化工学报 ›› 2025, Vol. 76 ›› Issue (3): 1243-1252.DOI: 10.11949/0438-1157.20240879

姚国家1( ), 王志2, 苏昂1, 冯东阁1, 唐宏1(

), 王志2, 苏昂1, 冯东阁1, 唐宏1( ), 孙灵芳1

), 孙灵芳1

收稿日期:2024-08-02

修回日期:2024-10-13

出版日期:2025-03-25

发布日期:2025-03-28

通讯作者:

唐宏

作者简介:姚国家(1996—),男,博士,讲师,yaoguojia@neepu.edu.cn

基金资助:

Guojia YAO1( ), Zhi WANG2, Ang SU1, Dongge FENG1, Hong TANG1(

), Zhi WANG2, Ang SU1, Dongge FENG1, Hong TANG1( ), Lingfang SUN1

), Lingfang SUN1

Received:2024-08-02

Revised:2024-10-13

Online:2025-03-25

Published:2025-03-28

Contact:

Hong TANG

摘要:

煤粉预热解燃烧方法是降低氮氧化物和稳定燃烧的有效途径。为了探究煤粉预热解燃烧特性,建立了适用于煤粉预热解燃烧的RPM-MSRM(random pore model-multiphase surface reaction model)模型,并探究了空气系数对热解气生成和燃料氮转化过程的影响。研究结果表明:煤粉预热解后挥发分热解和部分焦炭气化生成大量热解气[23%~38%(体积分数)]和高温焦炭(>800℃),烟气射流刚性增强,有助于提高燃烧稳定性;空气系数是影响煤粉预热解特征的主要因素,空气系数与出口温度呈正相关关系,与热解气浓度呈负相关关系;本装置的最佳预热解空气系数为0.3,此时装置出口NO x 浓度最低为26.82 mg/m3(@6%O2,标准工况),燃料氮的还原效率最高为99.51%。因此,煤粉预热解燃烧应尽量保持在最佳空气系数下进行以达到最佳的降氮效果。

中图分类号:

姚国家, 王志, 苏昂, 冯东阁, 唐宏, 孙灵芳. 空气系数对煤粉预热解燃烧特性的影响分析[J]. 化工学报, 2025, 76(3): 1243-1252.

Guojia YAO, Zhi WANG, Ang SU, Dongge FENG, Hong TANG, Lingfang SUN. Investigation of the effect of air coefficient on the combustion characteristics of pulverized coal pre-pyrolysis[J]. CIESC Journal, 2025, 76(3): 1243-1252.

| 煤 | 工业分析/% | 元素分析/% | Qar,net/(kJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mar | Aar | Var | FCar | Car | Har | Oar | Nar | Sar | ||

| 神华烟煤 | 14.50 | 7.37 | 28.67 | 49.46 | 65.10 | 3.25 | 8.08 | 0.66 | 0.71 | 23790 |

表1 煤的工业分析和元素分析

Table 1 Coal proximate and ultimate analyses data

| 煤 | 工业分析/% | 元素分析/% | Qar,net/(kJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mar | Aar | Var | FCar | Car | Har | Oar | Nar | Sar | ||

| 神华烟煤 | 14.50 | 7.37 | 28.67 | 49.46 | 65.10 | 3.25 | 8.08 | 0.66 | 0.71 | 23790 |

