化工学报 ›› 2023, Vol. 74 ›› Issue (6): 2281-2295.DOI: 10.11949/0438-1157.20230182

董茂林1( ), 陈李栋1, 黄六莲2, 吴伟兵1, 戴红旗1, 卞辉洋1,2(

), 陈李栋1, 黄六莲2, 吴伟兵1, 戴红旗1, 卞辉洋1,2( )

)

收稿日期:2023-03-01

修回日期:2023-05-03

出版日期:2023-06-05

发布日期:2023-07-27

通讯作者:

卞辉洋

作者简介:董茂林(1998—),男,硕士研究生,dml1405@njfu.edu.cn

基金资助:

Maolin DONG1( ), Lidong CHEN1, Liulian HUANG2, Weibing WU1, Hongqi DAI1, Huiyang BIAN1,2(

), Lidong CHEN1, Liulian HUANG2, Weibing WU1, Hongqi DAI1, Huiyang BIAN1,2( )

)

Received:2023-03-01

Revised:2023-05-03

Online:2023-06-05

Published:2023-07-27

Contact:

Huiyang BIAN

摘要:

木质纳米纤维素因具有制备工艺简单、环境友好、成本效益高等特点而在各领域受到广泛关注,其制备与应用已成为相关领域的研究热点。然而,木质纤维组分间的聚集结构和复杂的化学键(醚健、酯键等)结合形成了抗解聚屏障,需要对其进行预处理破除屏障。酸性助水溶剂体系具有溶解选择性高、产物易分离、可循环利用等优点,是一种高效环保的绿色预处理工艺,是木质纳米纤维素制备及高值化利用的重要预处理方法。本文首先介绍了酸性助水溶剂的概念及作用机理,综述了酸性助水溶剂体系制备木质纳米纤维素的方法及性能,讨论了木质纳米纤维素的功能化应用进展,最后总结了酸性助水溶剂体系存在的不足,并对其今后的研究方向进行了展望。

中图分类号:

董茂林, 陈李栋, 黄六莲, 吴伟兵, 戴红旗, 卞辉洋. 酸性助水溶剂制备木质纳米纤维素及功能应用研究进展[J]. 化工学报, 2023, 74(6): 2281-2295.

Maolin DONG, Lidong CHEN, Liulian HUANG, Weibing WU, Hongqi DAI, Huiyang BIAN. Research progress in preparation of lignonanocellulose by acid hydrotropes and their functional applications[J]. CIESC Journal, 2023, 74(6): 2281-2295.

| 原料 | 类型 | 助水溶剂 | 水解条件 | 机械方法 | 性能 | 文献 | |

|---|---|---|---|---|---|---|---|

| 直径/nm | 结晶度/% | ||||||

| 未漂硫酸盐混合木浆 | LCNC | 顺丁烯二酸 | 酸浓:60%~70%(质量); 120~130℃,60~180 min | 高速离心 | 10~30 | 72.0~81.7 | [ |

| LCNF | 微射流均质 | 9~26 | 69.0~79.8 | ||||

| 桦木浆 | LCNC | 对甲基苯磺酸 | 酸浓:50%、65%、80%(质量); 80℃,20 min | 透析 | — | — | [ |

| LCNF | 微射流均质 | 15.3~51.1 | 64.3~68.8 | ||||

| 麦草备料废渣 | LCNF | 对甲基苯磺酸 | 酸浓:80%(质量);80℃,20 min | 盘磨机械处理 | 60 | 50.5~59.1 | [ |

| 甘蔗渣粉 | LCNF | 对甲基苯磺酸 | 酸浓:50%~80%(质量);60~80℃,1.5 h | 微射流均质 | — | 54.2~65.7 | [ |

| 麦秸及其制浆固体残渣 | LCNF | 对甲基苯磺酸 | 酸浓:80%(质量);80℃,20 min | 盘式研磨 | 85.3 27.3 | 58.3 63.5 | [ |

| 桦木木材 | LCNF | 顺丁烯二酸 | 酸浓:30%~70%(质量); 80~100℃,60~120 min | 微射流均质 | 4~18 | — | [ |

| 未漂硫酸盐混合木浆 | LCNC | 顺丁烯二酸 | 酸浓:60%~70%(质量); 120~130℃,60~120 min | 高速离心 | 9.5~25.8 | 76.6~81.3 | [ |

| 碱性过氧化氢机械浆 | LCNF | 苯磺酸 | 酸浓:40%~70%(质量); 80℃,20 min | 高压均质 | 11.4~45.9 | 66.9~77.2 | [ |

| 麦秸 | LCNF | 对甲基苯磺酸 | 酸浓,70%(质量); 80℃,10 min | 超声处理 | 10.1~20.0 | 50~52 | [ |

| 柳木及其树皮 | LCNF | 对甲基苯磺酸 | 酸浓:60%、80%(质量); 80℃,20 min | 盘磨、超微粉碎 | 15.1~58.6 | — | [ |

| 剑麻 | LCNF | 顺丁烯二酸 | 酸浓:50%(质量); 90℃,2 h | 球磨 | 12.5 | 53.6 | [ |

表1 酸性助水溶剂制备木质纳米纤维素的工艺条件与性能

Table 1 Technological conditions and properties of lignonanocellulose prepared from acid hydrotropes

