化工学报 ›› 2021, Vol. 72 ›› Issue (10): 5226-5236.DOI: 10.11949/0438-1157.20210337

收稿日期:2021-03-08

修回日期:2021-05-22

出版日期:2021-10-05

发布日期:2021-10-05

通讯作者:

赵之平

作者简介:王艳芳(1995—),女,硕士,基金资助:

Yanfang WANG( ),Heng MAO,Weiwei CAI,Aoshuai ZHANG,Lihao XU,Zhiping ZHAO(

),Heng MAO,Weiwei CAI,Aoshuai ZHANG,Lihao XU,Zhiping ZHAO( )

)

Received:2021-03-08

Revised:2021-05-22

Online:2021-10-05

Published:2021-10-05

Contact:

Zhiping ZHAO

摘要:

蒸气渗透(VP)膜分离不存在膜污染风险,在生物乙醇生产中具有广阔的应用前景。将聚二甲基硅氧烷(PDMS)膜和以二维沸石咪唑骨架(ZIF-L)为填充基质制备的PDMS(ZIF-L/PDMS)混合基质膜,分别用于VP膜分离与菊粉水解液发酵制乙醇过程的耦合,分析了二者在耦合过程中的分离性能和发酵性能。探究了不同膜分离方式、不同类型膜及操作条件对膜分离性能的影响。实验结果表明,当料液浓度为5%(质量)、蒸气循环流量为1.5 L·min-1时,ZIF-L/PDMS混合基质膜的VP性能高于渗透汽化(PV),归一化总通量达到1148.78 g·m-2·h-1,分离因子高达19.14,显著提升了乙醇分离性能。ZIF-L/PDMS混合基质膜用于VP耦合发酵,实现了耦合过程的高渗透性和乙醇选择性,与文献报道相比,乙醇移除效果最优,乙醇产率和时空产率分别达到0.421 g·g-1、3.07 g·L-1·h-1,两个指标明显高于单独发酵,极大地提高了乙醇生产效率。因此,ZIF-L/PDMS混合基质膜在原位分离发酵乙醇方面具有很大的应用潜力。

中图分类号:

王艳芳,毛恒,蔡玮玮,张傲率,徐李昊,赵之平. ZIF-L/PDMS混合基质膜蒸气渗透耦合发酵强化乙醇生产效率的研究[J]. 化工学报, 2021, 72(10): 5226-5236.

Yanfang WANG,Heng MAO,Weiwei CAI,Aoshuai ZHANG,Lihao XU,Zhiping ZHAO. Enhancing ethanol production efficiency by ZIF-L/PDMS mixed matrix membrane via vapor permeation-fermentation coupling process[J]. CIESC Journal, 2021, 72(10): 5226-5236.

图2 PDMS膜表面(a)和截面(b)、ZIF-L/PDMS膜表面[(c)、(d)]和截面[(e)、(f)]的扫描电镜图

Fig.2 SEM images of the surface (a) and cross-section (b) morphologies of pure PDMS membrane and the surface [(c),(d)] and cross-section [(e),(f)] morphologies of ZIF-L/PDMS mixed matrix membrane

图4 不同料液浓度对PDMS膜VP分离性能的影响:通量(a);渗透侧乙醇浓度和分离因子(b)(操作条件:温度35℃,蒸气循环流量1.5 L·min-1,真空度0.095 MPa)

Fig.4 Effect of feed concentration on flux (a), ethanol concentration in permeate and separation factor (b) of VP by PDMS membrane

