化工学报 ›› 2021, Vol. 72 ›› Issue (9): 4816-4829.DOI: 10.11949/0438-1157.20210242

收稿日期:2021-02-08

修回日期:2021-03-20

出版日期:2021-09-05

发布日期:2021-09-05

通讯作者:

刘永忠

作者简介:蒋迎花(1992—),女,博士研究生,基金资助:

Yinghua JIANG1( ),Rusong HAN1,Lixia KANG1,2,Yongzhong LIU1,2,3(

),Rusong HAN1,Lixia KANG1,2,Yongzhong LIU1,2,3( )

)

Received:2021-02-08

Revised:2021-03-20

Online:2021-09-05

Published:2021-09-05

Contact:

Yongzhong LIU

摘要:

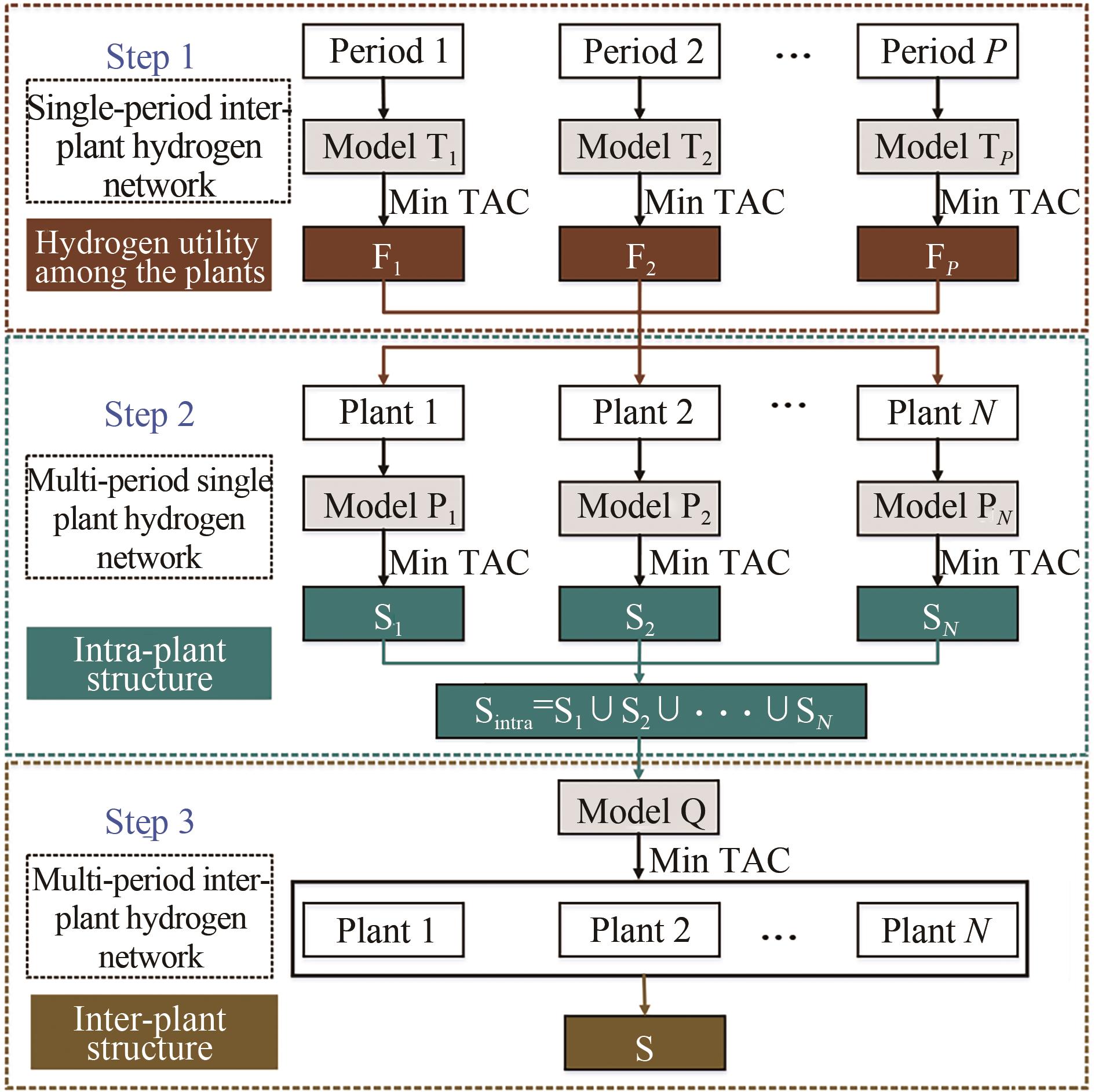

厂际氢气系统集成对于化工园区合理配置氢气系统和氢气资源具有重要意义。针对化工园区中多厂氢气网络多周期优化设计的问题,提出了一种三步求解策略优化设计多厂氢气网络的多周期优化设计。该方法首先采用厂际氢气网络的单周期优化模型获取各子周期下的氢气公用工程的传输量,然后采用单厂氢气网络的多周期优化设计模型获得各厂内的氢气系统结构,最后采用厂际氢气系统的多周期优化设计模型确定化工园区中厂际氢气系统的网络结构和氢气调度方案。研究表明,所提出的多厂氢气网络多周期优化设计方法可有效解决厂际氢气网络的优化设计问题,该策略在不增加氢气系统结构复杂度的前提下,可以获得较好的经济性,并可提高优化模型求解的计算效率。

中图分类号:

蒋迎花, 韩儒松, 康丽霞, 刘永忠. 厂际氢气网络多周期集成的分步优化方法[J]. 化工学报, 2021, 72(9): 4816-4829.

