化工学报 ›› 2023, Vol. 74 ›› Issue (2): 525-534.DOI: 10.11949/0438-1157.20221002

张梦波( ), 楼琳瑾, 冯艺荣, 郑雨婷, 张浩淼(

), 楼琳瑾, 冯艺荣, 郑雨婷, 张浩淼( ), 王靖岱, 阳永荣

), 王靖岱, 阳永荣

收稿日期:2022-07-19

修回日期:2022-10-10

出版日期:2023-02-05

发布日期:2023-03-21

通讯作者:

张浩淼

作者简介:张梦波(2000—),男,硕士研究生,22128096@zju.edu.cn

基金资助:

Mengbo ZHANG( ), Linjin LOU, Yirong FENG, Yuting ZHENG, Haomiao ZHANG(

), Linjin LOU, Yirong FENG, Yuting ZHENG, Haomiao ZHANG( ), Jingdai WANG, Yongrong YANG

), Jingdai WANG, Yongrong YANG

Received:2022-07-19

Revised:2022-10-10

Online:2023-02-05

Published:2023-03-21

Contact:

Haomiao ZHANG

摘要:

基于传统釜式反应器的烷基铝氧烷生产技术仍存在过程危险、控制难、收率低、经济性差等问题,首先回顾了传统烷基铝水解路线中将水以不同方式引入反应体系的过程,重点介绍了应用3D打印和流动化学技术的烷基铝氧烷合成系统设计,包括甲基铝氧烷(MAO)与异丁基铝氧烷(IBAO)合成、产物在线监测、反应焓测定以及改性甲基铝氧烷(MMAO)合成。流动化学系统将水以单分散微水滴的形式引入反应体系,提高了反应的传热、传质性能,实现了烷基铝氧烷的小型化、连续化、安全化生产,产品收率高,其助催化活性均达到或超过市售产品水平,并可通过微反应器放大技术进一步扩大生产能力。流动化学合成烷基铝氧烷的技术具有广阔应用前景,也为其他快速、强放热、多相反应提供了解决方案。

中图分类号:

张梦波, 楼琳瑾, 冯艺荣, 郑雨婷, 张浩淼, 王靖岱, 阳永荣. 烷基铝氧烷合成技术研究进展[J]. 化工学报, 2023, 74(2): 525-534.

Mengbo ZHANG, Linjin LOU, Yirong FENG, Yuting ZHENG, Haomiao ZHANG, Jingdai WANG, Yongrong YANG. Research progress on synthesis of alkylaluminoxanes[J]. CIESC Journal, 2023, 74(2): 525-534.

