化工学报 ›› 2020, Vol. 71 ›› Issue (4): 1520-1527.DOI: 10.11949/0438-1157.20191359

收稿日期:2019-11-11

修回日期:2020-01-06

出版日期:2020-04-05

发布日期:2020-04-05

通讯作者:

田凤国

作者简介:田凤国(1977—),男,博士,讲师,基金资助:

Fengguo TIAN( ),Tian ZHU,Dezheng KONG,Ming LEI

),Tian ZHU,Dezheng KONG,Ming LEI

Received:2019-11-11

Revised:2020-01-06

Online:2020-04-05

Published:2020-04-05

Contact:

Fengguo TIAN

摘要:

试验考察了非均匀布风配置对大颗粒在倾斜布风板流化床内停留时间分布的影响规律。结果表明,排渣管风速增加,E(t)曲线变平、波动增加,平均停留时间(MRT)呈指数增长;高风速区风速升高,先是分离过程占优,后转变为返混能力占优,MRT先减后增,存在一个适宜于分离的运行风速窗口;低风速区风速加快,混合能力增强,MRT变长。此外,还探讨了物性参数的影响。示踪物球形度越高、表面越光滑,越有利于分离,MRT变短。而尺寸的影响则与密度相关,对于重质示踪物,尺寸增加,MRT变短;而对于轻质示踪物,尺寸变大,MRT变长。试验所得停留时间分布(RTD)曲线形状、波峰时刻、峰值、波动等信息能够充分反映床内的颗粒流动与混合过程;对于内循环流动机理的探索、多组分流化床的工程应用具有一定的参考意义。

中图分类号:

田凤国, 朱田, 孔德正, 雷鸣. 非均匀布风流化床内大颗粒停留时间特性[J]. 化工学报, 2020, 71(4): 1520-1527.

Fengguo TIAN, Tian ZHU, Dezheng KONG, Ming LEI. Residence time of large particles in fluidized beds with non-uniform gas introducing[J]. CIESC Journal, 2020, 71(4): 1520-1527.

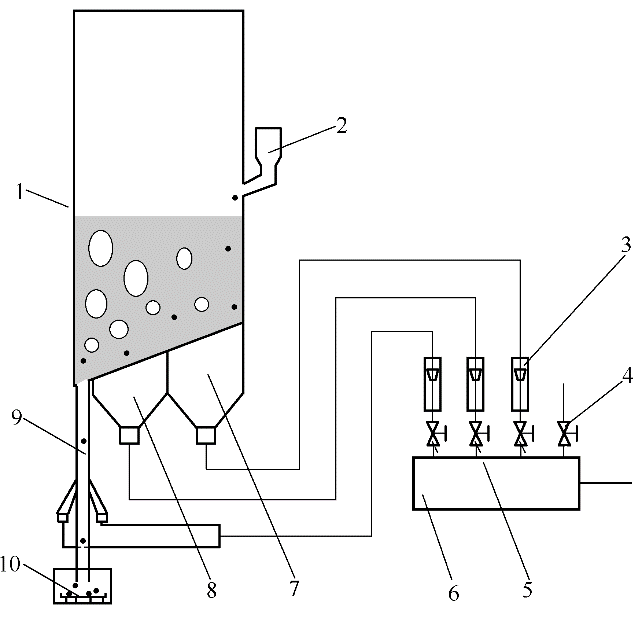

图1 内循环流化床RTD试验台

Fig.1 RTD test rig of internally circulating fluidized bed1—fluidized bed; 2—feeding port; 3—flowmeter; 4—bypass; 5—valve; 6—gas header; 7—wind box for low-gas-flow-rate-zone; 8—wind box for high-gas-flow-rate-zone; 9—discharging tube; 10—electronic balance