Yinghua JIANG, Rusong HAN, Lixia KANG, Yongzhong LIU. Step-wise approach to integrate inter-plant hydrogen networks under multi-period operations[J]. CIESC Journal, 2021, 72(9): 4816-4829.

图 2 厂际氢气网络的多周期优化设计模型分步求解流程

Fig.2 A schematic diagram of the three-step method to integrate an inter-plant hydrogen network under multi-period operations

| Subperiod | 1 | 2 | 3 | 4 | 5 | 6 | 7 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time/h | 0 | 1456 | 2388 | 3046 | 4177 | 5496 | 7022 | 8000 | |||||||||||

| |||||||||||||||||||

| Δtsubperiod /h | 1456 | 932 | 658 | 1131 | 1319 | 1526 | 978 | ||||||||||||

| Plant | S/K | Flowrate/(mol·s-1) | Purity/% (mol) | Pressure/MPa | |||||||||||||||

| A | S1 | 1115.0 | 1115.0 | 1115.0 | 1115.0 | 1115.0 | 1115.0 | 1115.0 | 0.95 | 2.1 | |||||||||

| S2 | 216.0 | 216.0 | 216.0 | 237.6 | 237.6 | 224.7 | 224.7 | 0.80 | 2.1 | ||||||||||

| S3 | 113.6 | 113.6 | 113.6 | 126.6 | 126.6 | 124.4 | 124.4 | 0.80 | 8.3 | ||||||||||

| S4 | 144.8 | 144.8 | 144.8 | 109.5 | 109.5 | 180.3 | 180.3 | 0.75 | 2.4 | ||||||||||

| S5 | 80.8 | 80.8 | 80.8 | 100.1 | 100.1 | 67.9 | 67.9 | 0.75 | 2.8 | ||||||||||

| S6 | 20.0 | 20.0 | 20.0 | 14.4 | 14.4 | 18.3 | 18.3 | 0.70 | 2.4 | ||||||||||

| S7 | 31.2 | 31.2 | 31.2 | 36.5 | 36.5 | 25.9 | 25.9 | 0.65 | 1.4 | ||||||||||

| K1 | 521.0 | 521.0 | 521.0 | 580.4 | 580.4 | 570.3 | 570.3 | 0.95 | 13.8 | ||||||||||

| K2 | 486.7 | 486.7 | 486.7 | 367.9 | 367.9 | 605.6 | 605.6 | 0.93 | 3.4 | ||||||||||

| K3 | 246.7 | 246.7 | 246.7 | 305.8 | 305.8 | 207.3 | 207.3 | 0.90 | 4.1 | ||||||||||

| K4 | 75.8 | 75.8 | 75.8 | 54.4 | 54.4 | 69.5 | 69.5 | 0.80 | 3.4 | ||||||||||

| K5 | 54.7 | 54.7 | 54.7 | 64.2 | 64.2 | 45.4 | 45.4 | 0.75 | 2.1 | ||||||||||

| B | S8 | 881.5 | 881.5 | 881.5 | 881.5 | 881.5 | 881.5 | 881.5 | 0.97 | 7 | |||||||||

| S9 | 312.1 | 312.1 | 312.1 | 312.1 | 312.1 | 312.1 | 312.1 | 0.95 | 1.2 | ||||||||||

| S10 | 312.1 | 312.1 | 312.1 | 312.1 | 312.1 | 312.1 | 312.1 | 0.95 | 1.2 | ||||||||||

| S11 | 124.9 | 124.9 | 133.6 | 133.6 | 133.6 | 133.6 | 131.3 | 0.90 | 1.4 | ||||||||||

| S12 | 536.9 | 536.9 | 509.2 | 509.2 | 509.2 | 509.2 | 589.3 | 0.92 | 1.1 | ||||||||||

| S13 | 5.4 | 5.4 | 7.1 | 7.1 | 7.1 | 7.1 | 6.1 | 0.60 | 1.4 | ||||||||||

| S14 | 20.9 | 20.9 | 24.0 | 24.0 | 24.0 | 24.0 | 16.5 | 0.46 | 1.6 | ||||||||||

| S15 | 13.2 | 13.2 | 10.9 | 10.9 | 10.9 | 10.9 | 17.3 | 0.71 | 1.5 | ||||||||||

| S16 | 24.8 | 24.8 | 30.9 | 30.9 | 30.9 | 30.9 | 19.2 | 0.83 | 1.5 | ||||||||||

| S17 | 90.5 | 90.5 | 55.4 | 55.4 | 55.4 | 55.4 | 81.6 | 0.76 | 1.2 | ||||||||||

| S18 | 61.2 | 61.2 | 52.8 | 52.8 | 52.8 | 52.8 | 69.3 | 0.65 | 1.2 | ||||||||||

| K6 | 74.4 | 74.4 | 98.6 | 98.6 | 98.6 | 98.6 | 85.0 | 0.90 | 7 | ||||||||||

| K7 | 47.4 | 47.4 | 54.7 | 54.7 | 54.7 | 54.7 | 37.5 | 0.87 | 5 | ||||||||||

| K8 | 156.1 | 156.1 | 129.0 | 129.0 | 129.0 | 129.0 | 203.6 | 0.92 | 7 | ||||||||||

| K9 | 299.7 | 299.7 | 372.8 | 372.8 | 372.8 | 372.8 | 232.1 | 0.96 | 7 | ||||||||||

| K10 | 287.2 | 287.2 | 175.7 | 175.7 | 175.7 | 175.7 | 259.0 | 0.98 | 10 | ||||||||||

| K11 | 549.4 | 549.4 | 474.5 | 474.5 | 474.5 | 474.5 | 622.1 | 0.94 | 20 | ||||||||||

| C | S19 | 496.0 | 496.0 | 496.0 | 496.0 | 496.0 | 496.0 | 496.0 | 0.999 | 3.5 | |||||||||

| S20 | 437.1 | 480.8 | 480.8 | 480.8 | 363.0 | 363.0 | 363.0 | 0.92 | 3.5 | ||||||||||

| S21 | 142.3 | 103.0 | 103.0 | 103.0 | 137.9 | 137.9 | 137.9 | 0.71 | 2.5 | ||||||||||

| S22 | 21.4 | 27.0 | 27.0 | 27.0 | 31.4 | 31.4 | 31.4 | 0.70 | 2.5 | ||||||||||

| K12 | 292.6 | 236.0 | 236.0 | 236.0 | 286.3 | 286.3 | 286.3 | 0.93 | 13.0 | ||||||||||

| K13 | 281.3 | 332.5 | 332.5 | 332.5 | 373.2 | 373.2 | 373.2 | 0.87 | 8.7 | ||||||||||

| K14 | 28.7 | 34.8 | 34.8 | 34.8 | 29.6 | 29.6 | 29.6 | 0.87 | 5.0 | ||||||||||

| K15 | 34.1 | 40.6 | 40.6 | 40.6 | 33.8 | 33.8 | 33.8 | 0.85 | 3.5 | ||||||||||

| K16 | 34.3 | 29.5 | 29.5 | 29.5 | 26.8 | 26.8 | 26.8 | 0.85 | 3.0 | ||||||||||

表1 各子周期下厂际氢气网络的流股数据

Table 1 Flowrate data of inter-plant hydrogen network in each subperiod

| Subperiod | 1 | 2 | 3 | 4 | 5 | 6 | 7 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time/h | 0 | 1456 | 2388 | 3046 | 4177 | 5496 | 7022 | 8000 | |||||||||||

| |||||||||||||||||||

| Δtsubperiod /h | 1456 | 932 | 658 | 1131 | 1319 | 1526 | 978 | ||||||||||||

| Plant | S/K | Flowrate/(mol·s-1) | Purity/% (mol) | Pressure/MPa | |||||||||||||||

