 | 3.02 | 85.1 |

| 3Ni/MS-700 | 25.63 | 0.92 | 78.4 |

| 3Ni/MS-800 | 10.58 | 0.12 | 42.4 |

| 3Ni/MS-900 | 52.53 | 1.32 | 72.6 |

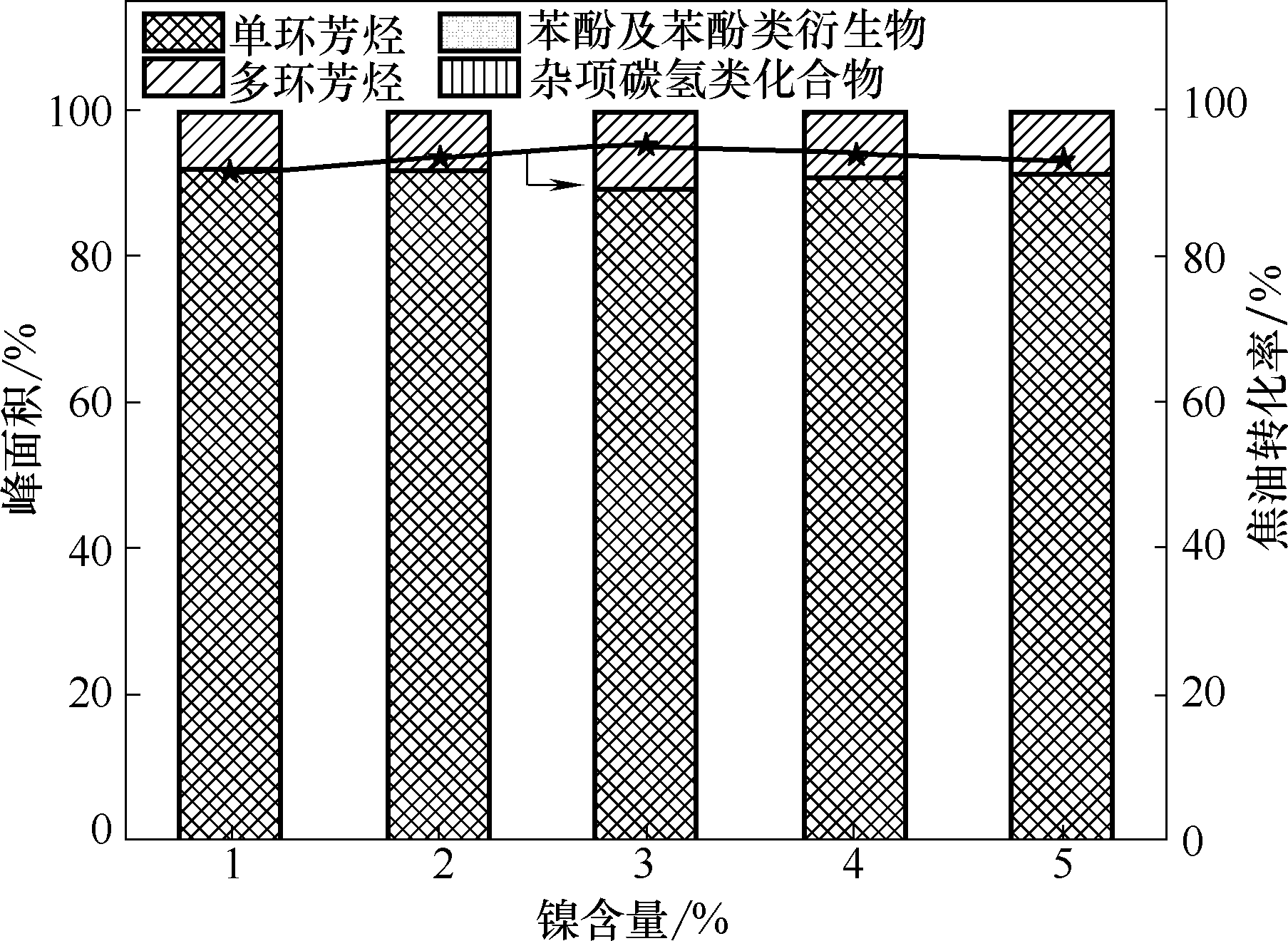

图3 镍含量对焦油组分和焦油转化率的影响(煅烧/催化温度为800℃,水碳比为0)

