化工学报 ›› 2021, Vol. 72 ›› Issue (5): 2560-2569.DOI: 10.11949/0438-1157.20201350

收稿日期:2020-09-22

修回日期:2020-12-22

出版日期:2021-05-05

发布日期:2021-05-05

通讯作者:

李慧君

作者简介:李慧君(1964—),男,博士,教授,

LI Huijun( ),LI Dong,WANG Yeku,PENG Wenping

),LI Dong,WANG Yeku,PENG Wenping

Received:2020-09-22

Revised:2020-12-22

Online:2021-05-05

Published:2021-05-05

Contact:

LI Huijun

摘要:

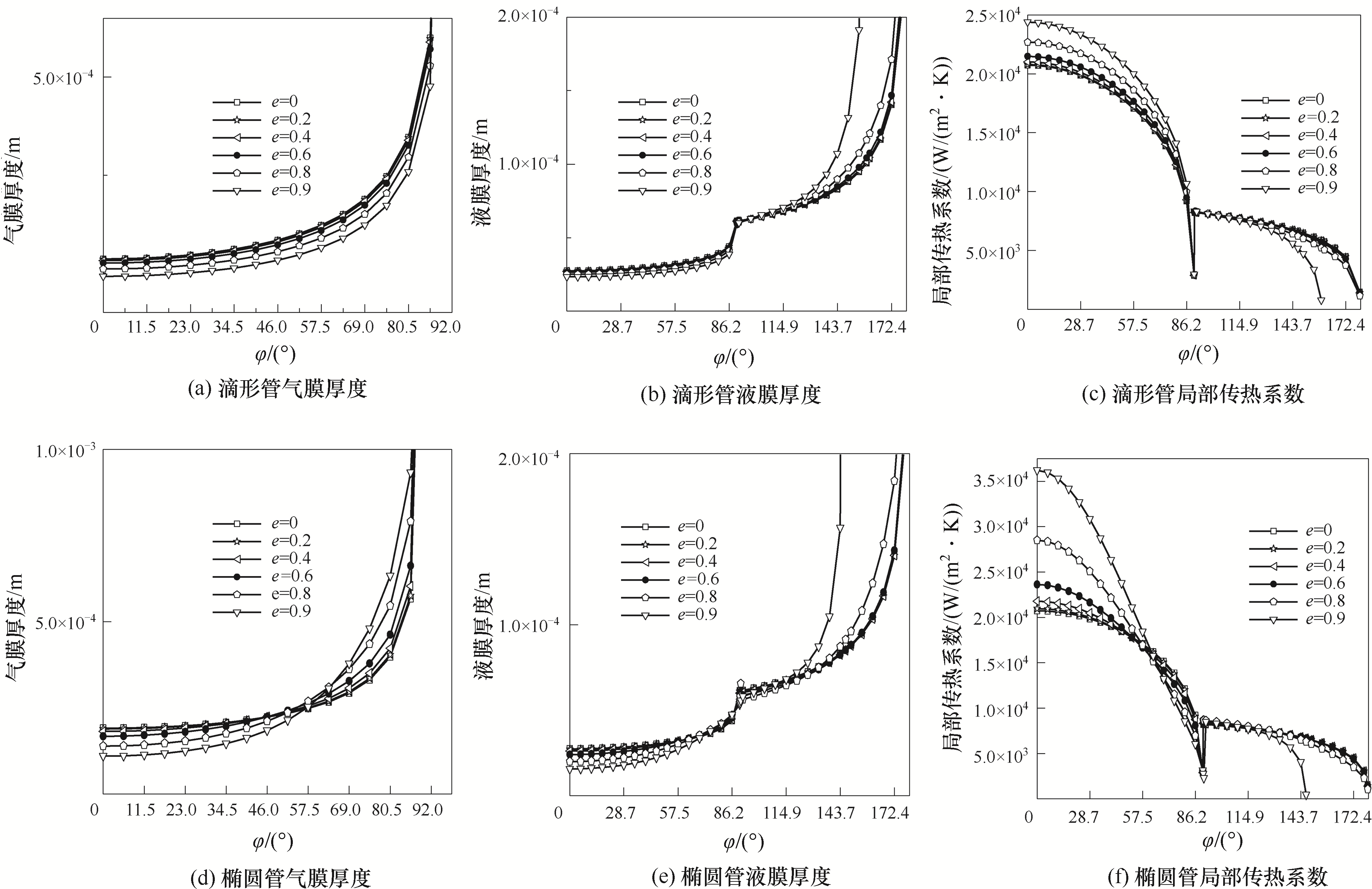

基于双膜理论及边界层理论,建立了圆管、椭圆管、滴形管的管外气、液膜厚度及传热系数的数学模型。以圆管传热系数为依据进行了模型验证,计算结果与实验值的平均偏差约为6%,基本符合工程实际要求。在给定条件下,通过对不同曲率下各管型管外传热系数的计算,得到了气、液膜厚度的分布规律及换热特性。结果表明:在有效换热面积相同时,三种管型的气、液膜厚度,传热系数在一定角度下,随曲率的增大而增大;当曲率相同时,椭圆管传热系数最大,圆管最小。同时,分析了不同管型及其曲率对气、液膜排泄的影响机理和分离机理。为强化换热提供一定理论指导。

中图分类号:

李慧君, 李东, 王业库, 彭文平. 异型管曲率对气液膜分布及凝结换热特性的影响[J]. 化工学报, 2021, 72(5): 2560-2569.

LI Huijun, LI Dong, WANG Yeku, PENG Wenping. Effect of the curvature of the special-shaped tube on gas-liquid film distribution and condensation heat transfer characteristics[J]. CIESC Journal, 2021, 72(5): 2560-2569.

| 分类依据 | 换热类型 |

|---|---|

| 凝结管型 | 圆管、椭圆管[ |

| 凝结表面及其布置 | 凝结表面有平板、管内、管外;布置方式分为水平和竖直[ |

| 介质流动方向 | 管外分为横掠和纵掠[ |

| 管内两相流流动 | 单相流、分层流以及环状流 |

| 强化表面 | 低肋管、低翅片管、波槽管、螺纹管、微肋管[ |

