化工学报 ›› 2021, Vol. 72 ›› Issue (4): 2190-2202.DOI: 10.11949/0438-1157.20201040

收稿日期:2020-07-28

修回日期:2020-08-27

出版日期:2021-04-05

发布日期:2021-04-05

通讯作者:

彭旭东

作者简介:江锦波(1989—),男,博士,讲师,基金资助:

JIANG Jinbo( ),TENG Liming,MENG Xiangkai,LI Jiyun,PENG Xudong(

),TENG Liming,MENG Xiangkai,LI Jiyun,PENG Xudong( )

)

Received:2020-07-28

Revised:2020-08-27

Online:2021-04-05

Published:2021-04-05

Contact:

PENG Xudong

摘要:

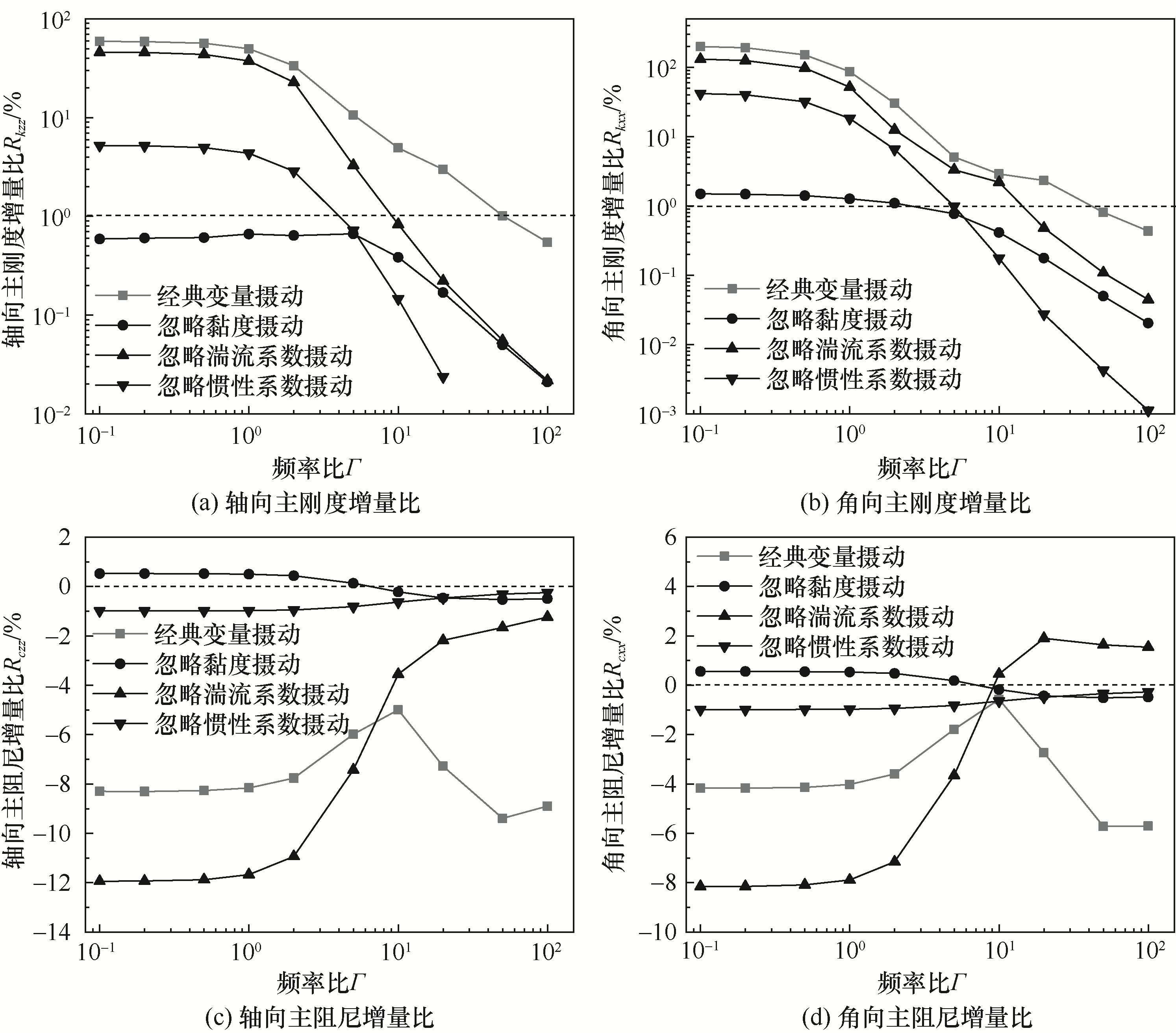

超临界CO2压缩机进口端干气密封工况处于临界点附近,强非线性物性及高Reynolds数流动使其密封特性异于常规介质干气密封。在综合考虑四种实际流体效应的稳态膜压求解模型基础上,基于摄动法推导了包括膜压、密度、黏度、Reynolds数、湍流系数和惯性系数在内的多变量摄动干气密封动特性数值模型。对比分析了超临界CO2和N2干气密封的动态特性,研究了不同频率比下各实际流体效应和变量摄动形式对超临界CO2干气密封动特性系数的影响规律,获得了不同条件下动态特性的关键影响因素。结果表明:高频下超临界CO2干气密封的刚度和阻尼系数较N2干气密封降幅超过50%,湍流效应和实际气体效应对干气密封动态特性影响显著,低频下采用经典变量摄动和忽略湍流系数摄动会使动特性系数计算偏差很大,而高频下经典变量摄动模型对刚度系数的预测精度可接受。

中图分类号:

江锦波, 滕黎明, 孟祥铠, 李纪云, 彭旭东. 基于多变量摄动的超临界CO2干气密封动态特性[J]. 化工学报, 2021, 72(4): 2190-2202.

JIANG Jinbo, TENG Liming, MENG Xiangkai, LI Jiyun, PENG Xudong. Dynamic characteristics of supercritical CO2 dry gas seal based on multi variables perturbation[J]. CIESC Journal, 2021, 72(4): 2190-2202.

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 密封端面内径ri/mm | 58.42 | 非开槽区气膜厚度hb/μm | 8 |

| 密封端面外径ro/mm | 77.78 | 高压腔介质压力po/MPa | 8 |

| 槽根半径rg/mm | 68.10 | 低压腔介质压力pi/MPa | 0.1 |

| 螺旋角β/(°) | 15 | 介质温度T0/K | 310 |

| 螺旋槽深度hg/μm | 5 | 密封端面平均线速度v/(m·s-1) | 100 |

| 螺旋槽数Ng | 12 | 频率比Γ | 1.0 |

| 周向槽宽堰宽比δ | 1 |

表1 本文干气密封动态特性数值计算初始参数

Table 1 Initial parameters adopted in the calculation of dynamic characteristics of dry gas seal

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 密封端面内径ri/mm | 58.42 | 非开槽区气膜厚度hb/μm | 8 |

| 密封端面外径ro/mm | 77.78 | 高压腔介质压力po/MPa | 8 |

| 槽根半径rg/mm | 68.10 | 低压腔介质压力pi/MPa | 0.1 |

| 螺旋角β/(°) | 15 | 介质温度T0/K | 310 |

