化工学报 ›› 2022, Vol. 73 ›› Issue (1): 213-221.DOI: 10.11949/0438-1157.20210863

收稿日期:2021-06-28

修回日期:2021-09-03

出版日期:2022-01-05

发布日期:2022-01-18

通讯作者:

朱春英

作者简介:费滢洁(1998—),女,硕士研究生,基金资助:

Yingjie FEI1( ),Chunying ZHU1(

),Chunying ZHU1( ),Taotao FU1,Xiqun GAO2,Youguang MA1

),Taotao FU1,Xiqun GAO2,Youguang MA1

Received:2021-06-28

Revised:2021-09-03

Online:2022-01-05

Published:2022-01-18

Contact:

Chunying ZHU

摘要:

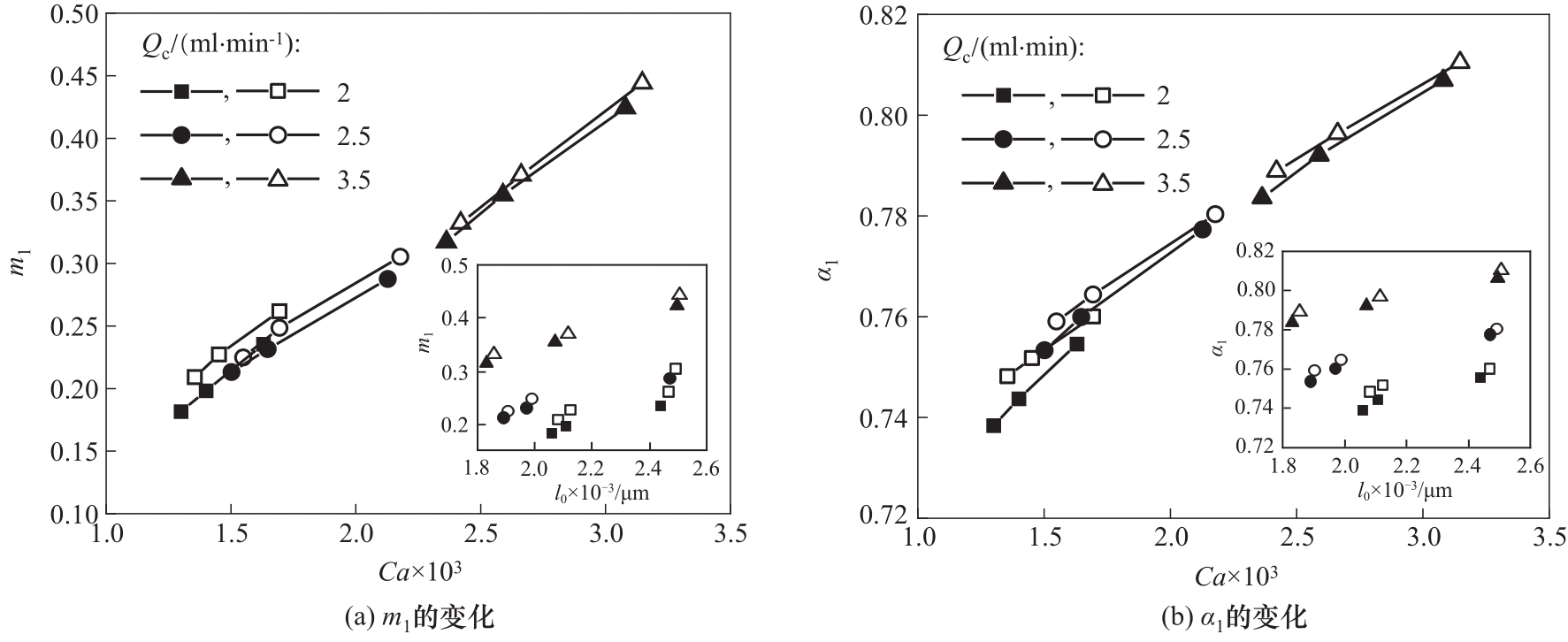

研究了Y型微通道吸附型纳米颗粒稳定气泡的完全阻塞破裂的动力学,破裂过程可划分为挤压阶段和快速夹断阶段,两阶段内无量纲气泡最小颈部宽度与时间均呈幂率关系。气泡破裂过程的颈部动力学表明颗粒的存在并不影响两阶段转变的临界颈部宽度,但吸附在气泡表面的颗粒层会减弱挤压阶段中连续相对气泡颈部的挤压作用,以及快速夹断阶段角区中连续相液体回流对气泡的挤压作用,进而阻碍气泡颈部的形变,延长了气泡的破裂过程。纳米颗粒稳定的气泡的指前因子m及幂率指数α均小于常规气泡,但其差值随着毛细管数Ca和气泡长度l0的增大而减小,颗粒对气泡破裂过程的影响逐渐减弱。此外,纳米颗粒稳定的气泡的头部曲率略小于常规气泡,颗粒对完全阻塞破裂过程气泡头部动力学的影响可以忽略。