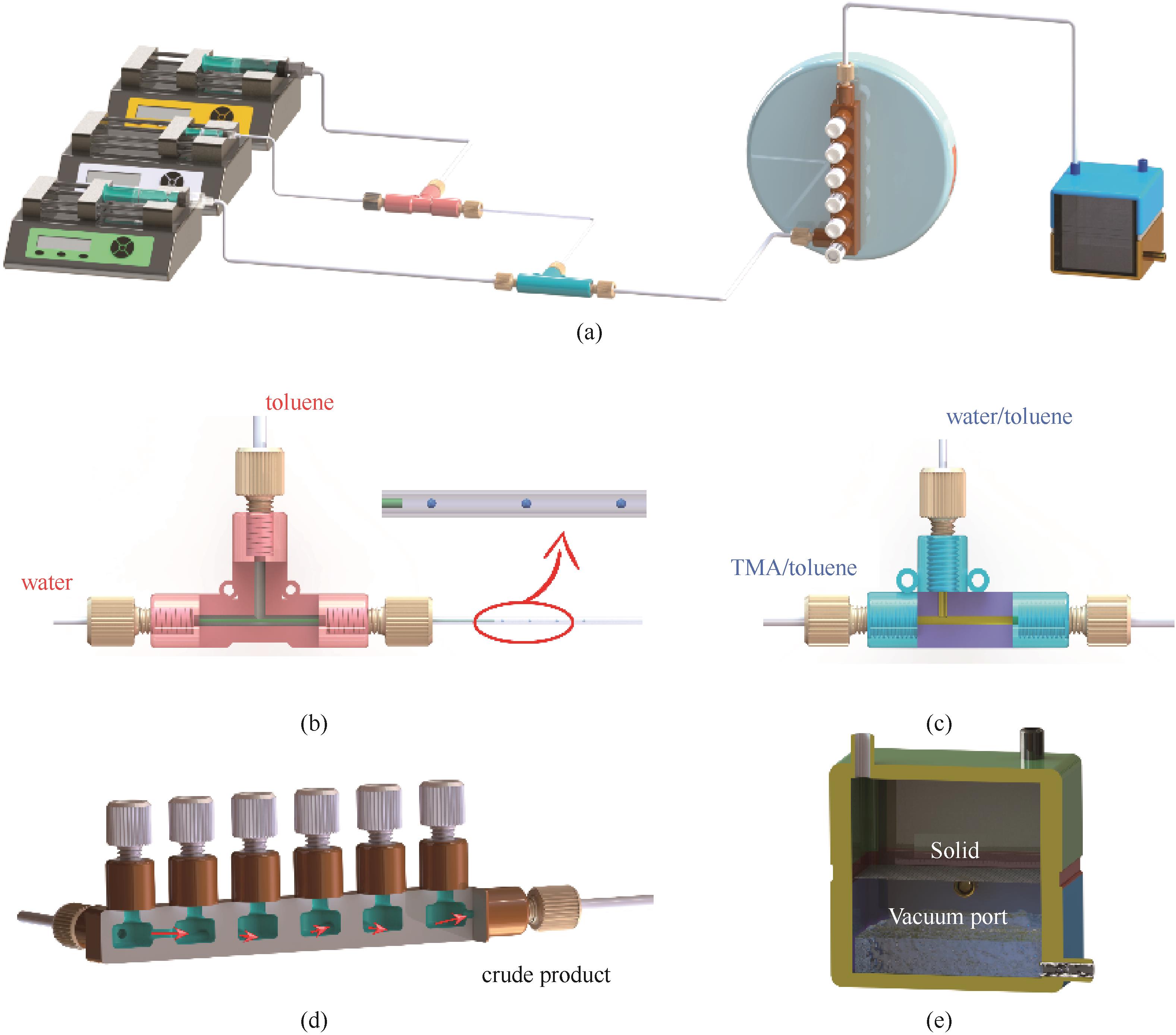

图2 MAO合成的流动化学平台 (a)、毛细管式微液滴生成器(b)、T型微混合器(c)、微型全混釜串联反应器(d)和气/液/固三相分离器(e)示意图[59]

Fig.2 Schematic of the flow platform for MAO synthesis (a), capillary-based microdroplet generator (b), T-micromixer (c), 6 μCSTRs-in-series (d), and gas/liquid/solid three-phase separator (e)[59]

