化工学报 ›› 2022, Vol. 73 ›› Issue (11): 5065-5077.DOI: 10.11949/0438-1157.20221035

李贵贤1,2( ), 王可1,2, 王健1,2, 孟文亮1,2, 李婧玮1,2, 杨勇1,2, 范宗良1,2, 王东亮1,2(

), 王可1,2, 王健1,2, 孟文亮1,2, 李婧玮1,2, 杨勇1,2, 范宗良1,2, 王东亮1,2( ), 周怀荣1,2(

), 周怀荣1,2( )

)

收稿日期:2022-07-20

修回日期:2022-08-16

出版日期:2022-11-05

发布日期:2022-12-06

通讯作者:

王东亮,周怀荣

作者简介:李贵贤(1966—),男,博士,教授,lgxwyf@163.com

基金资助:

Guixian LI1,2( ), Ke WANG1,2, Jian WANG1,2, Wenliang MENG1,2, Jingwei LI1,2, Yong YANG1,2, Zongliang FAN1,2, Dongliang WANG1,2(

), Ke WANG1,2, Jian WANG1,2, Wenliang MENG1,2, Jingwei LI1,2, Yong YANG1,2, Zongliang FAN1,2, Dongliang WANG1,2( ), Huairong ZHOU1,2(

), Huairong ZHOU1,2( )

)

Received:2022-07-20

Revised:2022-08-16

Online:2022-11-05

Published:2022-12-06

Contact:

Dongliang WANG, Huairong ZHOU

摘要:

全球CO2的排放量不断升高,导致气候问题频发。“双碳”目标下,如何高效、低成本地捕集燃煤电厂烟气CO2已经成为迫在眉睫的问题。传统的化学吸收法由于能耗高、成本高、溶剂易挥发等问题严重制约了其发展,而膜法碳捕集因为其操作简单、能耗低、环境污染小等优势被认为是最有前景的捕集方式。本文以PI中空纤维膜为分离膜,建立和求解了气体分离膜模型。并以燃煤电厂烟气CO2为捕集目标,利用多岛遗传算法求解了膜分离捕集CO2工艺的不同配置,并优化了分离过程中的关键参数(膜面积、操作压力)。结果显示:在二级膜分离工艺中,二级一段膜分离工艺的第一级膜和第二级膜操作压力分别为5.8 bar和7.1 bar,第一级膜和第二级膜的面积分别为448000 m2和180000 m2时,单位捕集成本为27.36 USD/t CO2。与二级二段膜分离以及其他几种传统的CO2捕集方法(MEA法、相变吸收法)相比,二级一段膜分离捕集CO2的捕集成本和能耗均最小。本研究将为CO2捕集实现低能耗和低成本化提供依据。

中图分类号:

李贵贤, 王可, 王健, 孟文亮, 李婧玮, 杨勇, 范宗良, 王东亮, 周怀荣. 膜分离捕集燃煤电厂烟气CO2过程优化设计[J]. 化工学报, 2022, 73(11): 5065-5077.

Guixian LI, Ke WANG, Jian WANG, Wenliang MENG, Jingwei LI, Yong YANG, Zongliang FAN, Dongliang WANG, Huairong ZHOU. Optimal design of membrane separation process for capturing CO2 from flue gas of coal-fired power plant[J]. CIESC Journal, 2022, 73(11): 5065-5077.

| 参数 | 数值 | 单位 | |

|---|---|---|---|

| 燃煤电厂功率 | 550 | MW | |

| 烟气流量 | 22 | kmol/s | |

| 烟气组成 | N2 | 68.8 | %(mol) |

| CO2 | 13.5 | %(mol) | |

| O2 | 2.4 | %(mol) | |

| H2O | 15.3 | %(mol) | |

| 温度 | 330 | K | |

| 压力 | 0.1 | MPa | |

表1 燃煤电厂数据

Table 1 Data of coal-fired power plant

| 参数 | 数值 | 单位 | |

|---|---|---|---|

| 燃煤电厂功率 | 550 | MW | |

| 烟气流量 | 22 | kmol/s | |

| 烟气组成 | N2 | 68.8 | %(mol) |

| CO2 | 13.5 | %(mol) | |

| O2 | 2.4 | %(mol) | |

| H2O | 15.3 | %(mol) | |

| 温度 | 330 | K | |

| 压力 | 0.1 | MPa | |

| 设备 | 投资系数 | 设备折 旧系数 | 使用 寿命/a | 维护费 用系数 | 设备 效率/% |

|---|---|---|---|---|---|

| 压缩机 | 96000 USD/(m3·s) | 0.064 | 25 | 0.036 | 85 |

| 换热器 | — | 0.064 | 25 | 0.036 | 80 |

| 膨胀机 | — | 0.064 | 25 | 0.036 | 85 |

| 膜元件 | 50 USD/m2 | 0.225 | 5 | 0.010 | — |

表2 设备参数[27]

