化工学报 ›› 2025, Vol. 76 ›› Issue (12): 6277-6288.DOI: 10.11949/0438-1157.20250492

收稿日期:2025-05-06

修回日期:2025-09-26

出版日期:2025-12-31

发布日期:2026-01-23

通讯作者:

李震

作者简介:张博(1996—),男,博士研究生,b-zhang21@mails.tsinghua.edu.cn

基金资助:

Bo ZHANG1( ), Hongrui LI1, Lu WANG1, Zhen LI1,2(

), Hongrui LI1, Lu WANG1, Zhen LI1,2( )

)

Received:2025-05-06

Revised:2025-09-26

Online:2025-12-31

Published:2026-01-23

Contact:

Zhen LI

摘要:

随着服务器功耗持续攀升,传统风冷技术因能耗高、噪声大及冷却能力不足等缺陷逐渐受限。单相浸没液冷技术凭借传热系数大、能耗低、噪声低等优势成为研究热点。首先,针对矿物油、硅油和氟碳液三种典型单相浸没冷却液的物性进行对比分析。结果显示,油基冷却液(矿物油与硅油)的密度约为氟碳液的1/2,比热容和热导率接近氟碳液的2倍,但黏度却高出氟碳液1~2个数量级,导致边界层厚度显著增加。其次,以典型服务器为研究对象,采用计算流体力学(CFD)方法模拟不同冷却液的冷却效果,并提出析热系数(HDC)作为性能评价指标。HDC分析表明,SS-110冷却液具有优异的流动换热特性,其核心优势在于极低的运动黏度。最后,设计并搭建单相浸没液冷实验系统,对矿物油的冷却效果进行实测。实验结果显示,在矿物油流量为1080 L/h时,可以带走1600 W的热量,但是存在流量分配不均匀现象,导致不同环氧树脂板上的发热片平均温度相差可达到9.8℃。此外,实验发现导热硅脂在硅油环境中出现部分溶解现象,因此,不建议将导热硅脂应用于以硅油为冷却介质的浸没液冷系统。

中图分类号:

张博, 李弘锐, 王露, 李震. 单相浸没冷却液及液冷系统的流动换热特性研究[J]. 化工学报, 2025, 76(12): 6277-6288.

Bo ZHANG, Hongrui LI, Lu WANG, Zhen LI. Research on the flow and heat transfer characteristics of single-phase immersion coolants and liquid cooling system[J]. CIESC Journal, 2025, 76(12): 6277-6288.