| 流动方式 | 自然对流、强迫对流和混合对流[ |

| 流动状态 | 层流和紊流 |

| 混合气体组成成分 | 蒸汽-空气、烟气-蒸汽、制冷剂(制冷剂、人工制冷剂替代物和自然工质)[ |

| 凝结方式 | 膜状凝结、珠状凝结、均匀凝结[ |

表1 汽-气凝结换热的类型

Tab 1 Types of steam-gas condensation heat transfer

| 分类依据 | 换热类型 |

|---|---|

| 凝结管型 | 圆管、椭圆管[ |

| 凝结表面及其布置 | 凝结表面有平板、管内、管外;布置方式分为水平和竖直[ |

| 介质流动方向 | 管外分为横掠和纵掠[ |

| 管内两相流流动 | 单相流、分层流以及环状流 |

| 强化表面 | 低肋管、低翅片管、波槽管、螺纹管、微肋管[ |

| 流动方式 | 自然对流、强迫对流和混合对流[ |

| 流动状态 | 层流和紊流 |

| 混合气体组成成分 | 蒸汽-空气、烟气-蒸汽、制冷剂(制冷剂、人工制冷剂替代物和自然工质)[ |

| 凝结方式 | 膜状凝结、珠状凝结、均匀凝结[ |

| 参数 | 取值 |

|---|---|

| 主流流速U∞/(m/s) | 0.1~5.0 |

| 曲率e | 0、0.2、0.4、0.6、0.8、0.9 |

| 主流温度Tb/K | 373.0 |

| 空气质量分数Wnc,b/% | 0.1~10 |

| 主流压力p/Pa | 101325 |

| 管壁温度Tw/K | 348.0~358.0 |

| 管径d/m | 0.0254 |

表2 混合气体计算参数

Table 2 Calculation parameters of mixed gas

| 参数 | 取值 |

|---|---|

| 主流流速U∞/(m/s) | 0.1~5.0 |

| 曲率e | 0、0.2、0.4、0.6、0.8、0.9 |

| 主流温度Tb/K | 373.0 |

| 空气质量分数Wnc,b/% | 0.1~10 |

| 主流压力p/Pa | 101325 |

| 管壁温度Tw/K | 348.0~358.0 |

| 管径d/m | 0.0254 |

图5 不同管型及其曲率下气、液膜厚度及局部传热系数沿管壁的分布

Fig.5 Distribution of gas, liquid film thickness and total heat transfer coefficient along the wall under different tube type and its curvature