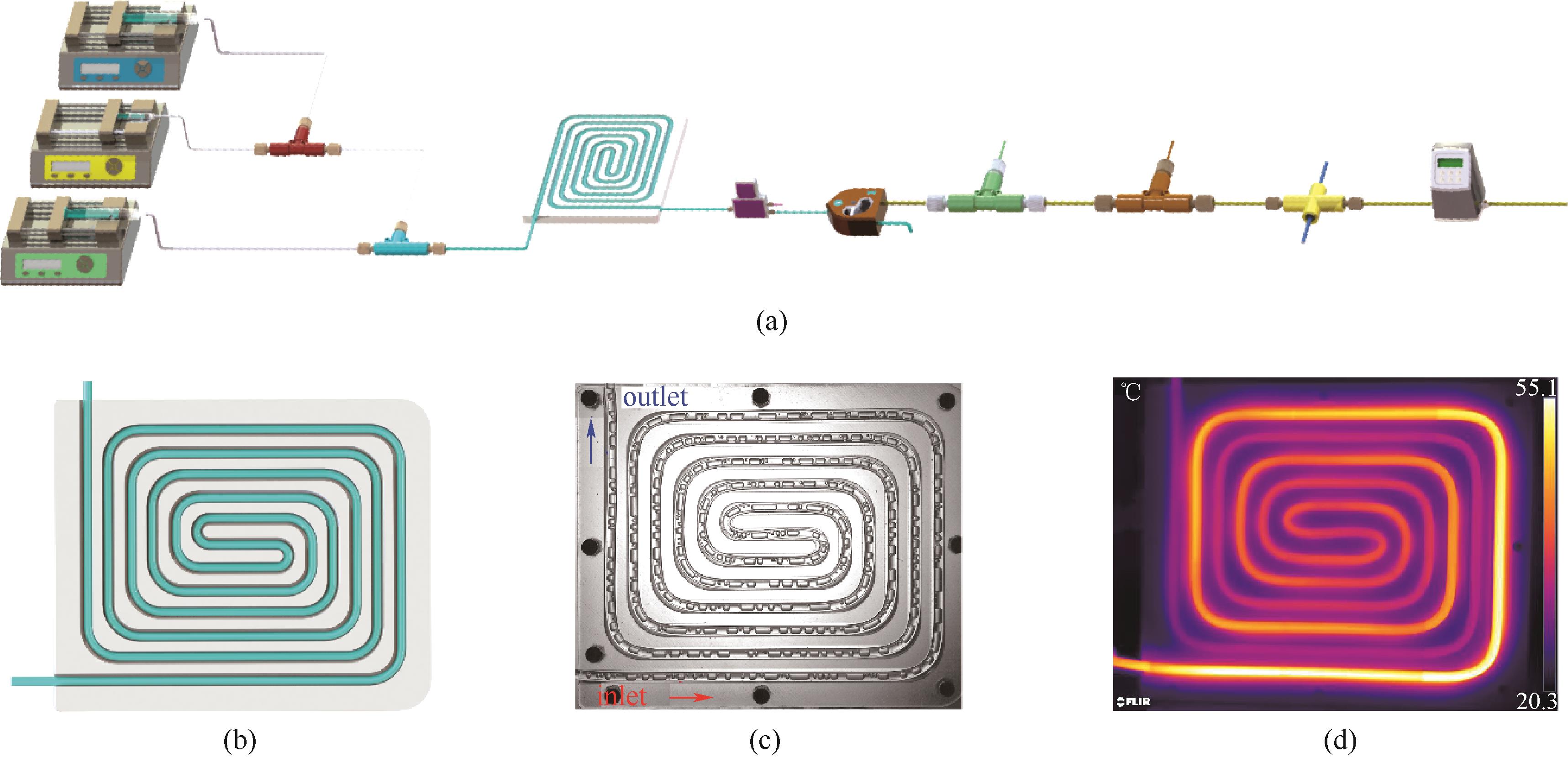

图3 (a) IBAO合成的流动化学反应平台示意图;(b)盘管式微反应器示意图;(c)反应时的两相流型分布;(d)反应时的温度分布[69]

Fig.3 (a) Schematic of the flow platform for IBAO synthesis; (b) Schematic of coiled tubular microreactor; (c) Two-phase flow pattern distribution during the reaction; (d) temperature distribution during the reaction [69]

| 产品名称 | 产品型号 | 分子式 | 溶剂 | CAS号 |

|---|---|---|---|---|

| 3A型改性甲基铝氧烷 | MMAO-3A | —[(CH3)0.7(i-C4H9)0.3AlO] x — | 正庚烷 | 146905-79-5 |

| 7型改性甲基铝氧烷 | MMAO-7 | —[(CH3)0.86(n-C8H17)0.14AlO] x — | Isopar ETM | 206451-54-9 |

| 12型改性甲基铝氧烷 | MMAO-12 | —[(CH3)0.95(n-C8H17)0.05AlO] x — | 甲苯 | 206-54-9 |

表1 代表性的市售MMAO产品

Table 1 Representative commercial MMAO products

| 产品名称 | 产品型号 | 分子式 | 溶剂 | CAS号 |

|---|---|---|---|---|

| 3A型改性甲基铝氧烷 | MMAO-3A | —[(CH3)0.7(i-C4H9)0.3AlO] x — | 正庚烷 | 146905-79-5 |

| 7型改性甲基铝氧烷 | MMAO-7 | —[(CH3)0.86(n-C8H17)0.14AlO] x — | Isopar ETM | 206451-54-9 |

