化工学报 ›› 2022, Vol. 73 ›› Issue (10): 4355-4365.DOI: 10.11949/0438-1157.20220608

收稿日期:2022-04-28

修回日期:2022-08-02

出版日期:2022-10-05

发布日期:2022-11-02

通讯作者:

许建良

作者简介:朱华兴(1998—),男,硕士研究生,1255094489@qq.com

基金资助:

Huaxing ZHU( ), Jingxiao WANG, Jianliang XU(

), Jingxiao WANG, Jianliang XU( ), Zhenghua DAI, Haifeng LIU

), Zhenghua DAI, Haifeng LIU

Received:2022-04-28

Revised:2022-08-02

Online:2022-10-05

Published:2022-11-02

Contact:

Jianliang XU

摘要:

煤炭分级利用是煤炭高效低碳利用的主要途径之一,提出一种同时制备热解气和合成气的分级气流床气化炉,炉体上部为煤热解室,下部为煤焦气化室。采用PV6M颗粒测速仪对气化炉内固体颗粒的速度和浓度分布进行测量,并运用CFD软件对气化炉内气固两相流场进行模拟。结果表明,在射流发展区域与射流碰撞后的折射流发展区域,颗粒速度较高;边壁区域颗粒速度较低且出现回流现象。在惯性和气流曳力作用下,热解室内大部分颗粒自流进入气化室。热解室上部径向颗粒浓度中心高边壁低;气化室下部径向颗粒浓度中心低边壁高。热解室与气化室进气量比、喷嘴角度及颗粒直径等对气化炉出口颗粒流出量分配有重要的影响。热解室进气量增大,颗粒从热解室出口流出占比先减小后增大;热解喷嘴偏转角与颗粒Stokes数增大,颗粒从热解室出口流出占比减小。

中图分类号:

朱华兴, 王景效, 许建良, 代正华, 刘海峰. 双出口分级气流床气化炉内颗粒速度和浓度分布[J]. 化工学报, 2022, 73(10): 4355-4365.

Huaxing ZHU, Jingxiao WANG, Jianliang XU, Zhenghua DAI, Haifeng LIU. Particle velocity and concentration distribution in double-exit staged entrained-flow gasifier[J]. CIESC Journal, 2022, 73(10): 4355-4365.

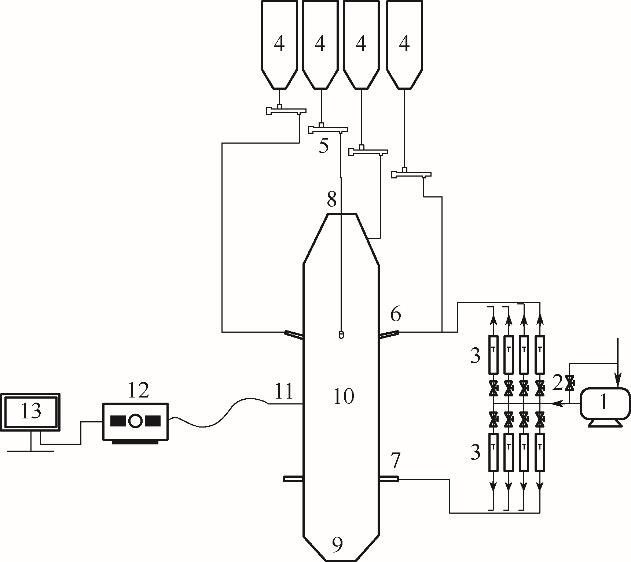

图2 实验流程图1—鼓风机;2—气体阀门;3—转子流量计;4—颗粒料仓;5—颗粒给料机;6—热解喷嘴;7—气化喷嘴;8—热解室出口;9—气化室出口;10—气化炉;11—探针;12—PV6M颗粒速度测量仪;13—计算机

Fig.2 Experiment process1—blower; 2—valve; 3—rotameter; 4—silos; 5—feeder; 6—P-nozzle; 7—G-nozzle; 8—P-exit; 9—G-exit; 10—gasifier; 11—probe; 12—PV6M particle velocimeter; 13—computer

| 热解喷嘴 下偏转角γ/(°) | 热解喷嘴 左偏转角θ/(°) | 颗粒流量/ (kg/h) | 总进气量/ (m3/h) | 热解室进气量/ (m3/h) | 气化室进气量/ (m3/h) | 进气量比α |

|---|---|---|---|---|---|---|

| 15 | 0 | 97.2×4 | 200 | 12.5×4 | 37.5×4 | 1∶3 |

| 10.0×4 | 40.0×4 | 1∶4 | ||||

| 8.3×4 | 41.7×4 | 1∶5 |

表1 实验工况

Table 1 Experimental conditions

| 热解喷嘴 下偏转角γ/(°) | 热解喷嘴 左偏转角θ/(°) | 颗粒流量/ (kg/h) | 总进气量/ (m3/h) | 热解室进气量/ (m3/h) | 气化室进气量/ (m3/h) | 进气量比α |

