化工学报 ›› 2019, Vol. 70 ›› Issue (8): 3058-3070.DOI: 10.11949/0438-1157.20190184

收稿日期:2019-03-04

修回日期:2019-05-22

出版日期:2019-08-05

发布日期:2019-08-05

通讯作者:

彭旭东

作者简介:章聪(1995—),男,硕士研究生,<email>zc_derek@163.com</email>

基金资助:

Cong ZHANG( ),Jinbo JIANG,Xudong PENG(

),Jinbo JIANG,Xudong PENG( ),Wenjing ZHAO,Jiyun LI

),Wenjing ZHAO,Jiyun LI

Received:2019-03-04

Revised:2019-05-22

Online:2019-08-05

Published:2019-08-05

Contact:

Xudong PENG

摘要:

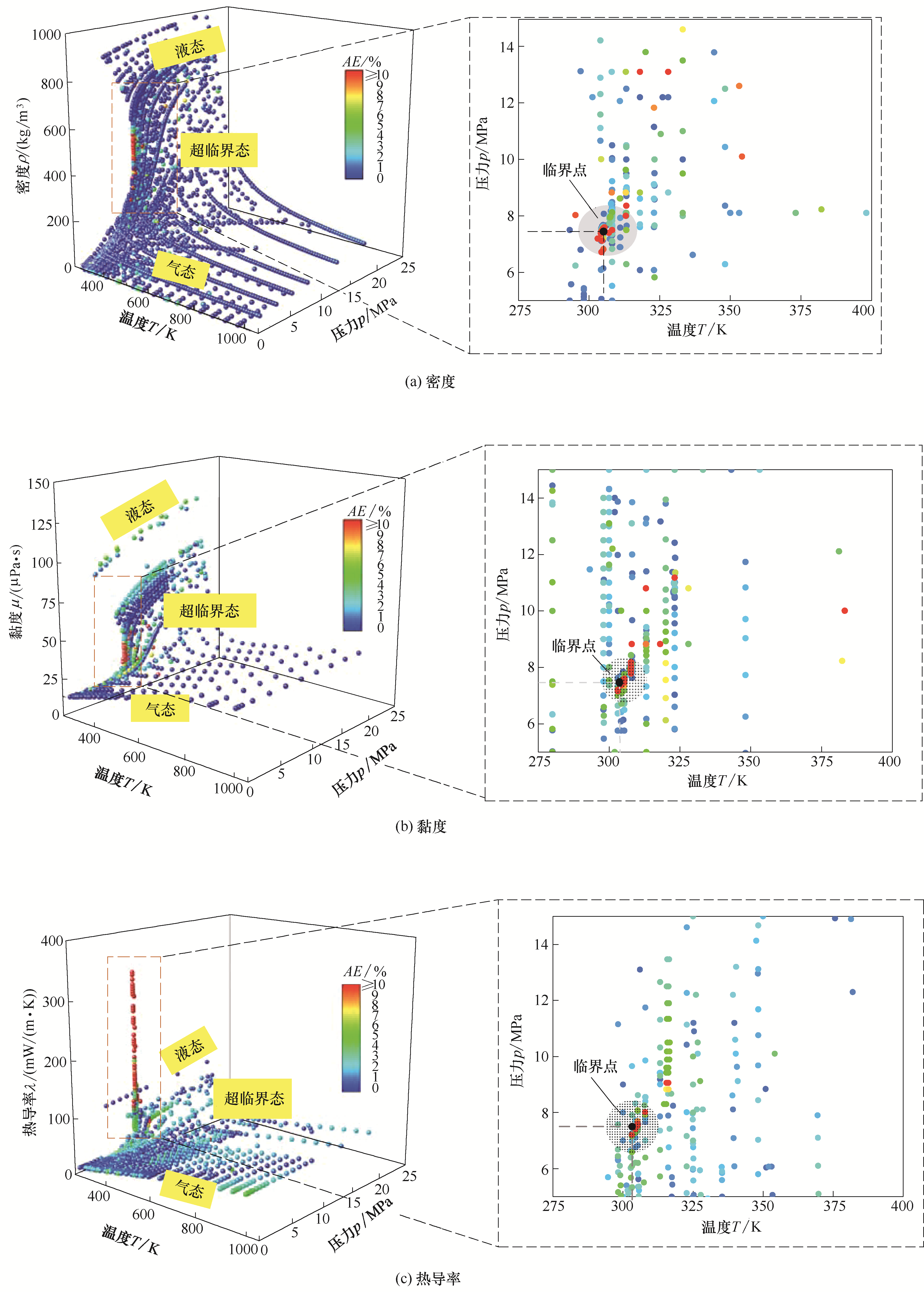

超临界二氧化碳(SCO2)布雷顿循环系统是未来极具潜力的发电能量转换系统,CO2物性表征模型对布雷顿循环系统中动力设备转轴密封和轴承性能的预测精度影响显著。在总结权威文献中不同温度和压力下CO2物性实验测试数据的基础上,对比分析了经典物性查询软件REFPROP软件中CO2密度、黏度和热导率预测模型的预测精度,获得了预测精度最高的物性预测模型及对应临界点附近误差较大的区域,采用人工神经网络算法获得了近临界区预测精度更高的CO2物性预测模型。结果表明:REFPROP软件中的FEK模型、VS1模型和TC1模型分别对CO2的密度、黏度和热导率具有最高的预测精度,不过其在近临界区的物性预测最大和平均误差仍分别达到40%和8%以上,利用神经网络算法所获得的CO2物性预测模型可使近临界点区的物性预测最大和平均误差分别降至30%和4%以下。

中图分类号:

章聪, 江锦波, 彭旭东, 赵文静, 李纪云. 近临界区CO2物性预测模型对比与修正[J]. 化工学报, 2019, 70(8): 3058-3070.