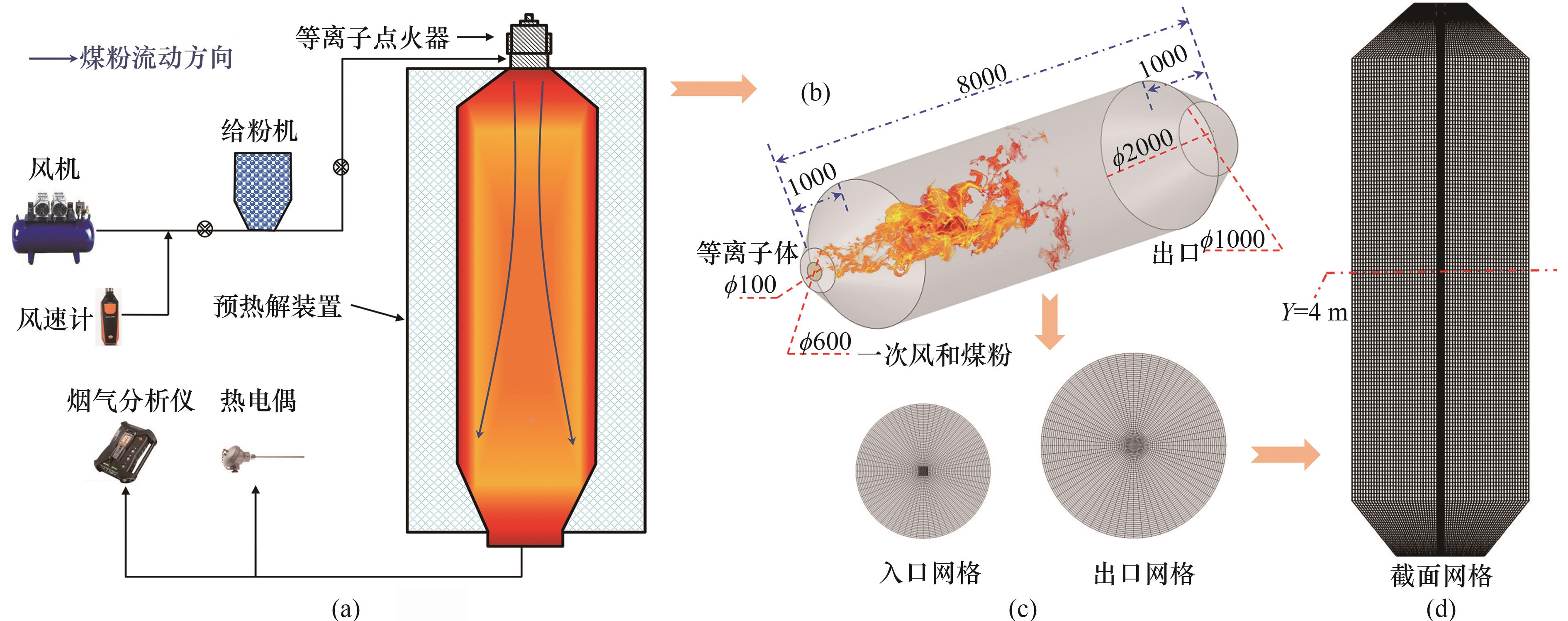

图2 预热解装置示意图和网格:(a)系统图;(b)结构图;(c)入口和出口网格;(d)截面网格

Fig.2 Pre-pyrolysis device schematic and grid: (a) system diagram; (b) structural diagram; (c) inlet and outlet grid,; (d) sectional grid

