化工学报 ›› 2021, Vol. 72 ›› Issue (4): 1847-1862.DOI: 10.11949/0438-1157.20200901

孙林泉1,2,3( ),王丽娜1,2,于宏东1,2,苏慧1,2,3,陈德胜1,2,齐涛1,2(

),王丽娜1,2,于宏东1,2,苏慧1,2,3,陈德胜1,2,齐涛1,2( )

)

收稿日期:2020-07-06

修回日期:2020-09-28

出版日期:2021-04-05

发布日期:2021-04-05

通讯作者:

齐涛

作者简介:孙林泉(1996—),男,博士研究生,基金资助:

SUN Linquan1,2,3( ),WANG Lina1,2,YU Hongdong1,2,SU Hui1,2,3,CHEN Desheng1,2,QI Tao1,2(

),WANG Lina1,2,YU Hongdong1,2,SU Hui1,2,3,CHEN Desheng1,2,QI Tao1,2( )

)

Received:2020-07-06

Revised:2020-09-28

Online:2021-04-05

Published:2021-04-05

Contact:

QI Tao

摘要:

随着电子、材料等尖端行业的迅速发展,铌因其独特的物化性质已被视为关键战略性金属资源,其需求量逐年递增,铌的冶金提取技术也受到越来越多的关注。我国白云鄂博地区铌资源丰富,但因铌品位低、矿相复杂、选矿分离难度大,目前尚未有效地开发利用。研究开发适用于我国低品位铌资源的提铌技术,具有重要的研究价值和战略意义。综述了主要的低品位铌资源提铌技术的研究现状,包括火法还原法、酸分解法、碱分解法、氯化法和火法-湿法联合法等,探讨了各种技术工艺的优势和特点,以及铌低品位条件对提铌效果的影响。近年来开发的亚熔盐法和焙烧-酸浸联合法也用于低品位铌资源提铌,这两类方法展现了良好的提取效果和应用价值,具有较为广阔的前景。前者由于分解率高、环境负担小而具有较大的潜力。现有研究表明后者可以较为高效地分解低品位铌矿,铌浸出率可达到98%。最后,对目前低品位铌资源提铌方法存在的问题和未来研究发展方向进行了总结和展望。

中图分类号:

孙林泉, 王丽娜, 于宏东, 苏慧, 陈德胜, 齐涛. 低品位含铌矿物中铌的提取工艺研究进展[J]. 化工学报, 2021, 72(4): 1847-1862.

SUN Linquan, WANG Lina, YU Hongdong, SU Hui, CHEN Desheng, QI Tao. Research progress on extraction technologies of niobium from low-grade niobium-bearing minerals[J]. CIESC Journal, 2021, 72(4): 1847-1862.

| 国家 | 铌矿 (矿山) | 主要矿物 | 原矿 品位/% | 精矿 品位/% | 文献 |

|---|---|---|---|---|---|

| 巴西 | Araxa | 烧绿石 | 1.5~3.5 | 55~60 | [ |

| 巴西 | Catalao | 烧绿石 | 0.8~1.5 | 63.7 | [ |

| 加拿大 | Niobec | 烧绿石 | 0.4 | 58 | [ |

| 加拿大 | Aley | 烧绿石、铌铁矿 | 0.5 | — | [ |

| 加拿大 | Nechalcho | 烧绿石、褐钇铌矿 | 0.4 | — | [ |

| 沙特 | Ghuray yah | 烧绿石、铌铁矿 | 0.28 | — | [ |

| 肯尼亚 | Mrima Hill | 烧绿石 | 0.7 | — | [ |

| 美国 | EIK Creek | 烧绿石 | 0.79 | — | [ |

| 澳大利亚 | Mt Weld | 烧绿石、铌铁金红石 | 1.4 | — | [ |

| 加纳 | Mabou nie | 烧绿石、铌铁矿 | 1.2 | — | [ |

| 中国 | 白云鄂博 | 铌铁金红石、钕易解石 | 0.10~0.15 | 1.0~5.0 | [ |

| 中国 | 宜春 | 铌钽铁矿、细晶石 | 0.008 | 25 | [ |

表1 世界主要铌矿(矿山)原矿和精矿铌品位(以Nb2O5计)

Table 1 Niobium (Nb2O5) grade of raw ores and concentrates of main niobium ores (mines) in the world

