化工学报 ›› 2023, Vol. 74 ›› Issue (1): 290-302.DOI: 10.11949/0438-1157.20221070

收稿日期:2022-08-01

修回日期:2022-11-01

出版日期:2023-01-05

发布日期:2023-03-20

通讯作者:

乔金硕,孙克宁

作者简介:郭祥(1994—),男,博士研究生,guoxiang0658@163.com

基金资助:

Xiang GUO( ), Jinshuo QIAO(

), Jinshuo QIAO( ), Zhenhua WANG, Wang SUN, Kening SUN(

), Zhenhua WANG, Wang SUN, Kening SUN( )

)

Received:2022-08-01

Revised:2022-11-01

Online:2023-01-05

Published:2023-03-20

Contact:

Jinshuo QIAO, Kening SUN

摘要:

直接碳燃料固体氧化物燃料电池(direct carbon-fueled solid oxide fuel cells,DC-SOFC)是一种通过电化学过程将碳燃料的化学能直接转化为电能的发电装置,具有优异的发电效率、高的燃料利用率及低的碳排放。然而,相比气体和液体燃料,固体燃料的流动性较低,因此如何提高固体燃料传输速率并有效促进阳极反应动力学过程,以及在工作状态下高效、便捷地添加燃料是目前DC-SOFC要解决的关键问题。本文综述了近年来直接碳固体氧化物燃料电池结构的研究进展,总结了电池宏观结构与阳极微观形貌方面的发展,讨论了碳燃料固体氧化物燃料电池亟待解决的问题及发展方向。

中图分类号:

郭祥, 乔金硕, 王振华, 孙旺, 孙克宁. 碳燃料固体氧化物燃料电池结构研究进展[J]. 化工学报, 2023, 74(1): 290-302.

Xiang GUO, Jinshuo QIAO, Zhenhua WANG, Wang SUN, Kening SUN. Progress of structure for carbon-fueled solid oxide fuel cells[J]. CIESC Journal, 2023, 74(1): 290-302.

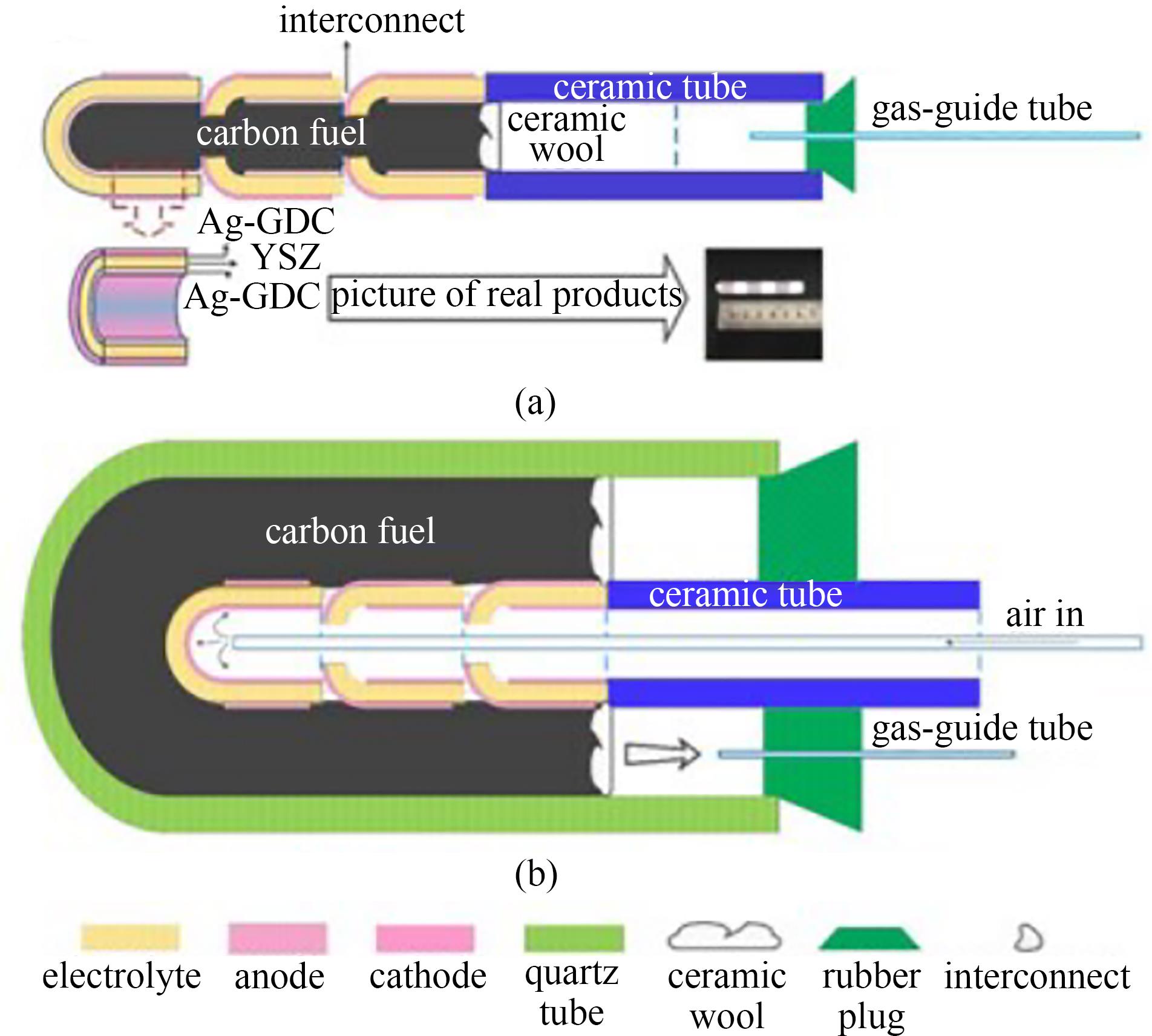

图5 三电池管状DC-SOFC电堆示意图[31]:(a)碳燃料在管内;(b)碳燃料在管外

Fig.5 Schematic diagram of the 3-cell-stacks of DC-SOFC system with carbon fuel inside (a) and outside (b) of stack[31]