| 项目 | 模型 | 参数 |

|---|---|---|

| 湍流模型 | Realizable k-ɛ模型 | |

| 辐射模型 | 离散坐标模型 | 方位4×4;像素2×2 |

| 烟气吸收系数 | 灰色气体加权和模型 | |

| 湍流反应速率模型 | 涡耗散概念模型 | |

| 拉格朗日随机追踪 | 颗粒随机轨道模型 | 迭代次数:10 |

| 颗粒辐射参数 | 发射率:0.9;散射系数:0.6 | |

| 气固耦合模型 | particle-source-in-cell方法 | |

| 热力型NO x 模型 | extended Zeldovich机理 | |

| 燃料型NO x 模型 | de Soete机理 | |

| 焦炭表面还原模型 | AE:焦炭比表面积,m2/kg;PNO:NO分压,Pa | |

| 再燃模型 | k1=108 m3/(mol·s);k2=1.4×106e-550/T m3/(mol·s);k3=2×105 m3/(mol·s) |

表2 数学模型和参数选择

Table 2 Mathematical model parameters

| 项目 | 模型 | 参数 |

|---|---|---|

| 湍流模型 | Realizable k-ɛ模型 | |

| 辐射模型 | 离散坐标模型 | 方位4×4;像素2×2 |

| 烟气吸收系数 | 灰色气体加权和模型 | |

| 湍流反应速率模型 | 涡耗散概念模型 | |

| 拉格朗日随机追踪 | 颗粒随机轨道模型 | 迭代次数:10 |

| 颗粒辐射参数 | 发射率:0.9;散射系数:0.6 | |

| 气固耦合模型 | particle-source-in-cell方法 | |

| 热力型NO x 模型 | extended Zeldovich机理 | |

| 燃料型NO x 模型 | de Soete机理 | |

| 焦炭表面还原模型 | AE:焦炭比表面积,m2/kg;PNO:NO分压,Pa | |

| 再燃模型 | k1=108 m3/(mol·s);k2=1.4×106e-550/T m3/(mol·s);k3=2×105 m3/(mol·s) |

| 反应 | 化学反应方程式 | Ar | Er /(J/kmol) | m | a | b | c | 文献 |

|---|---|---|---|---|---|---|---|---|

| R1 | Vol→x1CH4+x2CO+x3H2+x4SO2+x5N2 | 1018 | 0 | 0 | 0 | 0 | 0 | — |

| R2 | CO+0.5O2→CO2 | 2.239×1012 | 1.674×108 | 0 | 1 | 0.25 | 0.5[H2O] | [ |

| R3 | H2+0.5O2→H2O | 6.8×1015 | 1.67×108 | -1 | 0.25 | 1.5 | 0 | [ |

| R4 | CH4+2O2→CO2+2H2O | 2.119×1011 | 2.052×108 | 0 | 0.2 | 1.3 | 0 | [ |

| R5 | CO+H2O→CO2+H2 | 2.34×1010 | 2.883×108 | 0 | 0.5 | 1 | 0 | [ |

| R6 | CO2+H2→CO+H2O | 2.2×107 | 1.9×108 | 0 | 0.5 | 1 | 0 | [ |

| R7 | CH4+H2O→CO+3H2 | 8.0×107 | 2.51×108 | 0 | 0.5 | 1 | 0 | [ |

表3 气相反应和相关动力学参数

Table 3 Gas-phase reactions and related kinetic parameters

| 反应 | 化学反应方程式 | Ar | Er /(J/kmol) | m | a | b | c | 文献 |

|---|---|---|---|---|---|---|---|---|