Cong ZHANG, Jinbo JIANG, Xudong PENG, Wenjing ZHAO, Jiyun LI. Comparison and correction of CO2 properties model in critical region[J]. CIESC Journal, 2019, 70(8): 3058-3070.

| CO2 物性 | REFPROP模型 | 最大适用压力/MPa | 温度适用范围/K | 近临界区域相关系数R | 提出年份 |

|---|---|---|---|---|---|

密度 | FEQ | 800.0 | 216.59~2000.0 | 0.95536 | 1996 |

| FEK | 800.0 | 216.59~1100.0 | 0.95721 | 2007 | |

| BWR | 40.0 | 216.58~440.1 | 0.94394 | 1987 | |

| FES | 100.0 | 216.59~600.0 | 0.95490 | 2003 | |

黏度 | VS1 | 800.0 | 216.59~2000.0 | 0.94871 | 1998 |

| VS4 | 100.0 | 216.58~1000.0 | 0.94825 | 2006 | |

| 热导率 | TC1 | 800.0 | 216.58~2000.0 | 0.50567 | 1990 |

表1 REFPROP软件CO2物性模型对比

Table 1 Comparison of CO2 physical properties models in REFPROP

| CO2 物性 | REFPROP模型 | 最大适用压力/MPa | 温度适用范围/K | 近临界区域相关系数R | 提出年份 |

|---|---|---|---|---|---|

密度 | FEQ | 800.0 | 216.59~2000.0 | 0.95536 | 1996 |

| FEK | 800.0 | 216.59~1100.0 | 0.95721 | 2007 | |

| BWR | 40.0 | 216.58~440.1 | 0.94394 | 1987 | |

| FES | 100.0 | 216.59~600.0 | 0.95490 | 2003 | |

黏度 | VS1 | 800.0 | 216.59~2000.0 | 0.94871 | 1998 |

| VS4 | 100.0 | 216.58~1000.0 | 0.94825 | 2006 | |

| 热导率 | TC1 | 800.0 | 216.58~2000.0 | 0.50567 | 1990 |

图5 不同温度和压力下的CO2物性实测值及模型计算值相对误差

Fig.5 Experimental physical properties and corresponding relative error of calculated values of CO2 at different p and T

| T /K | p/kPa | ρe/ (kg/m3) | ρc/ (kg/m3) | AE/% | T/K | p/kPa | ρe/ (kg/m3) | ρc/ (kg/m3) | AE/% |

|---|---|---|---|---|---|---|---|---|---|

| 304.25 | 7408.60 | 379.91 | 544.55 | 43.34 | 304.25 | 7420.30 | 442.18 | 562.96 | 27.32 |

| 304.25 | 7405.30 | 374.69 | 535.69 | 42.97 | 304.65 | 7483.50 | 424.85 | 536.29 | 26.23 |

| 304.25 | 7412.30 | 388.11 | 551.81 | 42.18 | 304.23 | 7366.33 | 482.80 | 358.89 | 25.66 |

| 304.25 | 7416.00 | 402.05 | 557.52 | 38.67 | 304.27 | 7386.59 | 502.70 | 379.48 | 24.51 |

| 304.35 | 7428.20 | 392.50 | 544.01 | 38.60 | 304.26 | 7386.59 | 502.70 | 382.30 | 23.95 |

| 304.25 | 7417.70 | 411.13 | 559.79 | 36.16 | 308.15 | 7500.00 | 358.00 | 273.00 | 23.74 |

| 304.35 | 7418.70 | 373.83 | 508.89 | 36.13 | 304.95 | 7529.50 | 416.73 | 509.42 | 22.24 |

| 304.35 | 7432.70 | 407.35 | 552.04 | 35.52 | 304.31 | 7386.59 | 469.70 | 370.38 | 21.15 |

| 304.25 | 7419.00 | 416.37 | 561.42 | 34.84 | 304.95 | 7533.70 | 429.97 | 520.18 | 20.98 |

| 304.25 | 7419.30 | 422.83 | 561.78 | 32.86 | 304.95 | 7537.90 | 444.12 | 528.84 | 19.08 |

| 304.20 | 7366.33 | 532.90 | 363.52 | 31.78 | 304.33 | 7406.86 | 508.40 | 414.00 | 18.57 |

| 304.24 | 7376.46 | 532.90 | 369.73 | 30.62 | 304.37 | 7406.86 | 479.26 | 392.21 | 18.16 |

| 304.65 | 7475.30 | 398.34 | 514.33 | 29.12 | 304.95 | 7540.20 | 455.09 | 532.91 | 17.10 |

| 304.65 | 7480.00 | 412.43 | 528.54 | 28.15 | 304.16 | 7380.62 | 504.68 | 423.03 | 16.18 |

| 307.00 | 7399.08 | 213.93 | 273.86 | 28.02 | 304.95 | 7513.10 | 385.19 | 446.49 | 15.91 |

表2 近临界区CO2密度计算值误差较大的工况点及对应密度值

Table 2 Condition point and corresponding density values with large relative error of CO2 at near critical point

| T /K | p/kPa | ρe/ (kg/m3) | ρc/ (kg/m3) | AE/% | T/K | p/kPa | ρe/ (kg/m3) | ρc/ (kg/m3) | AE/% |

|---|---|---|---|---|---|---|---|---|---|

| 304.25 | 7408.60 | 379.91 | 544.55 | 43.34 | 304.25 | 7420.30 | 442.18 | 562.96 | 27.32 |

| 304.25 | 7405.30 | 374.69 | 535.69 | 42.97 | 304.65 | 7483.50 | 424.85 | 536.29 | 26.23 |

| 304.25 | 7412.30 | 388.11 | 551.81 | 42.18 | 304.23 | 7366.33 | 482.80 | 358.89 | 25.66 |

| 304.25 | 7416.00 | 402.05 | 557.52 | 38.67 | 304.27 | 7386.59 | 502.70 | 379.48 | 24.51 |

| 304.35 | 7428.20 | 392.50 | 544.01 | 38.60 | 304.26 | 7386.59 | 502.70 | 382.30 | 23.95 |