| 国家 | 铌矿 (矿山) | 主要矿物 | 原矿 品位/% | 精矿 品位/% | 文献 |

|---|---|---|---|---|---|

| 巴西 | Araxa | 烧绿石 | 1.5~3.5 | 55~60 | [ |

| 巴西 | Catalao | 烧绿石 | 0.8~1.5 | 63.7 | [ |

| 加拿大 | Niobec | 烧绿石 | 0.4 | 58 | [ |

| 加拿大 | Aley | 烧绿石、铌铁矿 | 0.5 | — | [ |

| 加拿大 | Nechalcho | 烧绿石、褐钇铌矿 | 0.4 | — | [ |

| 沙特 | Ghuray yah | 烧绿石、铌铁矿 | 0.28 | — | [ |

| 肯尼亚 | Mrima Hill | 烧绿石 | 0.7 | — | [ |

| 美国 | EIK Creek | 烧绿石 | 0.79 | — | [ |

| 澳大利亚 | Mt Weld | 烧绿石、铌铁金红石 | 1.4 | — | [ |

| 加纳 | Mabou nie | 烧绿石、铌铁矿 | 1.2 | — | [ |

| 中国 | 白云鄂博 | 铌铁金红石、钕易解石 | 0.10~0.15 | 1.0~5.0 | [ |

| 中国 | 宜春 | 铌钽铁矿、细晶石 | 0.008 | 25 | [ |

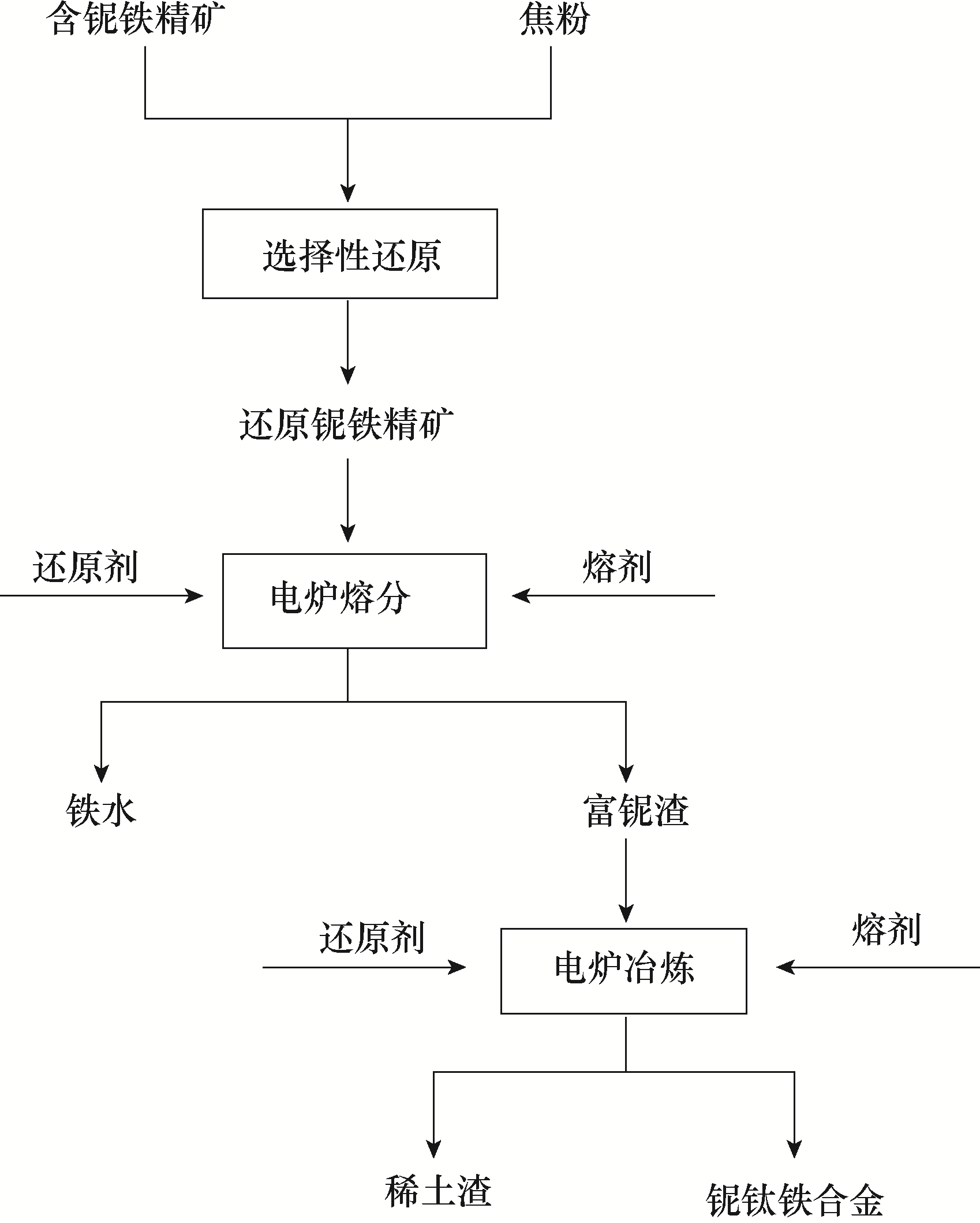

图6 隧道窑式选择性还原-中频电炉熔分-直流电弧炉碳热还原工艺流程

Fig.6 Flow diagram of selective reduction in tunnel kiln-smelting of intermediate frequency electric furnace-DC electric arc furnace carbothermal reduction process

| 原料 | 冶炼方法 | 产品 | 文献 |

|---|---|---|---|

| 铁水 | 铁水分段预处理、喷雾法连续提铌、氧气底(或顶)吹转炉提铌、空气侧吹转炉提铌 | 低级铌铁产品 | [ |

| 含铌铁水 | 中频感应电炉,脱硅-提铌-铌渣直接合金化 | 低硅含铌半钢 | [ |

| 含铌铁矿 | CO/CO2混合气体选择性热还原含铌铁矿、盐酸酸浸 | 含Nb2O5 29.6%,Nb/Fe=6,Nb/P≥12的酸浸渣 | [ |

| 含铌铁精矿 | 煤基直接还原 | Nb2O5 1.75%,回收率94% | [ |

表2 低品位含铌矿物的火法还原冶炼研究

Table 2 Low-grade niobium-containing minerals by pyrometallurgy

| 原料 | 冶炼方法 | 产品 | 文献 |

|---|---|---|---|

| 铁水 | 铁水分段预处理、喷雾法连续提铌、氧气底(或顶)吹转炉提铌、空气侧吹转炉提铌 | 低级铌铁产品 | [ |

| 含铌铁水 | 中频感应电炉,脱硅-提铌-铌渣直接合金化 | 低硅含铌半钢 | [ |

| 含铌铁矿 | CO/CO2混合气体选择性热还原含铌铁矿、盐酸酸浸 | 含Nb2O5 29.6%,Nb/Fe=6,Nb/P≥12的酸浸渣 | [ |

| 含铌铁精矿 | 煤基直接还原 | Nb2O5 1.75%,回收率94% | [ |

| 47 | Zhang B, Li C L, Jiang M F. Distribution ratio of niobium and phosphorus between slag and iron in the melting-separation process[J]. Journal of Northeastern University (Natural Science), 2014, 35(7): 983-986. |