|---|---|---|---|---|---|---|

| 15 | 0 | 97.2×4 | 200 | 12.5×4 | 37.5×4 | 1∶3 |

| 10.0×4 | 40.0×4 | 1∶4 | ||||

| 8.3×4 | 41.7×4 | 1∶5 |

| 进气量比α | 下偏转角γ/(°) | 左偏转角θ/(°) |

|---|---|---|

| 1∶4 | 10.0 | 0 |

| 12.5 | 0 | |

| 15.0 | 0 | |

| 17.5 | 0 | |

| 20.0 | 0 | |

| 15.0 | 3 | |

| 15.0 | 6 | |

| 15.0 | 9 | |

| 15.0 | 12 |

表2 模拟工况

Table 2 Simulated conditions

| 进气量比α | 下偏转角γ/(°) | 左偏转角θ/(°) |

|---|---|---|

| 1∶4 | 10.0 | 0 |

| 12.5 | 0 | |

| 15.0 | 0 | |

| 17.5 | 0 | |

| 20.0 | 0 | |

| 15.0 | 3 | |

| 15.0 | 6 | |

| 15.0 | 9 | |

| 15.0 | 12 |

| 1 | 谢和平, 任世华, 谢亚辰, 等. 碳中和目标下煤炭行业发展机遇[J]. 煤炭学报, 2021, 46(7): 2197-2211. |

| Xie H P, Ren S H, Xie Y C, et al. Development opportunities of the coal industry towards the goal of carbon neutrality[J]. Journal of China Coal Society, 2021, 46(7): 2197-2211. | |

| 2 | 王辅臣, 代正华. 煤气化——煤炭高效清洁利用的核心技术[J]. 化学世界, 2015, 56(1): 51-55. |

| Wang F C, Dai Z H. Coal gasification—core technology of the efficient and clean utilization of coal[J]. Chemical World, 2015, 56(1): 51-55. | |

| 3 | 黄戒介, 房倚天, 王洋. 现代煤气化技术的开发与进展[J]. 燃料化学学报, 2002, 30(5): 385-391. |

| Huang J J, Fang Y T, Wang Y. Development and progress of modern coal gasification technology[J]. Journal of Fuel Chemistry and Technology, 2002, 30(5): 385-391. | |

| 4 | 王辅臣, 于广锁, 龚欣, 等. 大型煤气化技术的研究与发展[J]. 化工进展, 2009, 28(2): 173-180. |

| Wang F C, Yu G S, Gong X, et al. Research and development of large-scale coal gasification technology[J]. Chemical Industry and Engineering Progress, 2009, 28(2): 173-180. | |

| 5 | 李相军. HT-L炉粉煤加压气化技术[J]. 河南化工, 2010, 27(17): 49-50, 62. |

| Li X J. Pressurized pulverized coal gasification technology of HT-L furnace[J]. Henan Chemical Industry, 2010, 27(17): 49-50, 62. | |

| 6 | He C, Feng X, Chu K H. Process modeling and thermodynamic analysis of Lurgi fixed-bed coal gasifier in an SNG plant[J]. Applied Energy, 2013, 111: 742-757. |

| 7 | Qin S Y, Chang S Y, Yao Q. Modeling, thermodynamic and techno-economic analysis of coal-to-liquids process with different entrained flow coal gasifiers[J]. Applied Energy, 2018, 229: 413-432. |

| 8 | 王辅臣. 煤气化技术在中国: 回顾与展望[J]. 洁净煤技术, 2021, 27(1): 1-33. |

| Wang F C. Coal gasification technologies in China: review and prospect[J]. Clean Coal Technology, 2021, 27(1): 1-33. | |

| 9 | 杨国辉, 褚夫奎, 李磊. 煤炭气化技术的比较与分析[J]. 山东化工, 2021, 50(23): 61-64, 67. |

| Yang G H, Chu F K, Li L. Comparison and analysis of coal gasification technology[J]. Shandong Chemical Industry, 2021, 50(23): 61-64, 67. | |

| 10 | 王欢, 范飞, 李鹏飞, 等. 现代煤气化技术进展及产业现状分析[J]. 煤化工, 2021, 49(4): 52-56. |

| Wang H, Fan F, Li P F, et al. Modern coal gasification technology progress and industry status analysis[J]. Coal Chemical Industry, 2021, 49(4): 52-56. | |

| 11 | 许建良, 刘海峰, 代正华, 等. 同时生产甲烷热解气和合成气的气化系统和气化方法: 107418632A[P]. 2017-12-01. |

| Xu J L, Liu H F, Dai Z H, et al. Gasification system and gasification method for producing methane pyrolysis gas and synthesis gas simultaneously: 107418632A[P]. 2017-12-01. | |

| 12 | Ma J L, Zitney S E. Computational fluid dynamic modeling of entrained-flow gasifiers with improved physical and chemical submodels[J]. Energy & Fuels, 2012, 26(12): 7195-7219. |

