化工学报 ›› 2025, Vol. 76 ›› Issue (5): 2410-2418.DOI: 10.11949/0438-1157.20241208

• 分离工程 • 上一篇

收稿日期:2024-10-30

修回日期:2025-02-04

出版日期:2025-05-25

发布日期:2025-06-13

通讯作者:

张瑛

作者简介:顾栋(1983—),男,学士,高级工程师,108188933@qq.com

Dong GU1( ), Xingjian PI2, Die ZHANG2, Ying ZHANG2(

), Xingjian PI2, Die ZHANG2, Ying ZHANG2( )

)

Received:2024-10-30

Revised:2025-02-04

Online:2025-05-25

Published:2025-06-13

Contact:

Ying ZHANG

摘要:

基于金属有机骨架(MOFs)的混合基质膜兼具聚合物与MOFs材料的性能优势,是H2/CO2气体分离领域的研究热点。利用原位聚合法将不同粒径的CAU-1分散到聚酰亚胺(PI)基质材料中,采用XRD、SEM、TG、FTIR等手段对MOFs填料和混合基质膜进行表征,探究粒径大小和热处理温度对CAU-1/PI混合基质膜的H2/CO2分离性能的影响。结果表明,相较于纯聚合物膜,混合基质膜的分离效果有明显改善,原位聚合法能够显著提高MOF与聚合物的界面相容性,CAU-1粒径和热处理温度优化后的PI/CAU-1膜的H2/CO2分离因子可达8.4。

中图分类号:

顾栋, 皮行健, 张叠, 张瑛. 不同粒径CAU-1/PI混合基质膜的构建与H2/CO2分离性能研究[J]. 化工学报, 2025, 76(5): 2410-2418.

Dong GU, Xingjian PI, Die ZHANG, Ying ZHANG. Construction and H2/CO2 separation performance evaluation of CAU-1/PI mixed matrix membrane with different nanoparticle sizes[J]. CIESC Journal, 2025, 76(5): 2410-2418.

| Membrane | CAU-1 | PI/g | 亚酰胺化温度/℃ |

|---|---|---|---|

| M0 | — | 0.40 | 150 |

| M1 | — | 0.40 | 180 |

| M-30-150 | CAU-1-30,0.04 g | 0.36 | 150 |

| M-30-180 | CAU-1-30,0.04 g | 0.36 | 180 |

| M-40-180 | CAU-1-40,0.04 g | 0.36 | 180 |

| M-50-180 | CAU-1-50,0.04 g | 0.36 | 180 |

| M-60-180 | CAU-1-60,0.04 g | 0.36 | 180 |

表1 纯PI膜和不同粒径CAU-1混合基质膜的合成方案

Table 1 Synthesis scheme of pure PI membrane and CAU-1 mixed matrix membrane with different particle sizes