| 304.25 | 7417.70 | 411.13 | 559.79 | 36.16 | 308.15 | 7500.00 | 358.00 | 273.00 | 23.74 |

| 304.35 | 7418.70 | 373.83 | 508.89 | 36.13 | 304.95 | 7529.50 | 416.73 | 509.42 | 22.24 |

| 304.35 | 7432.70 | 407.35 | 552.04 | 35.52 | 304.31 | 7386.59 | 469.70 | 370.38 | 21.15 |

| 304.25 | 7419.00 | 416.37 | 561.42 | 34.84 | 304.95 | 7533.70 | 429.97 | 520.18 | 20.98 |

| 304.25 | 7419.30 | 422.83 | 561.78 | 32.86 | 304.95 | 7537.90 | 444.12 | 528.84 | 19.08 |

| 304.20 | 7366.33 | 532.90 | 363.52 | 31.78 | 304.33 | 7406.86 | 508.40 | 414.00 | 18.57 |

| 304.24 | 7376.46 | 532.90 | 369.73 | 30.62 | 304.37 | 7406.86 | 479.26 | 392.21 | 18.16 |

| 304.65 | 7475.30 | 398.34 | 514.33 | 29.12 | 304.95 | 7540.20 | 455.09 | 532.91 | 17.10 |

| 304.65 | 7480.00 | 412.43 | 528.54 | 28.15 | 304.16 | 7380.62 | 504.68 | 423.03 | 16.18 |

| 307.00 | 7399.08 | 213.93 | 273.86 | 28.02 | 304.95 | 7513.10 | 385.19 | 446.49 | 15.91 |

| T/K | p/kPa | μe/(μPa·s) | μc/(μPa·s) | AE/% | T/K | p/kPa | μe/(μPa·s) | μc/(μPa·s) | AE/% |

|---|---|---|---|---|---|---|---|---|---|

| 304.25 | 7408.60 | 27.55 | 39.65 | 43.90 | 304.25 | 7420.30 | 32.93 | 41.14 | 24.91 |

| 304.25 | 7412.30 | 28.12 | 40.22 | 43.02 | 304.65 | 7485.70 | 31.87 | 39.30 | 23.34 |

| 304.35 | 7428.20 | 28.40 | 39.61 | 39.47 | 304.37 | 7406.86 | 36.04 | 27.67 | 23.22 |

| 304.35 | 7418.70 | 27.13 | 37.05 | 36.57 | 304.95 | 7529.50 | 30.00 | 36.86 | 22.89 |

| 304.35 | 7432.70 | 29.61 | 40.24 | 35.89 | 304.65 | 7467.40 | 27.61 | 33.76 | 22.28 |

| 304.20 | 7366.33 | 40.03 | 26.09 | 34.82 | 307.75 | 7995.56 | 42.30 | 33.09 | 21.77 |

| 304.25 | 7419.00 | 30.61 | 41.01 | 33.96 | 304.95 | 7533.70 | 30.99 | 37.69 | 21.64 |

| 305.35 | 7558.85 | 42.50 | 28.57 | 32.79 | 304.95 | 7522.50 | 28.87 | 34.87 | 20.79 |

| 304.25 | 7419.30 | 31.11 | 41.04 | 31.92 | 304.95 | 7537.90 | 32.10 | 38.36 | 19.49 |

| 304.65 | 7475.30 | 28.72 | 37.35 | 30.03 | 304.25 | 7420.70 | 34.48 | 41.18 | 19.44 |

| 304.23 | 7366.33 | 36.74 | 25.85 | 29.63 | 307.75 | 8058.38 | 45.40 | 36.68 | 19.21 |

| 304.65 | 7480.00 | 29.80 | 38.41 | 28.90 | 304.65 | 7489.40 | 33.55 | 39.76 | 18.53 |

| 304.25 | 7419.80 | 32.00 | 41.09 | 28.40 | 304.95 | 7540.20 | 32.89 | 38.67 | 17.58 |

| 304.35 | 7436.20 | 31.87 | 40.65 | 27.52 | 305.35 | 7535.54 | 32.30 | 26.86 | 16.83 |

| 304.65 | 7483.5 | 30.852 | 38.989 | 26.37 | 304.25 | 7420.80 | 35.46 | 41.19 | 16.15 |

表3 近临界区CO2黏度计算值误差较大的工况点及对应黏度值

Table 3 Condition point and corresponding viscosity values with large relative error of CO2 at near critical point

| T/K | p/kPa | μe/(μPa·s) | μc/(μPa·s) | AE/% | T/K | p/kPa | μe/(μPa·s) | μc/(μPa·s) | AE/% |

|---|---|---|---|---|---|---|---|---|---|

| 304.25 | 7408.60 | 27.55 | 39.65 | 43.90 | 304.25 | 7420.30 | 32.93 | 41.14 | 24.91 |

| 304.25 | 7412.30 | 28.12 | 40.22 | 43.02 | 304.65 | 7485.70 | 31.87 | 39.30 | 23.34 |

| 304.35 | 7428.20 | 28.40 | 39.61 | 39.47 | 304.37 | 7406.86 | 36.04 | 27.67 | 23.22 |

| 304.35 | 7418.70 | 27.13 | 37.05 | 36.57 | 304.95 | 7529.50 | 30.00 | 36.86 | 22.89 |

| 304.35 | 7432.70 | 29.61 | 40.24 | 35.89 | 304.65 | 7467.40 | 27.61 | 33.76 | 22.28 |

| 304.20 | 7366.33 | 40.03 | 26.09 | 34.82 | 307.75 | 7995.56 | 42.30 | 33.09 | 21.77 |

| 304.25 | 7419.00 | 30.61 | 41.01 | 33.96 | 304.95 | 7533.70 | 30.99 | 37.69 | 21.64 |

| 305.35 | 7558.85 | 42.50 | 28.57 | 32.79 | 304.95 | 7522.50 | 28.87 | 34.87 | 20.79 |

