化工学报 ›› 2021, Vol. 72 ›› Issue (12): 6361-6370.DOI: 10.11949/0438-1157.20211071

收稿日期:2021-08-02

修回日期:2021-09-23

出版日期:2021-12-05

发布日期:2021-12-22

通讯作者:

庹新林,杨万泰

作者简介:谢春杰(1991—),男,博士,基金资助:

Chunjie XIE( ),Ran HE,Xinlin TUO(

),Ran HE,Xinlin TUO( ),Wantai YANG(

),Wantai YANG( )

)

Received:2021-08-02

Revised:2021-09-23

Online:2021-12-05

Published:2021-12-22

Contact:

Xinlin TUO,Wantai YANG

摘要:

以对位芳纶纳米纤维(PANF)水凝胶为原料,将冻凝胶粉碎法与冷冻干燥法相结合,制备出PANF气凝胶粉体。系统研究了对位芳纶气凝胶粉体的微观结构及性能参数,以及制备条件对产物形貌的影响,并初步探究了其应用。结果表明,液氮冷冻制备的PANF气凝胶粉体具有多孔结构,松装密度约为17.0 kg?m-3,孔隙率约为98.8%,BET比表面积可达126.30 m2?g-1。PANF气凝胶粉体的耐热性优异,在氮气气氛下500℃前几乎无分解;热导率较低,约为0.03 W?m-1·K-1。气凝胶粉体具有吸附罗丹明B等染料的特征,同时可作为纳米填充材料增强聚氨酯乳胶膜等聚合物材料的硬度,其低热导率表明其有望应用于绝热领域。

中图分类号:

谢春杰, 何然, 庹新林, 杨万泰. 对位芳纶气凝胶粉体的制备与性能研究[J]. 化工学报, 2021, 72(12): 6361-6370.

Chunjie XIE, Ran HE, Xinlin TUO, Wantai YANG. Preparation and performance of para-aramid aerogel powders[J]. CIESC Journal, 2021, 72(12): 6361-6370.

| 项目 | PANF气凝胶 粉体 | PANF气凝胶 块体 |

|---|---|---|

| BET比表面积 /(m2?g-1) | 126.30 | 78.92 |

| 总孔体积 /(cm3?g-1) | 7.00 ×10-1① | 3.96 ×10-1② |

| BJH法累积吸附孔体积 /(cm3?g-1) | 7.03 ×10-1 | 4.01 ×10-1 |

| BJH法累积脱附孔体积 /(cm3?g-1) | 7.08 ×10-1 | 4.04 ×10-1 |

| SF法孔体积 /(cm3?g-1) | 4.15 ×10-2 | 2.48 ×10-2 |

表1 PANF气凝胶粉体和气凝胶块体的比表面积和孔体积对比

Table 1 Comparison of the surface area and pore volume of PANF aerogel powders and aerogel monoblock

| 项目 | PANF气凝胶 粉体 | PANF气凝胶 块体 |

|---|---|---|

| BET比表面积 /(m2?g-1) | 126.30 | 78.92 |

| 总孔体积 /(cm3?g-1) | 7.00 ×10-1① | 3.96 ×10-1② |

| BJH法累积吸附孔体积 /(cm3?g-1) | 7.03 ×10-1 | 4.01 ×10-1 |

| BJH法累积脱附孔体积 /(cm3?g-1) | 7.08 ×10-1 | 4.04 ×10-1 |

| SF法孔体积 /(cm3?g-1) | 4.15 ×10-2 | 2.48 ×10-2 |

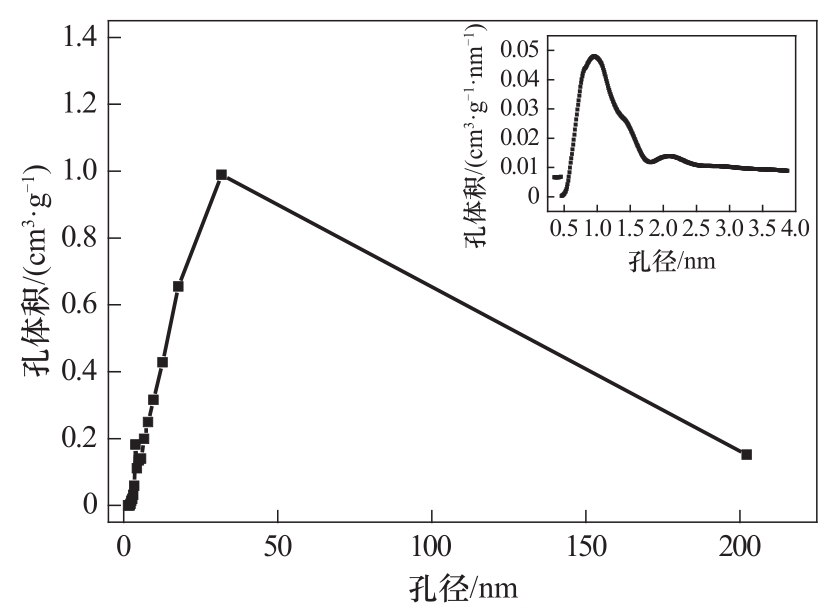

图5 PANF气凝胶粉体介孔和大孔孔体积分布(内插图为微孔孔体积分布)