| Membrane | CAU-1 | PI/g | 亚酰胺化温度/℃ |

|---|---|---|---|

| M0 | — | 0.40 | 150 |

| M1 | — | 0.40 | 180 |

| M-30-150 | CAU-1-30,0.04 g | 0.36 | 150 |

| M-30-180 | CAU-1-30,0.04 g | 0.36 | 180 |

| M-40-180 | CAU-1-40,0.04 g | 0.36 | 180 |

| M-50-180 | CAU-1-50,0.04 g | 0.36 | 180 |

| M-60-180 | CAU-1-60,0.04 g | 0.36 | 180 |

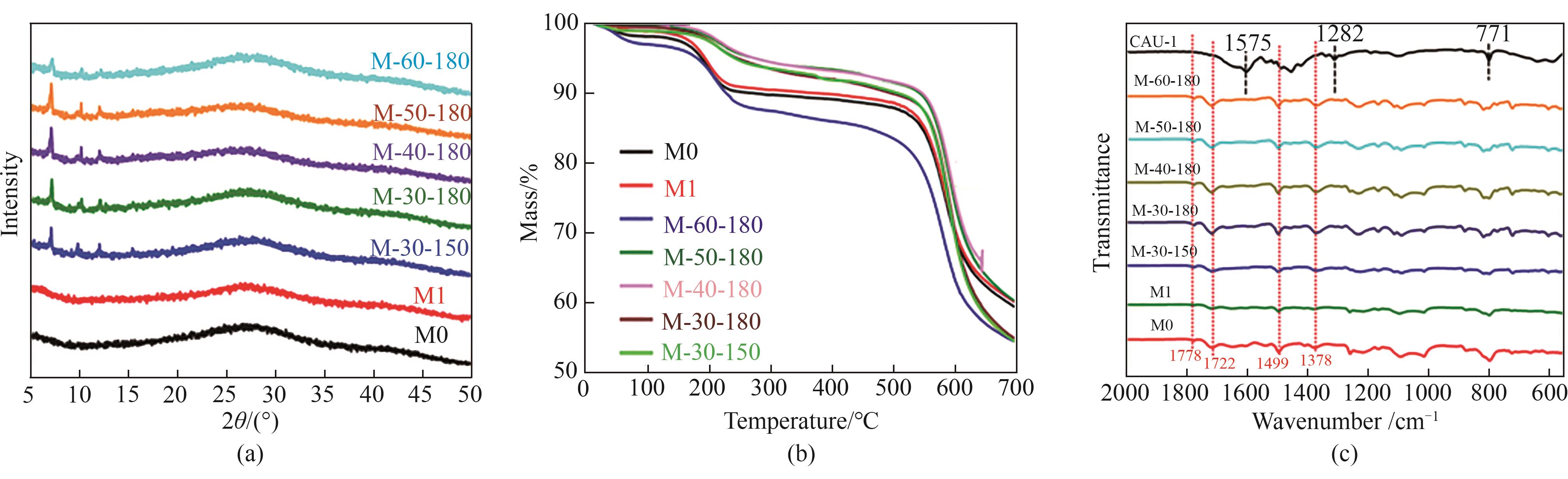

图5 纯PI膜和不同粒径CAU-1混合基质膜的X射线衍射、TGA与FTIR曲线

Fig.5 XRD patterns, TGA curves and FTIR spectra of pure PI membranes and CAU-1 mixed matrix membranes with different particle sizes

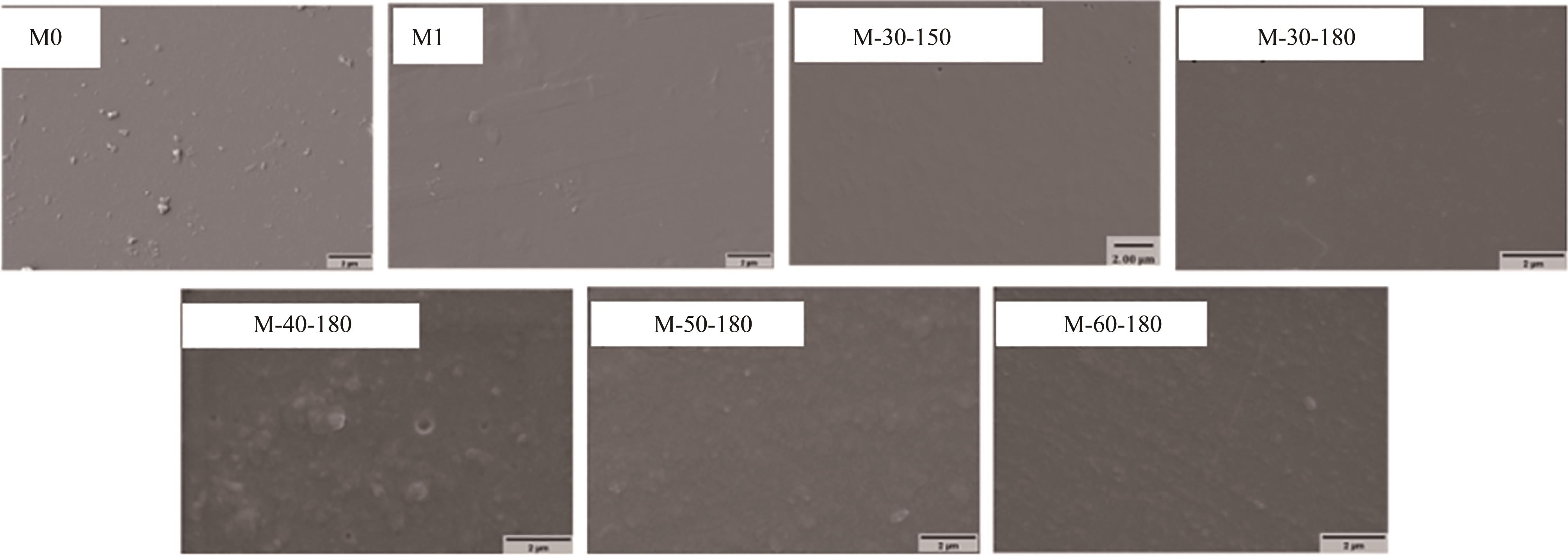

图6 纯PI膜和不同粒径CAU-1混合基质膜的表面SEM图(2 μm)