| 13 | Slezak A, Kuhlman J M, Shadle L J, et al. CFD simulation of entrained-flow coal gasification: coal particle density/sizefraction effects[J]. Powder Technology, 2010, 203(1): 98-108. |

| 14 | Giuffrida A, Romano M C, Lozza G. Thermodynamic analysis of air-blown gasification for IGCC applications[J]. Applied Energy, 2011, 88(11): 3949-3958. |

| 15 | Kumar M. Multiscale CFD simulations of entrained flow gasification[D]. Massachusetts: Massachusetts Institute of Technology, 2011. |

| 16 | Xu S S, Ren Y Q, Wang B M, et al. Development of a novel 2-stage entrained flow coal dry powder gasifier[J]. Applied Energy, 2014, 113: 318-323. |

| 17 | Ren Y Q, Xu S S, Li G Y. Experimental study on the operational performance of an advanced two-stage entrained-flow coal gasifier[J]. Energy & Fuels, 2014, 28(8): 4911-4917. |

| 18 | 张建胜, 胡文斌, 吴玉新, 等. 分级气流床气化炉模型研究[J]. 化学工程, 2007, 35(3): 14-18. |

| Zhang J S, Hu W B, Wu Y X, et al. Study on the modeling of staged entrained flow gasifier[J]. Chemical Engineering (China), 2007, 35(3): 14-18. | |

| 19 | Watanabe H, Tanno K, Umetsu H, et al. Modeling and simulation of coal gasification on an entrained flow coal gasifier with a recycled CO2 injection[J]. Fuel, 2015, 142: 250-259. |

| 20 | Watanabe H, Ahn S, Tanno K. Numerical investigation of effects of CO2 recirculation in an oxy-fuel IGCC on gasification characteristics of a two-stage entrained flow coal gasifier[J]. Energy, 2017, 118: 181-189. |

| 21 | González-Tello P, Camacho F, Vicaria J M, et al. A modified Nukiyama-Tanasawa distribution function and a Rosin-Rammler model for the particle-size-distribution analysis[J]. Powder Technology, 2008, 186(3): 278-281. |

| 22 | Li J W, An W, Gao H W, et al. An experimental study on oil droplet size distribution in subsurface oil releases[J]. Acta Oceanologica Sinica, 2018, 37(11): 88-95. |

| 23 | 秦军, 李伟锋, 代正华, 等. 受限气固两相射流的实验研究和数值模拟[J]. 高校化学工程学报, 2005, 19(5): 619-624. |

| Qin J, Li W F, Dai Z H, et al. Experimental study and numerical simulation of confined gas-solid two-phase jet[J]. Journal of Chemical Engineering of Chinese Universities, 2005, 19(5): 619-624. | |

| 24 | Li Y Z, Zhai G W, Zhang H T, et al. Experimental and predictive research on solids holdup distribution in a CFB riser[J]. Powder Technology, 2019, 344: 830-841. |

| 25 | Shih T H, Liou W W, Shabbir A, et al. A new k-ε eddy viscosity model for high Reynolds number turbulent flows[J]. Computers & Fluids, 1995, 24(3): 227-238. |

| 26 | Wu Y X, Zhang J S, Smith P J, et al. Three-dimensional simulation for an entrained flow coal slurry gasifier[J]. Energy & Fuels, 2010, 24(2): 1156-1163. |

| 27 | Sun Z H, Dai Z H, Zhou Z J, et al. Numerical simulation of industrial opposed multiburner coal-water slurry entrained flow gasifier[J]. Industrial & Engineering Chemistry Research, 2012, 51(6): 2560-2569. |

| 28 | Shi S P, Zitney S E, Shahnam M, et al. Modelling coal gasification with CFD and discrete phase method[J]. Journal of the Energy Institute, 2006, 79(4): 217-221. |

| 29 | Li C, Dai Z H, Xu J L, et al. Numerical study of the particle residence time and flow characters in an opposed multi-burner gasifier[J]. Powder Technology, 2015, 286: 64-72. |

| 30 | Choi Y C, Li X Y, Park T J, et al. Numerical study on the coal gasification characteristics in an entrained flow coal gasifier[J]. Fuel, 2001, 80(15): 2193-2201. |

| 31 | 谢军龙, 钟小普, 王嘉冰, 等. 亚音速射流实验与流场模拟[J]. 工程热物理学报, 2013, 34(8): 1457-1461. |

| Xie J L, Zhong X P, Wang J B, et al. Experiment study and flow field simulation of the subsonic jet[J]. Journal of Engineering Thermophysics, 2013, 34(8): 1457-1461. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [4] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [5] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [6] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [7] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [8] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [9] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [10] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [11] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [12] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [13] | 黄可欣, 李彤, 李桉琦, 林梅. 加装旋转叶轮T型通道流场的模态分解[J]. 化工学报, 2023, 74(7): 2848-2857. |

| [14] | 史方哲, 甘云华. 超薄热管启动特性和传热性能数值模拟[J]. 化工学报, 2023, 74(7): 2814-2823. |

| [15] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号