| A | S1 | 1115.0 | 1115.0 | 1115.0 | 1115.0 | 1115.0 | 1115.0 | 1115.0 | 0.95 | 2.1 | |||||||||

| S2 | 216.0 | 216.0 | 216.0 | 237.6 | 237.6 | 224.7 | 224.7 | 0.80 | 2.1 | ||||||||||

| S3 | 113.6 | 113.6 | 113.6 | 126.6 | 126.6 | 124.4 | 124.4 | 0.80 | 8.3 | ||||||||||

| S4 | 144.8 | 144.8 | 144.8 | 109.5 | 109.5 | 180.3 | 180.3 | 0.75 | 2.4 | ||||||||||

| S5 | 80.8 | 80.8 | 80.8 | 100.1 | 100.1 | 67.9 | 67.9 | 0.75 | 2.8 | ||||||||||

| S6 | 20.0 | 20.0 | 20.0 | 14.4 | 14.4 | 18.3 | 18.3 | 0.70 | 2.4 | ||||||||||

| S7 | 31.2 | 31.2 | 31.2 | 36.5 | 36.5 | 25.9 | 25.9 | 0.65 | 1.4 | ||||||||||

| K1 | 521.0 | 521.0 | 521.0 | 580.4 | 580.4 | 570.3 | 570.3 | 0.95 | 13.8 | ||||||||||

| K2 | 486.7 | 486.7 | 486.7 | 367.9 | 367.9 | 605.6 | 605.6 | 0.93 | 3.4 | ||||||||||

| K3 | 246.7 | 246.7 | 246.7 | 305.8 | 305.8 | 207.3 | 207.3 | 0.90 | 4.1 | ||||||||||

| K4 | 75.8 | 75.8 | 75.8 | 54.4 | 54.4 | 69.5 | 69.5 | 0.80 | 3.4 | ||||||||||

| K5 | 54.7 | 54.7 | 54.7 | 64.2 | 64.2 | 45.4 | 45.4 | 0.75 | 2.1 | ||||||||||

| B | S8 | 881.5 | 881.5 | 881.5 | 881.5 | 881.5 | 881.5 | 881.5 | 0.97 | 7 | |||||||||

| S9 | 312.1 | 312.1 | 312.1 | 312.1 | 312.1 | 312.1 | 312.1 | 0.95 | 1.2 | ||||||||||

| S10 | 312.1 | 312.1 | 312.1 | 312.1 | 312.1 | 312.1 | 312.1 | 0.95 | 1.2 | ||||||||||

| S11 | 124.9 | 124.9 | 133.6 | 133.6 | 133.6 | 133.6 | 131.3 | 0.90 | 1.4 | ||||||||||

| S12 | 536.9 | 536.9 | 509.2 | 509.2 | 509.2 | 509.2 | 589.3 | 0.92 | 1.1 | ||||||||||

| S13 | 5.4 | 5.4 | 7.1 | 7.1 | 7.1 | 7.1 | 6.1 | 0.60 | 1.4 | ||||||||||

| S14 | 20.9 | 20.9 | 24.0 | 24.0 | 24.0 | 24.0 | 16.5 | 0.46 | 1.6 | ||||||||||

| S15 | 13.2 | 13.2 | 10.9 | 10.9 | 10.9 | 10.9 | 17.3 | 0.71 | 1.5 | ||||||||||

| S16 | 24.8 | 24.8 | 30.9 | 30.9 | 30.9 | 30.9 | 19.2 | 0.83 | 1.5 | ||||||||||

| S17 | 90.5 | 90.5 | 55.4 | 55.4 | 55.4 | 55.4 | 81.6 | 0.76 | 1.2 | ||||||||||

| S18 | 61.2 | 61.2 | 52.8 | 52.8 | 52.8 | 52.8 | 69.3 | 0.65 | 1.2 | ||||||||||

| K6 | 74.4 | 74.4 | 98.6 | 98.6 | 98.6 | 98.6 | 85.0 | 0.90 | 7 | ||||||||||

| K7 | 47.4 | 47.4 | 54.7 | 54.7 | 54.7 | 54.7 | 37.5 | 0.87 | 5 | ||||||||||

| K8 | 156.1 | 156.1 | 129.0 | 129.0 | 129.0 | 129.0 | 203.6 | 0.92 | 7 | ||||||||||

| K9 | 299.7 | 299.7 | 372.8 | 372.8 | 372.8 | 372.8 | 232.1 | 0.96 | 7 | ||||||||||

| K10 | 287.2 | 287.2 | 175.7 | 175.7 | 175.7 | 175.7 | 259.0 | 0.98 | 10 | ||||||||||

| K11 | 549.4 | 549.4 | 474.5 | 474.5 | 474.5 | 474.5 | 622.1 | 0.94 | 20 | ||||||||||

| C | S19 | 496.0 | 496.0 | 496.0 | 496.0 | 496.0 | 496.0 | 496.0 | 0.999 | 3.5 | |||||||||

| S20 | 437.1 | 480.8 | 480.8 | 480.8 | 363.0 | 363.0 | 363.0 | 0.92 | 3.5 | ||||||||||