Fig.6 Surface SEM images of pure PI membranes and CAU-1 mixed matrix membranes with different particle sizes(2 μm)

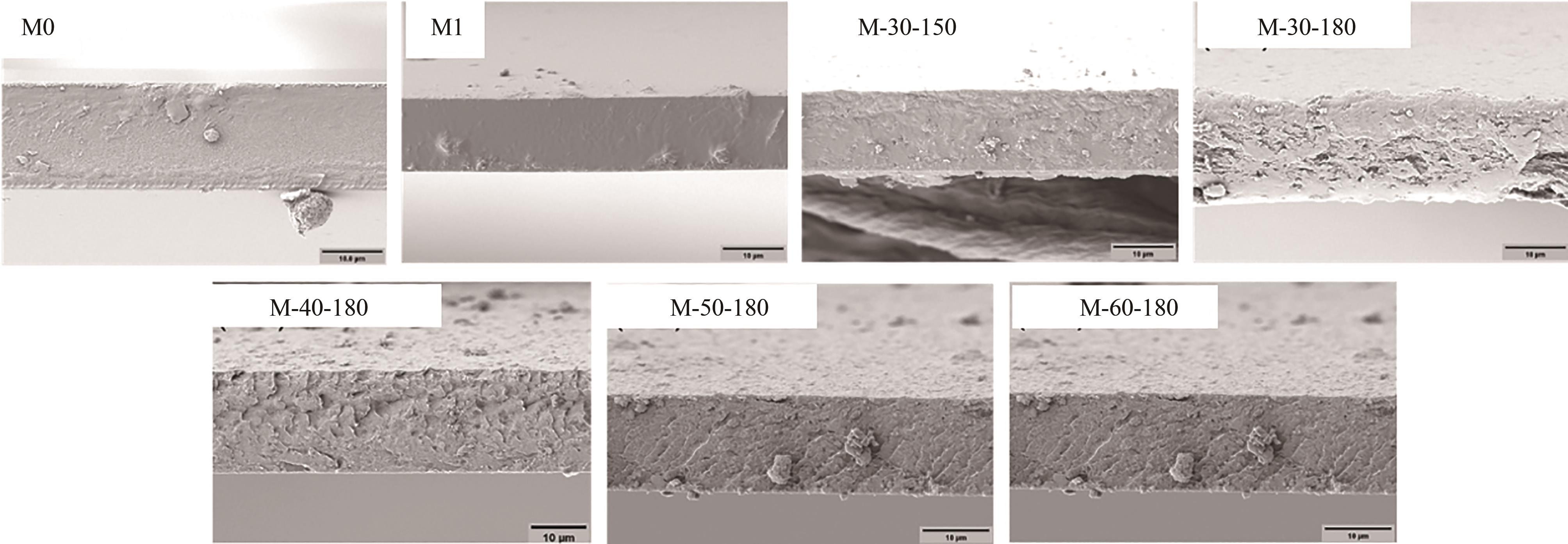

图7 纯PI膜和不同粒径CAU-1混合基质膜的截面SEM图(10 μm)

Fig.7 Cross-sectional SEM images of pure PI membranes and CAU-1 mixed matrix membranes with different particle sizes(10 μm)