| 螺旋槽深度hg/μm | 5 | 密封端面平均线速度v/(m·s-1) | 100 |

| 螺旋槽数Ng | 12 | 频率比Γ | 1.0 |

| 周向槽宽堰宽比δ | 1 |

图11 变量摄动对不同频率比下sCO2密封动特性系数影响

Fig.11 The influence of variable perturbation on dynamic characteristics of sCO2 dry gas seal at different frequency ratio

| 1 | Ahn Y, Bae S J, Kim M, et al. Review of supercritical CO2 power cycle technology and current status of research and development[J]. Nuclear Engineering and Technology, 2015, 47(6): 647-661. |

| 2 | Thatte A, Dheeradhad A V. Coupled physics performance predictions and risk assessment for dry gas seal operating in mw-scale supercritical CO2 turbine[C]//ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition. American Society of Mechanical Engineers Digital Collection, 2016. |

| 3 | Brun K, Friedman P, Dennis R. Foreword[M]//Fundamentals and Applications of Supercritical Carbon Dioxide (sCO2) Based Power Cycles. Amsterdam: Elsevier, 2017. |

| 4 | 李志刚, 袁韬, 方志, 等. 超临界二氧化碳旋转机械动密封技术研究进展[J]. 热力透平, 2019, 48(3): 166-174, 191. |

| Li Z G, Yuan T, Fang Z, et al. A review on dynamic sealing technology of supercritical carbon dioxide rotating machinery[J]. Thermal Turbine, 2019, 48(3): 166-174, 191. | |

| 5 | Conboy T M. Real-gas effects in foil thrust bearings operating in the turbulent regime[J]. Journal of Tribology, 2013, 135(3): 031703. |

| 6 | Qin K, Gollan R J, Jahn I H. Application of a wall function to simulate turbulent flows in foil bearings at high rotational speeds[J]. Tribology International, 2017, 115: 546-556. |

| 7 | Guenat E, Schiffmann J. Real-gas effects on aerodynamic bearings[J]. Tribology International, 2018, 120: 358-368. |

| 8 | Fairuz Z M, Jahn I. The influence of real gas effects on the performance of supercritical CO2 dry gas seals[J]. Tribology International, 2016, 102: 333-347. |