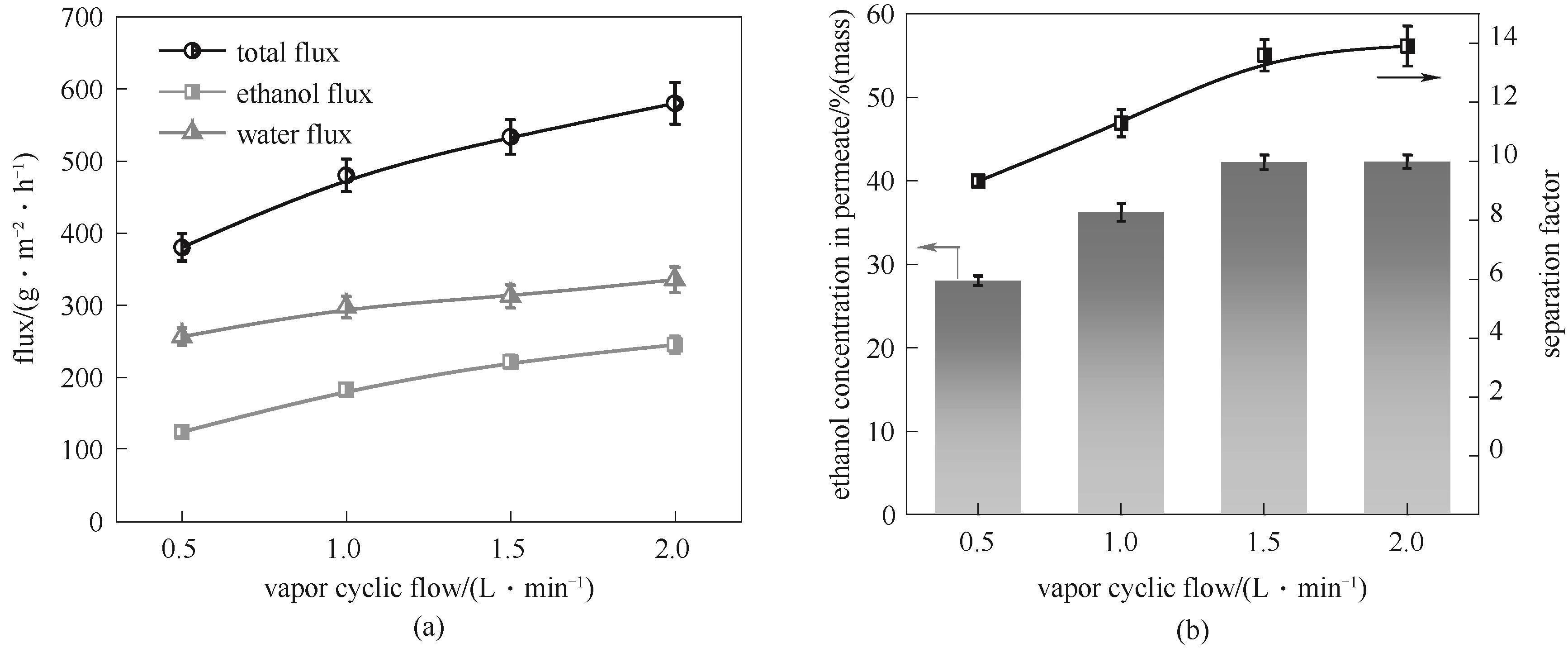

图5 不同蒸气循环流量对PDMS膜分离性能的影响:通量(a);渗透侧乙醇浓度和分离因子(b)(操作条件:温度35℃,料液浓度5%(质量),真空度0.095 MPa)

Fig.5 Effect of the vapor cyclic flow on flux (a), ethanol concentration in permeate and separation factor (b) of VP by PDMS membrane