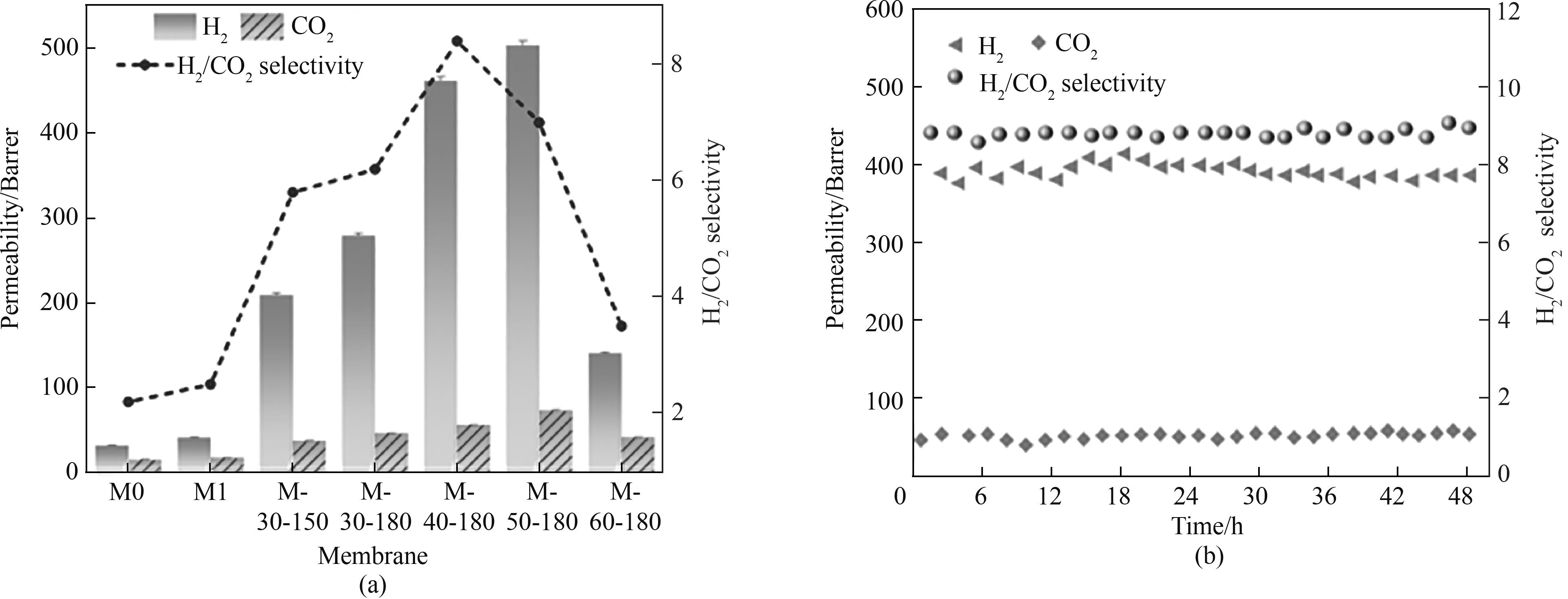

图8 (a)纯PI膜和混合基质膜的H2、CO2渗透性以及H2/CO2选择性;(b)M-40-180膜在25℃和1.5×105 Pa条件下的性能稳定性

Fig.8 (a)H2 and CO2 permeability and H2/CO2 selectivity of pure PI and mixed matrix membranes;(b) Evaluation of the performance stability of M-40-180 at 25 ℃ and 1.5×105 Pa

| 基体 | 填料及含量/%(质量) | H2渗透性/Barrer | H2/CO2选择性 | 温度T/℃ | 文献 |

|---|---|---|---|---|---|

| Matrimid®5218 | Zeolite 4A, 10 | 28.2 | 2.2 | 30 | [ |

| PBI | ZIF-7, 50 | 26.2 | 14.9 | 35 | [ |

| ZIF-8, 30 | 82.5 | 12.0 | 35 | [ | |

| ZIF-8, 60 | 1749.9 | 4.1 | 35 | [ | |

| ZIF-11, 39.5 | 464.7 | 3.6 | 25 | [ | |

| ZIF-90, 45 | 24.5 | 25 | 35 | [ | |

| Matrimid® | ZIF-8, 20 | 32 | 3.5 | 25 | [ |

| 6FDA-durene | ZIF-8, 33.3 | 2136 | 1.4 | 35 | [ |

| Polyimides | ZSM-5 | 1268 | 1.3 | 35 | [ |

| Cu(BTC)2, 3/6 | — | 18/27.8 | 25 | [ | |

| PMMA | CAU-1, 15 | 11000 | 13 | 25 | [ |

| PES | SAPO-34, 20 | 12.57 | 2.45 | 30 | [ |

| M-40-180 | CAU-1, 10 | 460.0 | 8.4 | 25 | 本文 |

| M-50-180 | CAU-1, 10 | 501.1 | 7.0 | 25 | 本文 |

表2 文献报道的MOF基混合基质膜的H2/CO2分离性能(常压)