中图分类号:

费滢洁, 朱春英, 付涛涛, 高习群, 马友光. Y型微通道内纳米颗粒稳定气泡的完全阻塞破裂动力学[J]. 化工学报, 2022, 73(1): 213-221.

Yingjie FEI, Chunying ZHU, Taotao FU, Xiqun GAO, Youguang MA. Breakup dynamics of bubbles stabilized by nanoparticles with permanent obstruction in a microfluidic Y-junction[J]. CIESC Journal, 2022, 73(1): 213-221.

图5 气泡完全阻塞破裂过程最小颈部宽度和时间的幂律关系 (Qc = 2.5 ml·min-1,Qd = 0.8 ml·min-1)

Fig.5 Power-law relationship between minimum neck width and time for bubble breakup with permanent obstruction (Qc = 2.5 ml·min-1,Qd = 0.8 ml·min-1)

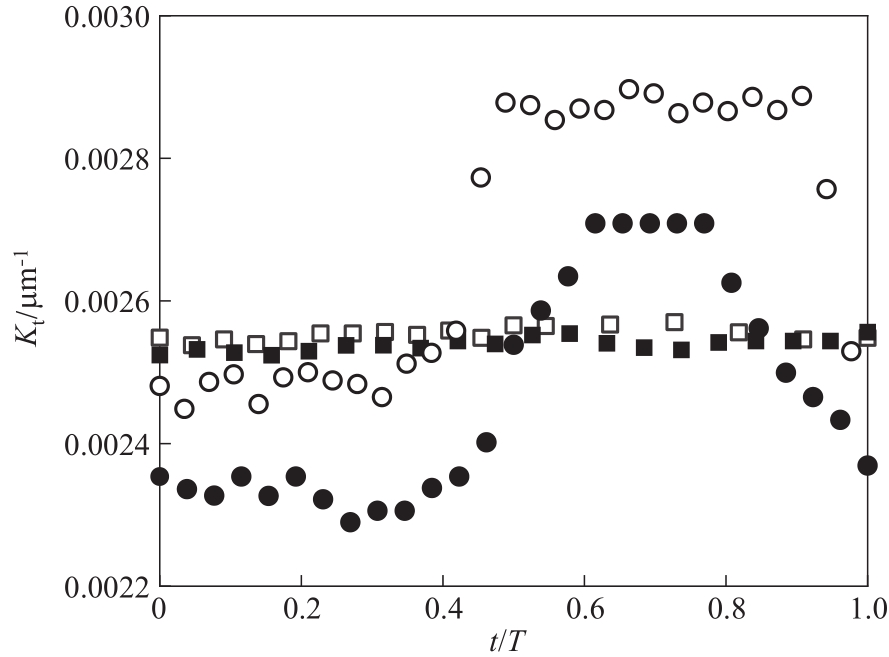

图6 气泡头部曲率的演化 (Qd = 0.8 ml·min-1)■,□ Qc = 2.5 ml·min-1,完全阻塞破裂; ●,○ Qc = 3 ml·min-1,部分阻塞破裂; 空心符号为常规气泡,实心符号为纳米颗粒稳定的气泡