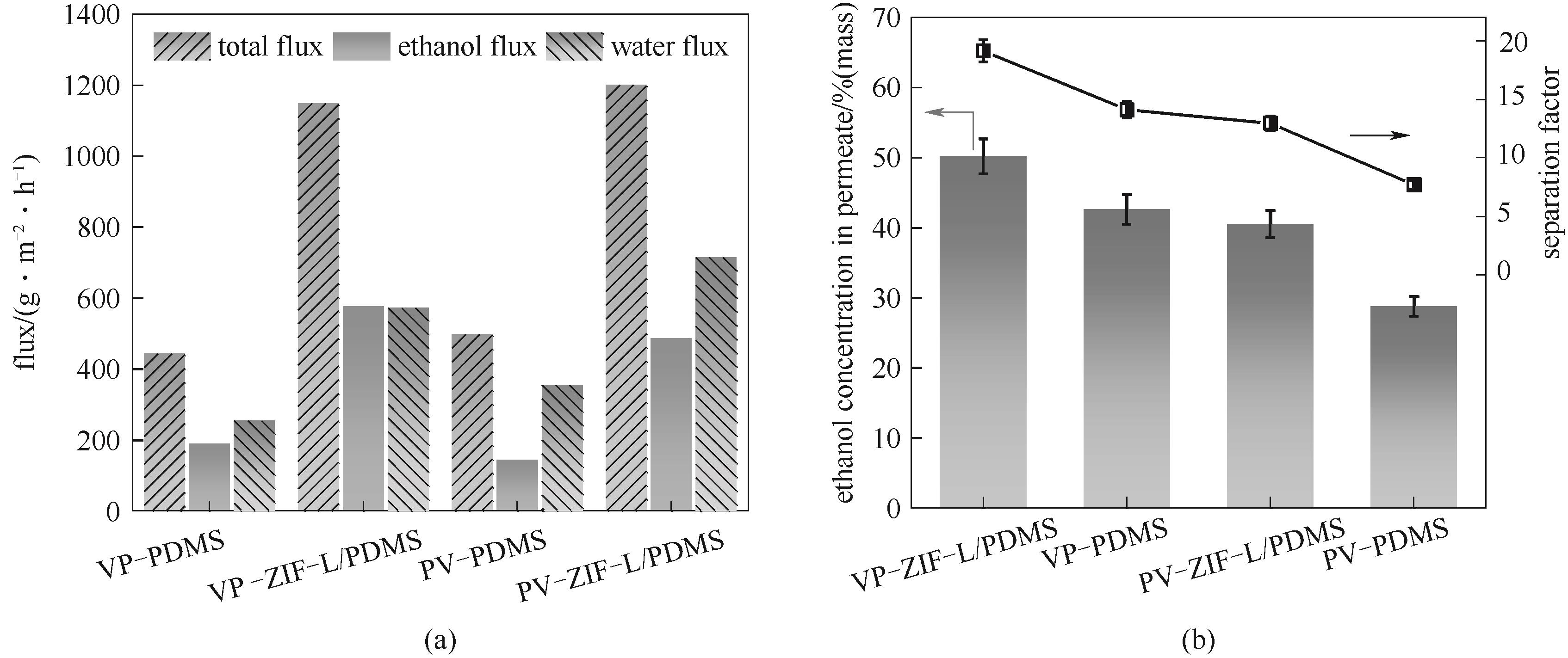

图6 不同膜类型的蒸气渗透(a)和渗透汽化(b)性能(操作条件:温度35℃,料液浓度5%(质量),蒸气循环流量1.5 L·min-1)

Fig.6 Effect of different membrane on membrane performance in PV(a) and VP(b) processes

图7 不同发酵过程中乙醇浓度(a)、还原糖浓度(b)、细胞浓度(c)随发酵时间的变化(操作条件:初始还原糖浓度150 g·L-1,发酵温度35℃,蒸气循环流量1.5 L·min-1)

Fig.7 Variations of ethanol concentration (a), reducing sugar concentration (b) and cell concentration (c) in broth during fermentation processes

| 发酵特性参数 | 单独发酵 | VP-ferment-PDMS | VP-ferment-ZIF-L/PDMS |

|---|---|---|---|

| 细胞浓度/(g·L-1) | 18.99 | 26.28 | 29.81 |

| 乙醇总产量/g | 23.23 | 25.01 | 24.54 |

| 乙醇产率/(g·g-1) | 0.418 | 0.436 | 0.421 |

| 乙醇时空产率/(g·L-1·h-1) | 1.79 | 2.61 | 3.07 |

表1 不同过程的发酵性能对比

Table 1 Comparation of fermentation performance in different processes

| 发酵特性参数 | 单独发酵 | VP-ferment-PDMS | VP-ferment-ZIF-L/PDMS |

|---|---|---|---|

| 细胞浓度/(g·L-1) | 18.99 | 26.28 | 29.81 |

| 乙醇总产量/g | 23.23 | 25.01 | 24.54 |

| 乙醇产率/(g·g-1) | 0.418 | 0.436 | 0.421 |

| 乙醇时空产率/(g·L-1·h-1) | 1.79 | 2.61 | 3.07 |

图8 VP-ferment-PDMS (a)和VP-ferment-ZIF-L/PDMS (b)中通量随发酵时间的变化

Fig.8 Variations of flux during the VP- fermentation process of PDMS (a) and ZIF-L/PDMS (b)

| 膜类型 | 膜分离 方法 | 发酵温度/ ℃ | 乙醇产率/ (g·g-1) | 乙醇时空产率/ (g·L-1·h-1) | 总通量/ (g·m-2·h-1) | 分离因子 | 乙醇移除速率①/(g·h-1) | 文献 |