Table 2 H2/CO2 separation performance of MOF-based mixed matrix membranes reported in the literature(atmospheric pressure)

| 基体 | 填料及含量/%(质量) | H2渗透性/Barrer | H2/CO2选择性 | 温度T/℃ | 文献 |

|---|---|---|---|---|---|

| Matrimid®5218 | Zeolite 4A, 10 | 28.2 | 2.2 | 30 | [ |

| PBI | ZIF-7, 50 | 26.2 | 14.9 | 35 | [ |

| ZIF-8, 30 | 82.5 | 12.0 | 35 | [ | |

| ZIF-8, 60 | 1749.9 | 4.1 | 35 | [ | |

| ZIF-11, 39.5 | 464.7 | 3.6 | 25 | [ | |

| ZIF-90, 45 | 24.5 | 25 | 35 | [ | |

| Matrimid® | ZIF-8, 20 | 32 | 3.5 | 25 | [ |

| 6FDA-durene | ZIF-8, 33.3 | 2136 | 1.4 | 35 | [ |

| Polyimides | ZSM-5 | 1268 | 1.3 | 35 | [ |

| Cu(BTC)2, 3/6 | — | 18/27.8 | 25 | [ | |

| PMMA | CAU-1, 15 | 11000 | 13 | 25 | [ |

| PES | SAPO-34, 20 | 12.57 | 2.45 | 30 | [ |

| M-40-180 | CAU-1, 10 | 460.0 | 8.4 | 25 | 本文 |

| M-50-180 | CAU-1, 10 | 501.1 | 7.0 | 25 | 本文 |

| 1 | Sazali N. A review of the application of carbon-based membranes to hydrogen separation[J]. Journal of Materials Science, 2020, 55(25): 11052-11070. |

| 2 | Mao D L, Griffin J M, Dawson R, et al. Metal organic frameworks for hydrogen purification[J]. International Journal of Hydrogen Energy, 2021, 46(45): 23380-23405. |

| 3 | Sidney L, Sriniva S, Weaver D E. High flow porous membranes for separating water from saline solutions: US3133137A[P]. 1964-05-12. |

| 4 | Stern S A, Mullhaupt J T, Gareis P J. The effect of pressure on the permeation of gases and vapors through polyethylene. Usefulness of the corresponding states principle[J]. AIChE Journal, 1969, 15(1): 64-73. |

| 5 | Guo H, Liu J Q, Li Y H, et al. Post-synthetic modification of highly stable UiO-66-NH2 membranes on porous ceramic tubes with enhanced H2 separation[J]. Microporous and Mesoporous Materials, 2021, 313: 110823. |

| 6 | Li P Y, Wang Z, Qiao Z H, et al. Recent developments in membranes for efficient hydrogen purification[J]. Journal of Membrane Science, 2015, 495: 130-168. |

| 7 | Al-Rowaili F N, Khaled M, Jamal A, et al. Mixed matrix membranes for H2/CO2 gas separation—a critical review[J]. Fuel, 2023, 333: 126285. |

| 8 | Wang S F, Li X Q, Wu H, et al. Advances in high permeability polymer-based membrane materials for CO2 separations[J]. Energy & Environmental Science, 2016, 9(6): 1863-1890. |

| 9 | Butler J A V. (1) Rational approach to chemical principles (2) the elements of physical chemistry (3) physical chemistry (4) physical chemistry[J]. Nature, 1948, 162: 125-126. |

| 10 | Chui S S Y, Lo S M F, Charmant J P H, et al. A chemically functionalizable nanoporous material [Cu3[TMA]2(H2O)3] n [J]. Science, 1999, 283(5405): 1148-1150. |

| 11 | Millward A R, Yaghi O M. Metal-organic frameworks with exceptionally high capacity for storage of carbon dioxide at room temperature[J]. Journal of the American Chemical Society, 2005, 127(51): 17998-17999. |

| 12 | Britt D, Furukawa H, Wang B, et al. Highly efficient separation of carbon dioxide by a metal-organic framework replete with open metal sites[J]. Proceedings of the National Academy of Sciences of the United States of America, 2009, 106(49): 20637-20640. |