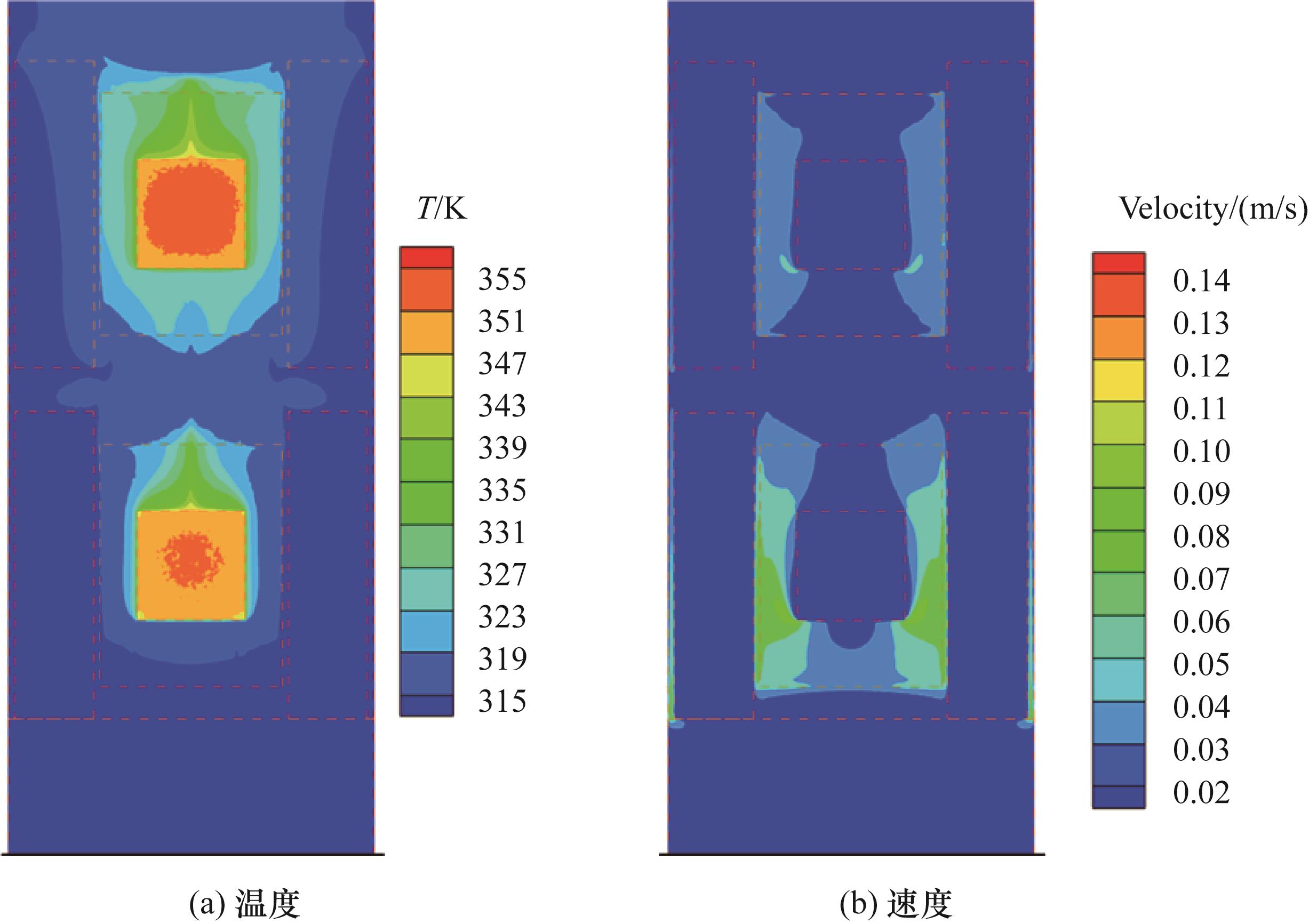

图6 使用SS-110冷却液时高度为0.21 cm处截面的温度和速度

Fig.6 The temperature profile and the velocity profile at the cross-section with a height of 0.21 cm when using SS-110 coolant