Fig.3 Effect of Ni content on tar composition and tar conversion (calcination/catalytic temperature 800℃, S/C = 0)

| 催化剂 | 轻质多环芳烃(area)/% | 重质多环芳烃(area)/% | 焦油露点温度 ① /℃ |

|---|---|---|---|

| 1Ni/MS-800 | 7.33 | 0.52 | 57.0 |

| 2Ni/MS-800 | 7.88 | 0.32 | 50.3 |

| 3Ni/MS-800 | 10.58 | 0.12 | 42.4 |

| 4Ni/MS-800 | 8.87 | 0.22 | 47.2 |

| 5Ni/MS-800 | 8.18 | 0.36 | 52.0 |

表4 不同镍含量下的多环芳烃组成及焦油露点温度

Table 4 Effect of Ni content on PAH composition categorized by molecular weight and tar dew point

| 催化剂 | 轻质多环芳烃(area)/% | 重质多环芳烃(area)/% | 焦油露点温度 ① /℃ |

|---|---|---|---|

| 1Ni/MS-800 | 7.33 | 0.52 | 57.0 |

| 2Ni/MS-800 | 7.88 | 0.32 | 50.3 |

| 3Ni/MS-800 | 10.58 | 0.12 | 42.4 |

| 4Ni/MS-800 | 8.87 | 0.22 | 47.2 |

| 5Ni/MS-800 | 8.18 | 0.36 | 52.0 |

图4 水碳比对焦油组分及焦油露点温度的影响(镍含量为3%,煅烧/催化温度为800℃)

Fig.4 Effect of S/C on tar composition and tar conversion (Ni content 3%, calcination/catalytic temperature 800℃)

| 催化剂 | 比表面积/ (m2/g) | 孔容①/(cm3/g) | 平均孔径②/nm |

|---|---|---|---|

| γ-Al2O3 | 98.24 | / | / |

| 3Ni/γ-Al2O3-800 | 69.92 | 0.38 | 16.21 |

| MS | 0.90 | / | / |

| 3Ni/MS-700 | 11.31 | 0.09 | 25.98 |

| 3Ni/MS-800 | 4.36 | 0.03 | 20.53 |

| 3Ni/MS-900 | 2.74 | 0.02 | 22.52 |

表5 原料和煅烧后催化剂的理化性质

Table 5 Physicochemical properties of raw materials and freshly calcined catalysts

| 催化剂 | 比表面积/ (m2/g) | 孔容①/(cm3/g) | 平均孔径②/nm |

|---|---|---|---|

| γ-Al2O3 | 98.24 | / | / |

| 3Ni/γ-Al2O3-800 | 69.92 | 0.38 | 16.21 |

| MS | 0.90 | / | / |

| 3Ni/MS-700 | 11.31 | 0.09 | 25.98 |

| 3Ni/MS-800 | 4.36 | 0.03 | 20.53 |

| 3Ni/MS-900 | 2.74 | 0.02 | 22.52 |

| 1 | 袁晓涛, 胡建杭, 张凤霞, 等 . 铜渣载镍催化剂催化气化松木屑的实验研究[J]. 化工进展, 2018, 37(10): 3919-3927. |

| Yuan X T , Hu J H , Zhang F X , et al . Experimental study on the catalytic gasification of pine sawdust over nickel catalyst supported by copper slag[J]. Chemical Industry and Engineering Progress, 2018, 37(10): 3919-3927. | |

| 2 | 于建华, 袁红艳, 徐绍平, 等 . Ni-Fe/坡缕石催化水蒸气重整杏核热解焦油制氢[J]. 西安交通大学学报, 2008, 42(8): 1049-1053. |