| 48 | 赵二雄. 白云鄂博低品位铌精矿铌铁冶炼新工艺研究[D]. 包头: 内蒙古科技大学, 2019. |

| Zhao E X. The study on new process of smelting niobium iron alloy from Bayan Obo low grade niobium concentrate fines[D]. Baotou: Inner Mongolia University of Science & Technology, 2019. | |

| 49 | 张波, 刘承军, 姜茂发. 白云鄂博稀土铌铁复合矿提铌工艺的研究[C]//第七届(2009)中国钢铁年会. 北京: 冶金工业出版社, 2009: 14-19. |

| Zhang B, Li C L, Jiang M F. Study on the technologies of extracting niobium from Bayan Obo REE-Fe-Nb ore[C]//2009 CSM Annual Meeting Proceedings: Complement. Beijing: Metallurgical Industry Press, 2009: 9-14. | |

| 50 | 李楠. 低硅含铌铁水提铌的研究[D]. 包头: 内蒙古科技大学, 2013. |

| Li N. The study of extracting niobium from low silicon Nb-bearing hot metal[D]. Baotou: Inner Mongolia University of Science & Technology, 2013. | |

| 51 | 陈宏, 韩其勇, 魏寿昆, 等. 从含铌铁矿中提铌及制铌铁的新方法[J]. 钢铁, 1999, 34(3): 13-19 |

| Chen H, Han Q Y, Wei S K, et al. A new method on the extraction of Nb from Nb-bearing iron ore for making FeNb[J]. Iron and Steel, 1999, 34(3): 13-19 | |

| 52 | 蒋曼, 孙体昌, 寇珏, 等. 含铌铁精矿煤基直接还原过程中铌的行为研究[J]. 稀有金属, 2011, 35(5): 731-735. |

| Jiang M, Sun T C, Kou J, et al. Distribution behavior of niobium in process of coal-based direct reduction roasting of Nb-bearing iron concentrates[J]. Chinese Journal of Rare Metals, 2011, 35(5): 731-735. | |

| 53 | 冯运来, 陈义胜, 闫永旺, 等. 碳直接还原富铌渣制取铌铁合金温度的影响矿产综合利用[J/OL]. [2020-06-30]. . |

| Feng Y L, Chen Y S, Yan Y W, et al. Effect of direct reduction of carbon-rich slag on the temperature of strontium iron alloy[J/OL]. [2020-06-30]. . | |

| 54 | 侯晓志, 杨占峰, 王振江, 等. 白云鄂博铌精矿矿物组成特征及铌的分布规律研究[J]. 有色金属(选矿部分), 2018, (2): 4-7, 11. |

| 1 | 翟明国, 吴福元, 胡瑞忠, 等. 战略性关键金属矿产资源: 现状与问题[J]. 中国科学基金, 2019, 33(2): 106-111. |

| Zhai M G, Wu F Y, Hu R Z, et al. Critical metal mineral resources: current research status and scientific issues[J]. Bulletin of National Natural Science Foundation of China, 2019, 33(2): 106-111. | |

| 2 | 何海洋, 何敏, 李建武. 我国铌矿资源供需形势分析[J]. 中国矿业, 2018, 27(11): 1-5. |

| He H Y, He M, Li J W. Analysis of the niobium resources supply and demand pattern in China[J]. China Mining Magazine, 2018, 27(11): 1-5. | |

| 3 | 曹飞, 杨卉芃, 张亮, 等. 全球钽铌矿产资源开发利用现状及趋势[J]. 矿产保护与利用, 2019, 39(5): 56-67, 89. |

| Cao F, Yang H P, Zhang L, et al. Current situation and trend analysis of global tantalum and niobium mineral resources[J]. Conservation and Utilization of Mineral Resources, 2019, 39(5): 56-67, 89. | |

| 4 | Gulley A L,Nassar N T,Xun S. China,the United States,and competition for resources that enable emerging technologies[J]. Proceedings of the National Academy of Sciences of the United States of America,2018, 115: 4111-4115. |

| 5 | Cordeiro P F D O, Brod J A, Palmieri M, et al. The Catalão I niobium deposit, central Brazil: resources, geology and pyrochlore chemistry[J]. Ore Geology Reviews, 2011, 41(1): 112-121. |

| 6 | 艾永亮, 范光. 世界主要烧绿石资源及选矿技术特点[J]. 中国矿业, 2015, 24(4): 130-133, 143. |

| Ai Y L, Fan G. Resources status and mineral processing of pyrochlore[J]. China Mining Magazine, 2015, 24(4): 130-133, 143. | |

| 7 | 程征, 伍喜庆, 杨平伟. 我国钽铌矿物资源概况及选矿技术现状与发展[J]. 中国矿业, 2013, 22(4): 151-157. |

| Cheng Z, Wu X Q, Yang P W. Overview of tantalum and niobium mineral resources in China and present status and development of beneficiation technologies[J]. China Mining Magazine, 2013, 22(4): 151-157. | |

| 8 | 刘玉宝. 浅议白云鄂博矿铌资源开发及展望[J]. 稀土信息, 2015, (9): 30-31. |

| Liu Y B. Development and prospect of niobium resources in Bayan Obo [J]. Rare Earth Information, 2015, (9): 30-31. | |

| 9 | 刘健, 凌明星, 李印, 等. 白云鄂博超大型REE-Nb-Fe矿床的稀土成矿模式综述[J]. 大地构造与成矿学, 2009, 33(2): 270-282. |

| Liu J, Ling M X, Li Y, et al. REE ore-forming models of giant Bayan Obo REE-Nb-Fe ore deposit: a review[J]. Geotectonica et Metallogenia, 2009, 33(2): 270-282. | |