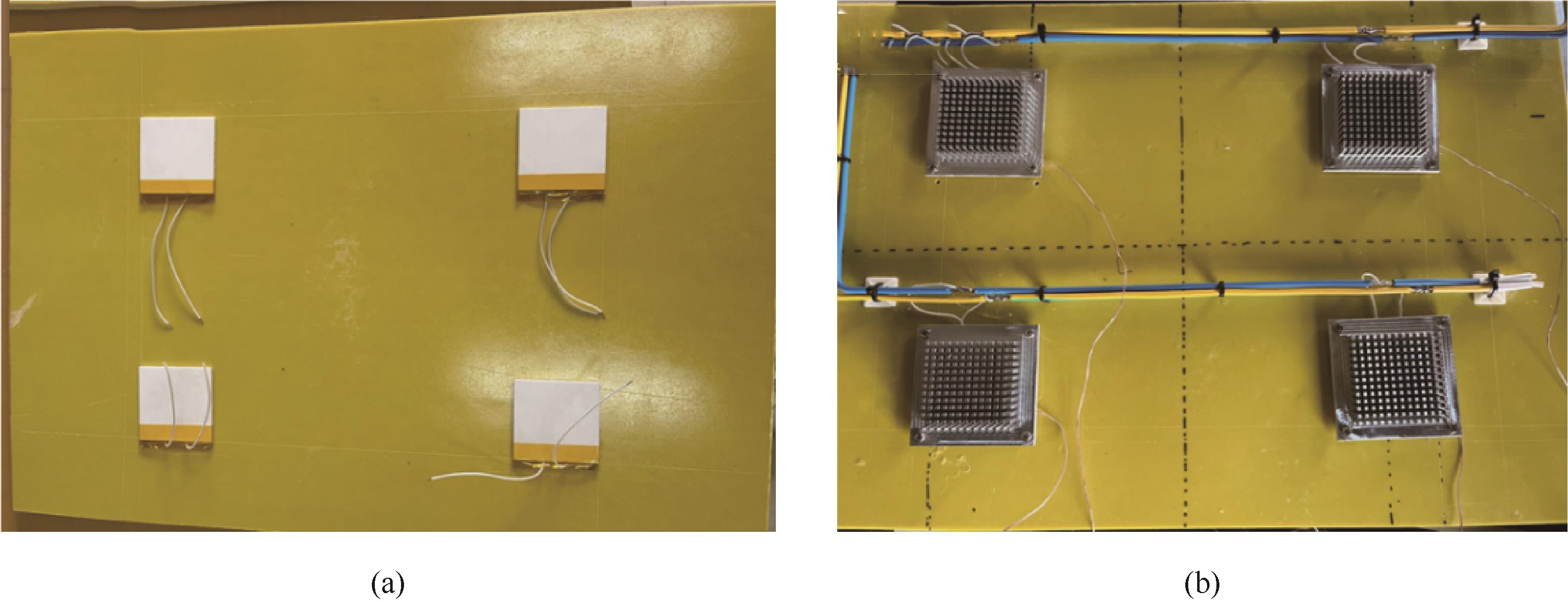

图10 (a)环氧树脂板和陶瓷发热片;(b)装有铝散热器的陶瓷发热片和环氧树脂板

Fig.10 (a) Epoxy resin board and ceramic heating element; (b) Ceramic heating element and epoxy resin board equipped with an aluminum radiator