| 13 | Valenzano L, Civalleri B, Chavan S, et al. Computational and experimental studies on the adsorption of CO, N2, and CO2 on Mg-MOF-74[J]. The Journal of Physical Chemistry C, 2010, 114(25): 11185-11191. |

| 14 | Song Y Y, He M G, Zhao J, et al. Structural manipulation of ZIF-8-based membranes for high-efficiency molecular separation[J]. Separation and Purification Technology, 2021, 270: 118722. |

| 15 | Guan W X, Dai Y, Dong C Y, et al. Zeolite imidazolate framework (ZIF)-based mixed matrix membranes for CO2 separation: a review[J]. Journal of Applied Polymer Science, 2020, 137(33): 48968. |

| 16 | Li Y S, Liang F Y, Bux H, et al. Zeolitic imidazolate framework ZIF-7 based molecular sieve membrane for hydrogen separation[J]. Journal of Membrane Science, 2010, 354(1/2): 48-54. |

| 17 | Kumar S, Jain S, Nehra M, et al. Green synthesis of metal-organic frameworks: a state-of-the-art review of potential environmental and medical applications[J]. Coordination Chemistry Reviews, 2020, 420: 213407. |

| 18 | Kandiah M, Nilsen M H, Usseglio S, et al. Synthesis and stability of tagged UiO-66 Zr-MOFs[J]. Chemistry of Materials, 2010, 22(24): 6632-6640. |

| 19 | Japip S, Liao K S, Chung T S. Molecularly tuned free volume of vapor cross-linked 6FDA-durene/ZIF-71 MMMs for H2/CO2 separation at 150℃[J]. Advanced Materials, 2017, 29(4): 1603833. |

| 20 | Klepić M, Setničková K, Lanč M, et al. Permeation and sorption properties of CO2-selective blend membranes based on polyvinyl alcohol (PVA) and 1-ethyl-3-methylimidazolium dicyanamide ([EMIM] [DCA]) ionic liquid for effective CO2/H2 separation[J]. Journal of Membrane Science, 2020, 597: 117623. |

| 21 | Li Y S, Liang F Y, Bux H, et al. Molecular sieve membrane: supported metal-organic framework with high hydrogen selectivity[J]. Angewandte Chemie International Edition, 2010, 49(3): 548-551. |

| 22 | Cao L J, Tao K, Huang A S, et al. A highly permeable mixed matrix membrane containing CAU-1-NH2 for H2 and CO2 separation[J]. Chemical Communications, 2013, 49(76): 8513-8515. |

| 23 | Jia Y, Liu P X, Liu Y B, et al. In-situ interfacial crosslinking of NH2-MIL-53 and polyimide in MOF-incorporated mixed matrix membranes for efficient H2 purification[J]. Fuel, 2023, 339:126938. |

| 24 | Ahmad J, Hägg M B. Development of matrimid/zeolite 4A mixed matrix membranes using low boiling point solvent[J]. Separation and Purification Technology, 2013, 115: 190-197. |

| 25 | Yang T X, Xiao Y C, Chung T S. Poly-/ metal-benzimidazole nano-composite membranes for hydrogen purification[J]. Energy & Environmental Science, 2011, 4(10): 4171-4180. |

| 26 | Yang T X, Chung T S. High performance ZIF-8/PBI nano-composite membranes for high temperature hydrogen separation consisting of carbon monoxide and water vapor[J]. International Journal of Hydrogen Energy, 2013, 38(1): 229-239. |

| 27 | Yang T X, Shi G M, Chung T S. Symmetric and asymmetric zeolitic imidazolate frameworks (ZIFs)/polybenzimidazole (PBI) nanocomposite membranes for hydrogen purification at high temperatures[J]. Advanced Energy Materials, 2012, 2(11): 1358-1367. |

| 28 | Li L X, Yao J F, Wang X J, et al. ZIF-11/Polybenzimidazole composite membrane with improved hydrogen separation performance[J]. Journal of Applied Polymer Science, 2014, 131(22): 41056. |

| 29 | Yang T X, Chung T S. Room-temperature synthesis of ZIF-90 nanocrystals and the derived nano-composite membranes for hydrogen separation[J]. Journal of Materials Chemistry A, 2013, 1(19): 6081-6090. |

| 30 | Ordoñez M J C, Balkus K J, Ferraris J P, et al. Molecular sieving realized with ZIF-8/Matrimid® mixed-matrix membranes[J]. Journal of Membrane Science, 2010, 361(1/2): 28-37. |