| 床料 | 平均粒径/mm | 堆积密度/ (kg/m3) | 真实密度/ (kg/m3) | 临界流化 风速/(m/s) |

|---|---|---|---|---|

| 树脂 | 0.65 | 740 | 1200 | 0.186 |

表1 床料物性参数

Table 1 Physical parameters of bed material

| 床料 | 平均粒径/mm | 堆积密度/ (kg/m3) | 真实密度/ (kg/m3) | 临界流化 风速/(m/s) |

|---|---|---|---|---|

| 树脂 | 0.65 | 740 | 1200 | 0.186 |

| 种类 | 颗粒密度/(kg/m3) | 颗粒尺寸/mm | 临界排出风速/(m/s) |

|---|---|---|---|

| 煤粒 | 1860 | 4.5 | 8.78 |

| 绿豆 | 1360 | 3.8 | 9.51 |

| 黄豆 | 1280 | 6.5 | 10.24 |

| 玻璃 | 2500 | 5×5×5 | 12.32 |

| 灰渣 | 2200 | 12 | 15.77 |

表2 大颗粒物性参数

Table 2 Physical parameters of large particles

| 种类 | 颗粒密度/(kg/m3) | 颗粒尺寸/mm | 临界排出风速/(m/s) |

|---|---|---|---|

| 煤粒 | 1860 | 4.5 | 8.78 |

| 绿豆 | 1360 | 3.8 | 9.51 |

| 黄豆 | 1280 | 6.5 | 10.24 |

| 玻璃 | 2500 | 5×5×5 | 12.32 |

| 灰渣 | 2200 | 12 | 15.77 |

| 9 | 刘典福, 孙雍春, 周超群. 非均匀布风内循环流化床中气泡特性的可视化研究[J]. 动力工程学报, 2019, 39(1): 1-6. |

| Liu D F, Sun Y C, Zhou C Q. Visualized research on bubbling characteristics in an internally circulating fluidized bed with uneven air distribution[J]. Journal of Chinese Society of Power Engineering, 2019, 39(1): 1-6. | |

| 10 | 田文栋, 魏小林, 黎军, 等. 非均匀和均匀布风流化床中颗粒的运动分析[J]. 工程热物理学报, 2001, 22(Suppl.): 160-163. |

| Tian W D, Wei X L, Li J, et al. An investigation of particle movement in fluidized bed with uneven and even arrangements of distribution air[J]. Journal of Engineering Thermophysics, 2001, 22(Suppl.): 160-163. | |

| 11 | Tian F G, Zhang M C, Fan H J, et al. Numerical study on microscopic mixing characteristics in fluidized beds via DEM[J]. Fuel Processing Technology, 2007, 88: 187-198. |

| 12 | 尹斌, 章明川, 唐春捷, 等. 内循环流化床气泡运动特性的可视化研究[J]. 动力工程, 2003, 23(1): 2143- 2145. |

| Yin B, Zhang M C, Tang C J, et al. Visualized research on movement characteristics of bubbles in an internally circulating fluidized bed[J]. Power Engineering, 2003, 23 (1): 2143-2145. | |

| 13 | Zhang Y, Jin B S, Zhong W Q.Experimental investigation on mixing and segregation behavior of biomass particle in fluidized bed[J]. Chemical Engineering and Processing: Process Intensification, 2009, 48(3): 745-754. |

| 14 | Khongprom P, Aimdilokwong A, Limtrakul S, et al. Axial gas and solids mixing in a down flow circulating fluidized bed reactor based on CFD simulation[J]. Chemical Engineering Science, 2012, 73: 8-19. |

| 15 | Lan X Y, Shi X G, Zhang Y H, et al. Solids back-mixing behavior and effect of the mesoscale structure in CFB risers[J]. Industry &. Engineering Chemistry Research, 2013, 52: 11888-11896. |

| 16 | Cano-Pleite E, Hernández-Jiménez F, Garcia-Gutierrez L M. Experimental study on the motion of solids around an isolated bubble rising in a vertically vibrated fluidized bed[J]. Chemical Engineering Journal, 2017, 330: 120-133. |

| 17 | Wiese J, Becker M, Yorath G, et al. An investigation into the relationship between particle shape and entrainment[J]. Minerals Engineering, 2015, 83: 211-216. |

| 1 | 李天涛, 郭飞强, 王岩, 等. 微型流化床内松木屑和煤泥等温混合热解特性[J]. 化工学报, 2017, 68(10): 3923- 3933. |