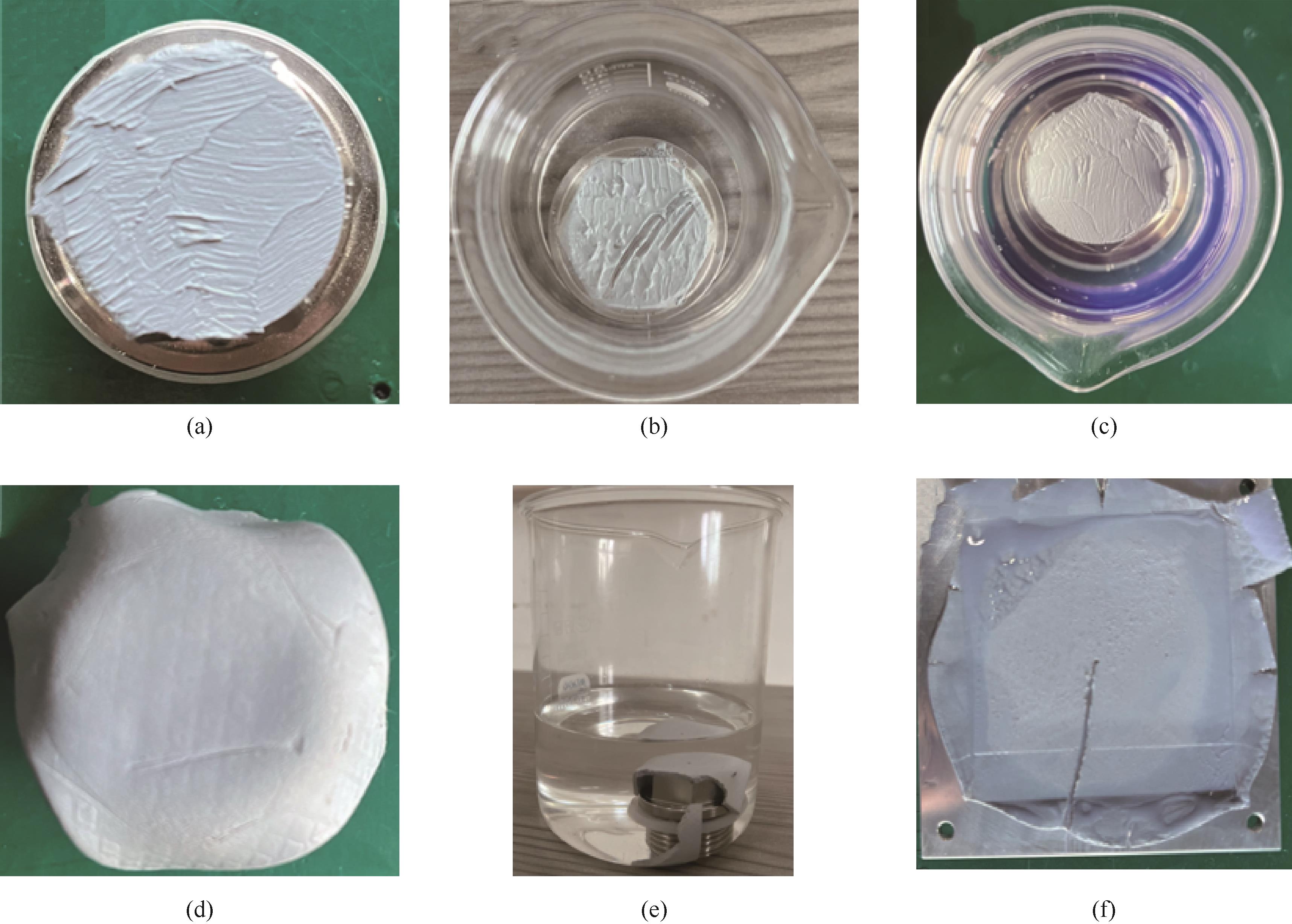

图14 放置在空气中(a)、硅油中(b)、矿物油(c)中的导热硅脂和放置在空气中(d)、硅油中(e)、矿物油中(f)的导热垫片

Fig.14 Thermal conductive grease placed in air (a), silicone oil (b), mineral oil (c) and thermal conductive pads placed in air (d), silicone oil (e), mineral oil (f)

| [1] | Masanet E, Shehabi A, Lei N A, et al. Recalibrating global data center energy-use estimates[J]. Science, 2020, 367(6481): 984-986. |

| [2] | Liu Y N, Wei X X, Xiao J Y, et al. Energy consumption and emission mitigation prediction based on data center traffic and PUE for global data centers[J]. Global Energy Interconnection, 2020, 3(3): 272-282. |

| [3] | Khattak Z, Ali H M. Air cooled heat sink geometries subjected to forced flow: a critical review[J]. International Journal of Heat and Mass Transfer, 2019, 130: 141-161. |

| [4] | Wu Z J, Zhang G Y, Lu S A, et al. A comprehensive review of cold plate liquid cooling technology for data centers[J]. Chemical Engineering Science, 2025, 310: 121525. |

| [5] | Zheng S, Su C S, Yang X P, et al. A comprehensive review of single-phase immersion cooling in data centres[J]. Applied Thermal Engineering, 2025, 272: 126385. |

| [6] | Zhang C, Wang H, Huang Y, et al. Immersion liquid cooling for electronics: materials, systems, applications and prospects[J]. Renewable and Sustainable Energy Reviews, 2025, 208: 114989. |

| [7] | Bansode P, Suthar R, Bhandari R, et al. Impact of immersion cooling on thermomechanical properties of halogen-free substrate core[J]. Journal of Electronic Packaging, 2024, 146(4): 041112. |

| [8] | Beau V V, Marion K, Pieter S. Performance evaluation of a next generation ester based dielectric for single-phase precision immersion cooling[C]//2024 IEEE 5th International Conference on Dielectrics (ICD). IEEE, 2024: 1-6. |

| [9] | Chauhan T, Bhandari R, Sivaraju K B, et al. Impact of immersion cooling on thermomechanical properties of low-loss material printed circuit boards[J]. Journal of Enhanced Heat Transfer, 2021, 28(7): 73-90. |

| [10] | Luo Q Y, Wang C H, Wen H P, et al. Research and optimization of thermophysical properties of sic oil-based nanofluids for data center immersion cooling[J]. International Communications in Heat and Mass Transfer, 2022, 131: 105863. |

| [11] | Shah J M, Padmanaban K, Singh H, et al. Evaluating the reliability of passive server components for single-phase immersion cooling[J]. Journal of Electronic Packaging, 2022, 144(2): 021109. |

| [12] | Shah J M, Eiland R, Rajmane P, et al. Reliability considerations for oil immersion-cooled data centers[J]. Journal of Electronic Packaging, 2019, 141(2): 021007. |