| 原料 | 类型 | 助水溶剂 | 水解条件 | 机械方法 | 性能 | 文献 | |

|---|---|---|---|---|---|---|---|

| 直径/nm | 结晶度/% | ||||||

| 未漂硫酸盐混合木浆 | LCNC | 顺丁烯二酸 | 酸浓:60%~70%(质量); 120~130℃,60~180 min | 高速离心 | 10~30 | 72.0~81.7 | [ |

| LCNF | 微射流均质 | 9~26 | 69.0~79.8 | ||||

| 桦木浆 | LCNC | 对甲基苯磺酸 | 酸浓:50%、65%、80%(质量); 80℃,20 min | 透析 | — | — | [ |

| LCNF | 微射流均质 | 15.3~51.1 | 64.3~68.8 | ||||

| 麦草备料废渣 | LCNF | 对甲基苯磺酸 | 酸浓:80%(质量);80℃,20 min | 盘磨机械处理 | 60 | 50.5~59.1 | [ |

| 甘蔗渣粉 | LCNF | 对甲基苯磺酸 | 酸浓:50%~80%(质量);60~80℃,1.5 h | 微射流均质 | — | 54.2~65.7 | [ |

| 麦秸及其制浆固体残渣 | LCNF | 对甲基苯磺酸 | 酸浓:80%(质量);80℃,20 min | 盘式研磨 | 85.3 27.3 | 58.3 63.5 | [ |

| 桦木木材 | LCNF | 顺丁烯二酸 | 酸浓:30%~70%(质量); 80~100℃,60~120 min | 微射流均质 | 4~18 | — | [ |

| 未漂硫酸盐混合木浆 | LCNC | 顺丁烯二酸 | 酸浓:60%~70%(质量); 120~130℃,60~120 min | 高速离心 | 9.5~25.8 | 76.6~81.3 | [ |

| 碱性过氧化氢机械浆 | LCNF | 苯磺酸 | 酸浓:40%~70%(质量); 80℃,20 min | 高压均质 | 11.4~45.9 | 66.9~77.2 | [ |

| 麦秸 | LCNF | 对甲基苯磺酸 | 酸浓,70%(质量); 80℃,10 min | 超声处理 | 10.1~20.0 | 50~52 | [ |

| 柳木及其树皮 | LCNF | 对甲基苯磺酸 | 酸浓:60%、80%(质量); 80℃,20 min | 盘磨、超微粉碎 | 15.1~58.6 | — | [ |

| 剑麻 | LCNF | 顺丁烯二酸 | 酸浓:50%(质量); 90℃,2 h | 球磨 | 12.5 | 53.6 | [ |

图4 不同酸浓度对AFM测量所得木质纤维纳米纤维(LCNF)高度概率密度分布的影响[43]

Fig.4 Effect of different acid concentration on the AFM-measured height probability density distribution of the resulting lignocellulosic nanofibrils (LCNF)[43]

图5 稀释分馏液以沉淀木质素,用树脂吸附残留的溶解木质素后通过蒸发冷却结晶回收酸[59]

Fig.5 Fractionation liquor dilution to precipitate lignin, followed by resin adsorption of residual dissolved lignin for recovering acid after evaporation by crystallization through cooling[59]