| 10 | 屈曙光, 毛拥军, 钟祥. 低品位铌精矿二步电炉熔炼Nb-Fe合金[J]. 矿冶工程, 1997, 17(2): 46-49. |

| Qu S G, Mao Y J, Zhong X. Smelting Nb Fe alloy from low and medium grade niobium concentrate by two-stage electric furnace process[J]. Mining and Metallurgical Engineering, 1997, 17(2): 46-49. | |

| 11 | 《稀有金属手册》编辑委员会. 稀有金属手册: 下册[M]. 北京: 冶金工业出版社, 1995. |

| Editorial Committee of “Handbook of Rare Metals”. Handbook of Rare Metals: Volume Ⅱ[M]. Beijing: Metallurgical Industry Press, 1995. | |

| 12 | 李小钢, 徐广尧. 开发内蒙古铌资源的战略意义[C]//2012年中国稀土资源综合利用与环境保护研讨会. 北京: 冶金工业出版社, 2012: 5-15. |

| Li X G, Xu G Y. Strategic significance of developing Inner Mongolia's niobium resources[C]//2012 China Rare Earth Resources Comprehensive Utilization and Environmental Protection Seminar Proceedings. Beijing: Metallurgical Industry Press, 2012: 5-15. | |

| 13 | 许延辉. 白云鄂博稀土矿清洁冶金现状及研究进展[J]. 稀土信息, 2015, (11): 10-13. |

| Xu Y H. The status and research progress of clean metallurgy of Bayan Obo rare earth ore [J]. Rare Earth Information, 2015, (11): 10-13. | |

| 14 | 郭财胜, 李梅, 柳召刚, 等. 白云鄂博稀土、铌资源综合利用现状及新思路[J]. 稀土, 2014, 35(1): 96-100. |

| Guo C S, Li M, Liu Z G, et al. Present status and new ideas on utilization of Bayan Obo rare earth and niobium resource[J]. Chinese Rare Earths, 2014, 35(1): 96-100. | |

| 15 | 董一诚, 孟涛. 包头矿选冶新流程的评价[J]. 包钢科技, 1988, 14(3): 36-39. |

| Dong Y C, Meng T. Evaluation of the novel process of beneficiation and smelting of Baotou ore [J]. Science & Technology of Baotou Steel (Group) Corporation, 1988, 14(3): 36-39. | |

| 16 | 何旭初, 范鹏, 杨天钧, 等. 提高高炉冶炼含铌铁矿铌回收率的研究[J]. 湖南冶金, 1990, 18(4): 1-3, 24. |

| He X C, Fan P, Yang T J, et al. Study on improving the recovery rate of niobium in Nb-bearing iron ore by blast furnace smelting [J]. Hunan Metallurgy, 1990, 18(4): 1-3, 24. | |

| 17 | 何旭初, 杨永宜, 董一诚. 富铌炉料还原冶炼时铌进入铁相过程的研究[J]. 湖南冶金, 1994, 22(5): 8-12. |

| He X C, Yang Y Y, Dong Y C. Study on the process of niobium entering iron phase during reduction smelting of niobium-rich furnace charge [J]. Hunan Metallurgy, 1994, 22(5): 8-12. | |

| 18 | 何旭初, 杨永宜, 董一诚. 富铌炉料中锰含量对还原冶炼时铌收率影响的研究[J]. 湖南冶金, 1991, 19(3): 16-20. |

| He X C, Yang Y Y, Dong Y C. Study on the effect of manganese content in niobium-rich furnace charge on niobium yield during reduction smelting [J]. Hunan Metallurgy, 1991, 19(3): 16-20. | |

| 19 | 何旭初, 杨永宜, 董一诚. 渣中铌向铁液传质行为的研究[J]. 稀有金属与硬质合金, 1992, 20(3): 1-6. |

| He X C, Yang Y Y, Dong Y C. Study on the mass transfer behavior of niobium in slag to molten iron [J]. Rare Metals and Cemented Carbides, 1992, 20(3): 1-6. | |

| 20 | 何旭初, 范鹏, 周渝生, 等. 高炉中铌还原产生的碳化铌滞留带[J]. 北京科技大学学报, 1990, 12(6): 504-509. |

| He X C, Fan P, Zhou Y S, et al. Formation of NbC detained layer in blast furnace process for Nb-bearing iron ore[J]. Journal of University of Science and Technology Beijing, 1990, 12(6): 504-509. | |

| 21 | 张波, 刘承军, 姜茂发. 白云鄂博尾矿中有价金属氧化物的选择性还原与富集[C]//中国稀土学会2017学术年会. 北京, 2017. |

| Zhang B, Liu C J, Jiang M F. Selective reduction and enrichment of valuable metal oxides in Bayan Obo tailings[C]//2017 Academic Annual Meeting of China Rare Earth Society. Beijing, 2017. | |

| 22 | 马伟, 钟祥, 贺泽全, 等. “两步”还原法制备中级铌铁新工艺中铌收率的研究[J]. 稀有金属, 1996, 20(4): 254-258. |

| Ma W, Zhong X, He Z Q, et al. Study on the niobium yield in the new process of preparation of intermediate ferro-niobium by “two-Step” reduction [J]. Chinese Journal of Rare Metals, 1996, 20(4): 254-258 | |

| 23 | 高强. 白云鄂博含铌铁精矿富氢熔融还原实验研究[D]. 包头: 内蒙古科技大学, 2015. |

| Gao Q. Study on the process of Bayan Obo iron ore with rich hydrogen smelting reduction[D]. Baotou: Inner Mongolia University of Science & Technology, 2015. | |