| Li T T, Guo F Q, Wang Y, et al. Characterization of co-pyrolysis of pine sawdust and coal slime under isothermal conditions in micro fluidized bed reactor[J]. CIESC Journal, 2017, 68(10): 3923-3933. | |

| 18 | Weinell C E, Dam-Johansen K, Johnsson J E. Single-particle behaviour in circulating fluidized beds[J]. Powder Technology, 1997, 92: 241-252. |

| 19 | Sanderson J, Rhodes M J. Hydrodynamic similarity of solids motion and mixing in bubbling fluidized beds[J]. AIChE Journal, 2003, 49: 2317-2327. |

| 20 | 李峰. 异形大颗粒在流化床内运动规律实验研究及数值模拟[D]. 重庆: 重庆大学, 2017. |

| Li F. Experimental and computational study on the motion behavior of special-shape large particles in a fluidized bed[D]. Chongqing: Chongqing University, 2017. | |

| 21 | 田凤国, 章明川, 范浩杰, 等. 内循环流化床大块物分布特性的试验研究[J]. 动力工程, 2005, 25(6): 68-72. |

| Tian F G, Zhang M C, Fan H J, et al. Distribution of lumped matter in internally circulating fluidized bed boilers[J]. Power Engineering, 2005, 25(6): 68-72. | |

| 22 | Yin B, Zhang M C, Tang C J, et al. Experimental research on residence time of bulk non-combustibility of waste in a cold position device of ICFB[J]. Power System Engineering, 2003, 19: 41-43. |

| 23 | Cai R R, Zhang Y G. Force characteristic of a large dense object in a fluidized bed equipped with an inclined air distributor[J]. Advanced Powder Technology, 2016, 27: 599-609. |

| 24 | Harris A T, Davidson J F, Thorpe R B. Particle residence time distributions in circulating fluidized beds[J]. Chemical Engineering Science, 2003, 58: 2181-2202. |

| 25 | Hua L N, Wang J W, Li J H. CFD simulation of solids residence time distribution in a CFB riser[J]. Chemical Engineering Science, 2014, 117: 264-282. |

| 26 | Shi X G, Sun R J, Lan X G, et al. CPFD simulation of solids residence time and back-mixing in CFB risers[J]. Powder Technology, 2015, 271: 16-25. |

| 27 | Gao Y, Muzzio F J, Ierapetritou M G. A review of the residence time distribution (RTD) applications in solid unit operations[J]. Powder Technology, 2012, 228: 416-423. |

| 28 | Chen J L, Keairns D L. Particle separation from a fluidized mixture — simulation of the Westinghouse coal gasification combustor/gasifier operation[J]. Industrial and Engineering Chemistry, Process Design and Development, 1978, 17: 135-141. |

| 29 | Hua L N, Wang J W. Residence time distribution of particles in circulating fluidized bed risers[J]. Chemical Engineering Science, 2018, 186: 168-190 |

| 30 | Nauman E B. Residence time theory[J]. Industry & Engineering Chemistry Research, 2008, 47: 3752-3766. |

| 31 | Rees A, Davidson J, Hayhurst A. The rise of a buoyant sphere in a gas fluidized bed[J]. Chemical Engineering Science, 2005, 60(4): 1143-1153. |

| 2 | Choi Y T, Kim S D. Bubble characteristics in an internally circulating fluidized bed[J]. Journal of Chemical Engineering of Japan, 1991, 24(2): 195-202. |

| 3 | Nienow A W, Rowe P N, Chiba T. Mixing and segregation of a small portion of large particles in gas fluidized beds of considerably smaller ones[J]. AIChE Symposium Series, 1978, 74: 45-53. |

| 4 | Liu X H, Xu G W, Gao S Q. Fluidization of extremely large and widely sized coal particles as well as its application in an advanced chain grate boiler[J]. Powder Technology, 2008, 188: 23-29. |

| 5 | 江国栋, 魏利平, 吴长松, 等. 隔板式内循环流化床颗粒循环速率实验与模型[J]. 化工学报, 2017, 68(9): 3427-3433. |

| Jiang G D, Wei L P, Wu C S, et al. Experimental and model studies on particle circulation rate in internal circulating clapboard-type fluidized bed[J]. CIESC Journal, 2017, 68(9): 3427-3433. | |