| Yu J H , Yuan H Y , Xu S P , et al . Steam reforming of apricot stone pyrolysis tar for hydrogen with Ni-Fe/attapulgite as catalyst[J]. Journal of Xi an Jiaotong University, 2008, 42(8): 1049-1053. | |

| 3 | Wang L , Li D , Koike M , et al . Catalytic performance and characterization of Ni-Co catalysts for the steam reforming of biomass tar to synthesis gas[J]. Fuel, 2013, 112: 654-661. |

| 4 | 林志峰, 胡日茗, 周晓龙 . 镍基催化剂的研究进展[J]. 化工学报, 2017, 68(S1): 26-36. |

| Lin Z F , Hu R M , Zhou X L .Research progress of Ni-based catalysts[J]. CIESC Journal, 2017, 68(S1): 26-36. | |

| 5 | 王延涛, 梁财, 周群, 等 . 凹凸棒石镍基催化剂对污泥气化焦油催化裂解的特性分析[J]. 化工进展, 2018, 37(10): 3895-3902. |

| Wang Y T , Liang C , Zhou Q , et al . Analysis of catalytic cracking of sludge gasification tar over palygorskite nickel-based catalyst[J]. Chemical Industry and Engineering Progress, 2018, 37(10): 3895-3902. | |

| 6 | Ashok J , Kathiraser Y , Ang M L , et al . Bi-functional hydrotalcite-derived NiO-CaO-Al2O3 catalysts for steam reforming of biomass and/or tar model compound at low steam-to-carbon conditions[J]. Appl. Catal. B, 2015, 172/173: 116-128. |

| 7 | Świerczyński D , Libs S , Courson C , et al . Steam reforming of tar from a biomass gasification process over Ni/olivine catalyst using toluene as a model compound[J]. Appl. Catal. B, 2007, 74: 211-222. |

| 8 | Qiu B , Deng N , Zhang Y , et al . Application of industrial solid wastes in catalytic pyrolysis[J]. Asia-Pacific Journal of Chemical Engineering, 2018, 13(1): e2150. |

| 9 | Jia L , Fan B G , Huo R P , et al . Study on quenching hydration reaction kinetics and desulfurization characteristics of magnesium slag[J]. Journal of Cleaner Production, 2018, 190: 12-23. |

| 10 | Qin K , Lin W , Jensen P A , et al . High-temperature entrained flow gasification of biomass[J]. Fuel, 2012, 93: 589-600. |

| 11 | Yu H M , Wu Z L , Chen G . Catalytic gasification characteristics of cellulose, hemicellulose and lignin[J]. Renewable Energy, 2018, 121: 559-567. |

| 12 | Li C , Suzuki K . Tar property, analysis, reforming mechanism and model for biomass gasification—an overview[J]. Renewable and Sustainable Energy Reviews, 2009, 13: 594-604. |

| 13 | Yu H M , Ma T , Shen Y L , et al . Experimental study on catalytic effect of biomass pyrolysis volatile over nickel catalyst supported by waste iron slag[J]. International Journal of Energy Research, 2017, 41: 2063-2073. |

| 14 | Shen Y L , Liu Y , Yu H M . Enhancement of the quality of syngas from catalytic steam gasification of biomass by the addition of methane/model biogas[J]. Int. J. Hydrogen Energy, 2018, 43: 20428. |

| 15 | Anis S , Zainal Z A . Tar reduction in biomass producer gas via mechanical, catalytic and thermal methods: a review[J]. Renewable and Sustainable Energy Reviews, 2011, 15: 2355-2377. |

| 16 | Tersites . The ECN tar dew point site[EB/OL]. . |

| 17 | Alauddin Z A B Z , Lahijani P , Mohammadi M , et al . Gasification of lignocellulosic biomass in fluidized beds for renewable energy development: a review[J]. Renewable and Sustainable Energy Reviews, 2010, 14: 2852-2862. |

| 18 | Guan G , Kaewpanha M , Hao X , et al . Catalytic steam reforming of biomass tar: prospects and challenges[J]. Renewable and Sustainable Energy Reviews, 2016, 58: 450-461. |