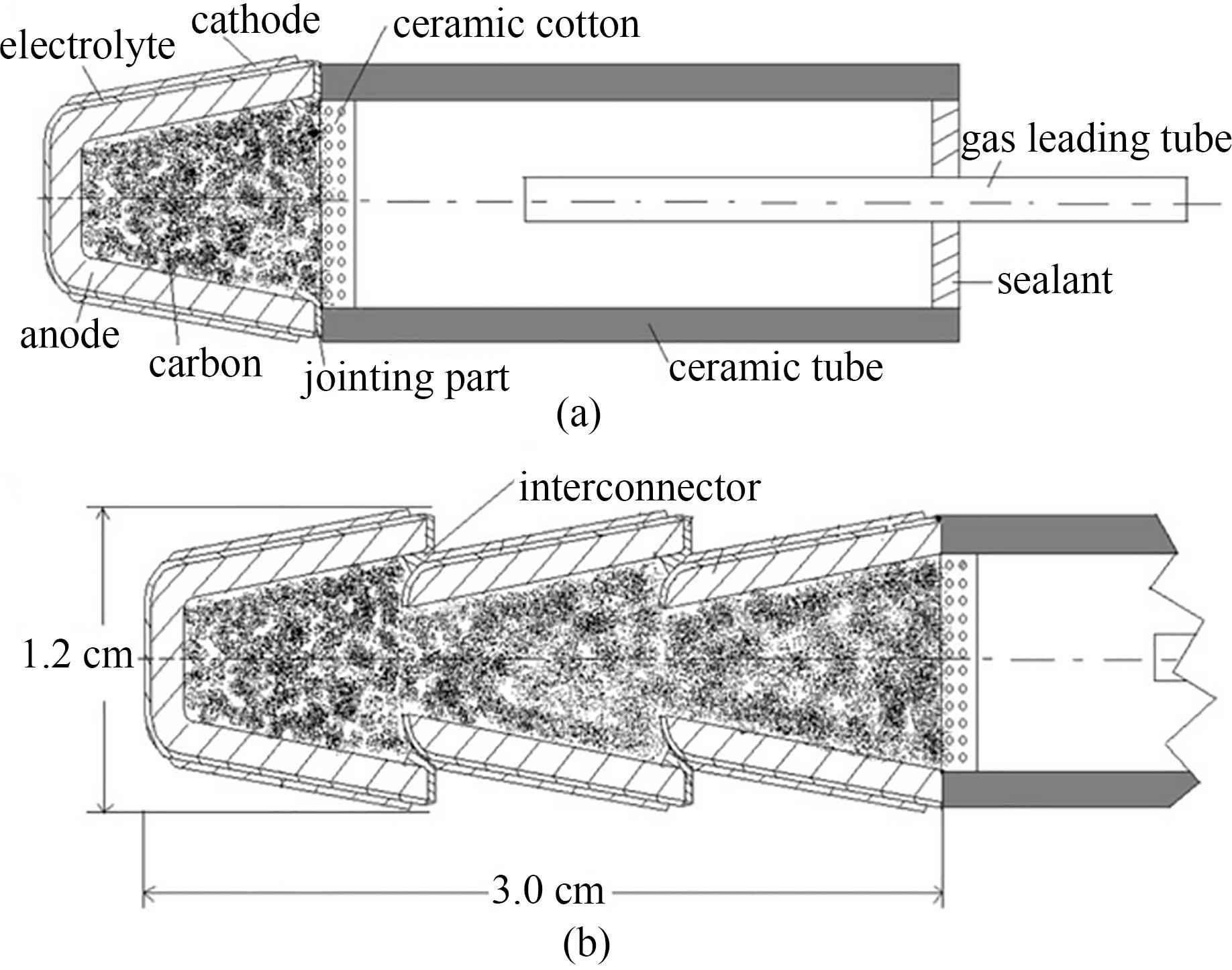

图8 锥形单SOFC (a)和带有分段串联结构(b)的带有碳燃料的SOFC电堆示意图[34]

Fig.8 Schematic illustrations of cone-shaped single SOFC (a) and SOFC stack with a segmented-in-series configuration (b) with carbon fuel[34]

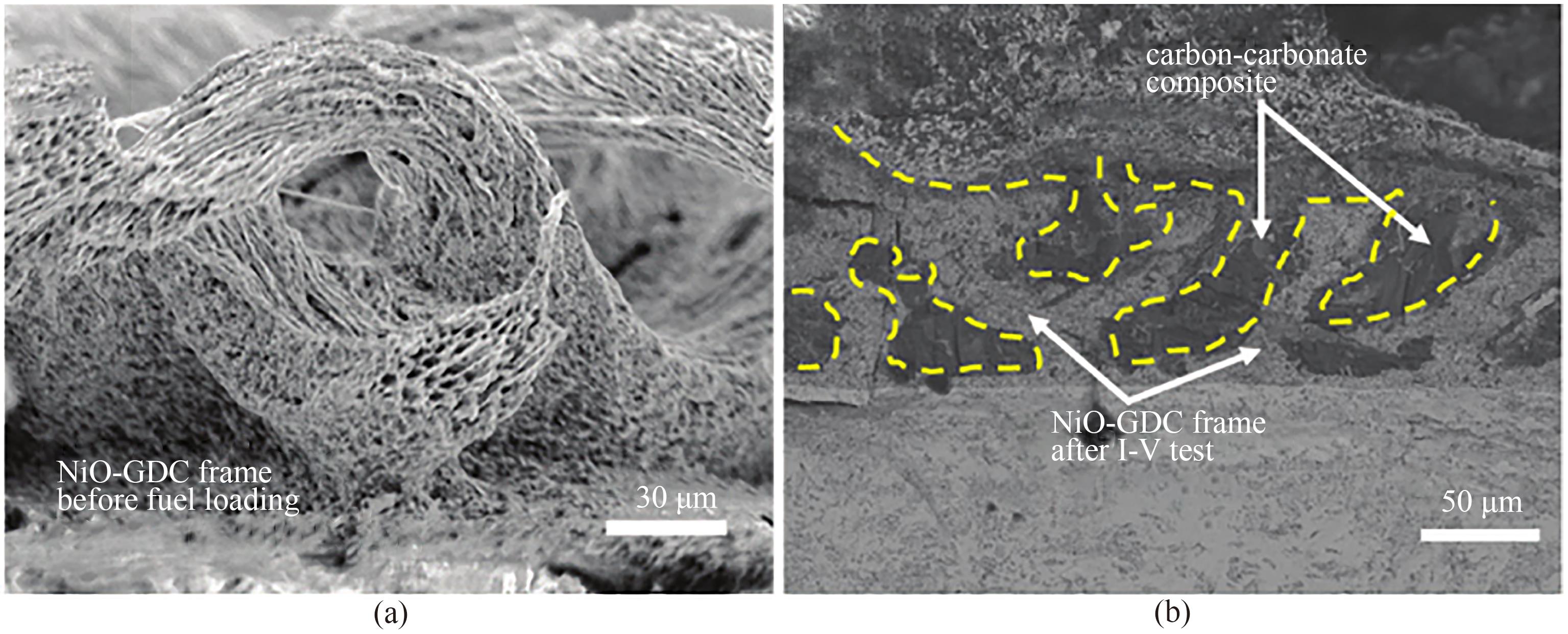

图10 棉质纤维制备的阳极结构[39](a)未装载燃料;(b)装载碳燃料并经过短暂测试

Fig.10 Structure of anode prepared from cotton fiber[39](a) before loading carbon; (b) after short electrochemical testing