| 304.25 | 7419.30 | 31.11 | 41.04 | 31.92 | 304.95 | 7537.90 | 32.10 | 38.36 | 19.49 |

| 304.65 | 7475.30 | 28.72 | 37.35 | 30.03 | 304.25 | 7420.70 | 34.48 | 41.18 | 19.44 |

| 304.23 | 7366.33 | 36.74 | 25.85 | 29.63 | 307.75 | 8058.38 | 45.40 | 36.68 | 19.21 |

| 304.65 | 7480.00 | 29.80 | 38.41 | 28.90 | 304.65 | 7489.40 | 33.55 | 39.76 | 18.53 |

| 304.25 | 7419.80 | 32.00 | 41.09 | 28.40 | 304.95 | 7540.20 | 32.89 | 38.67 | 17.58 |

| 304.35 | 7436.20 | 31.87 | 40.65 | 27.52 | 305.35 | 7535.54 | 32.30 | 26.86 | 16.83 |

| 304.65 | 7483.5 | 30.852 | 38.989 | 26.37 | 304.25 | 7420.80 | 35.46 | 41.19 | 16.15 |

| T/K | p/kPa | λe/ (mW/(m·K)) | λc/ (mW/(m·K)) | AE/% | T/K | p /kPa | λe/ (mW/(m·K)) | λc/ (mW/(m·K)) | AE/% |

|---|---|---|---|---|---|---|---|---|---|

| 304.39 | 7421.55 | 125.16 | 240.43 | 92.10 | 304.35 | 7412.23 | 146.09 | 208.28 | 42.57 |

| 304.36 | 7416.38 | 133.53 | 253.66 | 89.97 | 304.37 | 7409.29 | 226.04 | 134.82 | 40.35 |

| 304.38 | 7421.45 | 115.95 | 207.84 | 79.25 | 304.35 | 7405.95 | 217.66 | 132.62 | 39.07 |

| 304.40 | 7421.85 | 136.88 | 244.85 | 78.88 | 304.36 | 7406.96 | 213.48 | 132.09 | 38.12 |

| 304.35 | 7407.36 | 334.87 | 141.32 | 57.80 | 304.35 | 7409.90 | 246.97 | 157.52 | 36.22 |

| 304.35 | 7407.26 | 322.31 | 141.71 | 56.03 | 304.35 | 7409.70 | 246.97 | 158.79 | 35.70 |

| 304.35 | 7407.67 | 322.31 | 143.31 | 55.54 | 304.41 | 7421.85 | 153.62 | 203.36 | 32.38 |

| 304.35 | 7406.96 | 301.38 | 137.92 | 54.24 | 304.37 | 7412.03 | 209.29 | 152.93 | 26.93 |

| 304.35 | 7407.87 | 313.94 | 144.70 | 53.91 | 304.36 | 7407.16 | 171.62 | 128.06 | 25.38 |

| 304.37 | 7411.32 | 309.75 | 147.24 | 52.47 | 304.37 | 7408.07 | 166.60 | 128.51 | 22.86 |

| 304.35 | 7408.28 | 301.38 | 146.44 | 51.41 | 305.28 | 7548.41 | 134.37 | 107.48 | 20.01 |

| 304.35 | 7408.18 | 297.20 | 145.70 | 50.98 | 304.38 | 7413.95 | 197.99 | 158.64 | 19.88 |

| 304.35 | 7412.03 | 146.92 | 217.77 | 48.22 | 304.37 | 7407.06 | 149.02 | 123.47 | 17.14 |

| 305.20 | 7547.70 | 238.59 | 127.20 | 46.69 | 304.37 | 7406.86 | 141.90 | 122.78 | 13.47 |

| 304.35 | 7408.88 | 276.27 | 152.63 | 44.75 | 305.29 | 7588.43 | 109.67 | 120.69 | 10.05 |

表4 近临界区CO2热导率计算值误差较大的工况点及对应热导率值

Table 4 Condition point and corresponding thermal conductivity values with large relative error of CO2

| T/K | p/kPa | λe/ (mW/(m·K)) | λc/ (mW/(m·K)) | AE/% | T/K | p /kPa | λe/ (mW/(m·K)) | λc/ (mW/(m·K)) | AE/% |

|---|---|---|---|---|---|---|---|---|---|

| 304.39 | 7421.55 | 125.16 | 240.43 | 92.10 | 304.35 | 7412.23 | 146.09 | 208.28 | 42.57 |

| 304.36 | 7416.38 | 133.53 | 253.66 | 89.97 | 304.37 | 7409.29 | 226.04 | 134.82 | 40.35 |

| 304.38 | 7421.45 | 115.95 | 207.84 | 79.25 | 304.35 | 7405.95 | 217.66 | 132.62 | 39.07 |

| 304.40 | 7421.85 | 136.88 | 244.85 | 78.88 | 304.36 | 7406.96 | 213.48 | 132.09 | 38.12 |

| 304.35 | 7407.36 | 334.87 | 141.32 | 57.80 | 304.35 | 7409.90 | 246.97 | 157.52 | 36.22 |

| 304.35 | 7407.26 | 322.31 | 141.71 | 56.03 | 304.35 | 7409.70 | 246.97 | 158.79 | 35.70 |

| 304.35 | 7407.67 | 322.31 | 143.31 | 55.54 | 304.41 | 7421.85 | 153.62 | 203.36 | 32.38 |

| 304.35 | 7406.96 | 301.38 | 137.92 | 54.24 | 304.37 | 7412.03 | 209.29 | 152.93 | 26.93 |

| 304.35 | 7407.87 | 313.94 | 144.70 | 53.91 | 304.36 | 7407.16 | 171.62 | 128.06 | 25.38 |

| 304.37 | 7411.32 | 309.75 | 147.24 | 52.47 | 304.37 | 7408.07 | 166.60 | 128.51 | 22.86 |

| 304.35 | 7408.28 | 301.38 | 146.44 | 51.41 | 305.28 | 7548.41 | 134.37 | 107.48 | 20.01 |

