化工学报 ›› 2020, Vol. 71 ›› Issue (5): 2099-2108.DOI: 10.11949/0438-1157.20191432

方书起1,2( ),张欣悦1,李思齐1,白东豪1,白净1,2(

),张欣悦1,李思齐1,白东豪1,白净1,2( )

)

收稿日期:2019-11-26

修回日期:2020-02-28

出版日期:2020-05-05

发布日期:2020-05-05

通讯作者:

白净

作者简介:方书起(1964—),男,硕士,教授,基金资助:

Shuqi FANG1,2( ),Xinyue ZHANG1,Siqi LI1,Donghao BAI1,Jing BAI1,2(

),Xinyue ZHANG1,Siqi LI1,Donghao BAI1,Jing BAI1,2( )

)

Received:2019-11-26

Revised:2020-02-28

Online:2020-05-05

Published:2020-05-05

Contact:

Jing BAI

摘要:

实验考察了撞击流式反应釜内水合物法分离沼气中CO2的特性。选取纯水和十二烷基硫酸钠(SDS)两个不同的体系,考察了水合物生成过程中压力、温度、撞击强度的影响。实验结果表明在纯水体系和SDS体系下压力的升高均有利于水合物的快速生成,但并不利于沼气中的二氧化碳捕集;实验通过改变撞击流式反应器的撞击强度发现,当撞击强度为0.128时,CO2分离因子(S.F.)在纯水和SDS两种体系下均达到最大,纯水体系下S.F.的最大值为138.9,SDS体系下S.F.的最大值为64.5;实验结果表明添加剂SDS可以促进水合物的生成,最适宜的浓度为600 mg/L,此时耗气量、CO2水合率S.Fr.(CO2)和CH4水合率S.Fr.(CH4)达到最大,但SDS对CH4水合物生成过程的促进作用大于CO2水合物,反而不利于CO2的分离,降低CO2的分离因子。

中图分类号:

方书起, 张欣悦, 李思齐, 白东豪, 白净. 撞击流式反应器内水合物法分离沼气中CO2研究[J]. 化工学报, 2020, 71(5): 2099-2108.

Shuqi FANG, Xinyue ZHANG, Siqi LI, Donghao BAI, Jing BAI. Investigation on separation of CO2 from biogas by hydrate method in impinging stream reactor[J]. CIESC Journal, 2020, 71(5): 2099-2108.