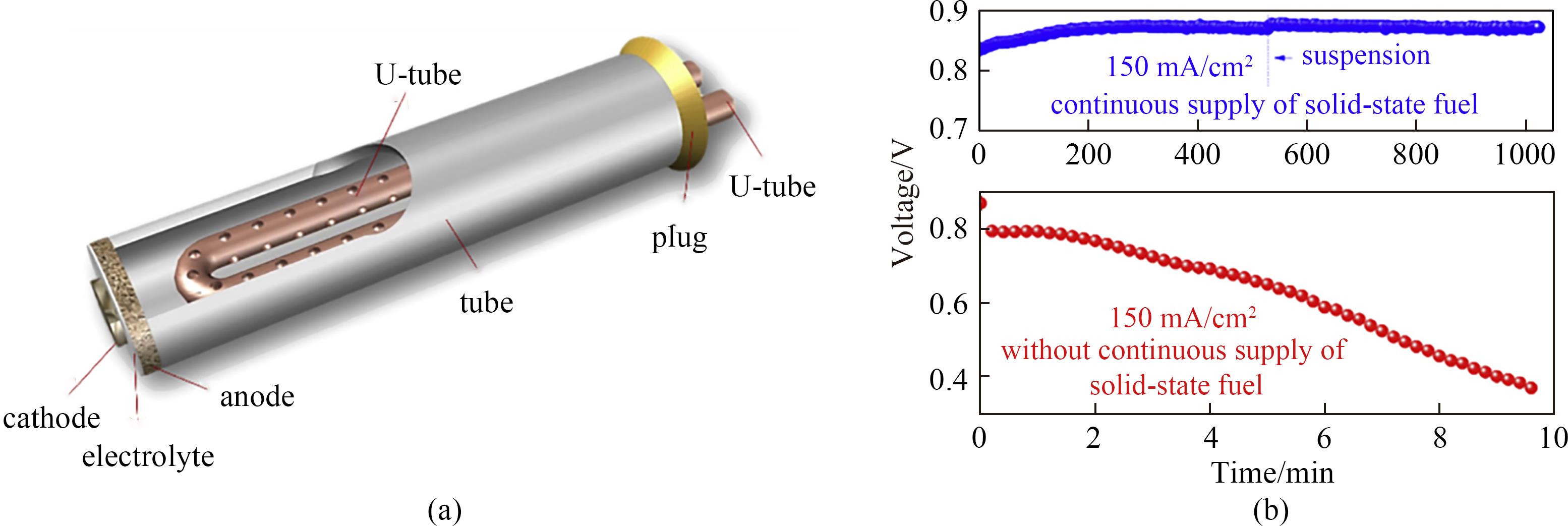

图15 (a)U形管状连续供给装置;(b)800℃下电流密度为150 mA/cm2的电池电压与时间函数[84]

Fig.15 (a) U-shaped tubular continuous supply device; (b) Cell voltage as a function of time at 800℃ under a constant polarization current density of 150 mA/cm2 [84]

| 燃料 | 辅助剂 | 阳极 | 电解质 | 阴极 | 温度/℃ | 最大功率密度/(mW/cm2) |

|---|---|---|---|---|---|---|

| 褐煤[ | — | Ag-Gd0.1Ce0.9O2-δ | YSZ | Ag-Gd0.1Ce0.9O2-δ | 850 | 221 |

| 牙签炭[ | — | La0.3Sr0.7Fe0.7Ti0.3O3-δ (LSFT) | YSZ | La0.3Sr0.7Fe0.7Ti0.3O3-δ (LSFT) | 850 | 223 |

| 活性炭[ | 5%(质量分数)BaCO3 | Ag-GDC | YSZ | Ag-GDC | 850 | 328.4 |

| 低硫(0.15%)阿拉斯加煤[ | CO2吹扫 | Ni-YSZ | YSZ | 钙钛矿 | 930 | 450 |

| 小麦秸秆炭[ | — | Ag-Ce0.8Gd0.2O1.9 | YSZ | Ag-Ce0.8Gd0.2O1.9 | 800 | 187 |

| 玉米芯炭[ | — | Ag-Ce0.8Gd0.2O1.9 | YSZ | Ag-Ce0.8Gd0.2O1.9 | 800 | 204 |

| 甘蔗渣炭[ | — | Ag-Ce0.8Gd0.2O1.9 | YSZ | Ag-Ce0.8Gd0.2O1.9 | 800 | 260 |

| 活性炭[ | — | La0.8Sr0.2Fe0.9Nb0.1O3-δ | ScSZ | LSM/ScSZ | 850 | 302.8 |

| 玉米秸秆炭[ | — | La0.8Sr0.2Fe0.9Nb0.1O3-δ | ScSZ | LSM/ScSZ | 850 | 218.5 |

| 石墨[ | Ar | Pt | YSZ | Pt | 950 | 16.8 |

| 活性炭[ | Li2CO3+K2CO3 Ar | Ni-SDC | SDC | Ba0.5Sr0.5Co0.8Fe0.2O3-δ | 750 | 158.3 |

| 废旧纸箱制炭[ | — | La0.3Sr0.7Fe0.7Ti0.3O3-δ | SSZ | La0.3Sr0.7Fe0.7Ti0.3O3-δ | 850 | 308.7 |

| 海带炭[ | — | Ag-GDC | YSZ | Ag-GDC | 850 | 285 |

| 核桃壳炭[ | Fe | Ag-GDC | YSZ | Ag-GDC | 800 | 205 |

| 兰花树叶炭[ | — | Ag-GDC | YSZ | Ag-GDC | 850 | 212 |

| 活性炭[ | — | Ni/Fe-YSZ | YSZ | La0.6Sr0.4Co0.2Fe0.8O3-GDC | 800 | 425~529 |

| 工业焦炭[ | Fe | Ag-GDC | YSZ | Ag-GDC | 850 | 217 |

| 小麦秸秆炭[ | Ca | Ag-GDC | YSZ | Ag-GDC | 800 | 258 |

| 椰壳炭[ | Fe | Ag-GDC | YSZ | Ag-GDC | 800 | 274 |

| 活性炭[ | Li2CO3+K2CO3 Ar | (PrBa)0.95Fe1.4Cu0.4Nb0.2O5+δ | LSGM | La0.6Sr0.4Co0.2Fe0.8O3 | 800 | 431 |