| R1 | Vol→x1CH4+x2CO+x3H2+x4SO2+x5N2 | 1018 | 0 | 0 | 0 | 0 | 0 | — |

| R2 | CO+0.5O2→CO2 | 2.239×1012 | 1.674×108 | 0 | 1 | 0.25 | 0.5[H2O] | [ |

| R3 | H2+0.5O2→H2O | 6.8×1015 | 1.67×108 | -1 | 0.25 | 1.5 | 0 | [ |

| R4 | CH4+2O2→CO2+2H2O | 2.119×1011 | 2.052×108 | 0 | 0.2 | 1.3 | 0 | [ |

| R5 | CO+H2O→CO2+H2 | 2.34×1010 | 2.883×108 | 0 | 0.5 | 1 | 0 | [ |

| R6 | CO2+H2→CO+H2O | 2.2×107 | 1.9×108 | 0 | 0.5 | 1 | 0 | [ |

| R7 | CH4+H2O→CO+3H2 | 8.0×107 | 2.51×108 | 0 | 0.5 | 1 | 0 | [ |

| 反应 | 反应方程式 | Ar | Er /(J/kmol) | n | 文献 |

|---|---|---|---|---|---|

| R8 | C(s)+0.5O2→CO | 113 | 1.3×108 | 0.68 | [ |

| R9 | C(s)+CO2→2CO | 62.3 | 2.531×108 | 1 | [ |

| R10 | C(s)+H2O→CO+H2 | 0.465 | 1.905×108 | 1 | [ |

表4 焦炭气化反应和相关动力学参数

Table 4 Char gasification reactions and related kinetic parameters

| 反应 | 反应方程式 | Ar | Er /(J/kmol) | n | 文献 |

|---|---|---|---|---|---|

| R8 | C(s)+0.5O2→CO | 113 | 1.3×108 | 0.68 | [ |

| R9 | C(s)+CO2→2CO | 62.3 | 2.531×108 | 1 | [ |

| R10 | C(s)+H2O→CO+H2 | 0.465 | 1.905×108 | 1 | [ |

| 工况 | 煤粉质量流量/(kg/s) | 一次风质量流量/(kg/s) | 空气系数 |

|---|---|---|---|

| 1 | 1.24 | 1.93 | 0.2 |

| 2 | 1.24 | 2.89 | 0.3 |

| 3 | 1.24 | 3.85 | 0.4 |

| 4 | 1.24 | 4.82 | 0.5 |

表5 数值模拟工况设计

Table 5 Numerical simulation cases setup

| 工况 | 煤粉质量流量/(kg/s) | 一次风质量流量/(kg/s) | 空气系数 |

|---|---|---|---|

| 1 | 1.24 | 1.93 | 0.2 |

| 2 | 1.24 | 2.89 | 0.3 |

| 3 | 1.24 | 3.85 | 0.4 |

| 4 | 1.24 | 4.82 | 0.5 |

| 项目 | 实验结果 | 计算结果 | 误差分析 | ||

|---|---|---|---|---|---|

| RPM-MSRM模型 | MSRM模型 | RPM-MSRM模型 | MSRM模型 | ||

| CH4体积分数/% | 2.93 | 2.81 | 1.91 | -4.09% | -34.81% |

| H2体积分数/% | 10.26 | 10.61 | 8.46 | +3.41% | -17.54% |

| CO体积分数/% | 16.83 | 17.88 | 12.97 | +6.24% | -22.94% |