| [13] | Shinde P A, Bansode P V, Saini S, et al. Experimental analysis for optimization of thermal performance of a server in single phase immersion cooling[C]//ASME 2019 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems. Anaheim, California, USA: American Society of Mechanical Engineers, 2019: 1-8. |

| [14] | Eiland R, Edward Fernandes J, Vallejo M, et al. Thermal performance and efficiency of a mineral oil immersed server over varied environmental operating conditions[J]. Journal of Electronic Packaging, 2017, 139(4): 041005. |

| [15] | Chhetri A, Kashyap D, Mali A, et al. Numerical simulation of the single-phase immersion cooling process using a dielectric fluid in a data server[J]. Materials Today: Proceedings, 2022, 51: 1532-1538. |

| [16] | Shrigondekar H, Lin Y C, Wang C-C. Investigations on performance of single-phase immersion cooling system[J]. International Journal of Heat and Mass Transfer, 2023, 206: 123961. |

| [17] | Chen X, Huang Y P, Xu S J, et al. Thermal performance evaluation of electronic fluorinated liquids for single-phase immersion liquid cooling[J]. International Journal of Heat and Mass Transfer, 2024, 220: 124951. |

| [18] | Wang H J, Yuan X J, Zhang K, et al. Performance evaluation and optimization of data center servers using single-phase immersion cooling[J]. International Journal of Heat and Mass Transfer, 2024, 221: 125057. |

| [19] | Hnayno M, Chehade A, Klaba H, et al. Experimental investigation of a data-centre cooling system using a new single-phase immersion/liquid technique[J]. Case Studies in Thermal Engineering, 2023, 45: 102925. |

| [20] | Kim J, Choi H, Lee S, et al. Computational study of single-phase immersion cooling for high-energy density server rack for data centers[J]. Applied Thermal Engineering, 2025, 264: 125476. |

| [21] | Zhang Y Y, Wang Y, Kosonen R, et al. Numerical research on the flow and heat transfer characteristics in the immersion jet cooling for servers[J]. Case Studies in Thermal Engineering, 2024, 60: 104748. |

| [22] | Huang Y P, Ge J L, Chen Y P, et al. Natural and forced convection heat transfer characteristics of single-phase immersion cooling systems for data centers[J]. International Journal of Heat and Mass Transfer, 2023, 207: 124023. |

| [23] | Zhang Y D, Lin Y C, Wang C C. Investigation of the single-phase immersion cold plate amid PAO-4 and Noah@3000A—an experimental approach and its numerical verification[J]. International Communications in Heat and Mass Transfer, 2024, 155: 107509. |

| [24] | Taddeo P, Romaní J, Summers J, et al. Experimental and numerical analysis of the thermal behaviour of a single-phase immersion-cooled data centre[J]. Applied Thermal Engineering, 2023, 234: 121260. |

| [25] | Liu Z, Sun X S, Ji S R, et al. A multi-objective optimization of a single-phase immersion cooling system at cabinet level[J]. Energy and Buildings, 2024, 312: 114221. |

| [26] | Kanbur B B, Wu C L, Fan S M, et al. System-level experimental investigations of the direct immersion cooling data center units with thermodynamic and thermoeconomic assessments[J]. Energy, 2021, 217: 119373. |

| [27] | Sun X S, Liu Z, Ji S R, et al. Experimental study on thermal performance of a single-phase immersion cooling unit for high-density computing power data center[J]. International Journal of Heat and Fluid Flow, 2025, 112: 109735. |

| [28] | Liu S C, Xu Z M, Wang Z M, et al. Optimization and comprehensive evaluation of liquid cooling tank for single-phase immersion cooling data center[J]. Applied Thermal Engineering, 2024, 245: 122864. |

| [29] | Li X Q, Guo S T, Sun H W, et al. Experimental study of the performance of liquid cooling tank used for single-phase immersion cooling data center[J]. Case Studies in Thermal Engineering, 2024, 63: 105386. |

| [30] | Lionello M, Rampazzo M, Beghi A, et al. Graph-based modelling and simulation of liquid immersion cooling systems[J]. Energy, 2020, 207: 118238. |