表1 直接碳燃料电池燃料及电极

Table 1 Fuels and electrodes of direct carbon fuel cells

| 燃料 | 辅助剂 | 阳极 | 电解质 | 阴极 | 温度/℃ | 最大功率密度/(mW/cm2) |

|---|---|---|---|---|---|---|

| 褐煤[ | — | Ag-Gd0.1Ce0.9O2-δ | YSZ | Ag-Gd0.1Ce0.9O2-δ | 850 | 221 |

| 牙签炭[ | — | La0.3Sr0.7Fe0.7Ti0.3O3-δ (LSFT) | YSZ | La0.3Sr0.7Fe0.7Ti0.3O3-δ (LSFT) | 850 | 223 |

| 活性炭[ | 5%(质量分数)BaCO3 | Ag-GDC | YSZ | Ag-GDC | 850 | 328.4 |

| 低硫(0.15%)阿拉斯加煤[ | CO2吹扫 | Ni-YSZ | YSZ | 钙钛矿 | 930 | 450 |

| 小麦秸秆炭[ | — | Ag-Ce0.8Gd0.2O1.9 | YSZ | Ag-Ce0.8Gd0.2O1.9 | 800 | 187 |

| 玉米芯炭[ | — | Ag-Ce0.8Gd0.2O1.9 | YSZ | Ag-Ce0.8Gd0.2O1.9 | 800 | 204 |

| 甘蔗渣炭[ | — | Ag-Ce0.8Gd0.2O1.9 | YSZ | Ag-Ce0.8Gd0.2O1.9 | 800 | 260 |

| 活性炭[ | — | La0.8Sr0.2Fe0.9Nb0.1O3-δ | ScSZ | LSM/ScSZ | 850 | 302.8 |

| 玉米秸秆炭[ | — | La0.8Sr0.2Fe0.9Nb0.1O3-δ | ScSZ | LSM/ScSZ | 850 | 218.5 |

| 石墨[ | Ar | Pt | YSZ | Pt | 950 | 16.8 |

| 活性炭[ | Li2CO3+K2CO3 Ar | Ni-SDC | SDC | Ba0.5Sr0.5Co0.8Fe0.2O3-δ | 750 | 158.3 |

| 废旧纸箱制炭[ | — | La0.3Sr0.7Fe0.7Ti0.3O3-δ | SSZ | La0.3Sr0.7Fe0.7Ti0.3O3-δ | 850 | 308.7 |

| 海带炭[ | — | Ag-GDC | YSZ | Ag-GDC | 850 | 285 |

| 核桃壳炭[ | Fe | Ag-GDC | YSZ | Ag-GDC | 800 | 205 |

| 兰花树叶炭[ | — | Ag-GDC | YSZ | Ag-GDC | 850 | 212 |

| 活性炭[ | — | Ni/Fe-YSZ | YSZ | La0.6Sr0.4Co0.2Fe0.8O3-GDC | 800 | 425~529 |

| 工业焦炭[ | Fe | Ag-GDC | YSZ | Ag-GDC | 850 | 217 |

| 小麦秸秆炭[ | Ca | Ag-GDC | YSZ | Ag-GDC | 800 | 258 |

| 椰壳炭[ | Fe | Ag-GDC | YSZ | Ag-GDC | 800 | 274 |

| 活性炭[ | Li2CO3+K2CO3 Ar | (PrBa)0.95Fe1.4Cu0.4Nb0.2O5+δ | LSGM | La0.6Sr0.4Co0.2Fe0.8O3 | 800 | 431 |

| 1 | Cao T Y, Huang K, Shi Y X, et al. Recent advances in high-temperature carbon-air fuel cells[J]. Energy & Environmental Science, 2017, 10(2): 460-490. |

| 2 | Cui C, Li S B, Gong J Y, et al. Review of molten carbonate-based direct carbon fuel cells[J]. Materials for Renewable and Sustainable Energy, 2021, 10(2): 1-24. |

| 3 | Ma M J, Yang X X, Qiao J S, et al. Progress and challenges of carbon-fueled solid oxide fuel cells anode[J]. Journal of Energy Chemistry, 2021, 56: 209-222. |

| 4 | 艾承燚, 乔金硕, 王振华, 等. 原位析出纳米合金的PrBaFe2O6- δ 基阳极构筑及其在固体碳燃料电池中的应用研究[J]. 化工学报, 2022, 73(8): 3708-3719. |

| Ai C Y, Qiao J S, Wang Z H, et al. Investigation on PrBaFe2O6- δ anode material with in situ FeNi nanoparticle in direct carbon solid oxide fuel cell[J]. CIESC Journal, 2022, 73(8): 3708-3719. | |

| 5 | Cao D X, Sun Y, Wang G L. Direct carbon fuel cell: fundamentals and recent developments[J]. Journal of Power Sources, 2007, 167(2): 250-257. |

| 6 | Jiang C R, Ma J J, Corre G, et al. Challenges in developing direct carbon fuel cells[J]. Chemical Society Reviews, 2017, 46(10): 2889-2912. |

| 7 | Dong Y X, Xing L, Li X F, et al. A membrane-less molten hydroxide direct carbon fuel cell with fuel continuously supplied at low temperatures: a modeling and experimental study[J]. Applied Energy, 2022, 324: 119585. |

| 8 | Wejrzanowski T, Cwieka K, Skibinski J, et al. Metallic foam supported electrodes for molten carbonate fuel cells[J]. Materials & Design, 2020, 193: 108864. |