| 1 | 杨宇伟, 阴继翔, 欧龙姣. 椭圆管外含不凝气体的蒸汽凝结传热的数值研究[J]. 科学技术与工程, 2016, 16(5): 71-76. |

| Yang Y W, Yin J X, Ou L J. Numerical simulation of vapor condensation with non-condensable gas outside of elliptical pipe[J]. Science Technology and Engineering, 2016, 16(5): 71-76. | |

| 2 | Memory S B, Adams V H, Marto P J. Free and forced convection laminar film condensation on horizontal elliptical tubes[J]. International Journal of Heat and Mass Transfer, 1997, 40(14): 3395-3406. |

| 3 | 李慧君. 滴形管凝结换热性能的实验研究[J]. 中国电机工程学报, 2009, 29(20): 79-84. |

| Li H J. Experimental study on the performance of condensation heat transfer with drop-shaped tubes[J]. Proceedings of the CSEE, 2009, 29(20): 79-84. | |

| 4 | 李倩, 欧阳新萍. 冷凝铜管排列方式对箱壁式冰箱换热性能的影响[J]. 制冷学报, 2016, 37(4): 101-105. |

| Li Q, Ouyang X P. Influence of condensation copper tube arrangement on the heat transfer performance for hot-wall refrigerator[J]. Journal of Refrigeration, 2016, 37(4): 101-105. | |

| 5 | 李俊, 吴新, 王帅, 等. 含湿气体横掠管束的凝结对流换热实验研究[J]. 热能动力工程, 2015, 30(2): 222-227, 318-319. |

| Li J, Wu X, Wang S, et al. Experimental study of the condensing convection heat transfer of a humidified gas laterally sweeping across a tube bundle[J]. Journal of Engineering for Thermal Energy and Power, 2015, 30(2): 222-227, 318-319. | |

| 6 | Park K J, Kang D G, Jung D. Condensation heat transfer coefficients of R1234yf on plain, low fin, and Turbo-C tubes[J]. International Journal of Refrigeration, 2011, 34(1): 317-321. |

| 7 | 李庆普, 陶乐仁, 吴生礼, 等. 水平内螺纹管内R410A流动凝结换热的实验研究[J]. 制冷学报, 2018, 39(6): 37-45. |

| Li Q P, Tao L R, Wu S L, et al. Experimental study on flow condensation heat transfer of R410A inside horizontal internal ribbed tube[J]. Journal of Refrigeration, 2018, 39(6): 37-45. | |

| 8 | 赵宇, 刘荔. 水平微肋管内R410A的冷凝换热特性[J]. 建筑节能, 2019, 47(9): 39-43. |

| Zhao Y, Liu L. The condensation heat transfer characteristics of R410A inside the horizontal micro-fin tube[J]. Building Energy Efficiency, 2019, 47(9): 39-43. | |

| 9 | 刘锋, 黄渭堂. 波槽管管外蒸汽凝结换热若干影响因素实验研究[J]. 应用科技, 2006, 33(5): 20-23. |

| Liu F, Huang W T. Experimental study on the influence factors of steam condensation outside circularly grooved tube[J]. Applied Science and Technology, 2006, 33(5): 20-23. | |

| 10 | 申道明, 桂超, 刘亚萍, 等. 内螺纹管换热器的综合性能分析[J]. 低温工程, 2019, (5): 14-20, 74. |

| Shen D M, Gui C, Liu Y P, et al. Comprehensive performance analysis of the heat exchanger with rifled tube[J]. Cryogenics, 2019, (5): 14-20, 74. | |

| 11 | Liao Y, Vierow K, Dehbi A, et al. Transition from natural to mixed convection for steam-gas flow condensing along a vertical plate[J]. International Journal of Heat and Mass Transfer, 2009, 52(1/2): 366-375. |