| S21 | 142.3 | 103.0 | 103.0 | 103.0 | 137.9 | 137.9 | 137.9 | 0.71 | 2.5 | ||||||||||

| S22 | 21.4 | 27.0 | 27.0 | 27.0 | 31.4 | 31.4 | 31.4 | 0.70 | 2.5 | ||||||||||

| K12 | 292.6 | 236.0 | 236.0 | 236.0 | 286.3 | 286.3 | 286.3 | 0.93 | 13.0 | ||||||||||

| K13 | 281.3 | 332.5 | 332.5 | 332.5 | 373.2 | 373.2 | 373.2 | 0.87 | 8.7 | ||||||||||

| K14 | 28.7 | 34.8 | 34.8 | 34.8 | 29.6 | 29.6 | 29.6 | 0.87 | 5.0 | ||||||||||

| K15 | 34.1 | 40.6 | 40.6 | 40.6 | 33.8 | 33.8 | 33.8 | 0.85 | 3.5 | ||||||||||

| K16 | 34.3 | 29.5 | 29.5 | 29.5 | 26.8 | 26.8 | 26.8 | 0.85 | 3.0 | ||||||||||

| Hydrogen source | |

|---|---|

| S1[ | 0.0108 |

| S8[ | 0.0088 |

| S9[ | 0.0108 |

| S10[ | 0.0108 |

| S19[ | 0.015 |

表2 各厂氢气公用工程的价格

Table 2 Prices of hydrogen utilities in each plant

| Hydrogen source | |

|---|---|

| S1[ | 0.0108 |

| S8[ | 0.0088 |

| S9[ | 0.0108 |

| S10[ | 0.0108 |

| S19[ | 0.015 |

| Subperiod | Hydrogen Utilities | Flowrate/(mol·s-1) | |||

|---|---|---|---|---|---|

| Plant A | Plant B | Plant C | |||

| 1 | Plant A | S1 | 846.6 | — | — |

| Plant B | S8 | 82.6 | 671.0 | 127.9 | |

| 2 | Plant A | S1 | 827.3 | — | — |

| Plant B | S8 | 102.0 | 671.0 | 108.6 | |

| 3 | Plant A | S1 | 739.5 | — | — |

| Plant B | S8 | 189.7 | 583.3 | 108.6 | |

| 4 | Plant A | S1 | 711.2 | — | — |

| Plant B | S8 | 189.7 | 583.3 | 108.6 | |

| 5 | Plant A | S1 | 898.0 | — | — |

| Plant B | S8 | — | 595.2 | 286.3 | |

| 6 | Plant A | S1 | 1008.4 | — | — |

| Plant B | S8 | — | 595.2 | 286.3 | |

| 7 | Plant A | S1 | 1008.4 | — | 27.4 |

| Plant B | S8 | — | 631.7 | 249.8 | |

表3 各厂在子周期中消耗的公用工程流量

Table 3 Hydrogen utility flowrates consumed by each plant in each subperiod

| Subperiod | Hydrogen Utilities | Flowrate/(mol·s-1) | |||

|---|---|---|---|---|---|

| Plant A | Plant B | Plant C | |||

| 1 | Plant A | S1 | 846.6 | — | — |

| Plant B | S8 | 82.6 | 671.0 | 127.9 | |

| 2 | Plant A | S1 | 827.3 | — | — |

| Plant B | S8 | 102.0 | 671.0 | 108.6 | |

| 3 | Plant A | S1 | 739.5 | — | — |

| Plant B | S8 | 189.7 | 583.3 | 108.6 | |

| 4 | Plant A | S1 | 711.2 | — | — |

| Plant B | S8 | 189.7 | 583.3 | 108.6 | |

| 5 | Plant A | S1 | 898.0 | — | — |

| Plant B | S8 | — | 595.2 | 286.3 | |

| 6 | Plant A | S1 | 1008.4 | — | — |

| Plant B | S8 | — | 595.2 | 286.3 | |

| 7 | Plant A | S1 | 1008.4 | — | 27.4 |

| Plant B | S8 | — | 631.7 | 249.8 | |

| Item | Individual hydrogen network | Inter-plant hydrogen network | |||||

|---|---|---|---|---|---|---|---|

| A | B | C | Total | Step 1-2 | Step 2-3 | Step 1-2-3 (This work) | |

| number of matches | 15 | 13 | 12 | 40 | 49 | 43 | 49 |

| cost of hydrogen×10-8/(CNY·a-1) | 2.937 | 2.234 | 0.731 | 5.902 | 4.965 | 5.700 | 4.966 |