| 9 | Wu H, Xiao J, Zeng X Y, et al. A high performance direct carbon solid oxide fuel cell—a green pathway for brown coal utilization[J]. Applied Energy, 2019, 248: 679-687. |

| 10 | Jiang C R, Ma J J, Bonaccorso A D, et al. Demonstration of high power, direct conversion of waste-derived carbon in a hybrid direct carbon fuel cell[J]. Energy and Environmental Science, 2012, 5: 6973-6980. |

| 11 | Giddey S, Kulkarni A, Munnings C, et al. Performance evaluation of a tubular direct carbon fuel cell operating in a packed bed of carbon[J]. Energy, 2014, 68: 538-547. |

| 12 | Gong S Q, Zeng H Y, Lin J, et al. A robust flat-chip solid oxide fuel cell coupled with catalytic partial oxidation of methane[J]. Journal of Power Sources, 2018, 402: 124-132. |

| 13 | Somalu M R, Muchtar A, Daud W R W, et al. Screen-printing inks for the fabrication of solid oxide fuel cell films: a review[J]. Renewable and Sustainable Energy Reviews, 2017, 75: 426-439. |

| 14 | Yang R J, Lee M C, Chang J C, et al. Fabrication and characterization of a Sm0.2Ce0.8O1.9 electrolyte film by the spin-coating method for a low-temperature anode-supported solid oxide fuel cells[J]. Journal of Power Sources, 2012, 206: 111-118. |

| 15 | Gurauskis J. Deposition via dip coating technique of dense yttrium stabilized zirconia layers[J]. International Journal of Applied Ceramic Technology, 2013, 10(1): 79-86. |

| 16 | Tanhaei M, Mozammel M. Yttria-stabilized zirconia thin film electrolyte deposited by EB-PVD on porous anode support for SOFC applications[J]. Ceramics International, 2017, 43(3): 3035-3042. |

| 17 | Choi H, Cho G Y, Cha S W. Fabrication and characterization of anode supported YSZ/GDC bilayer electrolyte SOFC using dry press process[J]. International Journal of Precision Engineering and Manufacturing-Green Technology, 2014, 1(2): 95-99. |

| 18 | Sivasankaran V, Combemale L, Pera M C, et al. Initial preparation and characterization of single step fabricated intermediate temperature solid oxide fuel cells (IT-SOFC)[J]. Fuel Cells, 2014, 14(3): 533-536. |

| 19 | Sinha A, Miller D N, Irvine J T S. Development of novel anode material for intermediate temperature SOFC (IT-SOFC)[J]. Journal of Materials Chemistry A, 2016, 4(28): 11117-11123. |

| 20 | Liu J, Yuan H, Qiao J S, et al. Hierarchical hollow nanofiber networks for high-performance hybrid direct carbon fuel cells[J]. Journal of Materials Chemistry A, 2017, 5(33): 17216-17220. |

| 21 | Ma M J, Yang X X, Ren R Z, et al. Honeycombed porous, size-matching architecture for high-performance hybrid direct carbon fuel cell anode[J]. ACS Applied Materials & Interfaces, 2020, 12(27): 30411-30419. |

| 22 | Lee A C, Li S W, Mitchell R E, et al. Conversion of solid carbonaceous fuels in a fluidized bed fuel cell[J]. Electrochemical and Solid-State Letters, 2008, 11(2): B20. |

| 23 | Wang W, Liu Z J, Zhang Y P, et al. A direct carbon solid oxide fuel cell stack on a single electrolyte plate fabricated by tape casting technique[J]. Journal of Alloys and Compounds, 2019, 794: 294-302. |

| 24 | Chen Q Y, Qiu Q Y, Yan X M, et al. A compact and seal-less direct carbon solid oxide fuel cell stack stepping into practical application[J]. Applied Energy, 2020, 278: 115657. |

| 25 | Li G D, Gou Y J, Qiao J S, et al. Recent progress of tubular solid oxide fuel cell: from materials to applications[J]. Journal of Power Sources, 2020, 477: 228693. |

| 26 | Li T, Wu Z T, Li K. Co-extrusion of electrolyte/anode functional layer/anode triple-layer ceramic hollow fibres for micro-tubular solid oxide fuel cells-electrochemical performance study[J]. Journal of Power Sources, 2015, 273: 999-1005. |

| 27 | Liu R Z, Zhao C H, Li J L, et al. A novel direct carbon fuel cell by approach of tubular solid oxide fuel cells[J]. Journal of Power Sources, 2010, 195(2): 480-482. |

| 28 | Xie Y M, Tang Y B, Liu J. An Al2O3-doped YSZ electrolyte-supporting solid oxide fuel cell fabricated by dip-coating and its direct operation on carbon fuel[J]. ECS Transactions, 2013, 57(1): 3039-3048. |

| 29 | Xie Y M, Wang X Q, Liu J, et al. Fabrication and performance of tubular electrolyte-supporting direct carbon solid oxide fuel cell by dip coating technique[J]. Acta Physico-Chimica Sinica, 2017, 33(2): 386-392. |

| 30 | Xie Y M, Cai W Z, Xiao J, et al. Electrochemical gas-electricity cogeneration through direct carbon solid oxide fuel cells[J]. Journal of Power Sources, 2015, 277: 1-8. |

| 31 | 王晓强, 刘江, 谢永敏, 等. 可用作便携式电源的高性能直接碳固体氧化物燃料电池组(英文)[J]. 物理化学学报, 2017(8):1614-1620. |

| Wang X Q, Liu J, Xie Y M, et al. A high performance direct carbon solid oxide fuel cell stack for portable applications[J]. Acta Physico-Chimica Sinica, 2017(8):1614-1620. | |

| 32 | Yang B B, Ran R, Zhong Y J, et al. A carbon-air battery for high power generation[J]. Angewandte Chemie International Edition, 2015, 54(12): 3722-3725. |

| 33 | Bai Y H, Wang C L, Ding J, et al. Direct operation of cone-shaped anode-supported segmented-in-series solid oxide fuel cell stack with methane[J]. Journal of Power Sources, 2010, 195(12): 3882-3886. |

| 34 | Bai Y H, Liu Y, Tang Y B, et al. Direct carbon solid oxide fuel cell—a potential high performance battery[J]. International Journal of Hydrogen Energy, 2011, 36(15): 9189-9194. |

| 35 | Yu F Y, Zhang Y P, Yu L, et al. All-solid-state direct carbon fuel cells with thin yttrium-stabilized-zirconia electrolyte supported on nickel and iron bimetal-based anodes[J]. International Journal of Hydrogen Energy, 2016, 41(21): 9048-9058. |