| CO2体积分数/% | 9.48 | 8.95 | 12.56 | -5.59% | +32.49% |

| 出口温度/K | 1257 | 1313 | 1125 | +4.46% | -10.50% |

表6 工况2的计算结果和实验结果对比

Table 6 Comparison between the CFD results and experimental data of case 2

| 项目 | 实验结果 | 计算结果 | 误差分析 | ||

|---|---|---|---|---|---|

| RPM-MSRM模型 | MSRM模型 | RPM-MSRM模型 | MSRM模型 | ||

| CH4体积分数/% | 2.93 | 2.81 | 1.91 | -4.09% | -34.81% |

| H2体积分数/% | 10.26 | 10.61 | 8.46 | +3.41% | -17.54% |

| CO体积分数/% | 16.83 | 17.88 | 12.97 | +6.24% | -22.94% |

| CO2体积分数/% | 9.48 | 8.95 | 12.56 | -5.59% | +32.49% |

| 出口温度/K | 1257 | 1313 | 1125 | +4.46% | -10.50% |

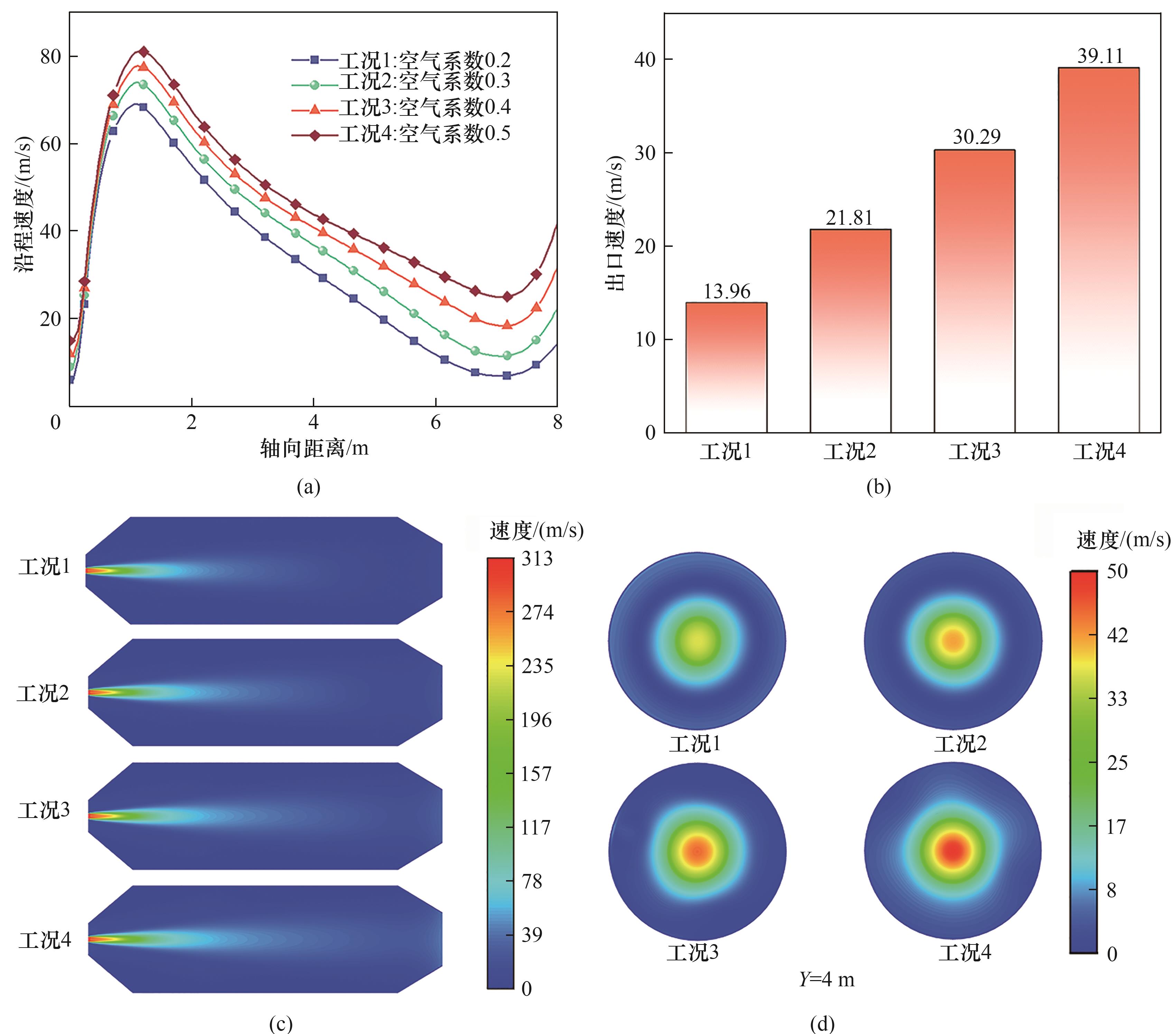

图3 预热解装置速度分布:(a)沿程速度;(b)出口速度;(c)纵截面速度云图;(d)横截面速度云图(Y=4 m)

Fig.3 Velocity distribution of pre-pyrolysis device: (a) along-travel velocity; (b) outlet velocity; (c) velocity distribution contours; (d) cross-sectional velocity distribution contours (Y=4 m)

| 工况 | 空气系数 | 颗粒转化率/% | 颗粒平均停留时间/s | |

|---|---|---|---|---|

| 挥发分 | 焦炭 | |||

| 1 | 0.2 | 100 | 31.53 | 2.68 |

| 2 | 0.3 | 100 | 50.97 | 1.87 |

| 3 | 0.4 | 100 | 65.23 | 1.18 |

| 4 | 0.5 | 100 | 74.78 | 0.82 |

表7 颗粒转化率和停留时间

Table 7 Summary of particles conversion ratio and residue time

| 工况 | 空气系数 | 颗粒转化率/% | 颗粒平均停留时间/s | |

|---|---|---|---|---|

| 挥发分 | 焦炭 | |||

| 1 | 0.2 | 100 | 31.53 | 2.68 |

| 2 | 0.3 | 100 | 50.97 | 1.87 |

| 3 | 0.4 | 100 | 65.23 | 1.18 |

| 4 | 0.5 | 100 | 74.78 | 0.82 |

| 1 | Glarborg P, Miller J A, Ruscic B, et al. Modeling nitrogen chemistry in combustion[J]. Progress in Energy and Combustion Science, 2018, 67: 31-68. |

| 2 | Wang Z, Peng X Y, Cao S X, et al. NO x emission prediction using a lightweight convolutional neural network for cleaner production in a down-fired boiler[J]. Journal of Cleaner Production, 2023, 389: 136060. |