| 304.35 | 7408.18 | 297.20 | 145.70 | 50.98 | 304.38 | 7413.95 | 197.99 | 158.64 | 19.88 |

| 304.35 | 7412.03 | 146.92 | 217.77 | 48.22 | 304.37 | 7407.06 | 149.02 | 123.47 | 17.14 |

| 305.20 | 7547.70 | 238.59 | 127.20 | 46.69 | 304.37 | 7406.86 | 141.90 | 122.78 | 13.47 |

| 304.35 | 7408.88 | 276.27 | 152.63 | 44.75 | 305.29 | 7588.43 | 109.67 | 120.69 | 10.05 |

| CO2物性模型 | 隐藏层传递函数 g(p*, T*) | 输出层传递函数 f(p*, T*) | 隐藏层神经元个数m |

|---|---|---|---|

| 密度预测模型 | logsig | tansig | 9 |

| 黏度预测模型 | tansig | tansig | 9 |

| 热导率预测模型 | logsig | purelin | 6 |

表6 CO2拟合物性模型的传递函数及神经元个数

Table 6 Transfer function and neurons number of CO2 fitted physical property models

| CO2物性模型 | 隐藏层传递函数 g(p*, T*) | 输出层传递函数 f(p*, T*) | 隐藏层神经元个数m |

|---|---|---|---|

| 密度预测模型 | logsig | tansig | 9 |

| 黏度预测模型 | tansig | tansig | 9 |

| 热导率预测模型 | logsig | purelin | 6 |

| CO2 物性 | i | |||||

|---|---|---|---|---|---|---|

密度 | 1 | -572.529 | 214.906 | -79.968 | 0.966 | -13.351 |

| 2 | -2.324 | 2.755 | 2.967 | -10.763 | — | |

| 3 | 60.386 | -158.569 | -77.113 | 23.150 | — | |

| 4 | -135.533 | 25.237 | -30.575 | -0.929 | — | |

| 5 | -39.418 | -419.105 | -184.927 | -0.602 | — | |

| 6 | -15.035 | 32.165 | 11.590 | -0.942 | — | |

| 7 | -66.029 | 174.221 | 84.738 | 22.221 | — | |

| 8 | -332.675 | 239.779 | -7.965 | -0.446 | — | |

| 9 | 30.406 | 27.444 | 43.399 | 1.326 | — | |

黏度 | 1 | -62.456 | 18.295 | -8.561 | 14.012 | 0.044 |

| 2 | 2.366 | 22.768 | 4.137 | -9.818 | — | |

| 3 | 2.893 | 88.865 | 21.973 | 0.466 | — | |

| 4 | -45.189 | 73.230 | 22.725 | 0.532 | — | |

| 5 | 80.073 | -108.726 | -34.601 | 0.382 | — | |

| 6 | 2.669 | 25.374 | 4.582 | 9.468 | — | |

| 7 | 1.192 | -1.270 | -0.318 | 1.513 | — | |

| 8 | -68.184 | 19.930 | -9.392 | -13.906 | — | |

| 9 | 11.116 | -19.621 | -5.947 | 0.714 | — | |

热导率 | 1 | 48.443 | 57.263 | -83.375 | -4.447 | -1.653 |

| 2 | 59.400 | 40.667 | -77.210 | 4.419 | — | |

| 3 | 176.335 | -142.068 | 1.555 | -26.882 | — | |

| 4 | 177.240 | -143.144 | 1.828 | 27.048 | — | |

| 5 | 7.515 | -3.207 | 12.705 | 0.797 | — | |

| 6 | 93.796 | -95.549 | -2.409 | -0.232 | — |

表7 基于神经网络的近临界区CO2拟合物性模型系数

Table 7 Fitted physical property model coefficients of CO2 at critical point based on ANN