| 9 | 沈伟, 彭旭东, 江锦波, 等. 高速超临界二氧化碳干气密封实际效应影响分析[J]. 化工学报, 2019, 70(7): 2645-2659. |

| Shen W, Peng X D, Jiang J B, et al. Analysis on real effect of supercritical carbon dioxide dry gas seal at high speed[J]. CIESC Journal, 2019, 70(7): 2645-2659. | |

| 10 | 许恒杰, 宋鹏云, 毛文元, 等. 层流状态下高压高转速二氧化碳干气密封的惯性效应分析[J]. 化工学报, 2018, 69(10): 4311-4323. |

| Xu H J, Song P Y, Mao W Y, et al. Analysis on inertia effect of carbon dioxide dry gas seal at high speed and pressure under laminar condition[J]. CIESC Journal, 2018, 69(10): 4311-4323. | |

| 11 | 严如奇, 洪先志, 包鑫, 等. 超临界二氧化碳干气密封相态分布规律与密封性能研究[J]. 化工学报, 2020, 71(8): 3681-3690. |

| Yan R Q, Hong X Z, Bao X, et al. Phase-distribution regularity and sealing performance of supercritical carbon dioxide dry gas seal[J]. CIESC Journal, 2020, 71(8): 3681-3690. | |

| 12 | 袁韬, 李志刚, 李军, 等. 螺旋槽结构对SCO2压气机轴端干气密封性能影响的数值研究[J]. 西安交通大学学报, 2020, 54(11): 37-45. |

| Yuan T, Li Z G, Li J, et al. Effect of spiral structure on the shaft end dry gas seal performance for supercritical carbon dioxide compressors[J]. Journal of Xi'an Jiaotong University, 2020, 54(11): 37-45. | |

| 13 | Malanoski S B, Pan C H T. The static and dynamic characteristics of the spiral-grooved thrust bearing[J]. Journal of Basic Engineering, 1965, 87(3): 547-555. |

| 14 | 刘雨川, 徐万孚, 王之栎, 等. 端面气膜密封动力特性系数的计算[J]. 清华大学学报(自然科学版), 2002, 42(2): 185-189. |

| Liu Y C, Xu W F, Wang Z L, et al. Dynamic coefficients for gas film face seal[J]. Journal of Tsinghua University (Science and Technology), 2002, 42(2): 185-189. | |

| 15 | Chen Y, Jiang J B, Peng X D. Gas film disturbance characteristics analysis of high-speed and high-pressure dry gas seal[J]. Chinese Journal of Mechanical Engineering, 2016, 29(6): 1226-1233. |

| 16 | 张树强, 李双喜, 蔡纪宁, 等. 动静压混合式气体密封追随性及主动调控振动特性数值分析[J]. 航空学报, 2012, 33(7): 1336-1346. |

| Zhang S Q, Li S X, Cai J N, et al. Numerical analysis for the tracking property and active regulation vibration characteristics of dynamichydrostatic hybrid gas seals[J]. Acta Aeronautica et Astronautica Sinica, 2012, 33(7): 1336-1346. | |

| 17 | 孟祥铠, 江莹莹, 赵文静, 等. 考虑空化效应的螺旋槽机械密封液膜动力学特性研究[J]. 摩擦学学报, 2019, 39(2): 171-180. |

| Meng X K, Jiang Y Y, Zhao W J, et al. Fluid film dynamic characteristics of spiral-grooved mechanical seals with cavitation effect[J]. Tribology, 2019, 39(2): 171-180. | |

| 18 | 许恒杰, 宋鹏云, 毛文元, 等. 考虑氢气实际气体效应和阻塞流效应的螺旋槽干气密封动态特性分析[J]. 化工学报, 2017, 68(12): 4675-4684. |

| Xu H J, Song P Y, Mao W Y, et al. Dynamic characteristics of spiral groove dry gas seals with consideration of hydrogen real gas and choked flow effects[J]. CIESC Journal, 2017, 68(12): 4675-4684. | |

| 19 | 宋鹏云, 胡晓鹏, 许恒杰. 实际气体对T槽干气密封动态特性的影响[J]. 化工学报, 2014, 65(4): 1344-1352. |

| Song P Y, Hu X P, Xu H J. Effect of real gas on dynamic performance of T-groove dry gas seal[J]. CIESC Journal, 2014, 65(4): 1344-1352. | |

| 20 | 沈伟, 彭旭东, 江锦波, 等. 惯性效应对超高速倾斜端面气膜密封稳动态特性影响[J]. 摩擦学学报, 2019, 39(4): 452-462. |