| 3 | 国家统计局. 中华人民共和国2023年国民经济和社会发展统计公报[J]. 中国统计, 2024(3): 4-21. |

| National Bureau of Statistics. Statistical communiqué of the People’s Republic of China on the 2023 national economic and social development[J]. China Statistics, 2024(3): 4-21. | |

| 4 | Wang Z, Peng X Y, Zhou H C, et al. A dynamic modeling method using channel-selection convolutional neural network: a case study of NO x emission[J]. Energy, 2024, 290: 130270. |

| 5 | Zhu S J, Hui J C, Lyu Q G, et al. Experimental study on pulverized coal combustion preheated by a circulating fluidized bed: preheating characteristics for peak shaving[J]. Fuel, 2022, 324: 124684. |

| 6 | Yao G J, Han X J, Liu Z D, et al. Low-NO x study of a 600 MW tangentially fired boiler based on pulverized coal preheating method[J]. Case Studies in Thermal Engineering, 2023, 48: 103156. |

| 7 | Rabovitser J, Bryan B, Knight R, et al. Development and testing of a novel coal preheating technology for NO x reduction from pulverized coal-fired boilers[J]. Gas, 2003, 1(2): 4. |

| 8 | Tang H, Liu Z D, Han X J, et al. Experimental study on combustion characteristics of a 40 MW pulverized coal boiler based on a new low NO x burner with preheating function[J]. Energy, 2024, 305: 132319. |

| 9 | Liu J Z, Liu Y H, Zhu J G, et al. Bituminous coal deep regulated ultra-low NO x flameless combustion with fluidized self-preheating fuel: a 2 MWth experimental study[J]. Fuel, 2021, 294: 120549. |

| 10 | Ouyang Z Q, Liu W, Man C B, et al. Experimental study on combustion, flame and NO x emission of pulverized coal preheated by a preheating burner[J]. Fuel Processing Technology, 2018, 179: 197-202. |

| 11 | Rahimipetroudi I, Rashid K, Yang J B, et al. Development of environment-friendly dual fuel pulverized coal-natural gas combustion technology for the co-firing power plant boiler: experimental and numerical analysis[J]. Energy, 2021, 228: 120550. |

| 12 | Lv Z M, Xiong X H, Ruan R H, et al. NO emission and burnout characteristics in co-combustion of coal and sewage sludge following high-temperature preheating[J]. Fuel, 2023, 331: 125887. |

| 13 | Zhu G Q, Xu L, Wang S, et al. Synergistic reduction on PM and NO source emissions during preheating-combustion of pulverized coal[J]. Fuel, 2024, 361: 130699. |

| 14 | Hui J C, Zhu S J, Zhang X Y, et al. Experimental study of deep and flexible load adjustment on pulverized coal combustion preheated by a circulating fluidized bed[J]. Journal of Cleaner Production, 2023, 418: 138040. |

| 15 | 吕清刚, 朱书骏, 朱建国, 等. 煤粉预热燃烧技术研发进展[J]. 中国电机工程学报, 2022, 42(18): 6535-6547. |

| Lyu Q G, Zhu S J, Zhu J G, et al. Research and development on preheated combustion of pulverized coal[J]. Proceedings of the CSEE, 2022, 42(18): 6535-6547. | |

| 16 | Chen D G, Zhang Z, Li Z S, et al. Optimizing in situ char gasification kinetics in reduction zone of pulverized coal air-staged combustion[J]. Combustion and Flame, 2018, 194: 52-71. |

| 17 | Zhu S J, Lyu Q G, Zhu J G, et al. Experimental study on NO x emissions of pulverized bituminous coal combustion preheated by a circulating fluidized bed[J]. Journal of the Energy Institute, 2019, 92(2): 247-256. |

| 18 | Ding H L, Ouyang Z Q, Shi Y S, et al. Effects of the T-abrupt exit configuration of riser on fuel properties, combustion characteristics and NO x emissions with coal self-preheating technology[J]. Fuel, 2023, 337: 126860. |

| 19 | Iwaszenko S, Howaniec N, Smoliński A. Determination of random pore model parameters for underground coal gasification simulation[J]. Energy, 2019, 166: 972-978. |