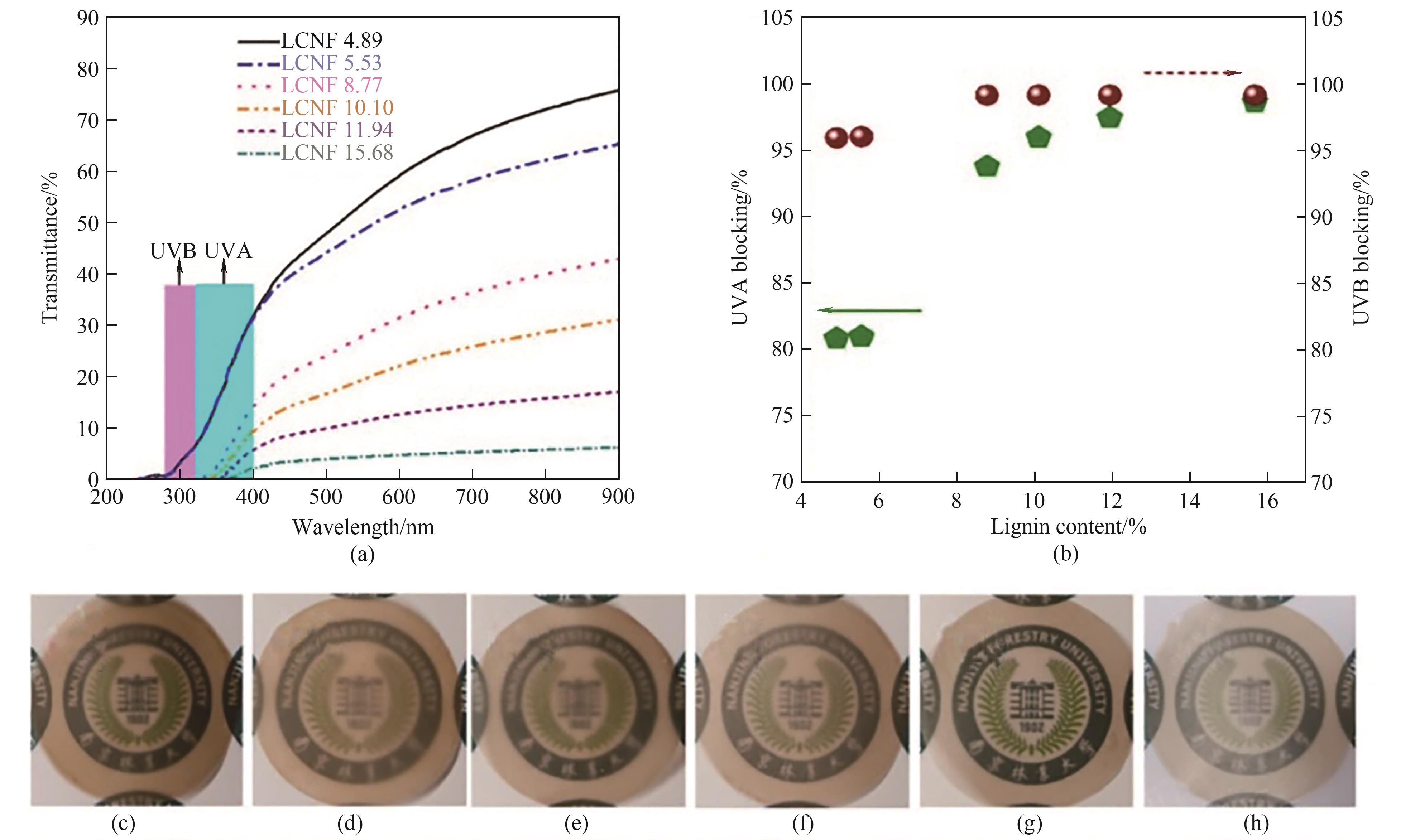

图7 (a)不同木质素含量LCNF膜的可见光-紫外透射光谱;(b)木质素含量对LCNF膜紫外屏蔽率的影响;(c)~(h)4.89%~15.68%木质素含量的LCNF膜照片[68]

Fig.7 (a) The UV-Vis transmission spectra of LCNF films with different residual lignin content; (b) Effects of the residual lignin content on the UVA and UVB blocking rate of the LCNF films; (c)—(h) Photographs of the LCNF films with different residual lignin content ranging from 4.89% to 15.68%[68]

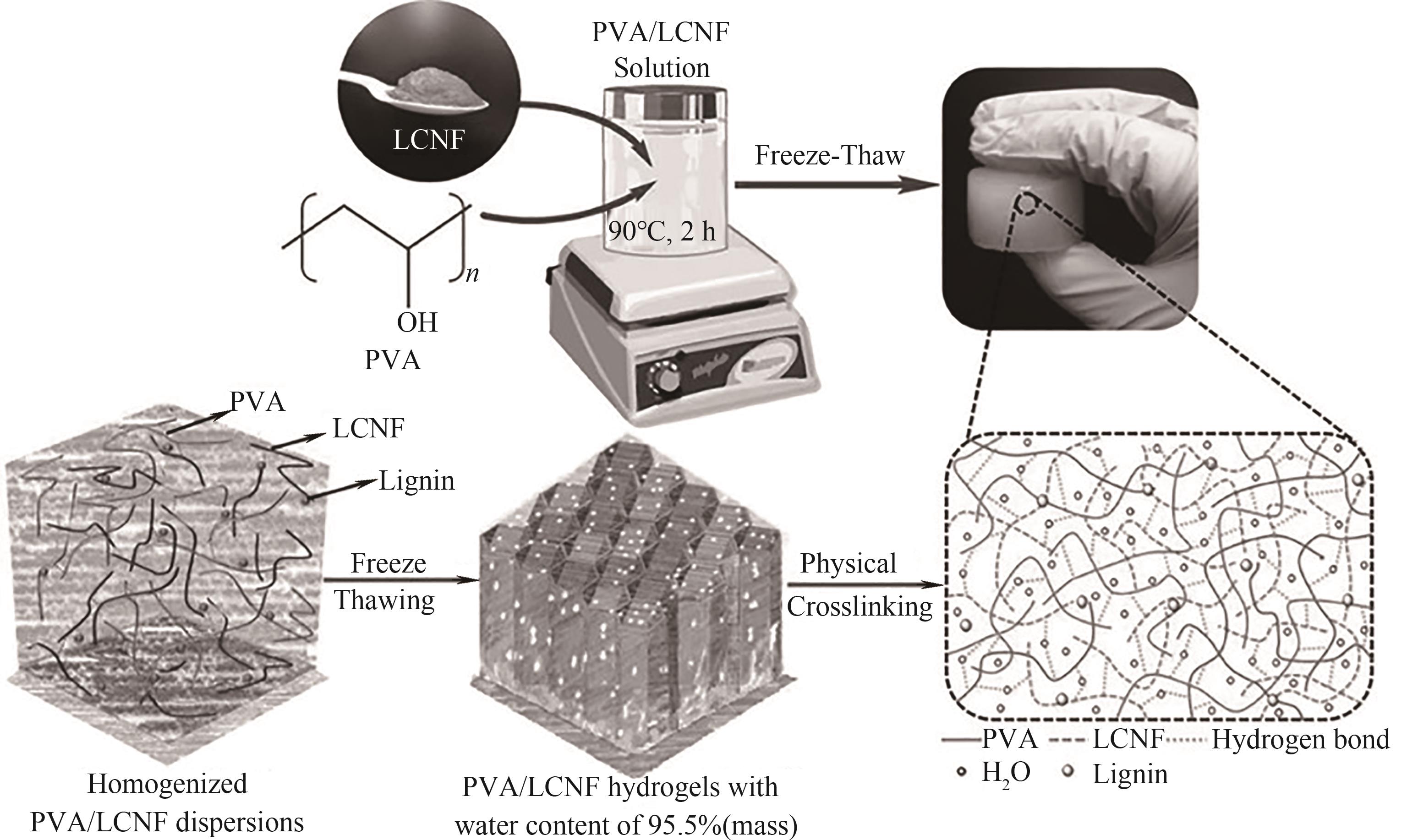

图9 木质纳米纤维素增强聚乙烯醇水凝胶的制备流程和机理示意图[82]