| 6 | Soria-Verdugo A, Garcia-Hernando N, Almendros-Lbanez J A, et al. Motion of a large object in a bubbling fluidized bed with a rotating distributor[J]. Chem. Eng. Process., 2011, 50: 859-868. |

| 7 | Cai R R, Zhang Y G, Li Q H, et al. Experimental characterizing the residence time distribution of large spherical objects immersed in a fluidized bed[J]. Powder Technology, 2014, 254: 22-29. |

| 8 | 尹斌, 章明川, 吴江, 等. L型定向风帽流化床中气-固流动的离散元素法模拟及可视化研究[J]. 中国电机工程学报, 2003, 23(7): 183-190. |

| Yin B, Zhang M C, Wu J, et al. Discrete particle simulation and visualized research of the gas-solid flow in fluidized beds with L-type wind cap[J]. Proceedings of the CSEE, 2003, 23(7): 183-190. |

| [1] | 仪显亨, 周骛, 蔡小舒, 蔡天意. 光纤后向动态光散射测量纳米颗粒的浓度适用范围研究[J]. 化工学报, 2023, 74(8): 3320-3328. |

| [2] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [3] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [4] | 李勇, 高佳琦, 杜超, 赵亚丽, 李伯琼, 申倩倩, 贾虎生, 薛晋波. Ni@C@TiO2核壳双重异质结的构筑及光热催化分解水产氢[J]. 化工学报, 2023, 74(6): 2458-2467. |

| [5] | 陈巨辉, 张谦, 舒崚峰, 李丹, 徐鑫, 刘晓刚, 赵晨希, 曹希峰. 基于DEM方法的旋转流化床纳米颗粒流动特性研究[J]. 化工学报, 2023, 74(6): 2374-2381. |

| [6] | 袁子涵, 王淑彦, 邵宝力, 谢磊, 陈曦, 马一玫. 基于幂律液固曳力模型流化床内湿颗粒流动特性的研究[J]. 化工学报, 2023, 74(5): 2000-2012. |

| [7] | 丁俊华, 俞树荣, 王世鹏, 洪先志, 包鑫, 丁雪兴. 多重效应下超高速干气密封流场模拟及密封性能试验[J]. 化工学报, 2023, 74(5): 2088-2099. |

| [8] | 王泽栋, 石至平, 刘丽艳. 考虑气泡非均匀耗散的矩形反应器声流场数值模拟及结构优化[J]. 化工学报, 2023, 74(5): 1965-1973. |

| [9] | 张浩, 徐惠斌, 高健, 刘帝宏, 周泽华. Geldart-D类湿颗粒倾斜落料行为及其强化[J]. 化工学报, 2023, 74(4): 1519-1527. |

| [10] | 曲国娟, 江涛, 刘涛, 马骧. 超分子策略调控金纳米团簇的发光行为[J]. 化工学报, 2023, 74(1): 397-407. |

| [11] | 黄心童, 耿宇昊, 刘恒源, 陈卓, 徐建鸿. 微流控制备新型功能纳米粒子研究进展[J]. 化工学报, 2023, 74(1): 355-364. |

| [12] | 张炜, 李昊阳, 徐纯刚, 李小森. 气体水合物生成微观机理及分析方法研究进展[J]. 化工学报, 2022, 73(9): 3815-3827. |

| [13] | 张鑫, 许蕊, 路馨语, 牛永安. SiO2@BiOCl-Bi24O31Cl10核壳微球的合成及光催化[J]. 化工学报, 2022, 73(8): 3636-3646. |

| [14] | 朱莲峰, 王超, 张梦娟, 刘方正, 贾鑫, 安萍, 许光文, 韩振南. 水蒸气/氧流化床两段煤气化制备低焦油合成气工艺实验[J]. 化工学报, 2022, 73(8): 3720-3730. |

| [15] | 张东旺, 杨海瑞, 周托, 黄中, 李诗媛, 张缦. 生物质锅炉对流受热面积灰冷态模拟实验研究[J]. 化工学报, 2022, 73(8): 3731-3738. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号