|---|---|---|---|---|---|---|---|---|

| PDMS | PV | 35 | — | — | 750 | 4.83 | — | [ |

| PDMS | VP | 35 | 0.414 | 3.33 | 350 | 10 | 0.27 | [ |

| PDMS | PV | 35 | 0.381 | 2.67 | 385 | 8.8 | 0.38 | [ |

| PDMS | PV | 35 | 0.45 | 3.05 | 355 | 6.3 | 0.47 | [ |

| CNT-PDMS | PV | 30 | 0.45 | 2.23 | 41.4 | 6.2 | — | [ |

| PDMS | PV | 35 | 0.38 | 2.31 | 370 | 9.5 | — | [ |

| PDMS | PV | 35 | 0.42 | 1.58 | 417.2 | 11.7 | — | [ |

| PDMS/CNT-GO | PV | 32 | — | — | 200 | 20 | — | [ |

| Silicalite-1/PDMS | PV | 30 | 0.42 | 1.6 | 416 | 9.8 | — | [ |

| PDMS | VP | 35 | 0.436 | 2.61 | 536 | 12.3 | 0.413 | 本工作 |

| ZIF-L/PDMS | VP | 35 | 0.421 | 3.07 | 675 | 19.5 | 0.616 | 本工作 |

表2 不同类型膜耦合过程中发酵性能与膜性能的文献对比

Table 2 Comparation of fermentation and membrane performance under different membrane types

| 膜类型 | 膜分离 方法 | 发酵温度/ ℃ | 乙醇产率/ (g·g-1) | 乙醇时空产率/ (g·L-1·h-1) | 总通量/ (g·m-2·h-1) | 分离因子 | 乙醇移除速率①/(g·h-1) | 文献 |

|---|---|---|---|---|---|---|---|---|

| PDMS | PV | 35 | — | — | 750 | 4.83 | — | [ |

| PDMS | VP | 35 | 0.414 | 3.33 | 350 | 10 | 0.27 | [ |

| PDMS | PV | 35 | 0.381 | 2.67 | 385 | 8.8 | 0.38 | [ |

| PDMS | PV | 35 | 0.45 | 3.05 | 355 | 6.3 | 0.47 | [ |

| CNT-PDMS | PV | 30 | 0.45 | 2.23 | 41.4 | 6.2 | — | [ |

| PDMS | PV | 35 | 0.38 | 2.31 | 370 | 9.5 | — | [ |

| PDMS | PV | 35 | 0.42 | 1.58 | 417.2 | 11.7 | — | [ |

| PDMS/CNT-GO | PV | 32 | — | — | 200 | 20 | — | [ |

| Silicalite-1/PDMS | PV | 30 | 0.42 | 1.6 | 416 | 9.8 | — | [ |

| PDMS | VP | 35 | 0.436 | 2.61 | 536 | 12.3 | 0.413 | 本工作 |

| ZIF-L/PDMS | VP | 35 | 0.421 | 3.07 | 675 | 19.5 | 0.616 | 本工作 |

图9 VP-ferment-PDMS和VP-ferment-ZIF-L/PDMS过程中渗透侧乙醇浓度(a)和分离因子随发酵时间的变化(b)

Fig.9 Variations of ethanol concentration in permeate (a) and separation factor (b) during the VP- fermentation process with PDMS membrane and ZIF-L/PDMS membrane

| 1 | Larcher D, Tarascon J M. Towards greener and more sustainable batteries for electrical energy storage[J]. Nature Chemistry, 2015, 7(1): 19-29. |

| 2 | Brennan L, Owende P. Biofuels from microalgae—A review of technologies for production, processing, and extractions of biofuels and co-products[J]. Renewable and Sustainable Energy Reviews, 2010, 14(2): 557-577. |

| 3 | Alonso D M, Bond J Q, Dumesic J A. Catalytic conversion of biomass to biofuels[J]. Green Chemistry, 2010, 12(9): 1493. |

| 4 | Nigam P S, Singh A. Production of liquid biofuels from renewable resources[J]. Progress in Energy and Combustion Science, 2011, 37(1): 52-68. |

| 5 | Jönsson L J, Martín C. Pretreatment of lignocellulose: formation of inhibitory by-products and strategies for minimizing their effects[J]. Bioresource Technology, 2016, 199: 103-112. |