| 磁力搅拌装置转速/(r/min) | 撞击强度(β) |

|---|---|

| 0 | 0 |

| 200 | 0.043 |

| 400 | 0.128 |

| 600 | 0.213 |

| 800 | 0.299 |

| 1000 | 0.384 |

表1 不同转速下的撞击强度

Table 1 Impact intensity under different rotational speeds

| 磁力搅拌装置转速/(r/min) | 撞击强度(β) |

|---|---|

| 0 | 0 |

| 200 | 0.043 |

| 400 | 0.128 |

| 600 | 0.213 |

| 800 | 0.299 |

| 1000 | 0.384 |

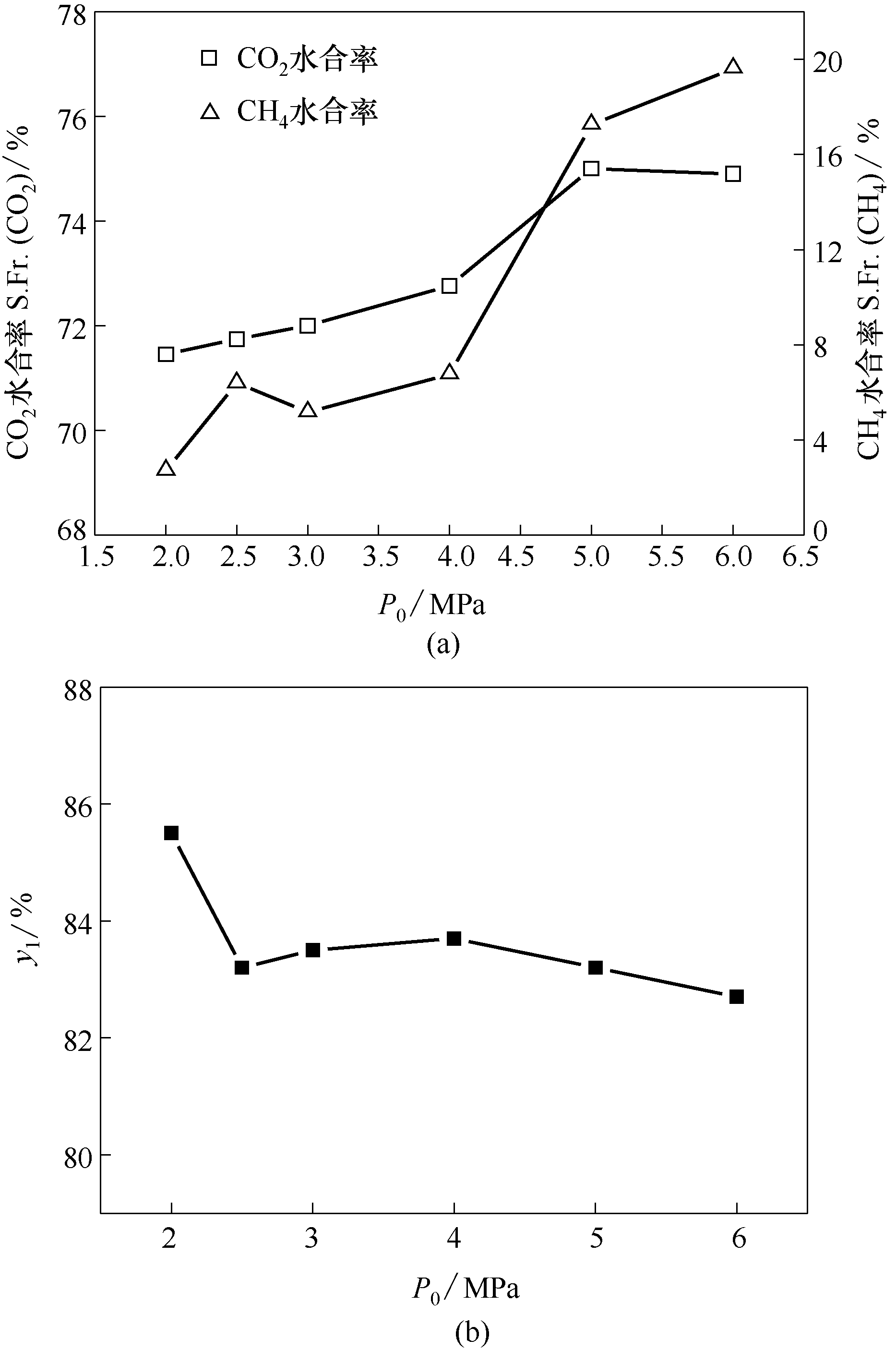

图4 纯水体系不同压力下的S.Fr.(CO2)、S.Fr.(CH4)和剩余气相CH4浓度 (y1)

Fig.4 CO2 recovery S.Fr.(CO2), CH4 recovery S.Fr.(CH4) and CH4 concentration of residual gas phase under different pressures in pure water system

图6 纯水体系不同温度下的S.Fr.(CO2)、S.Fr.(CH4)和剩余气相CH4浓度 (y1)

Fig.6 CO2 recovery S.Fr.(CO2), CH4 recovery S.Fr.(CH4) and CH4 concentration of residual gas phase under different temperatures in pure water system

图8 纯水体系不同撞击强度下的S.Fr.(CO2)、S.Fr.(CH4)和剩余气相CH4浓度 (y1)

Fig.8 CO2 recovery S.Fr.(CO2), CH4 recovery S.Fr.(CH4) and CH4 concentration of residual gas phase under different impact intensities in pure water system

图10 SDS体系不同浓度下的S.Fr.(CO2)、S.Fr.(CH4)和剩余气相CH4浓度 (y1)

Fig.10 CO2 recovery S.Fr.(CO2), CH4 recovery S.Fr.(CH4) and CH4 concentration of residual gas phase under different concentrations in SDS system

图16 不同撞击强度下的剩余气相CH4浓度 (y1)和CO2分离因子 (S.F.)对比

Fig.16 CH4 concentration of residual gas phase and separation factor (S.F.) under different impact intensities

| 5 | Yang X P, Liu H, Li Y. Research progress of separation technology based on hydrate formation[J]. CIESC Journal, 2017, 68(3): 831-840. |

| 6 | 聂江华, 樊栓狮, 郎雪梅, 等. 水合物法快速脱除天然气中二氧化碳[J]. 现代化工, 2011, 31(z2): 45-49. |

| Nie J H, Fan S S, Lang X M, et al. Quick capture of CO2 from natural gas with hydrate[J]. Modern Chemical Industry, 2011, 31(z2): 45-49. | |

| 7 | Ryckebosch E, Drouillon M, Vervaeren H. Techniques for transformation of biogas to biomethane[J]. Biomass and Bioenergy, 2011, 35(5):1633-1645. |

| 8 | Bauer F, Persson T, Hulteberg C, et al. Biogas upgrading - technology overview, comparison and perspectives for the future[J]. Biofuels, Bioproducts and Biorefining, 2013, 7(5): 499-511. |