| investment cost×10-8/(CNY·a-1) | 0.377 | 0.292 | 0.146 | 0.815 | 0.956 | 0.899 | 0.999 |

| operation cost×10-8/(CNY·a-1) | 2.579 | 1.482 | 0.756 | 4.817 | 4.476 | 4.637 | 4.423 |

| total cost×10-8/(CNY·a-1) | 2.956 | 1.774 | 0.901 | 5.631 | 5.432 | 5.536 | 5.422 |

表4 多厂集成与分厂集成的氢气系统费用对比

Table 4 Comparison of cost for the inter-plant integration and the individual plant integration

| Item | Individual hydrogen network | Inter-plant hydrogen network | |||||

|---|---|---|---|---|---|---|---|

| A | B | C | Total | Step 1-2 | Step 2-3 | Step 1-2-3 (This work) | |

| number of matches | 15 | 13 | 12 | 40 | 49 | 43 | 49 |

| cost of hydrogen×10-8/(CNY·a-1) | 2.937 | 2.234 | 0.731 | 5.902 | 4.965 | 5.700 | 4.966 |

| investment cost×10-8/(CNY·a-1) | 0.377 | 0.292 | 0.146 | 0.815 | 0.956 | 0.899 | 0.999 |

| operation cost×10-8/(CNY·a-1) | 2.579 | 1.482 | 0.756 | 4.817 | 4.476 | 4.637 | 4.423 |

| total cost×10-8/(CNY·a-1) | 2.956 | 1.774 | 0.901 | 5.631 | 5.432 | 5.536 | 5.422 |

| Methods | Operation cost×10-8/(CNY·a-1) | Investment cost×10-8/(CNY·a-1) | TAC×10-8/(CNY·a-1) | Number of matches | Computation time /s | ||||

|---|---|---|---|---|---|---|---|---|---|

| Hydrogen | Electricity | Fuel revenue | Pipeline | Purifier | Compressor | ||||

| Step 1-2 | 4.965 | 1.126 | 1.665 | 0.050 | 0.355 | 0.601 | 5.432 | 49 | 25 |

| Step 2-3 | 5.700 | 1.079 | 2.142 | 0.051 | 0.287 | 0.561 | 5.540 | 43 | 56 |

| Step 1-2-3 (this work) | 4.966 | 1.123 | 1.665 | 0.055 | 0.355 | 0.590 | 5.422 | 49 | 49 |

| Structure-merged method[ | 4.968 | 1.113 | 1.685 | 0.046 | 0.393 | 0.688 | 5.523 | 48 | 11 |

| Structure-fixed method[ | 4.948 | 1.120 | 1.673 | 0.050 | 0.393 | 0.641 | 5.478 | 43 | 36 |

| Simultaneous method[ | 4.940 | 1.112 | 1.623 | 0.048 | 0.345 | 0.581 | 5.403 | 51 | 1529 |

表5 不同厂际氢气网络多周期集成方法对比

Table 5 Comparison of the integration of inter-plant hydrogen network by different methods

| Methods | Operation cost×10-8/(CNY·a-1) | Investment cost×10-8/(CNY·a-1) | TAC×10-8/(CNY·a-1) | Number of matches | Computation time /s | ||||

|---|---|---|---|---|---|---|---|---|---|

| Hydrogen | Electricity | Fuel revenue | Pipeline | Purifier | Compressor | ||||

| Step 1-2 | 4.965 | 1.126 | 1.665 | 0.050 | 0.355 | 0.601 | 5.432 | 49 | 25 |

| Step 2-3 | 5.700 | 1.079 | 2.142 | 0.051 | 0.287 | 0.561 | 5.540 | 43 | 56 |

| Step 1-2-3 (this work) | 4.966 | 1.123 | 1.665 | 0.055 | 0.355 | 0.590 | 5.422 | 49 | 49 |

| Structure-merged method[ | 4.968 | 1.113 | 1.685 | 0.046 | 0.393 | 0.688 | 5.523 | 48 | 11 |

| Structure-fixed method[ | 4.948 | 1.120 | 1.673 | 0.050 | 0.393 | 0.641 | 5.478 | 43 | 36 |

| Simultaneous method[ | 4.940 | 1.112 | 1.623 | 0.048 | 0.345 | 0.581 | 5.403 | 51 | 1529 |

| Period | Hydrogen utilities | Flowrate/(mol·s-1) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plant A | Plant B | Plant C | |||||||||||||