Table 2 Equipment parameters [27]

| 设备 | 投资系数 | 设备折 旧系数 | 使用 寿命/a | 维护费 用系数 | 设备 效率/% |

|---|---|---|---|---|---|

| 压缩机 | 96000 USD/(m3·s) | 0.064 | 25 | 0.036 | 85 |

| 换热器 | — | 0.064 | 25 | 0.036 | 80 |

| 膨胀机 | — | 0.064 | 25 | 0.036 | 85 |

| 膜元件 | 50 USD/m2 | 0.225 | 5 | 0.010 | — |

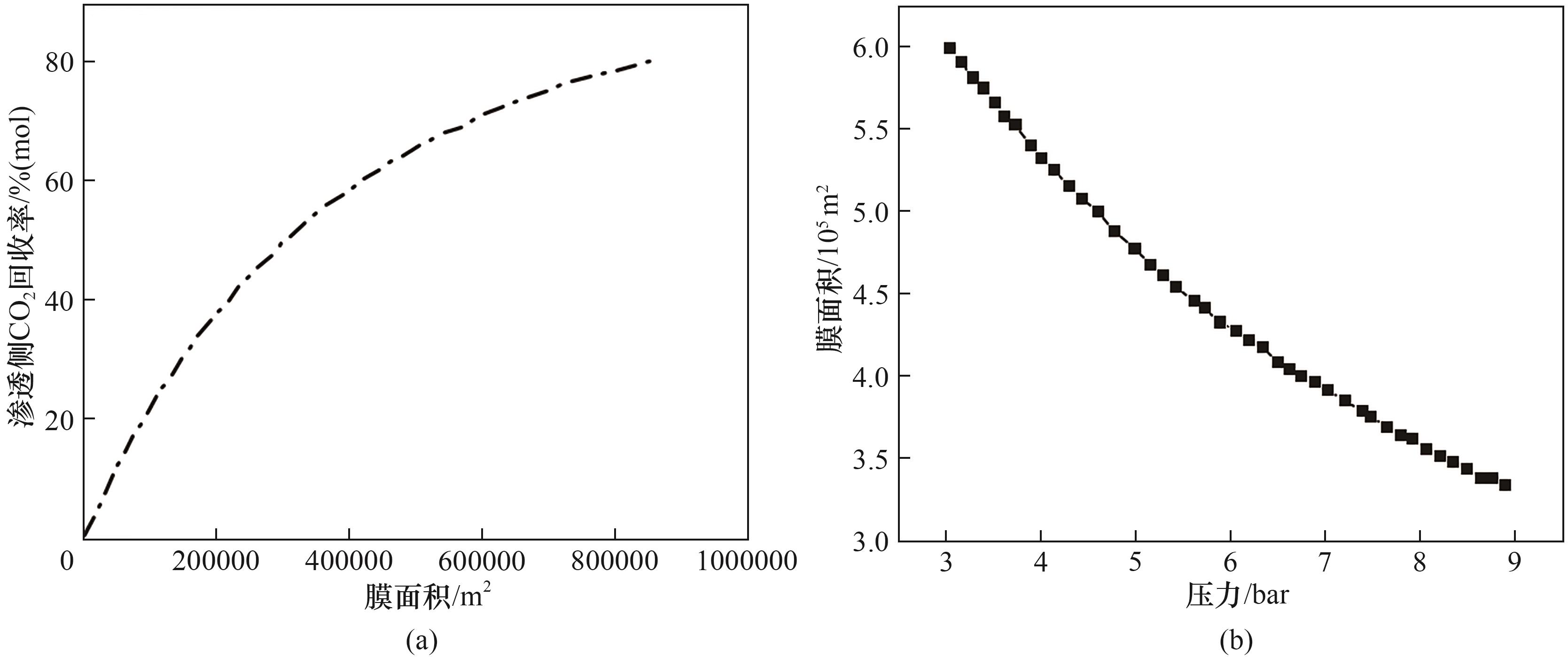

图5 一级膜分离过程回收率与膜面积(a)和膜面积与压力(b)的关系

Fig.5 Relationship between recovery rate and membrane area (a) and membrane area and operating pressure (b) in one-stage membrane process