Fig.6 The evaluation of bubble tip curvature (Qd = 0.8 ml·min-1)■,□ Qc = 2.5 ml·min-1, breakup with permanent obstruction; ●,○ Qc = 3 ml·min-1, breakup with partial obstruction; hollow symbols for original bubbles, solid symbols for hardening bubbles

图7 最小颈部宽度与时间的幂律关系 (空心符号为常规气泡,实心符号为纳米颗粒稳定的气泡)

Fig.7 Minimum width of the neck versus the dimensionless time (hollow symbols for original bubbles, solid symbols for hardening bubbles)

图8 挤压阶段指前因子m1和幂率指数α1随Ca和l0的变化 (空心符号为常规气泡,实心符号为纳米颗粒稳定的气泡)

Fig.8 The variation of pre-exponential factor m1 and power-law exponent α1 with Ca and l0 in squeezing stage (hollow symbols for original bubbles, solid symbols for hardening bubbles)

图9 快速夹断阶段指前因子m2和幂律指数α2随Ca和l0的变化 (空心符号为常规气泡,实心符号为纳米颗粒稳定的气泡)

Fig.9 The variation of pre-exponential factor m2 and power-law exponent α2 with Ca and l0 in pinch-off stage (hollow symbols for original bubbles, solid symbols for hardening bubbles)

| 1 | 陈光文, 袁权. 微化工技术[J]. 化工学报, 2003, 54(4): 427-439. |

| Chen G W, Yuan Q. Micro-chemical technology[J]. Journal of Chemical Industry and Engineering (China), 2003, 54(4): 427-439. | |

| 2 | Kashid M, Renken A, Kiwi-Minsker L. Mixing efficiency and energy consumption for five generic microchannel designs[J]. Chemical Engineering Journal, 2011, 167(2/3): 436-443. |

| 3 | 程曜峰, 张丽娟, 张炜, 等. 微萃取器在多粘菌素B萃取工艺中的应用[J]. 化学工业与工程, 2021, 38(2): 55-60. |

| Cheng Y F, Zhang L J, Zhang W, et al. Application of microextractor in polymyxin B extraction process[J]. Chemical Industry and Engineering, 2021, 38(2): 55-60. | |

| 4 | 王彦, 王靖涛. 微流控技术制备聚酰胺微胶囊的工艺研究[J]. 化学工业与工程, 2018, 35(6): 20-25. |

| Wang Y, Wang J T. Preparation of polyamide microcapsules based on microfluidics[J]. Chemical Industry and Engineering, 2018, 35(6): 20-25. | |

| 5 | Günther A, Jensen K F. Multiphase microfluidics: from flow characteristics to chemical and materials synthesis[J]. Lab on a Chip, 2006, 6(12): 1487-1503. |

| 6 | du Toit H, MacDonald T J, Huang H, et al. Continuous flow synthesis of citrate capped gold nanoparticles using UV induced nucleation[J]. RSC Advances, 2017, 7(16): 9632-9638. |

| 7 | 崔永晋, 李严凯, 王凯, 等. 微分散设备数量放大方式研究进展[J]. 化工学报, 2020, 71(10): 4350-4364. |

| Cui Y J, Li Y K, Wang K, et al. Recent advances of numbering-up technology of micro-dispersion devices[J]. CIESC Journal, 2020, 71(10): 4350-4364. | |

| 8 | Tetradis-Meris G, Rossetti D, Pulido de Torres C, et al. Novel parallel integration of microfluidic device network for emulsion formation[J]. Industrial & Engineering Chemistry Research, 2009, 48(19): 8881-8889. |