| 19 | Kudus M H A , Akil H M , Mohamad H , et al . Effect of catalyst calcination temperature on the synthesis of MWCNT–alumina hybrid compound using methane decomposition method[J]. J. Alloys. Compd., 2011, 509: 2784. |

| 20 | Zhou L , Li L , Wei N , et al . Effect of NiAl2O4 formation on Ni/Al2O3 stability during dry reforming of methane[J]. Chem. Cat. Chem., 2015, 7: 2508-2516. |

| 21 | Yue B , Wang X , Ai X , et al . Catalytic reforming of model tar compounds from hot coke oven gas with low steam/carbon ratio over Ni/MgO-Al2O3 catalysts[J]. Fuel Process. Technol., 2010, 91: 1098-1104. |

| 22 | Matas G B , Babich I V , Lefferts L , et al . Steam reforming of phenol over Ni-based catalysts—a comparative study[J]. Appl. Catal. B, 2011, 106: 280-286. |

| 23 | Williams P T , Horne P A . Analysis of aromatic hydrocarbons in pyrolytic oil derived from biomass[J]. J. Anal. Appl. Pyrolysis, 1995, 31: 15-37. |

| 24 | Fu P , Yi W , Li Z , et al . Investigation on hydrogen production by catalytic steam reforming of maize stalk fast pyrolysis bio-oil[J]. Int. J. Hydrogen Energy, 2014, 39: 13962-13971. |

| 25 | Artetxe M , Alvarez J , Nahil M A , et al . Steam reforming of different biomass tar model compounds over Ni/Al2O3 catalysts[J]. Energy Convers. Manage., 2017, 136: 119-126. |

| 26 | Feng D , Zhao Y , Zhang Y , et al . Effects of H2O and CO2 on the homogeneous conversion and heterogeneous reforming of biomass tar over biochar[J]. Int. J. Hydrogen Energy, 2017, 42: 13070-13084. |

| 27 | 史训旺, 李建芬, 辛馨, 等 . NiO-Fe2O3/PG-γ-Al2O3催化剂的制备及其在秸秆热解中的应用[J]. 燃料化学学报, 2017, 45(12): 1434-1440. |

| Shi X W , Li J F , Xin X , et al . Preparation of NiO-Fe2O3/PG-γ-Al2O3 catalysts and its application in pyrolysis of biomass straw[J]. Journal of Fuel Chemistry and Technology, 2017, 45(12): 1434-1440. | |

| 28 | Ma Z , Xiao R , Zhang H . Catalytic steam reforming of bio-oil model compounds for hydrogen-rich gas production using bio-char as catalyst[J]. Int. J. Hydrogen Energy, 2017, 42: 3579-3585. |

| 29 | Quan C , Xu S , Zhou C . Steam reforming of bio-oil from coconut shell pyrolysis over Fe/olivine catalyst[J]. Energy Convers Manage, 2017, 141: 40-47. |

| 30 | Zou X H , Chen T H , Zhang P , et al . High catalytic performance of Fe-Ni/palygorskite in the steam reforming of toluene for hydrogen production[J]. Applied Energy, 2018, 226: 827-837. |

| 31 | Wu C , Wang Z , Huang J , et al . Pyrolysis/gasification of cellulose, hemicellulose and lignin for hydrogen production in the presence of various nickel-based catalysts[J]. Fuel, 2013, 106: 697-706. |

| 32 | Świerczyński D , Courson C , Bedel L , et al . Characterization of Ni-Fe/MgO/olivine catalyst for fluidized bed steam gasification of biomass[J]. Chem. Mater., 2006, 18: 4025-4032. |

| 33 | Zamboni I , Courson C , Kiennemann A . Fe-Ca interactions in Fe-based/CaO catalyst/sorbent for CO2 sorption and hydrogen production from toluene steam reforming[J]. Appl. Catal. B, 2017, 203: 154-165. |

| 34 | Huang Z , Deng Z B , Chen D Z , et al . Thermodynamic analysis and kinetic investigations on biomass char chemical looping gasification using Fe-Ni bimetallic oxygen carrier[J]. Energy, 2017, 141: 1836-1844. |