| 24 | 宿洪亮. 白云鄂博含铌铁矿粉气基还原提铌过程中脱磷的研究[D]. 包头: 内蒙古科技大学, 2015. |

| Su H L. Study of dephosphorization on hydrogen selective-reduction of Bayan Obo niobium-bearing iron ore powder[D]. Baotou: Inner Mongolia University of Science & Technology, 2015. | |

| 25 | 任树波. 气基还原白云鄂博含铌铁矿过程硫的去除实验研究[D]. 包头: 内蒙古科技大学, 2015. |

| Ren S B. Study on removal sulfur in Bayan Obo niobium-containing iron ore gas based reduction process[D]. Baotou: Inner Mongolia University of Science & Technology, 2015. | |

| 26 | 邹廷信, 钟祥, 黄元琼, 等. 电弧炉两步法冶炼包头低品位铌精矿能量平衡[J]. 矿冶工程, 2000, 20(3): 51-54. |

| Zou T X, Zhong X, Huang Y Q, et al. Smelting low-grade niobium concentrate of Baotou by two-step arc-furnace method: energy equilibrium[J]. Mining and Metallurgical Engineering, 2000, 20(3): 51-54. | |

| 27 | 曹永仙, 徐永香. 一种处理炼锡炉渣的新方法[J]. 稀有金属与硬质合金, 1997, 25(3): 42-45. |

| Cao Y X, Xu Y X. A new technology for treatment of Sn smelter slag[J]. Rare Metals and Cemented Carbides, 1997, 25(3): 42-45. | |

| 28 | 李尚诣. 铌资源开发应用技术[M]. 北京: 冶金工业出版社, 1992: 234-236. |

| Li S Y. Development and Application Technologies of Niobium Resources [M]. Beijing: Metallurgical Industry Press, 1992: 234-236. | |

| 29 | 曹永仙, 高连让. 三相交流工频等离子体冶炼铌铁工艺[C]//第五届等离子体科学技术会议. 大连,1989. |

| Cao Y X, Gao L R. Three-phase AC power frequency plasma smelting ferro-niobium process[C]//The 5th Plasma Science and Technology Conference Proceedings. Dalian, 1989. | |

| 30 | 张波, 姜茂发. 利用白云鄂博含铌尾矿制备铌铁工艺的研究[J]. 工业加热, 2011, 40(3): 56-59. |

| Zhang B, Jiang M F. Study on preparation process of ferrocolubium utilizing niobium-bearing tailings from Bayan Obo ore[J]. Industrial Heating, 2011, 40(3): 56-59. | |

| 31 | 杨世山, 沈甦, 李治全, 等. 包头2号矿体选冶经济高效流程的开发[J]. 北京科技大学学报, 1995, 17(3): 218-223. |

| Yang S S, Shen S, Li Z Q, et al. New combined process of niobium enrichment from No.2 ore body of Baotou niobium-bearing iron ore[J]. Journal of University of Science and Technology Beijing, 1995, 17(3): 218-223. | |

| 32 | Zhang B, Fan Y, Liu C J, et al. Reduction characteristics of carbon-containing REE–Nb–Fe ore pellets[J]. Metals, 2018, 8(4): 204. |

| 33 | Liu M D, You Z X, Peng Z W, et al. Enrichment of rare earth and niobium from a REE-Nb-Fe associated ore via reductive roasting followed by magnetic separation[J]. JOM, 2016, 68(2): 567-576. |

| 34 | 方觉, 王志荣, 张家元, 等. 包头铌铁矿冶炼实验室研究[J]. 东北大学学报(自然科学版), 1996, 17(1): 35-40. |

| Fang J, Wang Z R, Zhang J Y, et al. Experiment research on smelting of Baotou niobium ore with high iron content[J]. Journal of Northeastern University (Natural Science), 1996, 17(1): 35-40. | |

| 35 | 李墨漪, 贾中帅, 周鑫, 等. 碳热还原白云鄂博稀选尾矿试验研究[J]. 包钢科技, 2018, 44(3): 34-38. |

| Li M Y, Jia Z S, Zhou X, et al. Experimental study on tailings after beneficiation of rare earth in Bayan Obo with carbon thermal reduction[J]. Science & Technology of Baotou Steel, 2018, 44(3): 34-38. | |

| 36 | 贾中帅, 王继平, 周鑫, 等. 微波碳热还原白云鄂博稀选尾矿试验[J]. 中国有色冶金, 2019, 48(6): 80-85. |

| Jia Z S, Wang J P, Zhou X, et al. Experimental study on carbothermal reduction of Bayan Obo RE-flotation tailings in microwave field[J]. China Nonferrous Metallurgy, 2019, 48(6): 80-85. | |

| 37 | 张家元, 方觉. 包头铌铁矿冶炼实验研究[J]. 湖南冶金, 2004, 32(2): 7-10, 14. |

| Zhang J Y, Fang J. Experiment research on smelting of Baotou niobium ore[J]. Hunan Metallurgy, 2004, 32(2): 7-10, 14. | |

| 38 | Pang Z D, Lv X, Ling J W, et al. Blast furnace ironmaking process with super high TiO2 in the slag: high-temperature structure of the slag[J]. Metallurgical and Materials Transactions B, 2020, 51(5): 2348-2357. |

| 39 | Qiu J Y, Liu C J. Subsolidus phase relations in the CaO–SiO2–Nb2O5–La2O3 quarternary system at 1273 K[J]. ISIJ International, 2017, 57(12): 2107-2114. |

| 40 | Zhang R, Wang Y, Zhao X, et al. Structure and viscosity of molten CaO-SiO2-FexO slag during the early period of basic oxygen steelmaking[J]. Metallurgical and Materials Transactions B, 2020, 51(5): 2021-2029. |