| 12型改性甲基铝氧烷 | MMAO-12 | —[(CH3)0.95(n-C8H17)0.05AlO] x — | 甲苯 | 206-54-9 |

| 1 | Kaminsky W. Discovery of methylaluminoxane as cocatalyst for olefin polymerization[J]. Macromolecules, 2012, 45(8): 3289-3297. |

| 2 | Kaminsky W. The discovery and evolution of metallocene-based olefin polymerization catalysts[J]. Rendiconti Lincei, 2017, 28(1): 87-95. |

| 3 | 吴江. 甲基铝氧烷合成技术研究[D]. 兰州: 兰州大学, 2007. |

| Wu J. Study in synthetic technology of methylaluminoxane[D]. Lanzhou: Lanzhou University, 2007. | |

| 4 | Zijlstra H S, Harder S. Methylalumoxane-history, production, properties, and applications[J]. European Journal of Inorganic Chemistry, 2015, 2015(1): 19-43. |

| 5 | Oliva L, Oliva P, Galdi N, et al. Solution structure and reactivity with metallocenes of AlMe2F: mimicking cation-anion interactions in metallocenium-methylalumoxane inner-sphere ion pairs[J]. Angewandte Chemie International Edition, 2017, 56(45): 14227-14231. |

| 6 | Rabinovich D. The allure of aluminium[J]. Nature Chemistry, 2012, 5: 76. |

| 7 | Glaser R, Sun X S. Thermochemistry of the initial steps of methylaluminoxane formation. Aluminoxanes and cycloaluminoxanes by methane elimination from dimethylaluminum hydroxide and its dimeric aggregates[J]. Journal of the American Chemical Society, 2011, 133(34): 13323-13336. |

| 8 | Linnolahti M, Severn J R, Pakkanen T A. Formation of nanotubular methylaluminoxanes and the nature of the active species in single-site α-olefin polymerization catalysis[J]. Angewandte Chemie International Edition, 2008, 47(48): 9279-9283. |

| 9 | Busico V, Cipullo R, Cutillo F, et al. Improving the performance of methylalumoxane: a facile and efficient method to trap “free” trimethylaluminum[J]. Journal of the American Chemical Society, 2003, 125(41): 12402-12403. |

| 10 | Linnolahti M, Severn J R, Pakkanen T A. Are aluminoxanes nanotubular? Structural evidence from a quantum chemical study[J]. Angewandte Chemie International Edition, 2006, 45(20): 3331-3334. |

| 11 | Pasynkiewicz S. Alumoxanes: synthesis, structures, complexes and rections[J]. Polyhedron, 1990, 9: 429-453. |

| 12 | Velthoen M E Z, Muñoz-Murillo A, Bouhmadi A, et al. The multifaceted role of methylaluminoxane in metallocene-based olefin polymerization catalysis[J]. Macromolecules, 2018, 51(2): 343-355. |

| 13 | Kleinschmidt R, van der leek Y, Reffke M, et al. Kinetics and mechanistic insight into propylene polymerization with different metallocenes and various aluminium alkyls as cocatalysts[J]. Journal of Molecular Catalysis A: Chemical, 1999, 148(1): 29-41. |

| 14 | Ioku A, Hasan T, Shiono T, et al. Effects of cocatalysts on propene polymerization with [t-BuNSiMe2(C5Me4)]TiMe2 [J]. Macromolecular Chemistry and Physics, 2002, 203(4): 748-755. |

| 15 | Hoff R. Handbook of Transition Metal Polymerization Catalysts [M]. 2nd ed. New Jersey: John Wiley & Sons, Inc., 2018. |

| 16 | Bochmann M. The chemistry of catalyst activation: the case of group 4 polymerization catalysts[J]. Organometallics, 2010, 29(21): 4711-4740. |

| 17 | Kaminsky W. The discovery of metallocene catalysts and their present state of the art[J]. Journal of Polymer Science Part A-Polymer Chemistry, 2004, 42(16): 3911-3921. |