| CO2 物性 | i | |||||

|---|---|---|---|---|---|---|

密度 | 1 | -572.529 | 214.906 | -79.968 | 0.966 | -13.351 |

| 2 | -2.324 | 2.755 | 2.967 | -10.763 | — | |

| 3 | 60.386 | -158.569 | -77.113 | 23.150 | — | |

| 4 | -135.533 | 25.237 | -30.575 | -0.929 | — | |

| 5 | -39.418 | -419.105 | -184.927 | -0.602 | — | |

| 6 | -15.035 | 32.165 | 11.590 | -0.942 | — | |

| 7 | -66.029 | 174.221 | 84.738 | 22.221 | — | |

| 8 | -332.675 | 239.779 | -7.965 | -0.446 | — | |

| 9 | 30.406 | 27.444 | 43.399 | 1.326 | — | |

黏度 | 1 | -62.456 | 18.295 | -8.561 | 14.012 | 0.044 |

| 2 | 2.366 | 22.768 | 4.137 | -9.818 | — | |

| 3 | 2.893 | 88.865 | 21.973 | 0.466 | — | |

| 4 | -45.189 | 73.230 | 22.725 | 0.532 | — | |

| 5 | 80.073 | -108.726 | -34.601 | 0.382 | — | |

| 6 | 2.669 | 25.374 | 4.582 | 9.468 | — | |

| 7 | 1.192 | -1.270 | -0.318 | 1.513 | — | |

| 8 | -68.184 | 19.930 | -9.392 | -13.906 | — | |

| 9 | 11.116 | -19.621 | -5.947 | 0.714 | — | |

热导率 | 1 | 48.443 | 57.263 | -83.375 | -4.447 | -1.653 |

| 2 | 59.400 | 40.667 | -77.210 | 4.419 | — | |

| 3 | 176.335 | -142.068 | 1.555 | -26.882 | — | |

| 4 | 177.240 | -143.144 | 1.828 | 27.048 | — | |

| 5 | 7.515 | -3.207 | 12.705 | 0.797 | — | |

| 6 | 93.796 | -95.549 | -2.409 | -0.232 | — |

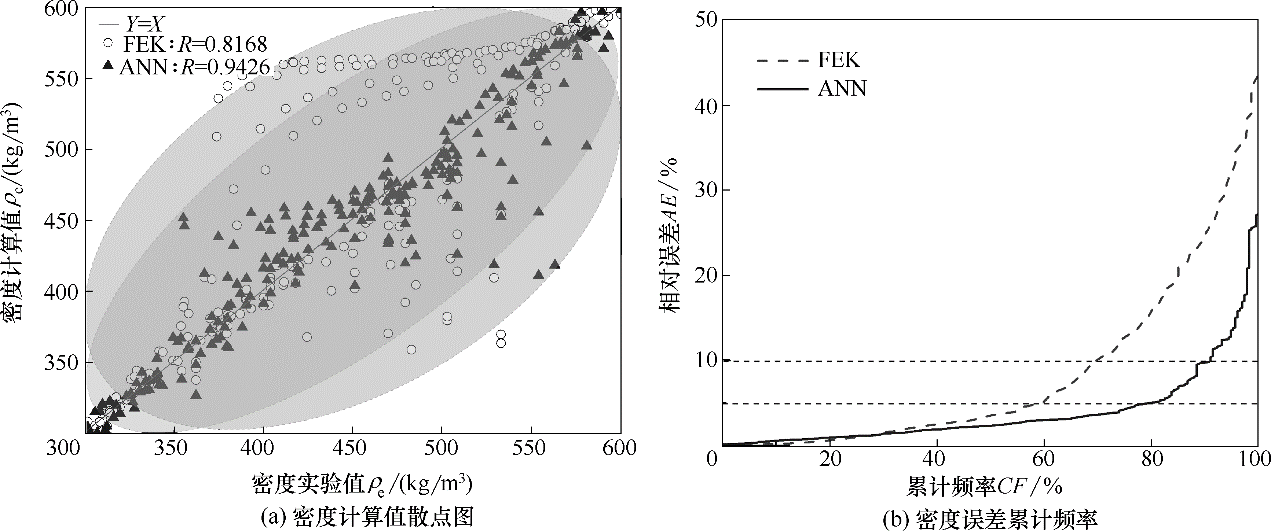

图7 人工神经网络拟合模型与REFPROP软件FEK模型密度计算值及相对误差

Fig.7 Density and corresponding relative error calculated by ANN fitted model and FEK model on REFPROP software

图8 人工神经网络拟合模型与REFPROP软件VS1模型黏度计算值及相对误差

Fig.8 Viscosity and corresponding relative error calculated by ANN fitted model and VS1 model on REFPROP software

图9 人工神经网络拟合模型与REFPROP软件TC1模型热导率计算值及相对误差

Fig.9 Thermal conductivity and corresponding relative error calculated by ANN fitted model and TC1 model on REFPROP software

| 物性 | 平均相对误差 AEav /% | 最大相对误差 AEmax /% | 相对误差10%内占比 /% | |||

|---|---|---|---|---|---|---|

| REFPROP | ANN | REFPROP | ANN | REFPROP | ANN | |

| 密度 | 8.32 | 3.84 | 43.34 | 27.19 | 69.79 | 91.06 |

| 黏度 | 9.60 | 3.86 | 43.90 | 29.09 | 65.09 | 91.51 |

| 热导率 | 26.52 | 3.61 | 92.10 | 22.14 | 34.41 | 93.55 |

表8 ANN拟合模型和REFPROP物性模型对应的物性计算值相对误差

Table 8 Relative error of calculated physical property values obtained by ANN fitted model and REFPROP software

| 物性 | 平均相对误差 AEav /% | 最大相对误差 AEmax /% | 相对误差10%内占比 /% | |||

|---|---|---|---|---|---|---|

| REFPROP | ANN | REFPROP | ANN | REFPROP | ANN | |

| 密度 | 8.32 | 3.84 | 43.34 | 27.19 | 69.79 | 91.06 |

| 黏度 | 9.60 | 3.86 | 43.90 | 29.09 | 65.09 | 91.51 |

| 热导率 | 26.52 | 3.61 | 92.10 | 22.14 | 34.41 | 93.55 |

| 1 | AhnY, BaeS J, KimM, et al. Review of supercritical CO2 power cycle technology and current status of research and development [J]. Nuclear Engineering & Technology, 2015, 47(6): 647-661. |

| 2 | 宋鹏云, 张帅, 许恒杰, 等. 同时考虑实际气体效应和滑移流效应螺旋槽干气密封性能分析[J]. 化工学报, 2016, 67(4): 1405-1415. |

| SongP Y, ZhangS, XuH J, et al. Analysis of performance of spiral groove dry gas seal considered effects of both real gas and slip flow[J]. CIESC Journal, 2016, 67(4): 1405-1415. | |

| 3 | 许恒杰, 宋鹏云, 毛文元, 等. 层流状态下高压高转速二氧化碳干气密封的惯性效应分析[J].化工学报, 2018, 69(10): 4311-4323. |

| XuH J, SongP Y, MaoW Y, et al. Analysis on inertia effect of carbon dioxide dry gas seal at high speed and pressure under laminar condition[J]. CIESC Journal, 2018, 69(10): 4311-4323. | |

| 4 | DuQ W, GaoK K, ZhangD, et al. Effects of grooved ring rotation and working fluid on the performance of dry gas seal[J]. International Journal of Heat and Mass Transfer, 2018, 126: 1323-1332. |

| 5 | DoustiS, AllaireP. A compressible hydrodynamic of journal bearings lubricated with supercritical carbon dioxide [C]//The 5th International Symposium - Supercritical CO2 Power Cycles. San Antonio, Texas, 2016. |

| 6 | WangZ, SunB, YanL. Improved density correlation for supercritical CO2 [J]. Chemical Engineering & Technology, 2015, 38(1): 75-84. |

| 7 | FenghourA, WakehamW A, VesovicV. The viscosity of carbon dioxide[J]. Journal of Physical and Chemical Reference Data, 1998, 27(1): 31-44. |