| 6 | 潘多涛, 史洪岩, 袁德成, 等. 酿酒酵母代谢过程的振荡分析[J]. 化工学报, 2017, 68(3): 964-969. |

| Pan D T, Shi H Y, Yuan D C, et al. Analysis of metabolic oscillation processes in Saccharomyces cerevisiae[J]. CIESC Journal, 2017, 68(3): 964-969. | |

| 7 | Hajilary N, Rezakazemi M, Shirazian S. Biofuel types and membrane separation[J]. Environmental Chemistry Letters, 2019, 17(1): 1-18. |

| 8 | He Y, Bagley D M, Leung K T, et al. Recent advances in membrane technologies for biorefining and bioenergy production[J]. Biotechnology Advances, 2012, 30(4): 817-858. |

| 9 | Wei P, Cheng L H, Zhang L, et al. A review of membrane technology for bioethanol production[J]. Renewable and Sustainable Energy Reviews, 2014, 30: 388-400. |

| 10 | Sasaki K, Tsuge Y, Sasaki D, et al. Increased ethanol production from sweet sorghum juice concentrated by a membrane separation process[J]. Bioresource Technology, 2014, 169: 821-825. |

| 11 | Trinh L T P, Cho E J, Lee Y J, et al. Pervaporative separation of bioethanol produced from the fermentation of waste newspaper[J]. Journal of Industrial and Engineering Chemistry, 2013, 19(6): 1910-1915. |

| 12 | Baeyens J, Kang Q, Appels L, et al. Challenges and opportunities in improving the production of bio-ethanol[J]. Progress in Energy and Combustion Science, 2015, 47: 60-88. |

| 13 | Zabed H, Sahu J N, Suely A, et al. Bioethanol production from renewable sources: current perspectives and technological progress[J]. Renewable and Sustainable Energy Reviews, 2017, 71: 475-501. |

| 14 | Fan S Q, Liu J Y, Tang X Y, et al. Process operation performance of PDMS membrane pervaporation coupled with fermentation for efficient bioethanol production[J]. Chinese Journal of Chemical Engineering, 2019, 27(6): 1339-1347. |

| 15 | Zhang Q, Wu D Y, Lin Y, et al. Substrate and product inhibition on yeast performance in ethanol fermentation[J]. Energy & Fuels, 2015, 29(2): 1019-1027. |

| 16 | Fan S Q, Xiao Z Y, Tang X Y, et al. Inhibition effect of secondary metabolites accumulated in a pervaporation membrane bioreactor on ethanol fermentation of Saccharomyces cerevisiae[J]. Bioresource Technology, 2014, 162: 8-13. |

| 17 | Gaykawad S S, Rütze D N, van der Wielen L A M, et al. Vapour permeation for ethanol recovery from fermentation off-gas[J]. Biochemical Engineering Journal, 2017, 124: 54-63. |

| 18 | Maus E, Brüschke H E A. Separation of methanol from methylesters by vapour permeation: experiences of industrial applications[J]. Desalination, 2002, 148(1/2/3): 315-319. |

| 19 | Sander U, Janssen H. Industrial application of vapour permeation[J]. Journal of Membrane Science, 1991, 61: 113-129. |

| 20 | Gong G H, Mamoru M, Nagasawa H, et al. Vapor-permeation dehydration of isopropanol using a flexible and thin organosilica membrane with high permeance[J]. Journal of Membrane Science, 2019, 588: 117226. |

| 21 | Fujita Y, Yoshikawa M. Vapor permeation of aqueous ethanol mixtures through agarose membranes[J]. Journal of Membrane Science, 2014, 459: 114-121. |

| 22 | Zhu C, Chen L J, Xue C, et al. A novel close-circulating vapor stripping-vapor permeation technique for boosting biobutanol production and recovery[J]. Biotechnology for Biofuels, 2018, 11(1): 1-13. |

| 23 | Mao H, Zhen H G, Ahmad A, et al. Highly selective and robust PDMS mixed matrix membranes by embedding two-dimensional ZIF-L for alcohol permselective pervaporation[J]. Journal of Membrane Science, 2019, 582: 307-321. |

| 24 | Xu L H, Li S H, Mao H, et al. An advanced necklace-like metal organic framework with an ultrahighly continuous structure in the membrane for superior butanol/water separation[J]. Journal of Materials Chemistry A, 2021, 9(19): 11853-11862. |