| 9 | Link D R, Anna S L, Weitz D A, et al. Geometrically mediated breakup of drops in microfluidic devices[J]. Physical Review Letters, 2004, 92(5): 054503. |

| 10 | Fu T T, Ma Y G, Funfschilling D, et al. Dynamics of bubble breakup in a microfluidic T-junction divergence[J]. Chemical Engineering Science, 2011, 66(18): 4184-4195. |

| 11 | Wang X D, Zhu C Y, Fu T T, et al. Critical lengths for the transition of bubble breakup in microfluidic T-junctions[J]. Chemical Engineering Science, 2014, 111: 244-254. |

| 12 | Leshansky A M, Afkhami S, Jullien M C, et al. Obstructed breakup of slender drops in a microfluidic T junction[J]. Physical Review Letters, 2012, 108(26): 264502. |

| 13 | Hoang D A, Portela L M, Kleijn C R, et al. Dynamics of droplet breakup in a T-junction[J]. Journal of Fluid Mechanics, 2013, 717: R4. |

| 14 | Yamada M, Doi S, Maenaka H, et al. Hydrodynamic control of droplet division in bifurcating microchannel and its application to particle synthesis[J]. Journal of Colloid and Interface Science, 2008, 321(2): 401-407. |

| 15 | Liang D, Ma R, Fu T T, et al. Dynamics and formation of alternating droplets under magnetic field at a T-junction[J]. Chemical Engineering Science, 2019, 200: 248-256. |

| 16 | Dubash N, Mestel A J. Breakup behavior of a conducting drop suspended in a viscous fluid subject to an electric field[J]. Physics of Fluids, 2007, 19(7): 072101. |

| 17 | Lang L Y, Li H B, Wang X, et al. Experimental study and field demonstration of air-foam flooding for heavy oil EOR[J]. Journal of Petroleum Science and Engineering, 2020, 185: 106659. |

| 18 | Andersons J, Kirpluks M, Cabulis P, et al. Bio-based rigid high-density polyurethane foams as a structural thermal break material[J]. Construction and Building Materials, 2020, 260: 120471. |

| 19 | Godefroidt T, Ooms N, Pareyt B, et al. Ingredient functionality during foam-type cake making: a review[J]. Comprehensive Reviews in Food Science and Food Safety, 2019, 18(5): 1550-1562. |

| 20 | Aichele J, Giammarinaro B, Reinwald M, et al. Capturing the shear and secondary compression waves: high-frame-rate ultrasound imaging in saturated foams[J]. Physical Review Letters, 2019, 123(14): 148001. |

| 21 | Zhao Y J, Jones S A, Brown M B. Dynamic foams in topical drug delivery[J]. Journal of Pharmacy and Pharmacology, 2010, 62(6): 678-684. |

| 22 | Binks B P, Horozov T S. Aqueous foams stabilized solely by silica nanoparticles[J]. Angewandte Chemie International Edition, 2005, 44(24): 3722-3725. |

| 23 | Ravera F, Santini E, Loglio G, et al. Effect of nanoparticles on the interfacial properties of liquid/liquid and liquid/air surface layers[J]. The Journal of Physical Chemistry. B, 2006, 110(39): 19543-19551. |

| 24 | Binks B P, Kirkland M, Rodrigues J A. Origin of stabilisation of aqueous foams in nanoparticle-surfactant mixtures[J]. Soft Matter, 2008, 4(12): 2373. |

| 25 | van Steijn V, Kleijn C R, Kreutzer M T. Flows around confined bubbles and their importance in triggering pinch-off[J]. Physical Review Letters, 2009, 103(21): 214501. |

| 26 | Jullien M C, Tsang Mui Ching M J, Cohen C, et al. Droplet breakup in microfluidic T-junctions at small capillary numbers[J]. Physics of Fluids, 2009, 21(7): 072001. |

| 27 | Garstecki P, Fuerstman M J, Stone H A, et al. Formation of droplets and bubbles in a microfluidic T-junction-scaling and mechanism of break-up[J]. Lab on a Chip, 2006, 6(3): 437-446. |