| 9 | Abatzoglou N, Boivin S. A review of biogas purification processes[J]. Biofuels, Bioproducts and Biorefining, 2009, 3(1): 42-71. |

| 10 | Koh C A, Sloan E D, Sum A K, et al. Fundamentals and applications of gas hydrates[J]. Annual Review of Chemical Biomolecular Engineering, 2011, 2: 237-257 |

| 11 | Eslamimanesh A, Mohammadi A H, Richon D, et al. Application of gas hydrate formation in separation processes: a review of experimental studies[J]. The Journal of Chemical Thermodynamics, 2012, 46: 62-71. |

| 1 | Ellersdorfer M, Weib C. Integration of biogas plants in the building materials industry[J]. Renewable Energy, 2014, 61(1): 125-131. |

| 2 | Li C, Liao Y, Wen X, et al. The development and countermeasures of household biogas in northwest grain for green project areas of China[J]. Renewable and Sustainable Energy Reviews, 2015, 44: 835-846. |

| 12 | Mohammadi A H, Richon D. Use of an artificial neural network algorithm to determine pressure-temperature phase diagrams of tert-butylamine+methane and tert-butylamine+ hydrogen binary hydrates[J]. Industrial & Engineering Chemistry Research, 2010, 49(20): 10141-10143. |

| 13 | Babu P, Linga P, Kumar R, et al. A review of the hydrate based gas separation (HBGS) process for carbon dioxide pre-combustion capture[J]. Energy, 2015, 85: 261-279 |

| 3 | Ryckebosch E, Drouillon M, Vervaeren H. Techniques for transformation of biogas to biomethane[J]. Biomass and Bioenergy, 2011, 35(5): 1633-1645. |

| 4 | 潘良, 徐晓秋, 高德玉,等. 沼气脱碳提纯技术研究进展[J]. 黑龙江科学, 2015, 6: 18-20. |

| 14 | Bai J, Zhen X, Xie G, et al. Kinetics investigation of hydrate-based CO2 capture from simulated flue gas by using an improved combinatorial promoter[J]. Energy & Fuels, 2018, 32(10): 10822-10829. |

| 15 | 伍沅. 撞击流性质及其应用[J]. 化工进展, 2001, 20(11): 8-13. |

| Wu Y. Impact stream properties and applications[J]. Chemical Industry and Engineering Progress, 2001, 20(11): 8-13. | |

| 16 | 梁腾波, 白净, 张璐, 等.撞击流技术在化学工程领域的研究与应用进展[J]. 石油化工, 2016, 45(3): 360-367. |

| Liang T B, Bai J, Zhang L, et al. Advances in application of impinging stream technology to chemical engineering[J]. Petrochemical Technology, 2016, 45(3): 360-367. | |

| 17 | Elperin I T. Heat and mass transfer in opposing currents[J]. Journal of Engineering Physics, 1961, 6: 62-68. |

| 18 | Tamir A, Sobhi S. A new two-impinging-streams emulsifier[J]. AIChE Journal, 1985, 31(12): 2089-2092. |

| 19 | Murakami T, Kuritsuka H, Fujii H, et al. Forming a structure-h hydrate using water and methylcyclohexane jets impinging on each other in a methane atmosphere[J]. Energy & Fuels, 2009, 23(3): 1619-1625. |

| 20 | 白净, 常春, 陈俊英, 等. 快速制备天然气水合物的撞击流反应器及配套系统和方法:104645899A[P]. 2015-02-11. |

| Bai J, Chang C, Chen J Y, et al. Impinging stream reactor for quickly preparing natural gas hydrate and assorted system as well as method:104645899A[P]. 2015-02-11. | |

| 4 | Pan L, Xu X Q, Gao D Y, et al. Progress in the decarbonization purification technology of biogas[J]. Heilongjiang Science, 2015, 6: 18-20. |

| 5 | 杨西萍, 刘煌, 李赟. 水合物法分离混合物技术研究进展[J]. 化工学报, 2017, 68(3): 831-840. |

| 21 | 白净, 梁腾波, 李凌乾, 等. 一种新型撞击流反应器导流筒及撞击流反应器结构:205412990U[P]. 2015-12-16. |

| Bai J, Liang T B, Li L Q, et al. Novel impinging stream reactor draft tube and impinging stream reactor structure:205412990U[P]. 2015-12-16. | |

| 22 | Bai J, Liang D, Li D, et al. Continuous formation process of CO2 gas hydrate via a vortex and impinging stream reactor[J]. Energy & Fuels, 2010, 24(2): 1207-1212. |

| 23 | 伍沅, 周玉新, 郭嘉, 等. 液体连续相撞击流强化过程特性及相关技术装备的研发和应用[J]. 化工进展, 2011, 30(3): 6-15. |