| 28 | Pfister M, Belaissaoui B, Favre E. Membrane gas separation processes from wet postcombustion flue gases for carbon capture and use: a critical reassessment[J]. Industrial & Engineering Chemistry Research, 2017, 56(2): 591-602. |

| 29 | Brinkmann T, Pohlmann J, Withalm U, et al. Theoretical and experimental investigations of flat sheet membrane module types for high capacity gas separation applications[J]. Chemie Ingenieur Technik, 2013, 85(8): 1210-1220. |

| 30 | Robeson L M. Correlation of separation factor versus permeability for polymeric membranes[J]. Journal of Membrane Science, 1991, 62(2): 165-185. |

| 31 | Tuinier M J, Hamers H P, van Sint Annaland M. Techno-economic evaluation of cryogenic CO2 capture—a comparison with absorption and membrane technology[J]. International Journal of Greenhouse Gas Control, 2011, 5(6): 1559-1565. |

| 32 | Johan A. Carbon dioxide capture using phase changing solvents a comparison with state-of-the-art MEA technologies[D]. Gothenburg, Sweden: Chalmers University of Technology, 2017. |

| 1 | IEA. Global energy review: CO2 emissions in 2021[R/OL]. Paris: International Energy Agency, 2021. . |

| 2 | Bui M, Adjiman C S, Bardow A, et al. Carbon capture and storage (CCS): the way forward[J]. Energy & Environmental Science, 2018, 11(5): 1062-1176. |

| 3 | 许咪咪, 王淑娟. 液-液相变溶剂捕集CO2技术研究进展[J]. 化工学报, 2018, 69(5): 1809-1818. |

| Xu M M, Wang S J. Research progress in CO2 capture technology using liquid-liquid biphasic solvents[J]. CIESC Journal, 2018, 69(5): 1809-1818. | |

| 4 | 徐冬, 张军, 翟玉春, 等. 变压吸附分离工业废气中二氧化碳的研究进展[J]. 化工进展, 2010, 29(1): 150-156, 162. |

| Xu D, Zhang J, Zhai Y C, et al. Progress in carbon dioxide capture from flue gas by pressure swing adsorption[J]. Chemical Industry and Engineering Progress, 2010, 29(1): 150-156, 162. | |

| 5 | 蔡博峰, 李琦, 张贤, 等. 中国二氧化碳捕集利用与封存(CCUS)年度报告(2021)——中国 CCUS 路径研究[R]. 生态环境部环境规划院, 中国科学院武汉岩土力学研究所, 中国 21 世纪议程管理中心, 2021. |

| Cai B F, Li Q, Zhang X, et al. Annual report on carbon dioxide capture, utilization and storage (CCUS) in China (2021) —study on CCUS path in China[R]. Chinese Academy of Environmental Planning, Institute of Rock and Soil Mechanics of Chinese Academy of Sciences, The Administrative Centre for China's Agenda 21, 2021. | |

| 6 | Lee S, Binns M, Lee J H, et al. Membrane separation process for CO2 capture from mixed gases using TR and XTR hollow fiber membranes: process modeling and experiments[J]. Journal of Membrane Science, 2017, 541: 224-234. |

| 7 | Lau H S, Yong W F. Recent progress and prospects of polymeric hollow fiber membranes for gas application, water vapor separation and particulate matter removal[J]. Journal of Materials Chemistry A, 2021, 9(47): 26454-26497. |

| 8 | Dai Z D, Ansaloni L, Deng L Y. Recent advances in multi-layer composite polymeric membranes for CO2 separation: a review[J]. Green Energy & Environment, 2016, 1(2): 102-128. |

| 9 | 赵子淇, 张忠孝, 江砚池, 等. 聚酰亚胺中空纤维膜分离CO2/N2的影响因素分析[J]. 能源工程, 2020(2): 61-65. |

| Zhao Z Q, Zhang Z X, Jiang Y C, et al. Study on influencing factors of polyimide hollow fiber membrane on CO2/N2 separation[J]. Energy Engineering, 2020(2): 61-65. | |

| 10 | Scholz M, Alders M, Lohaus T, et al. Structural optimization of membrane-based biogas upgrading processes[J]. Journal of Membrane Science, 2015, 474: 1-10. |

| 11 | Gabrielli P, Gazzani M, Mazzotti M. On the optimal design of membrane-based gas separation processes[J]. Journal of Membrane Science, 2017, 526: 118-130. |