Fig.9 Shematic illustration of the preparation and synthesis process of lignocellulosic nanofibrils reinforced polyvinyl alcohol hydrogels[82]

图10 通过LCNF在油水界面吸附形成Pickering乳液的示意图(非按比例)[87]

Fig.10 Schematic illustration (not to scale) of Pickering emulsion formation via LCNF adsorption at the oil-water interface[87]

| 1 | 李伟, 刘守新, 李坚. 纳米纤维素的制备与功能化应用基础[M]. 北京: 科学出版社, 2016. |

| Li W, Liu S X, Li J. Preparation and Functional Application Basis of Nano-cellulose[M]. Beijing: Science Press, 2016. | |

| 2 | Sacui I A, Nieuwendaal R C, Burnett D J, et al. Comparison of the properties of cellulose nanocrystals and cellulose nanofibrils isolated from bacteria, tunicate, and wood processed using acid, enzymatic, mechanical, and oxidative methods[J]. ACS Applied Materials & Interfaces, 2014, 6(9): 6127-6138. |

| 3 | Nguyen L H, Naficy S, Chandrawati R, et al. Nanocellulose for sensing applications[J]. Advanced Materials Interfaces, 2019, 6(18): 1900424. |

| 4 | Yi T, Zhao H Y, Mo Q, et al. From cellulose to cellulose nanofibrils—a comprehensive review of the preparation and modification of cellulose nanofibrils[J]. Materials, 2020, 13(22): 5062. |

| 5 | Liu K, Du H S, Zheng T, et al. Lignin-containing cellulose nanomaterials: preparation and applications[J]. Green Chemistry, 2021, 23(24): 9723-9746. |

| 6 | Wang Q B, Du H S, Zhang F, et al. Flexible cellulose nanopaper with high wet tensile strength, high toughness and tunable ultraviolet blocking ability fabricated from tobacco stalk via a sustainable method[J]. Journal of Materials Chemistry A, 2018, 6(27): 13021-13030. |

| 7 | 卞辉洋. 顺丁烯二酸预处理制备木质纳米纤维及其膜和水凝胶特性研究[D]. 南京: 南京林业大学, 2019. |

| Bian H Y. Preparation of lignocellulosic nanofibers using maleic acid pretreatment and their film and hydrogel properties[D]. Nanjing: Nanjing Forestry University, 2019. | |

| 8 | Agarwal U P, Ralph S A, Reiner R S, et al. Production of high lignin-containing and lignin-free cellulose nanocrystals from wood[J]. Cellulose, 2018, 25(10): 5791-5805. |

| 9 | Chen Y, Zhang H, Feng X, et al. Lignocellulose nanocrystals from pineapple peel: preparation, characterization and application as efficient Pickering emulsion stabilizers[J]. Food Research International, 2021, 150: 110738. |

| 10 | Spence K L, Venditti R A, Rojas O J, et al. The effect of chemical composition on microfibrillar cellulose films from wood pulps: water interactions and physical properties for packaging applications[J]. Cellulose, 2010, 17(4): 835-848. |

| 11 | Solala I, Iglesias M C, Peresin M S. On the potential of lignin-containing cellulose nanofibrils (LCNFs): a review on properties and applications[J]. Cellulose, 2020, 27(4): 1853-1877. |

| 12 | Ewulonu C M, Liu X R, Wu M, et al. Ultrasound-assisted mild sulphuric acid ball milling preparation of lignocellulose nanofibers (LCNFs) from sunflower stalks (SFS)[J]. Cellulose, 2019, 26(7): 4371-4389. |

| 13 | Jiang J G, Zhu Y L, Zargar S, et al. Rapid, high-yield production of lignin-containing cellulose nanocrystals using recyclable oxalic acid dihydrate[J]. Industrial Crops and Products, 2021, 173: 114148. |

| 14 | Bian H Y, Chen L D, Dong M L, et al. Cleaner production of lignocellulosic nanofibrils: potential of mixed enzymatic treatment[J]. Journal of Cleaner Production, 2020, 270: 122506. |

| 15 | Isogai A, Saito T, Fukuzumi H. TEMPO-oxidized cellulose nanofibers[J]. Nanoscale, 2011, 3(1): 71-85. |

| 16 | Zhu J Y, Chen L H, Cai C. Acid hydrotropic fractionation of lignocelluloses for sustainable biorefinery: advantages, opportunities, and research needs[J]. ChemSusChem, 2021, 14(15): 3031-3046. |