| [31] | Culham J R, Muzychka Y S. Optimization of plate fin heat sinks using entropy generation minimization[J]. IEEE Transactions on Components and Packaging Technologies, 2001, 24(2): 159-165. |

| [32] | Ferrouillat S, Bontemps A, Ribeiro J P, et al. Hydraulic and heat transfer study of SiO2/water nanofluids in horizontal tubes with imposed wall temperature boundary conditions[J]. International Journal of Heat and Fluid Flow, 2011, 32(2): 424-439. |

| [33] | Ehrenpreis C, El Bahi H, Xu H H, et al. Physically-motivated Figure of Merit (FOM) assessing the cooling performance of fluids suitable for the direct cooling of electrical components[C]//2020 19th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm). IEEE, 2020: 422-429. |

| [34] | Muneeshwaran M, Lin Y C, Wang C-C. Performance analysis of single-phase immersion cooling system of data center using FC-40 dielectric fluid[J]. International Communications in Heat and Mass Transfer, 2023, 145: 106843. |

| [1] | 郭松源, 周晓庆, 缪五兵, 汪彬, 耑锐, 曹庆泰, 陈成成, 杨光, 吴静怡. 火箭上升段含多孔板液氧贮箱增压输运数值研究[J]. 化工学报, 2025, 76(S1): 62-74. |

| [2] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [3] | 曹潇风, 张华海, 王江云, 王利民. 锥形气体层流元件结构设计及流动特性研究[J]. 化工学报, 2025, 76(9): 4440-4448. |

| [4] | 陈昇, 李子争, 苗超, 白学刚, 李飞, 刘家璇, 李天天, 杨爽, 吕蓉蓉, 王江云. 大尺度密集场景高危氯气非均匀湍流扩散特性三维CFD模拟[J]. 化工学报, 2025, 76(9): 4630-4643. |

| [5] | 解勤勤, 翁俊旗, 林振利, 叶光华, 周兴贵. 固定床反应器中甲醇制芳烃工业催化剂结构影响的研究[J]. 化工学报, 2025, 76(9): 4487-4498. |

| [6] | 贾志勇, 沈宪琨, 蓝晓程, 王铁峰. 气体密度对高压流态化影响的CFD-DEM模拟[J]. 化工学报, 2025, 76(9): 4383-4397. |

| [7] | 张帅, 徐嘉宇, 华蕾娜, 葛蔚. 气固系统的CG-DPM与MP-PIC耦合模拟方法[J]. 化工学报, 2025, 76(9): 4412-4424. |

| [8] | 苏国庆, 田学梅, 李彦, 张建文, 张志军. 气力输送系统弯管三通的冲蚀分析及改进[J]. 化工学报, 2025, 76(8): 3894-3904. |

| [9] | 马永丽, 安澍, 杨捷, 刘明言. 气液固流化床直接数值模拟研究进展[J]. 化工学报, 2025, 76(8): 3772-3788. |

| [10] | 王泽, 胡琼, 陈雅静, 王衍, 耿佳旭, 沈斐然. 液体自冲击密封泄漏特性、密封机理与优化设计[J]. 化工学报, 2025, 76(8): 4194-4204. |

| [11] | 陈曦, 王淑彦, 邵宝力, 丁诺, 谢磊. 基于颗粒动态恢复系数二阶矩模型的液固流化床数值模拟研究[J]. 化工学报, 2025, 76(7): 3246-3258. |

| [12] | 夏天炜, 王谙词, 句子涵, 孙晓霞, 胡定华. 基于三周期极小曲面结构的高密度储热器蓄放热特性研究[J]. 化工学报, 2025, 76(7): 3605-3614. |

| [13] | 王富玉, 周晅毅. 结合非定常伴随方程和遗传算法的化工区反演[J]. 化工学报, 2025, 76(6): 3104-3114. |

| [14] | 张亿韵, 陈恒志, 李洋, 慕长安, 王泉海. 湍流对双组分颗粒流化床气体径向扩散的影响[J]. 化工学报, 2025, 76(6): 2559-2568. |

| [15] | 谷德银, 杨豪, 李昌树, 刘作华. 分形穿流桨搅拌槽内假塑性流体的混合行为[J]. 化工学报, 2025, 76(6): 2569-2579. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号