| 31 | Wijenayake S N, Panapitiya N P, Versteeg S H, et al. Surface cross-linking of ZIF-8/polyimide mixed matrix membranes (MMMs) for gas separation[J]. Industrial & Engineering Chemistry Research, 2013, 52(21): 6991-7001. |

| 32 | Kanehashi S, Gu H, Shindo R, et al. Gas permeation and separation properties of polyimide/ZSM-5 zeolite composite membranes containing liquid sulfolane[J]. Journal of Applied Polymer Science, 2013, 128(6): 3814-3823. |

| 33 | Hu J, Cai H P, Ren H Q, et al. Mixed-matrix membrane hollow fibers of Cu3(BTC)2 MOF and polyimide for gas separation and adsorption[J]. Industrial & Engineering Chemistry Research, 2010, 49(24): 12605-12612. |

| 34 | Karatay E, Kalıpçılar H, Yılmaz L. Preparation and performance assessment of binary and ternary PES-SAPO 34-HMA based gas separation membranes[J]. Journal of Membrane Science, 2010, 364(1/2): 75-81. |

| [1] | 张冰, 李建惠, 马欣蓉, 陈杨, 李晋平, 李立博. 蒸气相辅助法制备MOF基材料的研究进展[J]. 化工学报, 2025, 76(5): 2026-2041. |

| [2] | 刘鑫, 郑皓仁, 陈强, 丁静怡, 黄康, 徐至. 全钒液流电池用纤维素纳米晶掺杂混合基质膜[J]. 化工学报, 2025, 76(5): 2294-2303. |

| [3] | 陶春珲, 李印辉, 傅钰, 段然, 赵泽一, 唐羽丰, 张罡, 马和平. 不同吸附剂对低浓度Kr气的选择性吸附与纯化[J]. 化工学报, 2025, 76(5): 2358-2366. |

| [4] | 赵浩帆, 任豪杰, 刘宗凯, 董冠英, 张亚涛. MOFs玻璃膜在气体分离领域的研究进展[J]. 化工学报, 2025, 76(5): 2042-2054. |

| [5] | 张越, 刘佳鑫, 马敬, 刘毅. 金属有机骨架膜应用于海水提铀研究进展[J]. 化工学报, 2025, 76(5): 2087-2100. |

| [6] | 宁丹东, 李建惠, 陈杨, 李晋平, 李立博. MIL-101(Cr)批量化生产中的絮凝工艺研究[J]. 化工学报, 2025, 76(5): 2327-2336. |

| [7] | 李远华, 凌思棋, 封科军, 冯颖, 郭于菁, 谢世桓. 基于cMOFs的固定化脂肪酶微反应器的构筑及其扁桃酸催化应用[J]. 化工学报, 2025, 76(3): 1170-1179. |

| [8] | 周印洁, 吉思蓓, 何松阳, 吉旭, 贺革. 机器学习辅助高通量筛选金属有机骨架用于富碳天然气中分离CO2[J]. 化工学报, 2025, 76(3): 1093-1101. |

| [9] | 代艳辉, 熊启钊, 房强, 杨东晓, 王毅, 陈杨, 李晋平, 李立博. 原位蒸汽辅助法用于一步制备多级孔Cu-BTC[J]. 化工学报, 2024, 75(9): 3329-3337. |

| [10] | 张文焱, 刘浩, 宋伟龙, 赵频, 王新华. 不同粒径UiO-66混掺改性TFN-FO膜的构建及性能评价[J]. 化工学报, 2024, 75(5): 1920-1928. |

| [11] | 莫滨宇, 张雅馨, 刘国振, 刘公平, 金万勤. 面向一/二价离子分离的金属有机骨架膜研究进展[J]. 化工学报, 2024, 75(4): 1183-1197. |

| [12] | 仪显亨, 周骛, 蔡小舒, 蔡天意. 光纤后向动态光散射测量纳米颗粒的浓度适用范围研究[J]. 化工学报, 2023, 74(8): 3320-3328. |

| [13] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [14] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [15] | 刘锋, 汪全, 吴攀宇, 魏国, 何祥. 内相粒径对现场混装乳化炸药基质抗振动性能的影响[J]. 化工学报, 2022, 73(9): 4217-4225. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号