| 12 | 黄志光, 汪荣顺, 石玉美, 等. 水平管外二氧化碳膜状凝结传热分析[J]. 制冷学报, 2005, 26(4): 6-11. |

| Huang Z G, Wang R S, Shi Y M, et al. Condensation heat transfer of CO2 on horizontal low-finned tubes[J]. Journal of Refrigeration, 2005, 26(4): 6-11. | |

| 13 | Ganguli A, Patel A G, Maheshwari N K, et al. Theoretical modeling of condensation of steam outside different vertical geometries (tube, flat plates) in the presence of noncondensable gases like air and helium[J]. Nuclear Engineering and Design, 2008, 238(9): 2328-2340. |

| 14 | 王佩. 圆管内凝结液膜分布及换热特性研究[D]. 北京: 华北电力大学, 2015. |

| Wang P. Research on distribution of liquid film and heat transfer characteristics for condensation in a tube[D]. Beijing: North China Electric Power University, 2015. | |

| 15 | 衣秋杰. 竖壁外含不凝气体蒸汽凝结传热特性研究[D]. 济南: 山东大学, 2018. |

| Yi Q J. Investigation on the mechanism of steam condensation heat and mass transfer with non-condensable gas on vertical plate[D]. Jinan: Shandong University, 2018. | |

| 16 | 王亚安, 陈建义, 叶松, 等. 管柱式气液旋流分离器液膜厚度的空间分布特性[J]. 化工学报, 2020, 71(11): 5216-5225. |

| Wang Y A, Chen J Y, Ye S, et al. Spatial distribution characteristics of liquid film thickness in gas-liquid cylindrical cyclone[J]. CIESC Journal, 2020, 71(11): 5216-5225. | |

| 17 | 胡昊, 周亚素, 王树信, 等. 半椭圆管水平降膜液膜厚度影响因素研究[J]. 化学工程, 2020, 48(8): 18-23, 35. |

| Hu H, Zhou Y S, Wang S X, et al. Research on interfering factors of thickness of falling liquid film outside horizontal semi-elliptical tube[J]. Chemical Engineering (China), 2020, 48(8): 18-23, 35. | |

| 18 | 谈周妥, 郭志罡, 杨剑, 等. 重力驱动颗粒流横掠倒置滴形管管外流动传热特性的数值研究[J]. 化工学报, 2019, 70: 94-100. |

| Tan Z T, Guo Z G, Yang J, et al. Numerical investigation on flow and heat transfer performance of gravity-driven granular flowing across inverted drop-shaped tube[J]. CIESC Journal, 2019, 70: 94-100. | |

| 19 | 王晶, 王亦飞, 颜留成, 等. 管内垂直下降液膜速度与厚度分布特性[J]. 化工学报, 2016, 67(6): 2239-2245. |

| Wang J, Wang Y F, Yan L C, et al. Characteristics of velocity and thickness distribution of liquid film in vertical falling tube[J]. CIESC Journal, 2016, 67(6): 2239-2245. | |

| 20 | 王伟洁, 杨丽, 王宗伟. 水平异型管降膜蒸发器管外液膜流动数值模拟[J]. 煤气与热力, 2020, 40(1): 22-28, 42. |

| Wang W J, Yang L, Wang Z W. Numerical simulation of liquid film flow outside tube of horizontal shaped tube falling film evaporator[J]. Gas & Heat, 2020, 40(1): 22-28, 42. | |

| 21 | 单思宇, 谭宏博. 基于扁管的蒸发式冷凝器管外传热传质特性研究[J]. 化工学报, 2019, 70: 69-78. |

| Shan S Y, Tan H B. Study on heat and mass transfer characteristics outside flat tube for evaporative condensers[J]. CIESC Journal, 2019, 70: 69-78. | |

| 22 | 武雅洁. 水平螺旋槽管壁面降液膜传热特性的研究[D]. 青岛: 中国海洋大学, 2005. |

| Wu Y J. A study on heat-transfer properties of falling liquid film on the surface of a horizontal spirally fluted tube[D]. Qingdao: Ocean University of China, 2005. | |