| 8 | 温建全. 超临界二氧化碳介质箔片轴承弹流耦合研究[D]. 哈尔滨: 哈尔滨工业大学, 2017. |

| WenJ Q. Theoretical study on characteristics of compliant foil bearings lubricated with supercritical carbon dioxide[D]. Harbin: Harbin Institute of Technology, 2017. | |

| 9 | ZakariyaM F, JahnI H J. Performance of supercritical CO2 dry gas seals near the critical point[C]//ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition. American Society of Mechanical Engineers, 2016:V009T36A007-V009T36A007. |

| 10 | FairuzZ M, JahnI. The influence of real gas effects on the performance of supercritical CO2 dry gas seals[J]. Tribology International, 2016, 102: 333-347. |

| 11 | HekayatiJ, RoostaA, JavanmardiJ. Volumetric properties of supercritical carbon dioxide from volume-translated and modified Peng-Robinson equations of state[J]. Korean Journal of Chemical Engineering, 2016, 33(11): 3231-3244. |

| 12 | BahadoriA, VuthaluruH B. Predictive tool for an accurate estimation of carbon dioxide transport properties[J]. International Journal of Greenhouse Gas Control, 2010, 4(3): 532-536. |

| 13 | OuyangL B. New correlations for predicting the thermodynamic properties of supercritical carbon dioxide[J]. Open Petroleum Engineering Journal, 2012, 5: 42-52. |

| 14 | HeidaryanE, JarrahianA. Modified Redlich-Kwong equation of state for supercritical carbon dioxide[J]. Journal of Supercritical Fluids, 2013, 81: 92-98. |

| 15 | 原华山, 银建中, 丁信伟.人工神经网络技术在超临界流体密度预测中的应用[J].计算机与应用化学, 2003, (6): 848-850. |

| YuanH S, YinJ Z, DingX W. Artificial neural network application to the density calculations for supercritical fluids[J]. Computers and Applied Chemistry, 2003, (6): 848-850. | |

| 16 | 任国宾, 王静康, 尹秋响, 等.人工神经网络在半水盐酸帕罗西汀溶解度预测中的应用[J]. 化工学报, 2006, 57(4): 853-860. |

| RenG B, WangJ K, YinQ X, et al. Artificial neural network approach to predict solubility of paroxetine hydrochloride hemihydrate in various solvents[J]. Journal of Chemical Industry and Engineering (China), 2006, 57(4): 853-860. | |

| 17 | 贺益君, 高华, 陈钟秀. 基于基团贡献神经网络集成法估算有机物常压凝固点[J]. 化工学报, 2004, 55(7): 1124-1130. |

| HeY J, GaoH, ChenZ X. Group-contribution based ensemble neural network approach to estimation of normal freezing point of organic compound[J]. Journal of Chemical Industry and Engineering (China), 2004, 55(7): 1124-1130. | |

| 18 | KennedyG C. Pressure-volume-temperature relations in CO2 at elevated temperatures and pressures[J]. American Journal of Science, 1954, 252(4): 225-241. |

| 19 | LangenfeldJ J, HawthorneS B, MillerD J, et al. Method for determining the density of pure and modified supercritical fluids[J]. Analytical Chemistry, 1992, 64(19): 2263-2266. |

| 20 | ZhangX, ZhangX, HanB, et al. Determination of constant volume heat capacity of mixed supercritical fluids and study on the intermolecular interaction[J]. Journal of Supercritical Fluids, 2002, 24(3): 193-201. |

| 21 | HojjatiM, YaminiY, KhajehM, et al. Solubility of some statin drugs in supercritical carbon dioxide and representing the solute solubility data with several density-based correlations[J]. The Journal of supercritical fluids, 2007, 41(2): 187-194. |

| 22 | KodamaD, SugiyamaK, OnoT, et al. Volumetric properties of carbon dioxide + isopropyl ethanoate mixtures at 308.15 and 313.15 K[J]. Journal of Supercritical Fluids, 2008, 47(2): 128-134. |

| 23 | TorresA, RomeroJ, MacanA, et al. Near critical and supercritical impregnation and kinetic release of thymol in LLDPE films used for food packaging[J]. The Journal of Supercritical Fluids, 2014, 85: 41-48. |

| 24 | ArausK A, CasadoV, del ValleJ M, et al. Cosolvent effect of ethanol on the solubility of lutein in supercritical carbon dioxide[J]. The Journal of Supercritical Fluids, 2019, 143: 205-210. |

| 25 | BazileJ P, NasriD, HamaniA W S, et al. Excess volume, isothermal compressibility, isentropic compressibility and speed of sound of carbon dioxide+ n-heptane binary mixture under pressure up to 70 MPa (Ⅰ): Experimental measurements[J]. The Journal of Supercritical Fluids, 2018, 140: 218-232. |

| 26 | IwasakiH, TakahashiM. Viscosity of carbon dioxide and ethane[J]. Journal of Chemical Physics, 1981, 74(3): 1930-1943. |

| 27 | VesovicV, WakehamW A, OlchowyG A, et al. The transport properties of carbon dioxide[J]. J. Phys.Chem. Ref. Data, 1990, 19(3): 763-808. |

| 28 | GulikP S V D . Viscosity of carbon dioxide in the liquid phase[J]. Physica A, 1997, 238(1/2/3/4): 81-112. |

| 29 | SuáreziglesiasO, MedinaI, PizarroC, et al. Diffusion of benzyl acetate, 2-phenylethyl acetate, 3-phenylpropyl acetate, and dibenzyl ether in mixtures of carbon dioxide and ethanol[J]. Industrial & Engineering Chemistry Research, 2007, 46(11): 3810-3819. |

| 30 | SihR, DehghaniF, FosterN R. Viscosity measurements on gas expanded liquid systems—methanol and carbon dioxide[J]. Journal of Supercritical Fluids, 2007, 41(1): 148-157. |