| 20 | Wang H Y, Zhang C Q, Liu X. Heat transfer calculation methods in three-dimensional CFD model for pulverized coal-fired boilers[J]. Applied Thermal Engineering, 2020, 166: 114633. |

| 21 | Wang H Y, Jin D H, Liu X, et al. Analytical and numerical investigations on the high temperature upgrading solution of subcritical boilers[J]. Applied Thermal Engineering, 2022, 200: 117628. |

| 22 | Adamczyk W P, Werle S, Ryfa A. Application of the computational method for predicting NO x reduction within large scale coal-fired boiler[J]. Applied Thermal Engineering, 2014, 73(1): 343-350. |

| 23 | Westbrook C K, Dryer F L. Simplified reaction mechanisms for the oxidation of hydrocarbon fuels in flames[J]. Combustion Science and Technology, 1981, 27(1/2): 31-43. |

| 24 | Jones W P, Lindstedt R P. Global reaction schemes for hydrocarbon combustion[J]. Combustion and Flame, 1988, 73(3): 233-249. |

| 25 | Bustamante F, Enick R M, Killmeyer R P, et al. Uncatalyzed and wall-catalyzed forward water-gas shift reaction kinetics[J]. AIChE Journal, 2005, 51(5): 1440-1454. |

| 26 | Ma J L, Zitney S E. Computational fluid dynamic modeling of entrained-flow gasifiers with improved physical and chemical submodels[J]. Energy & Fuels, 2012, 26(12): 7195-7219. |

| 27 | 仇鹏, 韩洋, 许建良, 等. 用于预测气流床煤气化的EDC模型参数研究[J]. 化工学报, 2023, 74(1): 428-437. |

| Qiu P, Han Y, Xu J L, et al. Study of EDC parameters for predicting entrained flow coal gasification[J]. CIESC Journal, 2023, 74(1): 428-437. | |

| 28 | Gran I R, Magnussen B F. A numerical study of a bluff-body stabilized diffusion flame(part 1): Influence of turbulence modeling and boundary conditions[J]. Combustion Science and Technology, 1996, 119(1/2/3/4/5/6): 171-190. |

| 29 | Zhang X Y, Zhu S J, Song W J, et al. Experimental study on conversion characteristics of anthracite and bituminous coal during preheating-gasification[J]. Fuel, 2022, 324: 124712. |

| 30 | Wang S, Niu Y Q, Zhu G Q, et al. NO formation and destruction during combustion of high temperature preheated pulverized coal[J]. Journal of the Energy Institute, 2021, 99: 82-87. |

| 31 | Kajitani S, Hara S, Matsuda H. Gasification rate analysis of coal char with a pressurized drop tube furnace[J]. Fuel, 2002, 81(5): 539-546. |

| 32 | Bhatia S K, Perlmutter D D. A random pore model for fluid-solid reactions(Ⅰ): Isothermal, kinetic control[J]. AIChE Journal, 1980, 26(3): 379-386. |

| 33 | Haugen N E L, Loong B K Y, Mitchell R E. Numerical approaches for thermochemical conversion of char[J]. Progress in Energy and Combustion Science, 2022, 91: 100993. |

| 34 | Smith I W. The combustion rates of coal chars: a review[J]. Symposium (International) on Combustion, 1982, 19(1):1045-1065. |

| 35 | Fluent A. Ansys Fluent Theory Guide[M]. USA: Ansys Inc, 2020. |

| 36 | Yao G J, Liu Z D, Tang H, et al. Prediction of reduction products in the preheating process[J]. Thermal Science, 2023, 27(5 Part B): 4021-4034. |

| 37 | Liu H, Liu Y H, Yi G Z, et al. Effects of air staging conditions on the combustion and NO x emission characteristics in a 600 MW wall fired utility boiler using lean coal[J]. Energy & Fuels, 2013, 27(10): 5831-5840. |

| 38 | Sánchez C, Arenas E, Chejne F, et al. A new model for coal gasification on pressurized bubbling fluidized bed gasifiers[J]. Energy Conversion and Management, 2016, 126: 717-723. |