| 25 | Zhao Z P, Zhang A S, Wang X L, et al. Controllable modification of polymer membranes by LDDLT plasma flow: grafting acidic ILs into PPF membrane for catalytic performance[J]. Journal of Membrane Science, 2018, 553: 99-110. |

| 26 | Zhao Z P, Wang X L, Zhou G Y, et al. Hydrolysis kinetics of inulin by imidazole-based acidic ionic liquid in aqueous media and bioethanol fermentation[J]. Chemical Engineering Science, 2016, 151: 16-24. |

| 27 | Fan S Q, Xiao Z Y, Zhang Y, et al. Enhanced ethanol fermentation in a pervaporation membrane bioreactor with the convenient permeate vapor recovery[J]. Bioresource Technology, 2014, 155: 229-234. |

| 28 | 韩小龙, 张杏梅, 马晓迅, 等. 碳纳米管填充PDMS膜的渗透汽化性能[J]. 化工学报, 2014, 65(1): 271-278. |

| Han X L, Zhang X M, Ma X X, et al. Pervaporation performance of carbon nanotube filled PDMS membranes[J]. CIESC Journal, 2014, 65(1): 271-278. | |

| 29 | Wu X M, Zhang Q G, Soyekwo F, et al. Pervaporation removal of volatile organic compounds from aqueous solutions using the highly permeable PIM-1 membrane[J]. AIChE Journal, 2016, 62(3): 842-851. |

| 30 | Sun W, Jia W, Xia C J, et al. Study of in situ ethanol recovery via vapor permeation from fermentation[J]. Journal of Membrane Science, 2017, 530: 192-200. |

| 31 | Zhong Z X, Yao J F, Chen R Z, et al. Oriented two-dimensional zeolitic imidazolate framework-L membranes and their gas permeation properties[J]. Journal of Materials Chemistry A, 2015, 3(30): 15715-15722. |

| 32 | Li Y B, Wee L H, Martens J A, et al. ZIF-71 as a potential filler to prepare pervaporation membranes for bio-alcohol recovery[J]. Journal of Materials Chemistry A, 2014, 2(26): 10034-10040. |

| 33 | Verploegh R J, Nair S, Sholl D S. Temperature and loading-dependent diffusion of light hydrocarbons in ZIF-8 as predicted through fully flexible molecular simulations[J]. Journal of the American Chemical Society, 2015, 137(50): 15760-15771. |

| 34 | Uchytil P, Petričkovič R. Vapor permeation and pervaporation of propan-1-ol and propan-2-ol in polyethylene membrane[J]. Journal of Membrane Science, 2002, 209(1): 67-79. |

| 35 | 曹中琦, 陈宁, 王庚, 等. 模拟发酵液中渗透汽化膜分离乙醇性能劣化研究[J]. 膜科学与技术, 2018, 38(6): 22-26, 40. |

| Cao Z Q, Chen N, Wang G, et al. Membrane degradation in pervaporation of a simulated fermentation broth[J]. Membrane Science and Technology, 2018, 38(6): 22-26, 40. | |

| 36 | Okamoto K, Tanihara N, Watanabe H, et al. Vapor permeation and pervaporation separation of water-ethanol mixtures through polyimide membranes[J]. Journal of Membrane Science, 1992, 68(1/2): 53-63. |

| 37 | Khalid A, Aslam M, Qyyum M A, et al. Membrane separation processes for dehydration of bioethanol from fermentation broths: Recent developments, challenges, and prospects[J]. Renewable and Sustainable Energy Reviews, 2019, 105: 427-443. |

| 38 | Cao Z Q, Xia C J, Jia W, et al. Enhancing bioethanol productivity by a yeast-immobilized catalytically active membrane in a fermentation-pervaporation coupling process[J]. Journal of Membrane Science, 2020, 595: 117485. |

| 39 | Chen C Y, Long S H, Li A R, et al. Performance comparison of ethanol and butanol production in a continuous and closed-circulating fermentation system with membrane bioreactor[J]. Preparative Biochemistry & Biotechnology, 2017, 47(3): 254-260. |

| 40 | Xue C, Wang Z X, Du G Q, et al. Integration of ethanol removal using carbon nanotube (CNT)-mixed membrane and ethanol fermentation by self-flocculating yeast for antifouling ethanol recovery[J]. Process Biochemistry, 2016, 51(9): 1140-1146. |