Fig.5 Pore volume distribution of mesopores and macropores of PANF aerogel powders(The inset is the pore volume distribution of micropores)

图9 通过纳米压痕法测试的PU乳胶膜和PU/PANF复合乳胶膜的硬度和模量对比

Fig.9 Comparison of the hardness and modulus of the PU latex film and PU/PANF composite latex film tested by nano indentation method

| 1 | Kistler S S. Coherent expanded aerogels and jellies[J]. Nature, 1931, 127(3211): 741. |

| 2 | Salimian S, Zadhoush A, Talebi Z. Interpenetrating organic–inorganic network: a short review on aerogel as a nanoporous filler in epoxy nanocomposite[J]. Material Design & Processing Communications, 2019, 1(6): e107. |

| 3 | Liu Q Z, Chen J H, Mei T, et al. A facile route to the production of polymeric nanofibrous aerogels for environmentally sustainable applications[J]. Journal of Materials Chemistry A, 2018, 6(8): 3692-3704. |

| 4 | Qian F, Lan P C, Freyman M C, et al. Ultralight conductive silver nanowire aerogels[J]. Nano Letters, 2017, 17(12): 7171-7176. |

| 5 | Li C, Ding Y W, Hu B C, et al. Temperature-invariant superelastic and fatigue resistant carbon nanofiber aerogels[J]. Advanced Materials, 2020, 32(2): e1904331. |

| 6 | Hayase G, Kanamori K, Abe K, et al. Polymethylsilsesquioxane-cellulose nanofiber biocomposite aerogels with high thermal insulation, bendability, and superhydrophobicity[J]. ACS Applied Materials & Interfaces, 2014, 6(12): 9466-9471. |

| 7 | Alwin S, Sahaya Shajan X. Aerogels: promising nanostructured materials for energy conversion and storage applications[J]. Materials for Renewable and Sustainable Energy, 2020, 9(2): 1-27. |

| 8 | Hüsing N, Schubert U. Aerogels-airy materials: chemistry, structure, and properties[J]. Angewandte Chemie, 1998, 37(1/2): 22-45. |

| 9 | Notario B, Pinto J, Rodriguez-Perez M A. Nanoporous polymeric materials: a new class of materials with enhanced properties[J]. Progress in Materials Science, 2016, 78/79: 93-139. |

| 10 | Pierre A C, Pajonk G M. Chemistry of aerogels and their applications[J]. Chemical Reviews, 2002, 102(11): 4243-4266. |

| 11 | Ge J, Zhao H Y, Zhu H W, et al. Advanced sorbents for oil-spill cleanup: recent advances and future perspectives[J]. Advanced Materials, 2016, 28(47): 10459-10490. |

| 12 | Jiang S H, Agarwal S, Greiner A. Low-density open cellular sponges as functional materials[J]. Angewandte Chemie International Edition, 2017, 56(49): 15520-15538. |

| 13 | Gorgolis G, Galiotis C. Graphene aerogels: a review[J]. 2D Materials, 2017, 4(3): 032001. |

| 14 | Wang H L, Hsu C Y, Wu K C W, et al. Functional nanostructured materials: aerosol, aerogel, and de novo synthesis to emerging energy and environmental applications[J]. Advanced Powder Technology, 2020, 31(1): 104-120. |

| 15 | Smith D M, Stein D, Anderson J M, et al. Preparation of low-density xerogels at ambient pressure[J]. Journal of Non-Crystalline Solids, 1995, 186: 104-112. |

| 16 | Liu N, Zhang S T, Fu R W, et al. Fabrication and structure of carbon aerogel spheres prepared by inverse suspension/emulsion polymerization and ambient pressure drying[J]. Journal of Applied Polymer Science, 2007, 104(5): 2849-2855. |

| 17 | Stojanovic A, Zhao S Y, Angelica E, et al. Three routes to superinsulating silica aerogel powder[J]. Journal of Sol-Gel Science and Technology, 2019, 90(1): 57-66. |

| 18 | Rani T S, Subha M C S, Venkata Reddy G, et al. Synthesis of water-glass-based silica aerogel powder via with and without squeezing of hydrogels[J]. Journal of Applied Polymer Science, 2010, 115(3): 1675-1679. |