| 23 | 张井志, 李蔚. 水平圆形与方形微小通道内R134a冷凝数值模拟[J]. 化工学报, 2016, 67(5): 1748-1754. |

| Zhang J Z, Li W. Numerical simulation of condensation in horizontal circular and square minichannels using R134a[J]. CIESC Journal, 2016, 67(5): 1748-1754. | |

| 24 | Chang T B, Yeh W Y. Theoretical investigation into condensation heat transfer on horizontal elliptical tube in stationary saturated vapor with wall suction[J]. Applied Thermal Engineering, 2011, 31(5): 946-953. |

| 25 | 杨世铭, 陶文铨. 传热学[M]. 4版. 北京: 高等教育出版社, 2006. |

| Yang S M, Tao W Q. Heat Transfer[M]. 4th ed. Beijing: Higher Education Press, 2006. | |

| 26 | 李慧君, 彭文平. 汽-气液滴形管与圆管外凝结换热的研究[J]. 制冷学报, 2013, 34(6): 84-89. |

| Li H J, Peng W P. The research on vapor-gas condensation heat transfer over a drop-shaped or circular tube[J]. Journal of Refrigeration, 2013, 34(6): 84-89. | |

| 27 | 孔珑. 流体力学[M]. 2版. 北京: 高等教育出版社, 2000: 23. |

| Kong L. Fluid Mechanics [M]. 2nd ed. Beijing: Higher Education Press, 2000: 23. | |

| 28 | 马玉宝. 水平管外蒸汽凝结仿真模型研究[D]. 哈尔滨: 哈尔滨工程大学, 2017. |

| Ma Y B. Research on simulation model of steam condensation outside a horizontal tube[D]. Harbin: Harbin Engineering University, 2017. | |

| 29 | Rose J W. Approximate equations for forced-convection condensation in the presence of a non-condensing gas on a flat plate and horizontal tube[J]. International Journal of Heat and Mass Transfer, 1980, 23(4): 539-546. |

| 30 | Osakabe M. Latent heat recovery from oxygen-combustion flue gas[C]// 35th Intersociety Energy Conversion Engineering Conference and Exhibit (IECEC). Las Vegas, NV, USA, 2000: 804-812. |

| 31 | 李慧君. 燃气锅炉排烟余热回收及最佳利用的研究[D]. 西安: 西安交通大学, 2004. |

| Li H J. Submitted in partial fulfillment of the requirements for the degree of doctor of engineering[D]. Xi'an: Xi'an Jiaotong University, 2004. |

| [1] | 苏伟, 马东旭, 金旭, 刘忠彦, 张小松. 表面润湿性对霜层传递特性影响可视化实验研究[J]. 化工学报, 2023, 74(S1): 122-131. |

| [2] | 周晓庆, 李春煜, 杨光, 蔡爱峰, 吴静怡. 液滴撞击不同曲率过冷波纹面结冰动力学行为及机理研究[J]. 化工学报, 2023, 74(S1): 141-153. |

| [3] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [4] | 吴延鹏, 李晓宇, 钟乔洋. 静电纺丝纳米纤维双疏膜油性细颗粒物过滤性能实验分析[J]. 化工学报, 2023, 74(S1): 259-264. |

| [5] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [6] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [7] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [8] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [9] | 胡亚丽, 胡军勇, 马素霞, 孙禹坤, 谭学诣, 黄佳欣, 杨奉源. 逆电渗析热机新型工质开发及电化学特性研究[J]. 化工学报, 2023, 74(8): 3513-3521. |

| [10] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [11] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| [12] | 韩奎奎, 谭湘龙, 李金芝, 杨婷, 张春, 张永汾, 刘洪全, 于中伟, 顾学红. 四通道中空纤维MFI分子筛膜用于二甲苯异构体分离[J]. 化工学报, 2023, 74(6): 2468-2476. |

| [13] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [14] | 陈朝光, 贾玉香, 汪锰. 以低浓度废酸驱动中和渗析脱盐的模拟与验证[J]. 化工学报, 2023, 74(6): 2486-2494. |

| [15] | 顾浩, 张福建, 刘珍, 周文轩, 张鹏, 张忠强. 力电耦合作用下多孔石墨烯膜时间维度的脱盐性能及机理研究[J]. 化工学报, 2023, 74(5): 2067-2074. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号