| 17 | Cai C, Hirth K, Gleisner R, et al. Maleic acid as a dicarboxylic acid hydrotrope for sustainable fractionation of wood at atmospheric pressure and ≤100℃: mode and utility of lignin esterification[J]. Green Chemistry, 2020, 22(5): 1605-1617. |

| 18 | Mehringer J, Kunz W. Carl Neuberg’s hydrotropic appearances (1916)[J]. Advances in Colloid and Interface Science, 2021, 294: 102476. |

| 19 | Devendra L P, Kumar M K, Pandey A. Evaluation of hydrotropic pretreatment on lignocellulosic biomass[J]. Bioresource Technology, 2016, 213: 350-358. |

| 20 | Subramanian D, Anisimov M A. Phase behavior and mesoscale solubilization in aqueous solutions of hydrotropes[J]. Fluid Phase Equilibria, 2014, 362: 170-176. |

| 21 | Dhapte V, Mehta P. Advances in hydrotropic solutions: an updated review[J]. St. Petersburg Polytechnical University Journal: Physics and Mathematics, 2015, 1(4): 424-435. |

| 22 | 尹崇鑫, 王敏, 程金兰, 等. 助水溶剂应用在生物质精炼领域的研究进展[J]. 林产化学与工业, 2021, 41(3): 134-140. |

| Yin C X, Wang M, Cheng J L, et al. Research progress of application of hydrotropes in biorefinery[J]. Chemistry and Industry of Forest Products, 2021, 41(3) : 134-140. | |

| 23 | Zhou X L, Liu J, Huang T J, et al. Near-complete enzymatic hydrolysis efficiency of Miscanthus using hydrotropic fractionation at atmospheric pressure[J]. Industrial Crops and Products, 2020, 149: 112365. |

| 24 | 王敏, 程金兰, 李鑫, 等. 酸性助水溶剂脱除木质素机理分析[J]. 化工学报, 2022, 73(5): 2206-2221. |

| Wang M, Cheng J L, Li X, et al. Delignification mechanism study of acid hydrotropes[J]. CIESC Journal, 2022, 73(5): 2206-2221. | |

| 25 | Wang Q Q, Zhu J Y, Reiner R S, et al. Approaching zero cellulose loss in cellulose nanocrystal (CNC) production: recovery and characterization of cellulosic solid residues (CSR) and CNC[J]. Cellulose, 2012, 19(6): 2033-2047. |

| 26 | Cheng M, Qin Z Y, Chen Y Y, et al. Efficient extraction of cellulose nanocrystals through hydrochloric acid hydrolysis catalyzed by inorganic chlorides under hydrothermal conditions[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(6): 4656-4664. |

| 27 | Wang Y C, Liu S S, Wang Q, et al. Performance of polyvinyl alcohol hydrogel reinforced with lignin-containing cellulose nanocrystals[J]. Cellulose, 2020, 27(15): 8725-8743. |

| 28 | Bian H Y, Chen L H, Dai H Q, et al. Integrated production of lignin containing cellulose nanocrystals (LCNC) and nanofibrils (LCNF) using an easily recyclable di-carboxylic acid[J]. Carbohydrate Polymers, 2017, 167: 167-176. |

| 29 | Hamad W Y, Hu T Q. Structure-process-yield interrelations in nanocrystalline cellulose extraction[J]. Canadian Journal of Chemical Engineering, 2010, 88(3): 392-402. |

| 30 | Chen L H, Wang Q Q, Hirth K, et al. Tailoring the yield and characteristics of wood cellulose nanocrystals (CNC) using concentrated acid hydrolysis[J]. Cellulose, 2015, 22(3): 1753-1762. |

| 31 | Merlini A, Claumann C, Zibetti A W, et al. Kinetic study of the thermal decomposition of cellulose nanocrystals with different crystal structures and morphologies[J]. Industrial & Engineering Chemistry Research, 2020, 59(30): 13428-13439. |

| 32 | Bian H Y, Chen L H, Gleisner R, et al. Producing wood-based nanomaterials by rapid fractionation of wood at 80℃ using a recyclable acid hydrotrope[J]. Green Chemistry, 2017, 19(14): 3370-3379. |

| 33 | Klemm D, Kramer F, Moritz S, et al. Nanocelluloses: a new family of nature-based materials[J]. Angewandte Chemie-International Edition, 2011, 50(24): 5438-5466. |

| 34 | Lavoine N, Desloges I, Dufresne A, et al. Microfibrillated cellulose-Its barrier properties and applications in cellulosic materials: a review[J]. Carbohydrate Polymers, 2012, 90(2): 735-764. |

| 35 | He M, Yang G H, Chen J C, et al. Production and characterization of cellulose nanofibrils from different chemical and mechanical pulps[J]. Journal of Wood Chemistry and Technology, 2018, 38(2): 149-158. |

| 36 | Gu L H, Jiang B, Song J L, et al. Effect of lignin on performance of lignocellulose nanofibrils for durable superhydrophobic surface[J]. Cellulose, 2019, 26(2): 933-944. |

| 37 | Zhang N, Tao P, Lu Y X, et al. Effect of lignin on the thermal stability of cellulose nanofibrils produced from bagasse pulp[J]. Cellulose, 2019, 26(13): 7823-7835. |

| 38 | Kaur R, Uppal S K, Sharma P. Antioxidant and antibacterial activities of sugarcane bagasse lignin and chemically modified lignins[J]. Sugar Tech, 2017, 19(6): 675-680. |