| 36 | Wang C Q, Lü Z, Su C X, et al. Effects of discharge mode and fuel treating temperature on the fuel utilization of direct carbon solid oxide fuel cell[J]. International Journal of Hydrogen Energy, 2019, 44(2): 1174-1181. |

| 37 | Bae Y, Lee S, Hong J. The effect of anode microstructure and fuel utilization on current relaxation and concentration polarization of solid oxide fuel cell under electrical load change[J]. Energy Conversion and Management, 2019, 201: 112152. |

| 38 | Xie Y M, Li J L, Hou J X, et al. Direct use of coke in a solid oxide fuel cell[J]. Journal of Fuel Chemistry and Technology, 2018, 46(10): 1168-1174. |

| 39 | Wu W, Zhang Y, Ding D, et al. A high-performing direct carbon fuel cell with a 3D architectured anode operated below 600℃[J]. Advanced Materials (Deerfield Beach, Fla.), 2018, 30(4): 1704745. |

| 40 | Bian W J, Wu W, Orme C J, et al. Direct carbon fuel cells: dual 3D ceramic textile electrodes: fast kinetics for carbon oxidation reaction and oxygen reduction reaction in direct carbon fuel cells at reduced temperatures[J]. Advanced Functional Materials, 2020, 30(19): 2070119. |

| 41 | Zhou W, Jiao Y, Li S D, et al. Anodes for carbon-fueled solid oxide fuel cells[J]. ChemElectroChem, 2016, 3(2): 193-203. |

| 42 | Duan N Q, Xue Y, Ma J Y, et al. Liquid antimony-silver alloys as anodes for direct carbon solid oxide fuel cells[J]. Journal of Power Sources, 2018, 397: 170-176. |

| 43 | Tao T, McPhee W, Koslowske M, et al. Liquid tin anode SOFC for direct fuel conversion-impact of coal and JP-8 impurities[J]. ECS Transactions, 2009, 25(2): 1115-1124. |

| 44 | Cao T Y, Song P D, Shi Y X, et al. Carbonate-tin composite liquid anode for solid oxide direct carbon fuel cell[J]. International Journal of Hydrogen Energy, 2017, 42(9): 6324-6331. |

| 45 | Jayakumar A, Lee S, Hornés A, et al. A comparison of molten Sn and Bi for solid oxide fuel cell anodes[J]. Journal of the Electrochemical Society, 2010, 157(3): B365. |

| 46 | Jayakumar A, Vohs J M, Gorte R J. Molten-metal electrodes for solid oxide fuel cells[J]. Industrial & Engineering Chemistry Research, 2010, 49(21): 10237-10241. |

| 47 | Jayakumar A, Küngas R, Roy S, et al. A direct carbon fuel cell with a molten antimony anode[J]. Energy & Environmental Science, 2011, 4(10): 4133. |

| 48 | Jayakumar A, Javadekar A, Gissinger J, et al. The stability of direct carbon fuel cells with molten Sb and Sb-Bi alloy anodes[J]. AIChE Journal, 2013, 59(9): 3342-3348. |

| 49 | Cao T Y, Shi Y X, Cai N S. Liquid antimony anode fluidization within a tubular direct carbon fuel cell[J]. Journal of the Electrochemical Society, 2015, 163(3): F127-F131. |

| 50 | Duan N Q, Cao Y, Hua B, et al. Tubular direct carbon solid oxide fuel cells with molten antimony anode and refueling feasibility[J]. Energy, 2016, 95: 274-278. |

| 51 | Duan N Q, Tan Y, Yan D, et al. Biomass carbon fueled tubular solid oxide fuel cells with molten antimony anode[J]. Applied Energy, 2016, 165: 983-989. |

| 52 | Ma J Y, Duan N Q, Han Y, et al. Hot corrosion of yttria-stabilized zirconia by liquid antimony and antimony oxide[J]. Journal of Power Sources, 2019, 434: 226764. |

| 53 | Cao T Y, Song P D, Shi Y X, et al. Oxy-combustion of coal in liquid-antimony-anode solid oxide fuel cell system[J]. Proceedings of the Combustion Institute, 2019, 37(3): 2841-2848. |

| 54 | Han Y, Ma J Y, Duan N Q, et al. Enhanced resistance of gadolinium-doped cerium oxide to liquid antimony and antimony oxide corrosions by addition of iron oxide[J]. Journal of Power Sources, 2020, 455: 227970. |

| 55 | Javadekar A, Jayakumar A, Pujara R, et al. Molten silver as a direct carbon fuel cell anode[J]. Journal of Power Sources, 2012, 214: 239-243. |

| 56 | Jafri N, Wong W Y, Doshi V, et al. A review on production and characterization of biochars for application in direct carbon fuel cells[J]. Process Safety and Environmental Protection, 2018, 118: 152-166. |

| 57 | Jain S L, Nabae Y, Lakeman B J, et al. Solid state electrochemistry of direct carbon/air fuel cells[J]. Solid State Ionics, 2008, 179(27/28/29/30/31/32): 1417-1421. |

| 58 | Wu Y Z, Su C, Zhang C M, et al. A new carbon fuel cell with high power output by integrating with in situ catalytic reverse Boudouard reaction[J]. Electrochemistry Communications, 2009, 11(6): 1265-1268. |

| 59 | Irvine J, Fuentes Cuesta A, Mottram A, et al. Utilisation of coal in direct carbon fuel cells[J]. ECS Transactions, 2015, 68(1): 2681-2684. |

| 60 | Liu J, Qiao J S, Yuan H, et al. Ni modified Ce(Mn, Fe)O2 cermet anode for high-performance direct carbon fuel cell[J]. Electrochimica Acta, 2017, 232: 174-181. |

| 61 | Li S B, Jiang C R, Liu J, et al. Mechanism of enhanced performance on a hybrid direct carbon fuel cell using sawdust biofuels[J]. Journal of Power Sources, 2018, 383: 10-16. |

| 62 | Xu H R, Chen B, Zhang H C, et al. Experimental and modeling study of high performance direct carbon solid oxide fuel cell with in situ catalytic steam-carbon gasification reaction[J]. Journal of Power Sources, 2018, 382: 135-143. |