| 41 | Fu C H, Cai D, Hu S, et al. Ethanol fermentation integrated with PDMS composite membrane: an effective process[J]. Bioresource Technology, 2016, 200: 648-657. |

| 42 | Shafiei Amrei S, Asghari M, Esfahanian M, et al. Highly selective carbon nanotube-coupled graphene oxide-incorporated polydimethylsiloxane membrane for pervaporative membrane bioreactor ethanol production[J]. Journal of Chemical Technology & Biotechnology, 2020, 95(5): 1604-1613. |

| 43 | Cai D, Hu S, Chen C J, et al. Immobilized ethanol fermentation coupled to pervaporation with silicalite-1/polydimethylsiloxane/polyvinylidene fluoride composite membrane[J]. Bioresource Technology, 2016, 220: 124-131. |

| [1] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| [2] | 尹驰, 张正国, 凌子夜, 方晓明. 含石蜡@二氧化硅纳米胶囊和碳纤维的相变热界面材料及其散热性能[J]. 化工学报, 2023, 74(4): 1795-1804. |

| [3] | 裴仁花, 王永洪, 张新儒, 李晋平. 碳纳米管/环糊精金属有机骨架协同强化混合基质膜的CO2分离[J]. 化工学报, 2022, 73(9): 3904-3914. |

| [4] | 王佳铭, 阮雪华, 贺高红. 面向不同工业二氧化碳分离体系的膜材料研究进展[J]. 化工学报, 2022, 73(8): 3417-3432. |

| [5] | 王立维, 王娟娟, 王永洪, 张新儒, 李晋平. 聚乙烯胺/Cu3(BTC)2-MMT-NH2混合基质膜的制备及气体传递性能[J]. 化工学报, 2022, 73(7): 3068-3077. |

| [6] | 于喆淼, 王志, 生梦龙, 邢广宇, 王纪孝. 界面聚合法制备用于脱氮提纯CH4的N2优先渗透ZIF-90/聚酰胺混合基质膜[J]. 化工学报, 2022, 73(7): 3273-3286. |

| [7] | 毛恒, 王月, 王森, 刘伟民, 吕静, 陈甫雪, 赵之平. APTES改性ZIF-L/PEBA混合基质膜强化渗透汽化分离苯酚研究[J]. 化工学报, 2022, 73(3): 1389-1402. |

| [8] | 李贵贤, 王可, 王健, 孟文亮, 李婧玮, 杨勇, 范宗良, 王东亮, 周怀荣. 膜分离捕集燃煤电厂烟气CO2过程优化设计[J]. 化工学报, 2022, 73(11): 5065-5077. |

| [9] | 靳卓, 王永洪, 张新儒, 白雪, 李晋平. Pebax/a-MoS2/MIP-202混合基质膜的制备及CO2分离性能[J]. 化工学报, 2022, 73(10): 4527-4538. |

| [10] | 吴中杰, 刘则艳, 谢连科, 崔美, 黄仁亮. 聚偏氟乙烯膜亲水改性及其乳液分离与重金属吸附应用[J]. 化工学报, 2021, 72(S1): 421-429. |

| [11] | 王绍宇, 马翰泽, 吴洪, 梁旭, 王洪建, 朱姿亭, 姜忠义. 有机框架膜在气体分离中的研究进展[J]. 化工学报, 2021, 72(7): 3488-3510. |

| [12] | 杜娟, 龚志强, 黄曹兴, 梁辰, 姚双全, 刘杨. 树脂吸附-超滤协同分离甘蔗渣碱法半纤维素[J]. 化工学报, 2021, 72(4): 2139-2147. |

| [13] | 周毅,王永洪,张新儒,李晋平. PEBA/氮硫共掺杂多孔碳球混合基质膜的制备及CO2分离性能研究[J]. 化工学报, 2021, 72(10): 5237-5246. |

| [14] | 王维, 姜雪迎, 李悦, 苏丽萍, 邹昀, 童张法. 亲水型ZSM-5分子筛填充PVA膜及分离乙酸乙酯/水的应用[J]. 化工学报, 2020, 71(8): 3807-3818. |

| [15] | 刘燕青, 胡听听, 鲁落义, 王维, 邹昀, 童张法. PDMS/ZSM-5膜的制备及渗透汽化分离水中乙酸正丁酯和乙酸乙酯[J]. 化工学报, 2020, 71(2): 843-853. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号