| 39 | 高莹, 卞辉洋, 焦亮, 等. 对甲基苯磺酸预处理麦草备料废渣制备纳米纤维素[J]. 纤维素科学与技术, 2019, 27(1): 31-37. |

| Gao Y, Bian H Y, Jiao L, et al. Lignocellulosic nanofibrils produced from waste wheat straw using p-toluenesulfonic acid prehydrolysis[J]. Journal of Cellulose Science and Technology, 2019, 27(1): 31-37. | |

| 40 | Liu Y F, Chen B Q, Lv Y C, et al. Insight into the performance of lignin-containing cellulose nanofibers (LCNFs) via lignin content regulation by p-toluenesulfonic acid delignification[J]. Cellulose, 2022, 29(4): 2273-2287. |

| 41 | Bian H Y, Gao Y, Luo J, et al. Lignocellulosic nanofibrils produced using wheat straw and their pulping solid residue: from agricultural waste to cellulose nanomaterials[J]. Waste Management, 2019, 91: 1-8. |

| 42 | Bian H Y, Chen L H, Dai H Q, et al. Effect of fiber drying on properties of lignin containing cellulose nanocrystals and nanofibrils produced through maleic acid hydrolysis[J]. Cellulose, 2017, 24(10): 4205-4216. |

| 43 | Dong M L, Wu C, Chen L D, et al. Benzenesulfonic acid-based hydrotropic system for achieving lignocellulose separation and utilization under mild conditions[J]. Bioresource Technology, 2021, 337: 125379. |

| 44 | Yang M Y, Zhang X, Guan S Y, et al. Preparation of lignin containing cellulose nanofibers and its application in PVA nanocomposite films[J]. International Journal of Biological Macromolecules, 2020, 158: 1259-1267. |

| 45 | Dou J Z, Bian H Y, Yelle D J, et al. Lignin containing cellulose nanofibril production from willow bark at 80℃ using a highly recyclable acid hydrotrope[J]. Industrial Crops and Products, 2019, 129: 15-23. |

| 46 | Yu W, Yi Y J, Wang H Y, et al. Light-colored cellulose nanofibrils produced from raw sisal fibers without costly bleaching[J]. Industrial Crops and Products, 2021, 172: 114009. |

| 47 | Feng C Q, Zhu J T, Cao L M, et al. Acidolysis mechanism of lignin from bagasse during p-toluenesulfonic acid treatment[J]. Industrial Crops and Products, 2022, 176: 114374. |

| 48 | Bian H Y, Dong M L, Chen L D, et al. On-demand regulation of lignocellulosic nanofibrils based on rapid fractionation using acid hydrotrope: kinetic study and characterization[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(25): 9569-9577. |

| 49 | Bian H Y, Gao Y, Yang Y Q, et al. Improving cellulose nanofibrillation of waste wheat straw using the combined methods of prewashing, p-toluenesulfonic acid hydrolysis, disk grinding, and endoglucanase post-treatment[J]. Bioresource Technology, 2018, 256: 321-327. |

| 50 | Su C, Hirth K, Liu Z L, et al. Acid hydrotropic fractionation of switchgrass at atmospheric pressure using maleic acid in comparison with p-TsOH: advantages of lignin esterification[J]. Industrial Crops and Products, 2021, 159: 113017. |

| 51 | Rojo E, Peresin M S, Sampson W W, et al. Comprehensive elucidation of the effect of residual lignin on the physical, barrier, mechanical and surface properties of nanocellulose films[J]. Green Chemistry, 2015, 17(3): 1853-1866. |

| 52 | Zhang X F, Huang H X, Qing Y, et al. A comparison study on the characteristics of nanofibrils isolated from fibers and parenchyma cells in bamboo[J]. Materials, 2020, 13(1): 237. |

| 53 | Su C, Hirth K, Liu Z L, et al. Maleic acid hydrotropic fractionation of wheat straw to facilitate value‐added multi‐product biorefinery at atmospheric pressure[J]. GCB Bioenergy, 2021, 13(9): 1407-1424. |

| 54 | He D, Zhuang J S, Jiang Y, et al. Fractionation of poplar wood using a bifunctional aromatic acid under mild conditions[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(15): 5364-5376. |

| 55 | Yang J Y, Guo T S, Xu Y H, et al. Structure and properties of eucalyptus lignin extracted with benzenesulfonic and p-toluenesulfonic acids under mild conditions[J]. Industrial Crops and Products, 2023, 194: 116269. |

| 56 | Peretz R, Sterenzon E, Gerchman Y, et al. Nanocellulose production from recycled paper mill sludge using ozonation pretreatment followed by recyclable maleic acid hydrolysis[J]. Carbohydrate Polymers, 2019, 216: 343-351. |

| 57 | Cheng J L, Hirth K, Ma Q L, et al. Toward sustainable and complete wood valorization by fractionating lignin with low condensation using an acid hydrotrope at low temperatures (≤80℃)[J]. Industrial & Engineering Chemistry Research, 2019, 58(17): 7063-7073. |

| 58 | Chen L H, Dou J Z, Ma Q L, et al. Rapid and near-complete dissolution of wood lignin at ≤80℃ by a recyclable acid hydrotrope[J]. Science Advances, 2017, 3(9): e1701735. |