| K1 | K2 | K3 | K4 | K5 | K6 | K9 | K10 | K11 | K12 | K13 | |||||

| 1 | Plant A | S1 | 427.4 | 131.0 | 164.5 | 69.1 | 54.7 | ||||||||

| Plant B | S8 | 82.6 | 66.0 | 131.6 | 473.4 | 127.9 | |||||||||

| 2 | Plant A | S1 | 405.5 | 133.6 | 164.5 | 69.1 | 54.7 | ||||||||

| Plant B | S8 | 102.0 | 66.0 | 131.6 | 473.4 | 71.3 | 37.2 | ||||||||

| 3 | Plant A | S1 | 306.6 | 144.6 | 164.5 | 69.1 | 54.7 | ||||||||

| Plant B | S8 | 190.0 | 13.6 | 139.1 | 26.2 | 404.4 | 71.3 | 37.2 | |||||||

| 4 | Plant A | S1 | 366.0 | 26.0 | 203.9 | 54.4 | 58 | ||||||||

| Plant B | S8 | 190.0 | 13.6 | 139.1 | 26.2 | 404.4 | 71.3 | 37.2 | |||||||

| 5 | Plant A | S1 | 580.4 | 7.50 | 203.9 | 48.2 | 58 | ||||||||

| Plant B | S8 | 13.6 | 139.1 | 20.1 | 422.4 | 127.9 | 158.4 | ||||||||

| 6 | Plant A | S1 | 570.3 | 145.5 | 201.1 | 69.5 | 21.1 | ||||||||

| Plant B | S8 | 13.6 | 139.1 | 20.1 | 422.4 | 127.9 | 158.4 | ||||||||

| 7 | Plant A | S1 | 570.3 | 145.5 | 201.1 | 69.5 | 21.1 | 27.4 | |||||||

| Plant B | S8 | 103.4 | 528.5 | 127.9 | 121.9 | ||||||||||

附表A1 厂际氢气网络氢气公用工程流股与氢阱流股匹配的流量(Step 1-2)

Table A1 The flowrate transported from hydrogen utilities to hydrogen sinks in the inter-plant hydrogen network(Step 1-2)

| Period | Hydrogen utilities | Flowrate/(mol·s-1) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plant A | Plant B | Plant C | |||||||||||||

| K1 | K2 | K3 | K4 | K5 | K6 | K9 | K10 | K11 | K12 | K13 | |||||

| 1 | Plant A | S1 | 427.4 | 131.0 | 164.5 | 69.1 | 54.7 | ||||||||

| Plant B | S8 | 82.6 | 66.0 | 131.6 | 473.4 | 127.9 | |||||||||

| 2 | Plant A | S1 | 405.5 | 133.6 | 164.5 | 69.1 | 54.7 | ||||||||

| Plant B | S8 | 102.0 | 66.0 | 131.6 | 473.4 | 71.3 | 37.2 | ||||||||

| 3 | Plant A | S1 | 306.6 | 144.6 | 164.5 | 69.1 | 54.7 | ||||||||

| Plant B | S8 | 190.0 | 13.6 | 139.1 | 26.2 | 404.4 | 71.3 | 37.2 | |||||||

| 4 | Plant A | S1 | 366.0 | 26.0 | 203.9 | 54.4 | 58 | ||||||||

| Plant B | S8 | 190.0 | 13.6 | 139.1 | 26.2 | 404.4 | 71.3 | 37.2 | |||||||

| 5 | Plant A | S1 | 580.4 | 7.50 | 203.9 | 48.2 | 58 | ||||||||

| Plant B | S8 | 13.6 | 139.1 | 20.1 | 422.4 | 127.9 | 158.4 | ||||||||

| 6 | Plant A | S1 | 570.3 | 145.5 | 201.1 | 69.5 | 21.1 | ||||||||

| Plant B | S8 | 13.6 | 139.1 | 20.1 | 422.4 | 127.9 | 158.4 | ||||||||

| 7 | Plant A | S1 | 570.3 | 145.5 | 201.1 | 69.5 | 21.1 | 27.4 | |||||||

| Plant B | S8 | 103.4 | 528.5 | 127.9 | 121.9 | ||||||||||

| Period | Hydrogen utilities | Flowrate/(mol·s-1) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plant A | Plant B | Plant C | |||||||||||||

| K1 | K2 | K3 | K4 | K5 | K6 | K9 | K10 | K11 | K12 | K13 | |||||

| 1 | Plant A | S1 | 427.4 | 131.0 | 164.5 | 69.1 | 54.7 | ||||||||

| Plant B | S8 | 82.6 | 66.0 | 131.6 | 473.4 | 127.9 | |||||||||

| 2 | Plant A | S1 | 368.2 | 133.6 | 164.5 | 69.1 | 54.7 | 37.2 | |||||||

| Plant B | S8 | 139.2 | 66.0 | 131.6 | 473.4 | 71.3 | |||||||||

| 3 | Plant A | S1 | 306.6 | 144.6 | 164.5 | 69.1 | 54.7 | ||||||||

| Plant B | S8 | 190.0 | 13.6 | 139.1 | 26.2 | 404.4 | 71.3 | 37.2 | |||||||

| 4 | Plant A | S1 | 366.0 | 26.0 | 203.9 | 54.4 | 58 | ||||||||

| Plant B | S8 | 190.0 | 13.6 | 139.1 | 26.2 | 404.4 | 71.3 | 37.2 | |||||||

| 5 | Plant A | S1 | 459.3 | 7.50 | 203.9 | 48.2 | 58 | 121.1 | |||||||

| Plant B | S8 | 121.1 | 13.6 | 139.1 | 20.1 | 422.4 | 127.9 | 37.2 | |||||||

| 6 | Plant A | S1 | 449.2 | 145.5 | 201.1 | 69.5 | 21.1 | 121.1 | |||||||

| Plant B | S8 | 121.1 | 13.6 | 139.1 | 20.1 | 422.4 | 127.9 | 37.2 | |||||||

| 7 | Plant A | S1 | 476.6 | 145.5 | 201.1 | 69.5 | 21.1 | 121.1 | |||||||

| Plant B | S8 | 93.7 | 103.4 | 528.5 | 127.9 | 28.2 | |||||||||

附表A2 厂际氢气网络氢气公用工程流股与氢阱流股匹配的流量(Step 1-2-3)