| 63 | Xu X Y, Zhou W, Liang F L, et al. A comparative study of different carbon fuels in an electrolyte-supported hybrid direct carbon fuel cell[J]. Applied Energy, 2013, 108: 402-409. |

| 64 | Tang Y B, Liu J. Effect of anode and Boudouard reaction catalysts on the performance of direct carbon solid oxide fuel cells[J]. International Journal of Hydrogen Energy, 2010, 35(20): 11188-11193. |

| 65 | Cai W Z, Liu J, Yu F Y, et al. A high performance direct carbon solid oxide fuel cell fueled by Ca-loaded activated carbon[J]. International Journal of Hydrogen Energy, 2017, 42(33): 21167-21176. |

| 66 | Fuente-Cuesta A, Jiang C R, Arenillas A, et al. Role of coal characteristics in the electrochemical behaviour of hybrid direct carbon fuel cells[J]. Energy & Environmental Science, 2016, 9(9): 2868-2880. |

| 67 | Xie Y M, Tang Y B, Liu J. A verification of the reaction mechanism of direct carbon solid oxide fuel cells[J]. Journal of Solid State Electrochemistry, 2013, 17(1): 121-127. |

| 68 | Lin J, Chen L, Liu T, et al. The beneficial effects of straight open large pores in the support on steam electrolysis performance of electrode-supported solid oxide electrolysis cell[J]. Journal of Power Sources, 2018, 374: 175-180. |

| 69 | Zhou M Y, Wang X Q, Zhang Y P, et al. Effect of counter diffusion of CO and CO2 between carbon and anode on the performance of direct carbon solid oxide fuel cells[J]. Solid State Ionics, 2019, 343: 115127. |

| 70 | Feng J, Qiao J S, Sun W, et al. Characteristic and preparation of Ce0.5Zr0.5O2 as the anode support for solid oxide fuel cells by phase inversion technology[J]. International Journal of Hydrogen Energy, 2015, 40(37): 12784-12789. |

| 71 | Li Y H, Chen L, Zhang L, et al. Millimeter tubular solid oxide electrolysis cells with modified asymmetric hydrogen electrode[J]. International Journal of Hydrogen Energy, 2016, 41(10): 5209-5214. |

| 72 | He W, Huang H, Gao J F, et al. Phase-inversion tape casting and oxygen permeation properties of supported ceramic membranes[J]. Journal of Membrane Science, 2014, 452: 294-299. |

| 73 | Huang H, Lin J, Wang Y L, et al. Facile one-step forming of NiO and yttrium-stabilized zirconia composite anodes with straight open pores for planar solid oxide fuel cell using phase-inversion tape casting method[J]. Journal of Power Sources, 2015, 274: 1114-1117. |

| 74 | Shi N, Su F, Huan D M, et al. Performance and DRT analysis of P-SOFCs fabricated using new phase inversion combined tape casting technology[J]. Journal of Materials Chemistry A, 2017, 5(37): 19664-19671. |

| 75 | Yang Y, Liu F S, Han X, et al. Highly efficient and stable fuel-catalyzed dendritic microchannels for dilute ethanol fueled solid oxide fuel cells[J]. Applied Energy, 2022, 307: 118222. |

| 76 | Gu D G, Shi N, Yu F, et al. Asymmetric anode substrate fabricated by phase inversion process and its interface modification for solid oxide fuel cells[J]. Journal of Alloys and Compounds, 2018, 742: 20-28. |

| 77 | Chen S N, Gu D G, Zheng Y F, et al. Enhanced performance of NiO-3YSZ planar anode-supported SOFC with an anode functional layer[J]. Journal of Materials Science, 2020, 55(1): 88-98. |

| 78 | Shi N, Xie Y, Yang Y, et al. Infiltrated Ni0.08Co0.02CeO2- x @Ni0.8Co0.2 catalysts for a finger-like anode in direct methane-fueled solid oxide fuel cells[J]. ACS Applied Materials & Interfaces, 2021, 13(4): 4943-4954. |

| 79 | Wang M M, Li N Z, Wang Z X, et al. Electrochemical performance and redox stability of solid oxide fuel cells supported on dual-layered anodes of Ni-YSZ cermet and Ni-Fe alloy[J]. International Journal of Hydrogen Energy, 2022, 47(8): 5453-5461. |

| 80 | Liu T, Wang Y, Zhang Y X, et al. Steam electrolysis in a solid oxide electrolysis cell fabricated by the phase-inversion tape casting method[J]. Electrochemistry Communications, 2015, 61: 106-109. |

| 81 | Li Y H, Li P, Hu B B, et al. A nanostructured ceramic fuel electrode for efficient CO2/H2O electrolysis without safe gas[J]. Journal of Materials Chemistry A, 2016, 4(23): 9236-9243. |

| 82 | Zheng M H, Wang S, Yang Y, et al. Barium carbonate as a synergistic catalyst for the H2O/CO2 reduction reaction at Ni-yttria stabilized zirconia cathodes for solid oxide electrolysis cells[J]. Journal of Materials Chemistry A, 2018, 6(6): 2721-2729. |

| 83 | Li N Z, Wang L M, Wang M M, et al. Ni-cermet with straight pore paths as cathode for solid oxide electrolysis cell enabling energy-efficient and coking-resistant conversion of CO2 [J]. Journal of Power Sources, 2022, 518: 230787. |

| 84 | Zhu X B, Li Y Q, Lü Z. Continuous conversion of biomass wastes in a La0.75Sr0.25Cr0.5Mn0.5O3- δ based carbon-air battery[J]. International Journal of Hydrogen Energy, 2016, 41(9): 5057-5062. |

| 85 | Zhang J, Ricote S, Hendriksen P V, et al. Advanced materials for thin-film solid oxide fuel cells: recent progress and challenges in boosting the device performance at low temperatures[J]. Advanced Functional Materials, 2022, 32(22): 2111205. |

| 86 | Tang H Q, Yu F Y, Wang Y S, et al. Enhancing the power output of direct carbon solid oxide fuel cell using Ba-loaded activated carbon fuel[J]. Energy Technology, 2019, 7(4): 1800885. |

| 87 | Gür T M, Homel M, Virkar A. High performance solid oxide fuel cell operating on dry gasified coal[J]. Journal of Power Sources, 2010, 195: 1085-1090. |

| 88 | Qiu Q Y, Zhou M Y, Cai W Z, et al. A comparative investigation on direct carbon solid oxide fuel cells operated with fuels of biochar derived from wheat straw, corncob, and bagasse[J]. Biomass and Bioenergy, 2019, 121: 56-63. |