| 19 | de Pooter S, Latré S, Desplentere F, et al. Optimized synthesis of ambient pressure dried thermal insulating silica aerogel powder from non-ion exchanged water glass[J]. Journal of Non-Crystalline Solids, 2018, 499: 217-226. |

| 20 | Liu R Y, Wang J, Du Y, et al. Phase-separation induced synthesis of superhydrophobic silica aerogel powders and granules[J]. Journal of Solid State Chemistry, 2019, 279: 120971. |

| 21 | Kirchnerova J, Klvana D, Chaouki J. Preparation and characterization of alumina and chromia cryogel-based catalysts[J]. Applied Catalysis A: General, 2000, 196(2): 191-198. |

| 22 | Bhagat S D, Kim Y H, Moon M J, et al. A cost-effective and fast synthesis of nanoporous SiO2 aerogel powders using water-glass via ambient pressure drying route[J]. Solid State Sciences, 2007, 9(7): 628-635. |

| 23 | Asare Bediako B B, Zhou P, Rugabirwa B, et al. A switchable hydrophilicity solvent mediated process to prepare fine silica aerogel powder as an excellent flatting agent[J]. Advanced Powder Technology, 2019, 30(3): 565-571. |

| 24 | Salimian S, Zadhoush A, Talebi Z, et al. Silica aerogel–epoxy nanocomposites: understanding epoxy reinforcement in terms of aerogel surface chemistry and epoxy–silica interface compatibility[J]. ACS Applied Nano Materials, 2018, 1(8): 4179-4189. |

| 25 | Kim Y N, Shao G N, Jeon S J, et al. Sol–gel synthesis of sodium silicate and titanium oxychloride based TiO2–SiO2 aerogels and their photocatalytic property under UV irradiation[J]. Chemical Engineering Journal, 2013, 231: 502-511. |

| 26 | 于照亮, 彭文联, 刘清海, 等. 碳气凝胶超细粉体的可控制备技术[J]. 中国粉体技术, 2021, 27(2): 17-21. |

| Yu Z L, Peng W L, Liu Q H, et al. Controllable preparation techniche of carbon aerogel ultrafine powder[J]. China Powder Science and Technology, 2021, 27(2): 17-21. | |

| 27 | 闫红梅, 王朝阳, 唐永建, 等. 制备条件对气凝胶粉末粒径的影响[J]. 强激光与粒子束, 2006, 18(6): 1027-1030. |

| Yan H M, Wang C Y, Tang Y J, et al. Influence of preparation factors on the size of aerogel powder[J]. High Power Laser and Particle Beams, 2006, 18(6): 1027-1030. | |

| 28 | 李轩科, 刘朗, 刘秀然, 等. 二元炭质-二氧化硅干凝胶和气凝胶前体的制备[J]. 无机材料学报, 2001, 16(1): 134-138. |

| Li X K, Liu L, Liu X R, et al. Preparation of binary carbonaceous-silica xerogel and aerogel precursors[J]. Journal of Inorganic Materials, 2001, 16(1): 134-138. | |

| 29 | 曹伟娜, 安彦飞, 严亚如, 等. PA66–气凝胶复合粉体制备及性能[J]. 工程塑料应用, 2020, 48(5): 23-28. |

| Cao W N, An Y F, Yan Y R, et al. Preparation and properties of PA66–aerogel composite powders[J]. Engineering Plastics Application, 2020, 48(5): 23-28. | |

| 30 | Tanner D, Fitzgerald J A, Phillips B R. The Kevlar story—an advanced materials case study[J]. Angewandte Chemie International Edition in English, 1989, 28(5): 649-654. |

| 31 | Singh T J, Samanta S. Characterization of Kevlar fiber and its composites: a review[J]. Materials Today: Proceedings, 2015, 2(4/5): 1381-1387. |

| 32 | Takayanagi M, Katayose T. N-substituted poly(p-phenylene terephthalamide)[J]. Journal of Polymer Science: Polymer Chemistry Edition, 1981, 19(5): 1133-1145. |

| 33 | Yang M, Cao K, Sui L, et al. Dispersions of aramid nanofibers: a new nanoscale building block[J]. ACS Nano, 2011, 5(9): 6945-6954. |

| 34 | Yang B, Wang L, Zhang M Y, et al. Timesaving, high-efficiency approaches to fabricate aramid nanofibers[J]. ACS Nano, 2019, 13(7): 7886-7897. |

| 35 | Ma Z, Kang S, Ma J, et al. Ultraflexible and mechanically strong double-layered aramid nanofiber-Ti3C2Tx MXene/silver nanowire nanocomposite papers for high-performance electromagnetic interference shielding[J]. ACS Nano, 2020, 14(7): 8368-8382. |

| 36 | Zhu J, Yang M, Emre A, et al. Branched aramid nanofibers[J]. Angewandte Chemie, 2017, 56(39): 11744-11748. |