Table A2 The flowrate transported from hydrogen utilities to hydrogen sinks in the inter-plant hydrogen network(Step 1-2-3)

| Period | Hydrogen utilities | Flowrate/(mol·s-1) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plant A | Plant B | Plant C | |||||||||||||

| K1 | K2 | K3 | K4 | K5 | K6 | K9 | K10 | K11 | K12 | K13 | |||||

| 1 | Plant A | S1 | 427.4 | 131.0 | 164.5 | 69.1 | 54.7 | ||||||||

| Plant B | S8 | 82.6 | 66.0 | 131.6 | 473.4 | 127.9 | |||||||||

| 2 | Plant A | S1 | 368.2 | 133.6 | 164.5 | 69.1 | 54.7 | 37.2 | |||||||

| Plant B | S8 | 139.2 | 66.0 | 131.6 | 473.4 | 71.3 | |||||||||

| 3 | Plant A | S1 | 306.6 | 144.6 | 164.5 | 69.1 | 54.7 | ||||||||

| Plant B | S8 | 190.0 | 13.6 | 139.1 | 26.2 | 404.4 | 71.3 | 37.2 | |||||||

| 4 | Plant A | S1 | 366.0 | 26.0 | 203.9 | 54.4 | 58 | ||||||||

| Plant B | S8 | 190.0 | 13.6 | 139.1 | 26.2 | 404.4 | 71.3 | 37.2 | |||||||

| 5 | Plant A | S1 | 459.3 | 7.50 | 203.9 | 48.2 | 58 | 121.1 | |||||||

| Plant B | S8 | 121.1 | 13.6 | 139.1 | 20.1 | 422.4 | 127.9 | 37.2 | |||||||

| 6 | Plant A | S1 | 449.2 | 145.5 | 201.1 | 69.5 | 21.1 | 121.1 | |||||||

| Plant B | S8 | 121.1 | 13.6 | 139.1 | 20.1 | 422.4 | 127.9 | 37.2 | |||||||

| 7 | Plant A | S1 | 476.6 | 145.5 | 201.1 | 69.5 | 21.1 | 121.1 | |||||||

| Plant B | S8 | 93.7 | 103.4 | 528.5 | 127.9 | 28.2 | |||||||||

| 1 | Liu X, Liu J, Deng C, et al. Synthesis of refinery hydrogen network integrated with hydrogen turbines for power recovery[J]. Energy, 2020, 201: 117623. |

| 2 | Deng C, Zhu M, Liu J, et al. Systematic retrofit method for refinery hydrogen network with light hydrocarbons recovery[J]. International Journal of Hydrogen Energy, 2020, 45(38): 19391-19404. |

| 3 | Reuß M, Welder L, Thürauf J, et al. Modeling hydrogen networks for future energy systems: a comparison of linear and nonlinear approaches[J]. International Journal of Hydrogen Energy, 2019, 44(60): 32136-32150. |

| 4 | 孟凡忠, 张英. 炼厂氢资源优化利用技术进展[J]. 化工进展, 2015, 34(S1): 66-70. |

| Meng F Z, Zhang Y. Reviews of hydrogen resources optimization technology in refineries [J]. J. Chemical Industry and Engineering Progress, 2015, 34(S1): 66-70. | |

| 5 | 孙晓岩, 宋泓阳, 刘博谦, 等. 氢夹点技术方法研究进展和评价[J]. 化工进展, 2017, 36(4): 1165-1172. |

| Sun X Y, Liu B Q, Song H Y, et al. Current status and evaluation of hydrogen pinch technology [J]. J. Chemical Industry and Engineering Progress, 2017, 36(4): 1165-1172. | |

| 6 | 周业扬, 邓春, 周凌子, 等. 多工况氢网络压缩机配置和运行优化[J]. 化工学报, 2017, 68(5): 1954-1960. |

| Zhou Y Y, Deng C, Zhou L Z, etal. Deployment and operation optimization of compressors in multi-scenario hydrogen network[J]. CIESC Journal, 2017, 68(5): 1954-1960. | |

| 7 | 梁肖强, 刘永忠. 氢气网络系统的操作灵活性分析与改进[J]. 高校化学工程学报, 2017, 31(1): 161-169. |

| Liang X Q, Liu Y Z. Analysis and improvement of operational flexibility of hydrogen distribution systems[J]. J. Chem. Eng. Chin. Univ., 2017, 31(01): 161-169. | |

| 8 | Lou J, Liao Z, Jiang B, et al. Robust optimization of hydrogen network[J]. International Journal of Hydrogen Energy, 2014, 39(3): 1210-1219. |

| 9 | Jiao Y, Su H, Hou W, et al. Optimization of refinery hydrogen network based on chance constrained programming[J]. Chemical Engineering Research and Design, 2012, 90(10): 1553-1567. |

| 10 | Chen Y, Lin M, Jiang H, et al. Optimal design and operation of refinery hydrogen systems under multi-scale uncertainties[J]. Computers & Chemical Engineering, 2020, 138: 106822. |

| 11 | Tan R R, Andiappan V, Wan Y K, et al. An optimization-based cooperative game approach for systematic allocation of costs and benefits in interplant process integration[J]. Chemical Engineering Research and Design, 2016, 106: 43-58. |

| 12 | Shehata W M. Automated targeting technique for indirect inter-plant hydrogen integration[J]. Egyptian Journal of Petroleum, 2016, 25(4): 539-553. |