| 59 | Cai C, Li J, Hirth K, et al. Comparison of two acid hydrotropes for sustainable fractionation of birch wood[J]. ChemSusChem, 2020, 13(17): 4649-4659. |

| 60 | Zhao Y D, Tagami A, Dobele G, et al. The impact of lignin structural diversity on performance of cellulose nanofiber (CNF)-starch composite films[J]. Polymers, 2019, 11(3): 538. |

| 61 | 岳凤霞, 林敏生, 钱勇, 等. 木质素抗紫外辐射性能应用研究进展[J]. 林业工程学报, 2021, 6(2): 12-20. |

| Yue F X, Lin M S, Qian Y, et al. Recent advances of anti-UV radiation of lignin [J]. Journal of Forestry Engineering, 2021, 6(2): 12-20. | |

| 62 | Nanbu T, Shimada J, Kobayashi M, et al. Anti-UV activity of lignin-carbohydrate complex and related compounds[J]. In Vivo, 2013, 27(1): 133-139. |

| 63 | Faustino H, Gil N, Baptista C, et al. Antioxidant activity of lignin phenolic compounds extracted from kraft and sulphite black liquors[J]. Molecules, 2010, 15(12): 9308-9322. |

| 64 | 黄曹兴, 何娟, 梁辰, 等. 木质素的高附加值应用研究进展[J]. 林业工程学报, 2019, 4(1): 17-26. |

| Huang C X, He J, Liang C, et al. Progress in applications of high value-added lignin materials[J]. Journal of Forestry Engineering, 2019, 4(1): 17-26. | |

| 65 | Huang C X, Dong H L, Zhang Z P, et al. Procuring the nano-scale lignin in prehydrolyzate as ingredient to prepare cellulose nanofibril composite film with multiple functions[J]. Cellulose, 2020, 27(16): 9355-9370. |

| 66 | Bian H Y, Gao Y, Wang R B, et al. Contribution of lignin to the surface structure and physical performance of cellulose nanofibrils film[J]. Cellulose, 2018, 25(2): 1309-1318. |

| 67 | Sakakibara K, Yano H, Tsujii Y. Surface engineering of cellulose nanofiber by adsorption of diblock copolymer dispersant for green nanocomposite materials[J]. ACS Applied Materials & Interfaces, 2016, 8(37): 24893-24900. |

| 68 | Bian H Y, Chen L D, Dong M L, et al. Natural lignocellulosic nanofibril film with excellent ultraviolet blocking performance and robust environment resistance[J]. International Journal of Biological Macromolecules, 2021, 166: 1578-1585. |

| 69 | 卢贝丽, 林强, 尹铸, 等. 抗紫外改性纳米纤维素填料的制备及其性能表征[J]. 福建农林大学学报(自然科学版), 2020, 49(6): 859-864. |

| Lu B L, Lin Q, Yin Z, et al. Preparation and characterization of modified nanocellulose filler with UV resistance [J]. Journal of Fujian Agriculture and Forestry University(Natural Science Edition), 2020, 49(6): 859-864. | |

| 70 | Pang L, Gao Z D, Zhang S N, et al. Preparation and anti-UV property of modified cellulose membranes for biopesticides controlled release[J]. Industrial Crops and Products, 2016, 89: 176-181. |

| 71 | Zhang X H, Li Y T, Guo M M, et al. Antimicrobial and UV blocking properties of composite chitosan films with curcumin grafted cellulose nanofiber[J]. Food Hydrocolloids, 2021, 112: 106337. |

| 72 | 李慧敏. 抗紫外线PVA/纳米TiO2复合膜的制备与性能研究[D]. 株洲: 湖南工业大学, 2012. |

| Li H M. Research on the preparation and properties of anti-ultraviolet PVA/nano-TiO2 composite film[D]. Zhuzhou: Hunan University of Technology, 2012. | |

| 73 | Wu Y, Qian Y, Zhang A C, et al. Light color dihydroxybenzophenone grafted lignin with high UVA/UVB absorbance ratio for efficient and safe natural sunscreen[J]. Industrial & Engineering Chemistry Research, 2020, 59(39): 17057-17068. |

| 74 | Peng Y, Nair S S, Chen H Y, et al. Effects of lignin content on mechanical and thermal properties of polypropylene composites reinforced with micro particles of spray dried cellulose nanofibrils[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(8): 11078-11086. |

| 75 | Liu W, Zhang S Y, Liu K, et al. Sustainable preparation of lignocellulosic nanofibrils and cellulose nanopaper from poplar sawdust[J]. Journal of Cleaner Production, 2023, 384: 135582. |

| 76 | Nair S S, Yan N. Effect of high residual lignin on the thermal stability of nanofibrils and its enhanced mechanical performance in aqueous environments[J]. Cellulose, 2015, 22(5): 3137-3150. |

| 77 | 王凌媛, 惠岚峰. 纳米纤维素疏水改性的研究进展[J]. 林产化学与工业, 2021, 41(3): 125-133. |

| Wang L Y, Hui L F. Research progress of hydrophobic modification of nanocellulose [J]. Chemistry and Industry of Forest Products, 2021, 41(3): 125-133. | |

| 78 | Zhao C X, Mark L H, Alshrah M, et al. Challenge in manufacturing nanofibril composites with low matrix viscosity: effects of matrix viscosity and fibril content[J]. European Polymer Journal, 2019, 121: 109310. |