| 41 | Ma J, Li W, Fu G Q, et al. Viscous flow behaviors of Cr-bearing high-titanium melting slag with different MgO contents[J]. Steel Research International, 2020, 91(7): 1-8. |

| 42 | 陈衍彪. 白云鄂博铁精矿预还原烧结过程中磷的迁移行为[D]. 包头: 内蒙古科技大学, 2019. |

| Chen Y B. Phosphorus migration behavior in pre-reduction sintering process of Bayan Obo iron concentrate[D]. Baotou: Inner Mongolia University of Science & Technology, 2019. | |

| 43 | You Z M, Jung I H. Critical evaluation and thermodynamic optimization of the Fe-P system[J]. Metallurgical and Materials Transactions B, 2020, 51(6): 3108-3129. |

| 44 | Yang J G, Park J H. Distribution behavior of aluminum and titanium between nickel-based alloys and molten slags in the electro slag remelting (ESR) process[J]. Metallurgical and Materials Transactions B, 2017, 48(4): 2147-2156. |

| 45 | 李春龙, 李小钢, 徐广尧. 白云鄂博共伴生矿资源综合利用技术开发与产业化[J]. 稀土, 2015, 36(5): 151-158. |

| Li C L, Li X G, Xu G Y. Technology development and industrialization of resources comprehensive utilization of intergrowth and associated ore in Baiyun Obo[J]. Chinese Rare Earths, 2015, 36(5): 151-158. | |

| 46 | 赵磊, 赵增武, 李岩. 白云鄂博铌精矿碳还原直接合金化热力学研究[J]. 内蒙古科技大学学报, 2014, 33(3): 230-233, 248. |

| Zhao L, Zhao Z W, Li Y. Thermodynamic analysis of Nb2O5 direct alloying by carbon reducing agent[J]. Journal of Inner Mongolia University of Science and Technology, 2014, 33(3): 230-233, 248. | |

| 47 | 张波, 李春龙, 姜茂发. 熔分过程中铌、磷在渣铁两相间的分配比[J]. 东北大学学报(自然科学版), 2014, 35(7): 983-986. |

| 54 | Hou X Z, Yang Z F, Wang Z J, et al. Study on minerals composition characteristics of niobium concentrate and distribution of niobium in Bayan Obo[J]. Nonferrous Metals (Mineral Processing Section), 2018, (2): 4-7, 11. |

| 55 | 张轰玉, 杨占峰, 焦登铭, 等. 白云鄂博主矿霓石型铌稀土铁矿石中铌在独立矿物中的富集状态和分布规律研究[J]. 有色金属(选矿部分), 2020, (1): 6-12. |

| Zhang H Y, Yang Z F, Jiao D M, et al. Distribution regularity and enrichment state of niobium in independent minerals in aegirine-type niobium rare earth iron ore in Bayan Obo main mine[J]. Nonferrous Metals (Mineral Processing Section), 2020, (1): 6-12. | |

| 56 | 《有色金属提取治金手册》编辑委员会. 有色金属提取冶金手册: 稀有高熔点金属下[M]. 北京: 冶金工业出版社, 1999: 32-35. |

| Editorial Committee of “Manual for Extraction of Nonferrous Metals”. Nonferrous Metals Extraction Metallurgy Manual: Rare High Melting Point Metals(Volume 2)[M]. Beijing: Metallurgical Industry Press, 1999: 32-35. | |

| 57 | Krismer B, Hoppe A. Process for recovering niobium and/or tantalum compounds from such residues further containing complexes of uranium, thorium, titanium and/or rare earth metals: US4446116[P]. 1984-05-01. |

| 58 | Rodriguez M H, Rosales G D, Pinna E G, et al. Extraction of niobium and tantalum from ferrocolumbite by hydrofluoric acid pressure leaching[J]. Hydrometallurgy, 2015, 156: 17-20. |

| 59 | Kasikova N I, Kasikov A G, Korotkova G V. Extraction of niobium from hydrochloric solutions with tertiary amines in aprotic diluents[J]. Russian Journal of Applied Chemistry, 2010, 83(3): 424-429. |

| 60 | El Hussaini O M, Rice N M. Liquid-liquid extraction of niobium and tantalum from aqueous sulphate/fluoride solutions by a tertiary amine[J]. Hydrometallurgy, 2004, 72(3/4): 259-267. |

| 61 | 韩建设, 周勇. 钽铌萃取分离工艺与设备进展[J]. 稀有金属与硬质合金, 2004, 32(2): 15-20. |

| Han J S, Zhou Y. Development of Ta & Nb extraction and stripping technology and equipment[J]. Rare Metals and Cemented Carbides, 2004, 32(2): 15-20. | |

| 62 | 匡国珍, 周火根, 张浩, 等. 仲辛醇-HF-H2SO4体系制取超高纯氧化钽和超高纯氧化铌[J]. 稀有金属与硬质合金, 2005, 33(2): 1-3, 8. |

| Kuang G Z, Zhou H G, Zhang H, et al. Production of ultra-pure tantalum oxide/ultra-pure niobium oxide from CH3(CH2)5 CHOHCH3-HF-H2SO4 system[J]. Rare Metals and Cemented Carbides, 2005, 33(2): 1-3, 8. | |

| 63 | Swain N, Mishra S. A review on the recovery and separation of rare earths and transition metals from secondary resources[J]. Journal of Cleaner Production, 2019, 220: 884-898. |

| 64 | El-Hazek M N, Amer T E, Abu El-Azm M G, et al. Liquid-liquid extraction of tantalum and niobium by octanol from sulfate leach liquor[J]. Arabian Journal of Chemistry, 2012, 5(1): 31-39. |

| 65 | Gupta C K, Suri A K. Extractive Metallurgy of Niobium[M]. London: CRC Press, 1994: 98-127. |