| 13 | Cho S, Kim J. Multi-site and multi-period optimization model for strategic planning of a renewable hydrogen energy network from biomass waste and energy crops[J]. Energy, 2019, 185: 527-540. |

| 14 | Zhang Q, Yang Y, Feng X, et al. The integration of hybrid hydrogen networks for refinery and synthetic plant of chemicals[J]. International Journal of Hydrogen Energy, 2021, 46(2): 1473-1487. |

| 15 | Kuo C C, Chang C T. Improved model formulations for multiperiod hydrogen network designs[J]. Industrial & Engineering Chemistry Research, 2014, 53(52): 20204-20222. |

| 16 | Kang L, Liang X, Liu Y. Design of multiperiod hydrogen network with flexibilities in subperiods and redundancy control[J]. International Journal of Hydrogen Energy, 2018, 43(2): 861-871. |

| 17 | Jiao Y, Su H, Hou W, et al. A multiperiod optimization model for hydrogen system scheduling in refinery[J]. Ind.Eng.Chem.Res., 2012, 51(17): 6085-6098. |

| 18 | Ahmad M I, Zhang N, Jobson M. Modelling and optimisation for design of hydrogen networks for multi-period operation[J]. Journal of Cleaner Production, 2010, 18(9): 889-899. |

| 19 | Huang L, Liu G. Optimization of the hydrogen separator based on the hydrogen network integration[J]. Journal of Cleaner Production, 2019, 235: 1399-1408. |

| 20 | Han R, Kang L, Jiang Y, et al. Optimization of an inter-plant hydrogen network: a simultaneous approach to solving multi-period optimization problems[J]. Processes, 2020, 8(12): 1548. |

| 21 | Shehata W M, Shoaib A M, Gad F K. Inter-plant hydrogen integration with regeneration placement and multi-period consideration[J]. Egyptian Journal of Petroleum, 2018, 27(4): 553-565. |

| 22 | Wu L, Wang Y, Zheng L, et al. Stepwise optimization of hydrogen network integrated sulfur compound removal kinetics and a fluid catalytic cracker[J]. Chemical Engineering Research and Design, 2019, 151: 168-178. |

| 23 | Lou Y, Liao Z, Sun J, et al. A novel two-step method to design inter-plant hydrogen network[J]. International Journal of Hydrogen Energy, 2019, 44(12): 5686-5695. |

| 24 | Deng C, Zhou Y, Li Y, et al. Flowrate targeting for interplant hydrogen networks[J]. Chemical Engineering Transactions, 2014, 39: 19-24. |

| 25 | Deng C, Zhou Y, Chen C-L, et al. Systematic approach for targeting interplant hydrogen networks[J]. Energy, 2015, 90: 68-88. |

| 26 | Kang L, Liang X, Liu Y. Optimal design of inter-plant hydrogen networks with intermediate headers of purity and pressure[J]. International Journal of Hydrogen Energy, 2018, 43(34): 16638-16651. |

| 27 | Hallale N, Liu F. Refinery hydrogen management for clean fuels production[J]. Advances in Environmental Research, 2001, 6(1): 81-98. |

| 28 | Elkamel A, Alhajri I, Almansoori A, et al. Integration of hydrogen management in refinery planning with rigorous process models and product quality specifications[J]. International Journal of Process Systems Engineering, 2011, 1(3/4): 302-330. |

| 29 | Liao Z, Wang J, Yang Y, et al. Integrating purifiers in refinery hydrogen networks: a retrofit case study[J]. Journal of Cleaner Production, 2010, 18(3): 233-241. |

| 30 | Liang X, Kang L, Liu Y. Impacts of subperiod partitioning on optimization of multiperiod hydrogen networks[J]. Industrial & Engineering Chemistry Research, 2017, 56(38): 10733-10742. |

| 31 | Rosenthal R E. Gams - a user's guide[J]. Gams Development Corporation, 2010, 49(7): 397-400. |

| [1] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [2] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [3] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [4] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [5] | 李贵贤, 曹阿波, 孟文亮, 王东亮, 杨勇, 周怀荣. 耦合固体氧化物电解槽的CO2制甲醇过程设计与评价研究[J]. 化工学报, 2023, 74(7): 2999-3009. |

| [6] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [7] | 王光, 单发顺, 钱禹丞, 焦建芳. 基于集成学习传递熵的化工过程微小故障检测方法[J]. 化工学报, 2023, 74(7): 2967-2978. |

| [8] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [9] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| [10] | 刘尚豪, 贾胜坤, 罗祎青, 袁希钢. 基于梯度提升决策树的三组元精馏流程结构最优化[J]. 化工学报, 2023, 74(5): 2075-2087. |

| [11] | 周必茂, 许世森, 王肖肖, 刘刚, 李小宇, 任永强, 谭厚章. 烧嘴偏转角度对气化炉渣层分布特性的影响[J]. 化工学报, 2023, 74(5): 1939-1949. |

| [12] | 王泽栋, 石至平, 刘丽艳. 考虑气泡非均匀耗散的矩形反应器声流场数值模拟及结构优化[J]. 化工学报, 2023, 74(5): 1965-1973. |

| [13] | 李纪元, 李金旺, 周刘伟. 不同扰流结构冷板传热性能研究[J]. 化工学报, 2023, 74(4): 1474-1488. |

| [14] | 许文烜, 江锦波, 彭新, 门日秀, 刘畅, 彭旭东. 宽速域三种典型型槽油气密封泄漏与成膜特性对比研究[J]. 化工学报, 2023, 74(4): 1660-1679. |

| [15] | 张生安, 刘桂莲. 高效太阳能电解水制氢系统及其性能的多目标优化[J]. 化工学报, 2023, 74(3): 1260-1274. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号