| 79 | Wei L Q, Agarwal U P, Matuana L, et al. Performance of high lignin content cellulose nanocrystals in poly(lactic acid)[J]. Polymer, 2018, 135: 305-313. |

| 80 | Chen H Y, Nair S S, Chauhan P, et al. Lignin containing cellulose nanofibril application in pMDI wood adhesives for drastically improved gap-filling properties with robust bondline interfaces[J]. Chemical Engineering Journal, 2019, 360: 393-401. |

| 81 | Luo J, Huang K X, Xu Y, et al. A comparative study of lignocellulosic nanofibrils isolated from celery using oxalic acid hydrolysis followed by sonication and mechanical fibrillation[J]. Cellulose, 2019, 26(9): 5237-5246. |

| 82 | Bian H Y, Wei L Q, Lin C X, et al. Lignin-containing cellulose nanofibril-reinforced polyvinyl alcohol hydrogels[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(4): 4821-4828. |

| 83 | Bian H Y, Duan S, Wu J, et al. Lignocellulosic nanofibril aerogel via gas phase coagulation and diisocyanate modification for solvent absorption[J]. Carbohydrate Polymers, 2022, 278: 119011. |

| 84 | 卞辉洋, 扶艳荞, 陈李栋, 等. 疏水亲油木质纳米纤维素气凝胶的制备及表征[J]. 林产化学与工业, 2021, 41(5): 45-50. |

| Bian H Y, Fu Y Q, Chen L D, et al. Preparation and characterization of hydrophobic and lipophilic lignocellulosic nanofibrils-based aerogel[J]. Chemistry and Industry of Forest Products, 2021, 41(5): 45-50. | |

| 85 | 郜梦茜, 张慧, 陈甜甜, 等. 疏水性纤维素纳米纤丝气凝胶的制备及性能研究[J]. 功能材料, 2020, 51(2): 2107-2112. |

| Gao M X, Zhang H, Chen T T, et al. Preparation and characterization of hydrophobic cellulose nanofibril aerogels[J]. Journal of Functional Materials, 2020, 51(2): 2107-2112. | |

| 86 | Lou Z C, Wang Q Y, Kara U I, et al. Biomass-derived carbon heterostructures enable environmentally adaptive wideband electromagnetic wave absorbers[J]. Nano-Micro Letters, 2022, 14(1): 11. |

| 87 | Guo S S, Li X, Kuang Y S, et al. Residual lignin in cellulose nanofibrils enhances the interfacial stabilization of Pickering emulsions[J]. Carbohydrate Polymers, 2021, 253: 117223. |

| [1] | 金伟其, 吴月荣, 王霞, 李力, 裘溯, 袁盼, 王铭赫. 化工园区工业气体泄漏气云红外成像检测技术与国产化装备进展[J]. 化工学报, 2023, 74(S1): 32-44. |

| [2] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [3] | 刘远超, 关斌, 钟建斌, 徐一帆, 蒋旭浩, 李耑. 单层XSe2(X=Zr/Hf)的热电输运特性研究[J]. 化工学报, 2023, 74(9): 3968-3978. |

| [4] | 陈佳起, 赵万玉, 姚睿充, 侯道林, 董社英. 开心果壳基碳点的合成及其对Q235碳钢的缓蚀行为研究[J]. 化工学报, 2023, 74(8): 3446-3456. |

| [5] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [6] | 邢美波, 张中天, 景栋梁, 张洪发. 磁调控水基碳纳米管协同多孔材料强化相变储/释能特性[J]. 化工学报, 2023, 74(7): 3093-3102. |

| [7] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [8] | 葛加丽, 管图祥, 邱新民, 吴健, 沈丽明, 暴宁钟. 垂直多孔碳包覆的FeF3正极的构筑及储锂性能研究[J]. 化工学报, 2023, 74(7): 3058-3067. |

| [9] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [10] | 杨琴, 秦传鉴, 李明梓, 杨文晶, 赵卫杰, 刘虎. 用于柔性传感的双形状记忆MXene基水凝胶的制备及性能研究[J]. 化工学报, 2023, 74(6): 2699-2707. |

| [11] | 刘远超, 蒋旭浩, 邵钶, 徐一帆, 钟建斌, 李耑. 几何尺寸及缺陷对石墨炔纳米带热输运特性的影响[J]. 化工学报, 2023, 74(6): 2708-2716. |

| [12] | 葛泽峰, 吴雨青, 曾名迅, 查振婷, 马宇娜, 侯增辉, 张会岩. 灰化学成分对生物质气化特性的影响规律[J]. 化工学报, 2023, 74(5): 2136-2146. |

| [13] | 刘海芹, 李博文, 凌喆, 刘亮, 俞娟, 范一民, 勇强. 羟基-炔点击化学改性半乳甘露聚糖薄膜的制备及性能研究[J]. 化工学报, 2023, 74(3): 1370-1378. |

| [14] | 祖凌鑫, 胡荣庭, 李鑫, 陈余道, 陈广林. 木质生物质化学组分的碳释放产物特征和反硝化利用程度[J]. 化工学报, 2023, 74(3): 1332-1342. |

| [15] | 刘定平, 陈爱桦, 张向阳, 何文浩, 王海. 铝灰半干法水解脱氮研究[J]. 化工学报, 2023, 74(3): 1294-1302. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号