| 37 | Yang B, Wang L, Zhang M Y, et al. Fabrication, applications, and prospects of aramid nanofiber[J]. Advanced Functional Materials, 2020, 30(22): 2000186. |

| 38 | Williams J C, Nguyen B N, McCorkle L, et al. Highly porous, rigid-rod polyamide aerogels with superior mechanical properties and unusually high thermal conductivity[J]. ACS Applied Materials & Interfaces, 2017, 9(2): 1801-1809. |

| 39 | Wang L, Zhang M, Yang B, et al. Highly compressible, thermally stable, light-weight, and robust aramid nanofibers/Ti3AlC2 MXene composite aerogel for sensitive pressure sensor[J]. ACS Nano, 2020, 14(8): 10633-10647. |

| 40 | Hu P, Lyu J, Fu C, et al. Multifunctional aramid nanofiber/carbon nanotube hybrid aerogel films[J]. ACS Nano, 2020, 14(1): 688-697. |

| 41 | Lyu J, Liu Z, Wu X, et al. Nanofibrous Kevlar aerogel films and their phase-change composites for highly efficient infrared stealth[J]. ACS Nano, 2019, 13(2): 2236-2245. |

| 42 | Xie C, He L, Shi Y, et al. From monomers to a lasagna-like aerogel monolith: an assembling strategy for aramid nanofibers[J]. ACS Nano, 2019, 13(7): 7811-7824. |

| 43 | Xie C, Liu S, Zhang Q, et al. Macroscopic-scale preparation of aramid nanofiber aerogel by modified freezing-drying method[J]. ACS Nano, 2021, 15(6): 10000-10009. |

| 44 | Yan H C, Li J L, Tian W T, et al. A new approach to the preparation of poly(p-phenylene terephthalamide) nanofibers[J]. RSC Advances, 2016, 6(32): 26599-26605. |

| 45 | Xie C J, Guo Z X, Qiu T, et al. Construction of aramid engineering materials via polymerization-induced para-aramid nanofiber hydrogel[J]. Advanced Materials, 2021: 2101280. |

| 46 | Rao Y, Waddon A J, Farris R J. The evolution of structure and properties in poly(p-phenylene terephthalamide) fibers[J]. Polymer, 2001, 42(13): 5925-5935. |

| 47 | Nie C X, Peng Z H, Yang Y, et al. Kevlar based nanofibrous particles as robust, effective and recyclable absorbents for water purification[J]. Journal of Hazardous Materials, 2016, 318: 255-265. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [3] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [4] | 盛冰纯, 于建国, 林森. 铝基锂吸附剂分离高钠型地下卤水锂资源过程研究[J]. 化工学报, 2023, 74(8): 3375-3385. |

| [5] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [6] | 胡兴枝, 张皓焱, 庄境坤, 范雨晴, 张开银, 向军. 嵌有超小CeO2纳米粒子的碳纳米纤维的制备及其吸波性能[J]. 化工学报, 2023, 74(8): 3584-3596. |

| [7] | 陈吉, 洪泽, 雷昭, 凌强, 赵志刚, 彭陈辉, 崔平. 基于分子动力学的焦炭溶损反应及其机理研究[J]. 化工学报, 2023, 74(7): 2935-2946. |

| [8] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [9] | 王志龙, 杨烨, 赵真真, 田涛, 赵桐, 崔亚辉. 搅拌时间和混合顺序对锂离子电池正极浆料分散特性的影响[J]. 化工学报, 2023, 74(7): 3127-3138. |

| [10] | 张澳, 罗英武. 低模量、高弹性、高剥离强度丙烯酸酯压敏胶[J]. 化工学报, 2023, 74(7): 3079-3092. |

| [11] | 王杰, 丘晓琳, 赵烨, 刘鑫洋, 韩忠强, 许雍, 蒋文瀚. 聚电解质静电沉积改性PHBV抗氧化膜的制备与性能研究[J]. 化工学报, 2023, 74(7): 3068-3078. |

| [12] | 朱风, 陈凯琳, 黄小凤, 鲍银珠, 李文斌, 刘嘉鑫, 吴玮强, 高王伟. KOH改性电石渣脱除羰基硫的性能研究[J]. 化工学报, 2023, 74(6): 2668-2679. |

| [13] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [14] | 崔张宁, 胡紫璇, 吴雷, 周军, 叶干, 刘田田, 张秋利, 宋永辉. 可降解纤维素基材料的耐水性能研究进展[J]. 化工学报, 2023, 74(6): 2296-2307. |

| [15] | 王新悦, 王俊杰, 曹思贤, 王翠, 李灵坤, 吴宏宇, 韩静, 吴昊. 玻璃内包材界面修饰对机械应力诱导的单克隆抗体聚集体形成的影响[J]. 化工学报, 2023, 74(6): 2580-2588. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号