| Wu Y, Zhou Y X, Guo J, et al. Features of LIS intensifying processes and development and applications of related technical devices[J]. Chemical Industry and Engineering Progress, 2011, 30(3): 6-15. | |

| 24 | Li X S, Xia Z M, Chen Z Y, et al. Precombustion capture of carbon dioxide and hydrogen with a one-stage hydrate/membrane process in the presence of tetra-n-butylammonium bromide (TBAB)[J]. Energy & Fuels, 2011, 25(3): 1302–1309. |

| 25 | Xia Z, Li X, Chen Z, et al. Hydrate-based acidic gases capture for clean methane with new synergic additives[J]. Applied Energy, 2017, 207(1): 584-593. |

| 26 | Linga P, Kumar R, Englezos P. The clathrate hydrate process for post and pre-combustion capture of carbon dioxide[J]. Journal of Hazardous Materials, 2007, 149(3): 625-629. |

| 27 | Adisasmito S. Hydrates of carbon dioxide and methane mixtures[J]. Journal of Chemical & Engineering Data, 1991, (36): 68-71. |

| 28 | Adisasmito S, Sloan E D. Hydrates of hydrocarbon gases containing carbon dioxide[J]. Journal of Chemical & Engineering Data, 1992, 37(3): 343-349 |

| 29 | Belandria V, Eslamimanesh A, Mohammadi A H, et al. Gas hydrate formation in carbon dioxide+nitrogen+water system: compositional analysis of equilibrium phases[J]. Industrial & Engineering Chemistry Research, 2011, 50(8): 4722-4730. |

| 30 | 严红玉. 气体水合物促进剂的研究进展[J]. 能源化工, 2018, 39(3):79-85. |

| Yan H Y. Research process of gas hydrate promoter[J]. Energy Chemical Industry, 2018, 39(3):79-85. | |

| 31 | 丁家祥, 史伶俐, 申小东, 等. SDS对甲烷水合物生成动力学和微观结构的影响[J]. 化工学报, 2017, 68(12): 4802-4807. |

| Ding J X, Shi L L, Shen X D, et al. SDS effect on formation kinetics and microstructure of methane hydrate[J]. CIESC Journal, 2017, 68(12): 4802-4807. | |

| 32 | Tang J, Zeng D, Wang C, et al. Study on the influence of SDS and THF on hydrate-based gas separation performance[J]. Chemical Engineering Research and Design, 2013, 91(9): 1777-1782. |

| [1] | 赵亚欣, 张雪芹, 王荣柱, 孙国, 姚善泾, 林东强. 流穿模式离子交换层析去除单抗聚集体[J]. 化工学报, 2023, 74(9): 3879-3887. |

| [2] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [3] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [4] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [5] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [6] | 于旭东, 李琪, 陈念粗, 杜理, 任思颖, 曾英. 三元体系KCl + CaCl2 + H2O 298.2、323.2及348.2 K相平衡研究及计算[J]. 化工学报, 2023, 74(8): 3256-3265. |

| [7] | 张缘良, 栾昕奇, 苏伟格, 李畅浩, 赵钟兴, 周利琴, 陈健民, 黄艳, 赵祯霞. 离子液体复合萃取剂选择性萃取尼古丁的研究及DFT计算[J]. 化工学报, 2023, 74(7): 2947-2956. |

| [8] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [9] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [10] | 韩奎奎, 谭湘龙, 李金芝, 杨婷, 张春, 张永汾, 刘洪全, 于中伟, 顾学红. 四通道中空纤维MFI分子筛膜用于二甲苯异构体分离[J]. 化工学报, 2023, 74(6): 2468-2476. |

| [11] | 朱兴驰, 郭志远, 纪志永, 汪婧, 张盼盼, 刘杰, 赵颖颖, 袁俊生. 选择性电渗析镁锂分离过程模拟优化[J]. 化工学报, 2023, 74(6): 2477-2485. |

| [12] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| [13] | 龙臻, 王谨航, 任俊杰, 何勇, 周雪冰, 梁德青. 离子液体协同PVCap抑制天然气水合物生成实验研究[J]. 化工学报, 2023, 74(6): 2639-2646. |

| [14] | 徐文超, 孙志高, 李翠敏, 李娟, 黄海峰. 静态条件下表面活性剂E-1310对HCFC-141b水合物生成的影响[J]. 化工学报, 2023, 74(5): 2179-2185. |

| [15] | 蔺彩虹, 王丽, 吴瑜, 刘鹏, 杨江峰, 李晋平. 沸石中碱金属阳离子对CO2/N2O吸附分离性能的影响[J]. 化工学报, 2023, 74(5): 2013-2021. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号