| 66 | El-Hussaini O M, El-Hakam Mahdy M A. Extraction of niobium and tantalum from nitrate and sulfate media by using MIBK[J]. Mineral Processing and Extractive Metallurgy Review, 2002, 22(4/5/6): 633-650. |

| 67 | Nete M, Purcell W, Nel J T. Non-fluoride dissolution of tantalum and niobium oxides and their separation using ion exchange[J]. Hydrometallurgy, 2017, 173: 192-198. |

| 68 | Rodriguez M, Rivarola J, del C Ruiz M. The effects of carboxylic acid addition on hydrofluoric acid autoclave leaching of a ferrocolumbite[J]. Hydrometallurgy, 2004, 74(1/2): 39-46. |

| 69 | Majima H, Awakura Y, Mashima M, et al. Dissolution of columbite and tantalite in acidic fluoride media[J]. Metallurgical Transactions B, 1988, 19(3): 355-363. |

| 70 | Yang X L, Huang W F, Fang Q, et al. Pressure leaching of manganotantalite by sulfuric acid using ammonium fluoride as an assistant reagent[J]. Hydrometallurgy, 2018, 175: 348-353. |

| 71 | El-Hussaini O M, Mahdy M A. Sulfuric acid leaching of Kab Amiri niobium-tantalum bearing minerals, Central Eastern Desert, Egypt[J]. Hydrometallurgy, 2002, 64(3): 219-229. |

| 72 | Balinski A, Atanasova P, Wiche O, et al. Recovery of REEs, Zr(+Hf), Mn and Nb by H2SO4 leaching of eudialyte concentrate[J]. Hydrometallurgy, 2019, 186: 176-186. |

| 73 | Yang X L, Zhang J W, Fang X H, et al. Kinetics of pressure leaching of niobium ore by sulfuric acid[J]. International Journal of Refractory Metals and Hard Materials, 2014, 45: 218-222. |

| 74 | 杨小红. 含铌稀有金属矿中铌的分选与综合利用工艺研究[D]. 湘潭: 湘潭大学, 2014. |

| Yang X H. Separation of niobium and comprehensive utilization of some rare metal ore[D]. Xiangtan: Xiangtan University, 2014. | |

| 75 | 刘勇, 刘牡丹, 刘珍珍. 复杂稀有金属伴生矿富集渣提取稀土和铌的工艺研究[J]. 稀有金属与硬质合金, 2015, 43(1): 21-25. |

| Liu Y, Liu M D, Liu Z Z. Technological study on rare earth and niobium extraction from tailings of beneficiated complex rare metal associated ore[J]. Rare Metals and Cemented Carbides, 2015, 43(1): 21-25. | |

| 76 | Toromanoff I, Habashi F. Hydrometallurgical production of technical niobium oxide from pyrochlore concentrates[J]. Journal of the Less Common Metals, 1983, 91(1): 71-82. |

| 77 | 秦希黎. KOH碱性水热法提铌基础研究[D]. 沈阳: 东北大学, 2015. |

| Qin X L. Fundamental research on niobium extraction by KOH alkaline hydrothermal process[D]. Shenyang: Northeastern University, 2015. | |

| 78 | Zhou H M, Zheng S L, Zhang Y. Leaching of a low-grade niobium-tantalum ore by highly concentrated caustic potash solution[J]. Hydrometallurgy, 2005, 80(1/2): 83-89. |

| 79 | 王中磊, 段赟, 沈少波, 等. 氯化法从包头铁矿尾矿中提取铌和稀土的研究[J]. 中国稀土学报, 2008, 26: 501-505. |

| Wang Z L, Duan Y, Shen S B, et al. Study on the extraction of niobium and rare earths from tailings of Baotou iron ores by carbochlorination[J]. Journal of the Chinese Rare Earth Society, 2008, 26: 501-505. | |

| 80 | 于秀兰. 碳热氯化法提取包钢选矿厂尾矿中有价元素可行性分析[J]. 化工进展, 2009, 28(S1): 544-547. |

| Yu X L. Feasibility analysis of extracting valuable elements from BaoSteel concentrator tailing by carbothermic chlorination [J]. Chemical Industry and Engineering Progress, 2009, 28(S1): 544-547. | |

| 81 | 于秀兰, 王之昌, 韩跃新, 等. AlCl3脱氟-碳热氯化法提取包钢选矿厂尾矿中稀土[J]. 稀土, 2006, 27(4): 30-34. |

| Yu X L, Wang Z C, Han Y X, et al. Extraction of rare earths from Baogang tailings by carbochlorination reaction taking AlCl3 as defluorinating agent[J]. Chinese Rare Earths, 2006, 27(4): 30-34. | |

| 82 | Zhang L Q, Wang Z C, Tong S X, et al. Rare earth extraction from bastnaesite concentrate by stepwise carbochlorination-chemical vapor transport-oxidation[J]. Metallurgical and Materials Transactions B, 2004, 35(2): 217-221. |

| 83 | 于秀兰, 王之昌, 韩跃新, 等. 碳热氯化法分解包钢选矿厂尾矿工艺的研究[J]. 金属矿山, 2007, (9): 113-115, 130. |

| Yu X L, Wang Z C, Han Y X, et al. Study on process of decomposition of BaoSteel concentrator tailing by carbothermic chlorination[J]. Metal Mine, 2007, (9): 113-115, 130. | |

| 84 | Wang Z C, Lei P X, Chi M Y, et al. Rare earth extraction and separation from mixed bastnaesite-monazite concentrate by stepwise carbochlorination-chemical vapor transport[J]. Metallurgical and Materials Transactions B, 2002, 33(5): 661-668. |

| 85 | 于秀兰, 郎晓川, 王之昌. MgO焙烧-碳热氯化法提取包钢选矿厂尾矿中的稀土[J]. 中国稀土学报, 2009, 27(2): 309-312. |