| 31 | LiuK, KiranE. Viscosity, density and excess volume of acetone + carbon dioxide mixtures at high pressures[J]. Industrial & Engineering Chemistry Research, 2007, 46(16): 5453-5462. |

| 32 | PensadoA S, PaduaA A H, ComuñasM J P, et al. Viscosity and density measurements for carbon dioxide pentaerythritol ester lubricant mixtures at low lubricant concentration[J]. The Journal of Supercritical Fluids, 2008, 44(2): 172-185. |

| 33 | PinhoB, StéphaneG, FrédéricB, et al. Simultaneous measurement of fluids density and viscosity using HP/HT capillary devices[J]. Journal of Supercritical Fluids, 2015, 105: 186-192. |

| 34 | MichelsA, SengersJ V, GulikP S V D. The thermal conductivity of carbon dioxide in the critical region (Ⅱ): Measurements and conclusions[J]. Physica, 1962, 28(12): 1216-1237. |

| 35 | LeneindreB, TufeuR, BuryP, et al. Thermal conductivity of carbon dioxide and steam in the supercritical region[J]. Berichte der Bunsengesellschaft für Physikalische Chemie, 1973, 77(4): 262-275. |

| 36 | YorizaneM, YoshimuraS, MasuokaH, et al. Thermal conductivity of pure gases at high pressures by use of a coaxial cylindrical cell[J]. Industrial & Engineering Chemistry Fundamentals, 1983, 22(4): 454-458. |

| 37 | ScottA C, JohnsA I, WatsonJ T R, et al. Thermal conductivity of carbon dioxide in the temperature range 300—348 K and pressures up to 25 MPa[J]. Journal of the Chemical Society, Faraday Transactions 1: Physical Chemistry in Condensed Phases, 1983, 79(3): 733-740. |

| 38 | MillatJ, MustafaM, RossM, et al. The thermal conductivity of argon, carbon dioxide and nitrous oxide[J]. Physica A Statistical Mechanics & Its Applications, 1987, 145(3): 461-497. |

| 39 | DohrnR, TreckmannR, HeinemannT. Vapor-phase thermal conductivity of 1, 1, 1, 2, 2-pentafluoropropane, 1, 1, 1, 3, 3-pentafluoropropane, 1, 1, 2, 2, 3-pentafluoropropane and carbon dioxide[J]. Fluid Phase Equilibria, 1999, 158: 1021-1028. |

| 40 | PátekJ, KlomfarJ, ČaplaL, et al. Thermal conductivity of carbon dioxide-methane mixtures at temperatures between 300 and 425 K and at pressures up to 12 MPa[J]. International Journal of Thermophysics, 2005, 26(3): 577-592. |

| 41 | ScalabrinG, MarchiP, FinezzoF, et al. A reference multiparameter thermal conductivity equation for carbon dioxide with an optimized functional form[J]. Journal of Physical & Chemical Reference Data, 2006, 35(4): 1549-1575. |

| 42 | 刘桂荣.统计学原理[M].上海: 华东理工大学出版社, 2010. |

| LiuG R. Principle of Statistics [M]. Shanghai: East China University of Science and Technology Press, 2010. | |

| 43 | HuangF H, LiM H, LeeL L, et al. An accurate equation of state for carbon dioxide[J]. Journal of Chemical Engineering of Japan, 1985, 18(6): 490-496. |

| 44 | 谭飞, 杨基础, 沈忠耀, 等. 超临界流体p-V-T方程的研究[J]. 化工学报, 1988, 39(6): 688-697. |

| TanF, YangJ C, ShenZ Y, et al. A study on the p-V-T equations of supercritical fluids[J]. Journal of Chemical Industry and Engineering (China), 1988, 39(6): 688-697. | |

| 45 | BahadoriA, VuthaluruH B, MokhatabS. New correlations predict aqueous solubility and density of carbon dioxide[J]. International Journal of Greenhouse Gas Control, 2009, 3(4): 474-480. |

| 46 | OuyangL B. New correlations for predicting the density and viscosity of supercritical carbon dioxide under conditions expected in carbon capture and sequestration operations[J]. The Open Petroleum Engineering Journal, 2011, 4(1): 13-21. |

| [1] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [4] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [5] | 尹刚, 李伊惠, 何飞, 曹文琦, 王民, 颜非亚, 向禹, 卢剑, 罗斌, 卢润廷. 基于KPCA和SVM的铝电解槽漏槽事故预警方法[J]. 化工学报, 2023, 74(8): 3419-3428. |

| [6] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [7] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [8] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [9] | 闫琳琦, 王振雷. 基于STA-BiLSTM-LightGBM组合模型的多步预测软测量建模[J]. 化工学报, 2023, 74(8): 3407-3418. |

| [10] | 徐野, 黄文君, 米俊芃, 申川川, 金建祥. 多源信息融合的离心式压缩机喘振诊断方法[J]. 化工学报, 2023, 74(7): 2979-2987. |

| [11] | 张琦钰, 高利军, 苏宇航, 马晓博, 王翊丞, 张亚婷, 胡超. 碳基催化材料在电化学还原二氧化碳中的研究进展[J]. 化工学报, 2023, 74(7): 2753-2772. |

| [12] | 高学金, 姚玉卓, 韩华云, 齐咏生. 基于注意力动态卷积自编码器的发酵过程故障监测[J]. 化工学报, 2023, 74(6): 2503-2521. |

| [13] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| [14] | 黄磊, 孔令学, 白进, 李怀柱, 郭振兴, 白宗庆, 李平, 李文. 油页岩添加对准东高钠煤灰熔融行为影响的研究[J]. 化工学报, 2023, 74(5): 2123-2135. |

| [15] | 蔺彩虹, 王丽, 吴瑜, 刘鹏, 杨江峰, 李晋平. 沸石中碱金属阳离子对CO2/N2O吸附分离性能的影响[J]. 化工学报, 2023, 74(5): 2013-2021. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号