| 12 | Kim M, Kim J. Optimization model for the design and feasibility analysis of membrane-based gas separation systems for CO2 enhanced coal bed methane (CO2-ECBM) applications[J]. Chemical Engineering Research and Design, 2018, 132: 853-864. |

| 13 | Hasan M M F, Baliban R C, Elia J A, et al. Modeling, simulation, and optimization of postcombustion CO2 capture for variable feed concentration and flow rate(part 2): Pressure swing adsorption and vacuum swing adsorption processes[J]. Industrial & Engineering Chemistry Research, 2012, 51(48): 15665-15682. |

| 14 | Song C F, Sun Y W, Fan Z C, et al. Parametric study of a novel cryogenic-membrane hybrid system for efficient CO2 separation[J]. International Journal of Greenhouse Gas Control, 2018, 72: 74-81. |

| 15 | 张淑君, 王诗慧, 张欣, 等. 集成轻烃回收单元代理模型的氢气网络多目标优化[J]. 化工学报, 2022, 73(4): 1658-1672. |

| Zhang S J, Wang S H, Zhang X, et al. Surrogate-assisted multi-objective optimization of hydrogen networks with light hydrocarbon recovery unit[J]. CIESC Journal, 2022, 73(4): 1658-1672. | |

| 16 | 石向成, 赵志坚, 巩金龙. 遗传算法在催化体系的全局结构优化中的应用[J]. 化工学报, 2021, 72(1): 27-41. |

| Shi X C, Zhao Z J, Gong J L. Application of genetic algorithm in the global structure optimization of catalytic system[J]. CIESC Journal, 2021, 72(1): 27-41. | |

| 17 | Zhang X P, He X Z, Gundersen T. Post-combustion carbon capture with a gas separation membrane: parametric study, capture cost, and exergy analysis[J]. Energy & Fuels, 2013, 27(8): 4137-4149. |

| 18 | Xu J Y, Wang Z, Qiao Z H, et al. Post-combustion CO2 capture with membrane process: practical membrane performance and appropriate pressure[J]. Journal of Membrane Science, 2019, 581: 195-213. |

| 19 | Zhao L, Riensche E, Blum L, et al. Multi-stage gas separation membrane processes used in post-combustion capture: energetic and economic analyses[J]. Journal of Membrane Science, 2010, 359(1/2): 160-172. |

| 20 | Ramasubramanian K, Verweij H, Winston Ho W S. Membrane processes for carbon capture from coal-fired power plant flue gas: a modeling and cost study[J]. Journal of Membrane Science, 2012, 421/422: 299-310. |

| 21 | 王志, 原野, 生梦龙, 等. 膜法碳捕集技术: 研究现状及展望[J]. 化工进展, 2022, 41(3): 1097-1101. |

| Wang Z, Yuan Y, Sheng M L, et al. Membrane technology for carbon capture—research status and prospects[J]. Chemical Industry and Engineering Progress, 2022, 41(3): 1097-1101. | |

| 22 | Pan C Y. Gas separation by permeators with high-flux asymmetric membranes[J]. AIChE Journal, 1983, 29(4): 545-552. |

| 23 | Weller S, Steiner W A. Separation of gases by fractional permeation through membranes[J]. Journal of Applied Physics, 1950, 21(4): 279-283. |

| 24 | Shindo Y, Hakuta T, Yoshitome H, et al. Calculation methods for multicomponent gas separation by permeation[J]. Separation Science and Technology, 1985, 20(5/6): 445-459. |

| 25 | Lim Y I, Floquet P, Joulia X, et al. Multiobjective optimization in terms of economics and potential environment impact for process design and analysis in a chemical process simulator[J]. Industrial & Engineering Chemistry Research, 1999, 38(12): 4729-4741. |

| 26 | 张琳, 胡斌, 王霞, 等. PI中空纤维膜分离模拟燃煤脱硫烟气中的CO2 [J]. 中国电机工程学报, 2017, 37(9): 2637-2644. |

| Zhang L, Hu B, Wang X, et al. CO2 separation by PI hollow fiber membrane from desulfurized flue gas[J]. Proceedings of the CSEE, 2017, 37(9): 2637-2644. | |

| 27 | Black J. Cost and performance comparison baseline for fossil energy plants[R]. Washington, DC, USA: U.S. Department of Energy, 2010. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [4] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [5] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [6] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [7] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [8] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [9] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [10] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [11] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [12] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [13] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [14] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [15] | 黄可欣, 李彤, 李桉琦, 林梅. 加装旋转叶轮T型通道流场的模态分解[J]. 化工学报, 2023, 74(7): 2848-2857. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号