| Yu X L, Lang X C, Wang Z C. Extraction of rare earths from Baotou concentrating mill's tailing by MgO roasting and carbochlorination reaction[J]. Journal of the Chinese Rare Earth Society, 2009, 27(2): 309-312. | |

| 86 | Wang X H, Zheng S L, Xu H B, et al. Leaching of niobium and tantalum from a low-grade ore using a KOH roast-water leach system[J]. Hydrometallurgy, 2009, 98(3/4): 219-223. |

| 87 | 杨秀丽. 难分解钽铌矿低碱分解新工艺及应用基础研究[D]. 昆明: 昆明理工大学, 2013. |

| Yang X L. Fundamental research on novel technology and application of low alkali decomposition of refractory tantalum and niobium ore[D]. Kunming: Kunming University of Science and Technology, 2013. | |

| 88 | 胡根火. 钽铌湿法冶金分离方法评述[J]. 稀有金属与硬质合金, 2015, 43(1): 29-32. |

| Hu G H. Review of tantalum-niobium hydrometallurgical separation processes[J]. Rare Metals and Cemented Carbides, 2015, 43(1): 29-32. | |

| 89 | 李光伟, 许延辉, 赵文怡, 等. 富铌渣硫酸浸出液中铌的分离工艺研究[J]. 稀土, 2013, 34(4): 57-62. |

| Li G W, Xu Y H, Zhao W Y, et al. Study on separation process of Nb in sulfuric acid leaching solution of Nb-rich slag[J]. Chinese Rare Earths, 2013, 34(4): 57-62. | |

| 90 | 杨秀丽, 张军伟, 方夕辉. 低品位铌矿硫酸焙烧: 草酸浸出回收铌[J]. 有色金属工程, 2014, 4(3): 48-50. |

| Yang X L, Zhang J W, Fang X H. Recovery of niobium from low-grade niobium ore by sulfuric acid roasting-oxalic acid leaching [J]. Nonferrous Metals Engineering, 2014, 4(3): 48-50. | |

| 91 | 张德文, 赵文怡, 许延辉, 等. 活化焙烧硫酸分解提取富铌渣中铌、钛、钪和稀土[J]. 稀土, 2013, 34(6): 56-60. |

| Zhang D W, Zhao W Y, Xu Y H, et al. Extracting Ni, Ti, Sc and RE from niobium-enriched slag by CaCl2 roasing and H2SO4 decomposition method[J]. Chinese Rare Earths, 2013, 34(6): 56-60. | |

| 92 | Gao W C, Wen J K, Wu B, et al. Extraction of niobium, yttrium, and cerium from a low-grade niobium-bearing ore by roasting (NH4)2SO4-Na2SO4-H2SO4 system[J]. Rare Metals, 2014, 33(6): 754-760. |

| 93 | Zhang B, Liu C J, Li C L, et al. Separation and recovery of valuable metals from low-grade REE-Nb-Fe ore[J]. International Journal of Mineral Processing, 2016, 150: 16-23. |

| [1] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [2] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [3] | 杨百玉, 寇悦, 姜峻韬, 詹亚力, 王庆宏, 陈春茂. 炼化碱渣湿式氧化预处理过程DOM的化学转化特征[J]. 化工学报, 2023, 74(9): 3912-3920. |

| [4] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [5] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [6] | 吕龙义, 及文博, 韩沐达, 李伟光, 高文芳, 刘晓阳, 孙丽, 王鹏飞, 任芝军, 张光明. 铁基导电材料强化厌氧去除卤代有机污染物:研究进展及未来展望[J]. 化工学报, 2023, 74(8): 3193-3202. |

| [7] | 黄可欣, 李彤, 李桉琦, 林梅. 加装旋转叶轮T型通道流场的模态分解[J]. 化工学报, 2023, 74(7): 2848-2857. |

| [8] | 李盼, 马俊洋, 陈志豪, 王丽, 郭耘. Ru/α-MnO2催化剂形貌对NH3-SCO反应性能的影响[J]. 化工学报, 2023, 74(7): 2908-2918. |

| [9] | 张琦钰, 高利军, 苏宇航, 马晓博, 王翊丞, 张亚婷, 胡超. 碳基催化材料在电化学还原二氧化碳中的研究进展[J]. 化工学报, 2023, 74(7): 2753-2772. |

| [10] | 朱理想, 罗默也, 张晓东, 龙涛, 余冉. 醌指纹法指示三氯乙烯污染土功能微生物活性应用研究[J]. 化工学报, 2023, 74(6): 2647-2654. |

| [11] | 张艳梅, 袁涛, 李江, 刘亚洁, 孙占学. 高效SRB混合菌群构建及其在酸胁迫条件下的性能研究[J]. 化工学报, 2023, 74(6): 2599-2610. |

| [12] | 胡南, 陶德敏, 杨照岚, 王学兵, 张向旭, 刘玉龙, 丁德馨. 铁炭微电解与硫酸盐还原菌耦合修复铀尾矿库渗滤水的研究[J]. 化工学报, 2023, 74(6): 2655-2667. |

| [13] | 张谭, 刘光, 李晋平, 孙予罕. Ru基氮还原电催化剂性能调控策略[J]. 化工学报, 2023, 74(6): 2264-2280. |

| [14] | 张建华, 陈萌萌, 孙雅雯, 彭永臻. 部分短程硝化同步除磷耦合Anammox实现生活污水高效脱氮除磷[J]. 化工学报, 2023, 74(5): 2147-2156. |

| [15] | 胡香凝, 尹渊博, 袁辰, 是赟, 刘翠伟, 胡其会, 杨文, 李玉星. 成品油在土壤中运移可视化的实验研究[J]. 化工学报, 2023, 74(4): 1827-1835. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号