| 39 | Zhao L L, Zhou Q T, Zhao C S. Flame characteristics in a novel petal swirl burner[J]. Combustion and Flame, 2008, 155(1/2): 277-288. |

| 40 | Glarborg P, Alzueta M U, Dam-Johansen K, et al. Kinetic modeling of hydrocarbon/nitric oxide interactions in a flow reactor[J]. Combustion and Flame, 1998, 115(1/2): 1-27. |

| [1] | 徐芳, 张锐, 崔达, 王擎. ReaxFF-MD揭示木质素热解反应机制的分子动力学研究[J]. 化工学报, 2025, 76(3): 1253-1263. |

| [2] | 李中青, 王志远, 栾小建, 梁四凯, 王凯. 电沉积-低氧分压法制备MnO涂层及其抑制石脑油热裂解结焦性能研究[J]. 化工学报, 2025, 76(3): 1050-1063. |

| [3] | 谢楠楠, 陈和, 叶光华, 束忠明, 傅送保, 周兴贵. 气液搅拌釜多层桨叶相互作用及组合优化[J]. 化工学报, 2025, 76(2): 564-575. |

| [4] | 黄娜, 蒋云龙, 王东涵, 吴明婷, 蒋雪莉, 钟豫. 通道振动频率对超临界正癸烷裂解流动换热影响的数值研究[J]. 化工学报, 2025, 76(1): 173-183. |

| [5] | 李彦, 郭红利, 苏国庆, 张建文. 加氢装置空冷器气液两相流动与冲刷腐蚀问题[J]. 化工学报, 2025, 76(1): 141-150. |

| [6] | 郭骐瑞, 任丽媛, 陈康, 黄翔宇, 马卫华, 肖乐勤, 周伟良. 用于HTPB推进剂浆料的静态混合管数值模拟[J]. 化工学报, 2024, 75(S1): 206-216. |

| [7] | 黄正梁, 冯铭瑞, 宋琦, 任聪静, 杨遥, 孙婧元, 王靖岱, 阳永荣. 预混进料对废树脂流化裂解反应中颗粒团聚的抑制作用[J]. 化工学报, 2024, 75(9): 3094-3102. |

| [8] | 王舒英, 左涛, 石志伟, 范小明, 张卫新. 阳离子交换树脂基介孔石墨化碳合成与储钠性能[J]. 化工学报, 2024, 75(9): 3338-3347. |

| [9] | 祝赫, 张仪, 齐娜娜, 张锴. 欧拉-欧拉双流体模型中颗粒黏性对液固散式流态化的影响[J]. 化工学报, 2024, 75(9): 3103-3112. |

| [10] | 丁湧, 李文建, 陈昭宇, 曹立辉, 刘轩铭, 任强强, 胡松, 向军. 废旧晶体硅光伏组件EVA有氧热解动力学与产物特性[J]. 化工学报, 2024, 75(9): 3310-3319. |

| [11] | 吴学红, 韦新, 侯加文, 吕财, 刘勇, 刘鹤, 常志娟. 热解法制备碳纳米管及其在散热涂层中的应用研究[J]. 化工学报, 2024, 75(9): 3360-3368. |

| [12] | 罗正航, 李敬宇, 陈伟雄, 种道彤, 严俊杰. 摇摆运动下低流率蒸汽冷凝换热特性和气泡受力数值模拟[J]. 化工学报, 2024, 75(8): 2800-2811. |

| [13] | 李倩, 张蓉民, 林子杰, 战琪, 蔡伟华. 基于机器学习的印刷电路板式换热器流动换热预测与仿真[J]. 化工学报, 2024, 75(8): 2852-2864. |

| [14] | 曹佳蕾, 孙立岩, 曾德望, 尹凡, 高子翔, 肖睿. 双流化床化学链制氢反应器的数值模拟[J]. 化工学报, 2024, 75(8): 2865-2874. |

| [15] | 金虎, 杨帆, 戴梦瑶. 基于格子Boltzmann方法的液滴在圆柱壁面上运动过程研究[J]. 化工学报, 2024, 75(8): 2897-2908. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号