| Shen W, Peng X D, Jiang J B, et al. The influence of inertia effect on steady performance and dynamic characteristic of super high-speed tilted gas face seal[J]. Tribology, 2019, 39(4): 452-462. | |

| 21 | 李世聪, 钱才富, 李双喜, 等. 油气两相动压密封动态特性的热流固耦合研究[J]. 化工学报, 2020, 71(5): 2190-2201. |

| Li S C, Qian C F, Li S X, et al. Study of thermal-fluid-solid coupling on dynamic characteristics of oil-gas miscible backflow pumping seal[J]. CIESC Journal, 2020, 71(5): 2190-2201. | |

| 22 | 李庆展, 郑娆, 李双喜, 等. 基于流固热耦合的油气两相动压密封追随动态特性[J]. 哈尔滨工业大学学报, 2020, 52(7): 122-132. |

| Li Q Z, Zheng R, Li S X, et al. Follows dynamic characteristics of oil-gas two-phase hydrodynamic seals based on fluid-solid-thermal coupling[J]. Journal of Harbin Institute of Technology, 2020, 52(7): 122-132. | |

| 23 | 温建全. 超临界二氧化碳介质箔片轴承弹流耦合研究[D]. 哈尔滨: 哈尔滨工业大学, 2017. |

| Wen J Q. Theoretical study on characteristics of compliant foil bearings lubricated with supercritical carbon dioxide[D]. Harbin: Harbin Institute of Technology, 2017. | |

| 24 | Bi C X, Han D J, Yang J F. The frequency perturbation method for predicting dynamic coefficients of supercritical carbon dioxide lubricated bearings[J]. Tribology International, 2020, 146: 106256. |

| 25 | Thatte A, Loghin A, Martin E, et al. Multi-scale coupled physics models and experiments for performance and life prediction of supercritical CO2 turbomachinery components[C]//5th International Symposium-Supercritical CO2 Power Cycles. 2016. |

| 26 | Gabriel R P. Fundamental of spiral groove noncontacting face seals [J]. Lubrication Engineering, 1994, 50: 215-224. |

| 27 | Thatte A, Zheng X Q. Hydrodynamics and sonic flow transition in dry gas seals[C]//Proceedings of ASME Turbo Expo 2014: Turbine Technical Conference and Exposition. Düsseldorf, Germany, 2014. |

| 28 | Ochiai M, Hashimoto H. Staic and dynamic characteristics of high-speed, stepped thrust gas-film bearings. theoretical analysis considering fluid inertia forces[J]. Transactions of the Japan Society of Mechanical Engineers Series C, 1997, 63(613): 3249-3256. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [3] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [4] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [5] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [6] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [7] | 丁俊华, 俞树荣, 王世鹏, 洪先志, 包鑫, 丁雪兴. 多重效应下超高速干气密封流场模拟及密封性能试验[J]. 化工学报, 2023, 74(5): 2088-2099. |

| [8] | 张伟政, 赵吉军, 马学忠, 张琦璇, 庞益祥, 张俊涛. 湍流效应对高速机械密封端面型槽冷却性能影响分析[J]. 化工学报, 2023, 74(3): 1228-1238. |

| [9] | 朱兵国, 何吉祥, 徐进良, 彭斌. 冷却条件下渐扩/渐缩管内超临界压力二氧化碳的传热特性[J]. 化工学报, 2023, 74(3): 1062-1072. |

| [10] | 王永倩, 王平, 程康, 毛晨林, 刘文锋, 尹智成, Ferrante Antonio. 氨气/甲烷贫预混旋转湍流火焰稳定性及NO生成[J]. 化工学报, 2022, 73(9): 4087-4094. |

| [11] | 张建伟, 高伟峰, 董鑫, 冯颖. 浸没式撞击流反应器流场涡特性的数值研究[J]. 化工学报, 2022, 73(8): 3553-3564. |

| [12] | 王利民, 郭舒宇, 向星, 付少童. 湍流系统的能量最小多尺度模型研究进展[J]. 化工学报, 2022, 73(6): 2415-2426. |

| [13] | 施炜斌, 龙姗姗, 杨晓钢, 蔡心悦. 计及气泡诱导与剪切湍流的气泡破碎、湍流相间扩散及传质模型[J]. 化工学报, 2022, 73(6): 2573-2588. |

| [14] | 李岩, 田阿慧, 周毅. 反应性双射流中标量输运和化学反应特性[J]. 化工学报, 2022, 73(5): 1947-1963. |

| [15] | 戚子豪, 钟文琪, 陈曦, 周冠文, 赵小亮, 辛美静, 陈翼, 朱永长. 基于混合建模的水泥生料分解过程动态特性研究[J]. 化工学报, 2022, 73(5): 2039-2051. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号