| 35 | Moulijn J A , Cerfontain M B , Kapteijn F . Mechanism of the potassium catalysed gasification of carbon in CO2 [J]. Fuel, 1984, 63: 1043-1047. |

| 36 | Zhuang Q , Kyotani T , Tomita A . Desorption behavior of surface oxygen complexes on carbon in an inert gas and in O2-gasification atmosphere[J]. Energy & Fuels, 1996, 10: 169-172. |

| 37 | Shen Y , Zhao P , Shao Q , et al . In-situ catalytic conversion of tar using rice husk char-supported nickel-iron catalysts for biomass pyrolysis/gasification[J]. Appl. Catal. B, 2014, 152/153: 140-151. |

| 38 | Meng J G , Zhao Z L , Wang X B , et al . Comparative study on phenol and naphthalene steam reforming over Ni-Fe alloy catalysts supported on olivine synthesized by different methods[J]. Energy Convers. Manage., 2018, 168: 60-73. |

| 39 | Zou X H , Chen T H , Liu H B , et al . An insight into the effect of calcination conditions on catalytic cracking of toluene over 3Fe8Ni/palygorskite: catalysts characterization and performance[J]. Fuel, 2017, 190: 47-57. |

| [1] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [2] | 杨绍旗, 赵淑蘅, 陈伦刚, 王晨光, 胡建军, 周清, 马隆龙. Raney镍-质子型离子液体体系催化木质素平台分子加氢脱氧制备烷烃[J]. 化工学报, 2023, 74(9): 3697-3707. |

| [3] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [4] | 陈佳起, 赵万玉, 姚睿充, 侯道林, 董社英. 开心果壳基碳点的合成及其对Q235碳钢的缓蚀行为研究[J]. 化工学报, 2023, 74(8): 3446-3456. |

| [5] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [6] | 董茂林, 陈李栋, 黄六莲, 吴伟兵, 戴红旗, 卞辉洋. 酸性助水溶剂制备木质纳米纤维素及功能应用研究进展[J]. 化工学报, 2023, 74(6): 2281-2295. |

| [7] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [8] | 葛泽峰, 吴雨青, 曾名迅, 查振婷, 马宇娜, 侯增辉, 张会岩. 灰化学成分对生物质气化特性的影响规律[J]. 化工学报, 2023, 74(5): 2136-2146. |

| [9] | 衣思敏, 马亚丽, 刘伟强, 张金帅, 岳岩, 郑强, 贾松岩, 李雪. 微晶菱镁矿蒸氨及水化动力学研究[J]. 化工学报, 2023, 74(4): 1578-1586. |

| [10] | 刘海芹, 李博文, 凌喆, 刘亮, 俞娟, 范一民, 勇强. 羟基-炔点击化学改性半乳甘露聚糖薄膜的制备及性能研究[J]. 化工学报, 2023, 74(3): 1370-1378. |

| [11] | 陈瑞哲, 程磊磊, 顾菁, 袁浩然, 陈勇. 纤维增强树脂复合材料化学回收技术研究进展[J]. 化工学报, 2023, 74(3): 981-994. |

| [12] | 祖凌鑫, 胡荣庭, 李鑫, 陈余道, 陈广林. 木质生物质化学组分的碳释放产物特征和反硝化利用程度[J]. 化工学报, 2023, 74(3): 1332-1342. |

| [13] | 郑杰元, 张先伟, 万金涛, 范宏. 丁香酚环氧有机硅树脂的制备及其固化动力学研究[J]. 化工学报, 2023, 74(2): 924-932. |

| [14] | 赵焕娟, 刘婧, 周冬雷, 林敏. 多孔材料对氢气爆轰的抑制作用[J]. 化工学报, 2023, 74(2): 968-976. |

| [15] | 张娜, 潘鹤林, 牛波, 张亚运, 龙东辉. 酚醛树脂热裂解反应机理的密度泛函理论研究[J]. 化工学报, 2023, 74(2): 843-860. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号