| 89 | Li J W, Wei B, Wang C Q, et al. High-performance and stable La0.8Sr0.2Fe0.9Nb0.1O3- δ anode for direct carbon solid oxide fuel cells fueled by activated carbon and corn straw derived carbon[J]. International Journal of Hydrogen Energy, 2018, 43(27): 12358-12367. |

| 90 | Kim J P, Lim H, Jeon C H, et al. Performance evaluation of tubular fuel cells fuelled by pulverized graphite[J]. Journal of Power Sources, 2010, 195(22): 7568-7573. |

| 91 | Wang C Q, Lü Z, Li J W, et al. Efficient use of waste carton for power generation, tar and fertilizer through direct carbon solid oxide fuel cell[J]. Renewable Energy, 2020, 158: 410-420. |

| 92 | Wu H, Xiao J, Hao S R, et al. In-situ catalytic gasification of kelp-derived biochar as a fuel for direct carbon solid oxide fuel cells[J]. Journal of Alloys and Compounds, 2021, 865: 158922. |

| 93 | Xie Y M, Xiao J, Liu Q S, et al. Highly efficient utilization of walnut shell biochar through a facile designed portable direct carbon solid oxide fuel cell stack[J]. Energy, 2021, 227: 120456. |

| 94 | Cai W Z, Zhou Q, Xie Y M, et al. A direct carbon solid oxide fuel cell operated on a plant derived biofuel with natural catalyst[J]. Applied Energy, 2016, 179: 1232-1241. |

| 95 | Cai W Z, Liu J, Liu P P, et al. A direct carbon solid oxide fuel cell fueled with char from wheat straw[J]. International Journal of Energy Research, 2019, 43(7): 2468-2477. |

| 96 | 丘倩媛, 陈倩阳, 刘志军, 等. 以椰壳生物质炭为燃料的直接炭固体氧化物燃料电池[J]. 燃料化学学报, 2019, 47(3): 352-360. |

| Qiu Q Y, Chen Q Y, Liu Z J, et al. Biochar derived from coconut as fuel for the direct carbon solid oxide fuel cell[J]. Journal of Fuel Chemistry and Technology, 2019, 47(3): 352-360. | |

| 97 | Ma M J, Qiao J S, Yang X X, et al. Enhanced stability and catalytic activity on layered perovskite anode for high-performance hybrid direct carbon fuel cells[J]. ACS Applied Materials & Interfaces, 2020, 12(11): 12938-12948. |

| 98 | Cai W Z, Zhou Q, Xie Y M, et al. A facile method of preparing Fe-loaded activated carbon fuel for direct carbon solid oxide fuel cells[J]. Fuel, 2015, 159: 887-893. |

| 99 | Yu X K, Shi Y X, Wang H J, et al. Using potassium catalytic gasification to improve the performance of solid oxide direct carbon fuel cells: experimental characterization and elementary reaction modeling[J]. Journal of Power Sources, 2014, 252: 130-137. |

| 100 | Xie Y M, Lu Z B, Ma C C, et al. High-performance gas-electricity cogeneration using a direct carbon solid oxide fuel cell fueled by biochar derived from camellia oleifera shells[J]. International Journal of Hydrogen Energy, 2020, 45(53): 29322-29330. |

| 101 | Li X, Zhu Z H, Chen J L, et al. Surface modification of carbon fuels for direct carbon fuel cells[J]. Journal of Power Sources, 2009, 186(1): 1-9. |

| [1] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [2] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [3] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [4] | 胡亚丽, 胡军勇, 马素霞, 孙禹坤, 谭学诣, 黄佳欣, 杨奉源. 逆电渗析热机新型工质开发及电化学特性研究[J]. 化工学报, 2023, 74(8): 3513-3521. |

| [5] | 张琦钰, 高利军, 苏宇航, 马晓博, 王翊丞, 张亚婷, 胡超. 碳基催化材料在电化学还原二氧化碳中的研究进展[J]. 化工学报, 2023, 74(7): 2753-2772. |

| [6] | 张蒙蒙, 颜冬, 沈永峰, 李文翠. 电解液类型对双离子电池阴阳离子储存行为的影响[J]. 化工学报, 2023, 74(7): 3116-3126. |

| [7] | 葛加丽, 管图祥, 邱新民, 吴健, 沈丽明, 暴宁钟. 垂直多孔碳包覆的FeF3正极的构筑及储锂性能研究[J]. 化工学报, 2023, 74(7): 3058-3067. |

| [8] | 刘春雨, 周桓宇, 马跃, 岳长涛. CaO调质含油污泥干燥特性及数学模型[J]. 化工学报, 2023, 74(7): 3018-3027. |

| [9] | 屈园浩, 邓文义, 谢晓丹, 苏亚欣. 活性炭/石墨辅助污泥电渗脱水研究[J]. 化工学报, 2023, 74(7): 3038-3050. |

| [10] | 张谭, 刘光, 李晋平, 孙予罕. Ru基氮还原电催化剂性能调控策略[J]. 化工学报, 2023, 74(6): 2264-2280. |

| [11] | 郭旭, 张永政, 夏厚兵, 杨娜, 朱真珍, 齐晶瑶. 碳基材料电氧化去除水体污染物的研究进展[J]. 化工学报, 2023, 74(5): 1862-1874. |

| [12] | 张正, 何永平, 孙海东, 张荣子, 孙正平, 陈金兰, 郑一璇, 杜晓, 郝晓刚. 蛇形流场电控离子交换装置用于选择性提锂[J]. 化工学报, 2023, 74(5): 2022-2033. |

| [13] | 李瑞康, 何盈盈, 卢维鹏, 王园园, 丁皓东, 骆勇名. 电化学强化钴基阴极活化过一硫酸盐的研究[J]. 化工学报, 2023, 74(5): 2207-2216. |

| [14] | 王承泽, 顾凯丽, 张晋华, 石建轩, 刘艺娓, 李锦祥. 硫化协同老化零价铁增效去除水中Cr(Ⅵ)的作用机制[J]. 化工学报, 2023, 74(5): 2197-2206. |

| [15] | 罗来明, 张劲, 郭志斌, 王海宁, 卢善富, 相艳. 1~5 kW高温聚合物电解质膜燃料电池堆的理论模拟与组装测试[J]. 化工学报, 2023, 74(4): 1724-1734. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号