| 28 | Fei W J, Gu Y, Bishop K J M. Active colloidal particles at fluid-fluid interfaces[J]. Current Opinion in Colloid & Interface Science, 2017, 32: 57-68. |

| 29 | Fei Y J, Zhu C Y, Fu T T, et al. The breakup dynamics of bubbles stabilized by nanoparticles in a microfluidic Y-junction[J]. Chemical Engineering Science, 2021, 245: 116867. |

| 30 | Wu Y N, Wang R Y, Dai C L, et al. Precisely tailoring bubble morphology in microchannel by nanoparticles self-assembly[J]. Industrial & Engineering Chemistry Research, 2019, 58(9): 3707-3713. |

| 31 | Burton J C, Waldrep R, Taborek P. Scaling and instabilities in bubble pinch-off[J]. Physical Review Letters, 2005, 94(18): 184502. |

| 32 | Eggers J, Fontelos M A, Leppinen D, et al. Theory of the collapsing axisymmetric cavity[J]. Physical Review Letters, 2007, 98(9): 094502. |

| 33 | Du W, Fu T T, Zhang Q D, et al. Self-similar breakup of viscoelastic thread for droplet formation in flow-focusing devices[J]. AIChE Journal, 2017, 63(11): 5196-5206. |

| [1] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [2] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [3] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [4] | 曾如宾, 沈中杰, 梁钦锋, 许建良, 代正华, 刘海峰. 基于分子动力学模拟的Fe2O3纳米颗粒烧结机制研究[J]. 化工学报, 2023, 74(8): 3353-3365. |

| [5] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [6] | 王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879. |

| [7] | 陈巨辉, 张谦, 舒崚峰, 李丹, 徐鑫, 刘晓刚, 赵晨希, 曹希峰. 基于DEM方法的旋转流化床纳米颗粒流动特性研究[J]. 化工学报, 2023, 74(6): 2374-2381. |

| [8] | 王泽栋, 石至平, 刘丽艳. 考虑气泡非均匀耗散的矩形反应器声流场数值模拟及结构优化[J]. 化工学报, 2023, 74(5): 1965-1973. |

| [9] | 张银宁, 王进卿, 冯致, 詹明秀, 徐旭, 张光学, 池作和. 升温条件下多孔介质内气泡的生长和聚并行为[J]. 化工学报, 2023, 74(4): 1509-1518. |

| [10] | 邓璐, 巨晓洁, 张文杰, 谢锐, 汪伟, 刘壮, 潘大伟, 褚良银. 微流控法可控制备放射性壳聚糖栓塞微球[J]. 化工学报, 2023, 74(4): 1781-1794. |

| [11] | 贾露凡, 王艺颖, 董钰漫, 李沁园, 谢鑫, 苑昊, 孟涛. 微流控双水相贴壁液滴流动强化酶促反应研究[J]. 化工学报, 2023, 74(3): 1239-1246. |

| [12] | 项星宇, 王忠东, 董艳鹏, 李守川, 朱春英, 马友光, 付涛涛. 微通道内屈服应力型流体的流变特性及多相流研究进展[J]. 化工学报, 2023, 74(2): 546-558. |

| [13] | 黄心童, 耿宇昊, 刘恒源, 陈卓, 徐建鸿. 微流控制备新型功能纳米粒子研究进展[J]. 化工学报, 2023, 74(1): 355-364. |

| [14] | 盛林, 昌宇, 邓建, 骆广生. 阶梯式T型微通道内有序气泡群的形成和流动特性研究[J]. 化工学报, 2023, 74(1): 416-427. |

| [15] | 张童, 杨扬, 叶丁丁, 陈蓉, 朱恂, 廖强. 催化剂分布对可渗透阳极微流体燃料电池性能特性影响的研究[J]. 化工学报, 2022, 73(9): 4156-4162. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号