| 18 | Edwards D N, Briggs J R, Marcinkowsky A E, et al. Process for the preparation of aluminoxanes: US4772736[P]. 1988-09-20. |

| 19 | Giannetti E, Nicoletti G M, Mazzocchi R. Homogeneous Ziegler Natta catalysis.2. Ethylene polymerization by IVB transition-metal complexes/methyl aluminoxane catalyst systems[J]. Journal of Polymer Science Part A: Polymer Chemistry, 1985, 23(8): 2117-2134. |

| 20 | Deavenport D L, Hodges Iii J T, Malpass D B, et al. Preparation of aluminoxanes: US5041585[P]. 1991-08-20. |

| 21 | 吴江, 韦少义, 陈雪蓉, 等. 一种雾化合成装置及其在烷基铝氧烷合成方面的应用: 102190677B[P]. 2010-03-03. |

| Wu J, Wei S Y, Chen X R, et al. A kind of atomization synthesis device and its application in the synthesis of alkyl aluminoxide: 102190677B[P]. 2010-03-03. | |

| 22 | Smith G Z Jr. Falling film aluminoxane process: US5103031[P]. 1992-04-07. |

| 23 | Kilpatrick A F R, Buffet J-C, Nørby P, et al. Synthesis and characterization of solid polymethylaluminoxane: a bifunctional activator and support for slurry-phase ethylene polymerization[J]. Chemistry of Materials, 2016, 28(20): 7444-7450. |

| 24 | 韦少义, 朱博超, 陈雪蓉, 等. 烷基铝氧烷的制备方法: 100413870C[P]. 2008-08-27. |

| Wei S Y, Zhu B C, Chen X R, et al. Preparation method of alkyl aluminoxicane: 100413870C[P]. 2008-08-27. | |

| 25 | Sinn H. Proposals for structure and effect of methylalumoxane based on mass balances and phase separation experiments[J]. Macromolecular Symposia, 1995, 97(1): 27-52. |

| 26 | Sinn H, Clausnitzer D, Winter H. Process for producing aluminum oxanes, in particular methylaluminum oxane, from water and organoaluminum compounds, in particular trimethylaluminum, in inert hydrocarbons: US5087713[P]. 1992-02-11. |

| 27 | Roberg J K, Burt E A. High yield aluminoxane synthesis process: US5663394[P]. 1997-09-02. |

| 28 | Cam D, Albizzati E, Cinquina P. Characterization of methylalumoxane by means of gel-permeation chromatography[J]. Makromolekulare Chemie-Macromolecular Chemistry and Physics, 1990, 191(7): 1641-1647. |

| 29 | Resconi L, Bossi S, Abis L. Study on the role of methylalumoxane in homogeneous olefin polymerization[J]. Macromolecules, 1990, 23(20): 4489-4491. |

| 30 | Soga K, Yu C H, Shiono T. Polymerization of alpha-olefins with the catalyst system prepared from a hydrated transition-metal compound and trimethylaluminum[J]. Makromolekulare Chemie-Rapid Communications, 1988, 9(3): 141-144. |

| 31 | Okajima Y, Nakayama Y, Shiono T, et al. Preparation of methylaluminoxane from CO2 and Me3Al[J]. European Journal of Inorganic Chemistry, 2019(18): 2392-2395. |

| 32 | Kinnunen T J J, Haukka M, Pakkanen T, et al. Four-coordinated bipyridine complexes of nickel for ethene polymerization — the role of ligand structure[J]. Journal of Organometallic Chemistry 2000, 613: 257-262. |

| 33 | Dalet T, Cramail H, Deffieux A. Non-hydrolytic route to aluminoxane-type derivative for metallocene activation towards olefin polymerisation[J]. Macromolecular Chemistry and Physics, 2004, 205(10): 1394-1401. |

| 34 | Jensen K F. Microreaction engineering — is small better?[J]. Chemical Engineering Science, 2001, 56(2): 293-303. |

| 35 | Newman S G, Jensen K F. The role of flow in green chemistry and engineering[J]. Green Chemistry, 2013, 15(6): 1456-1472. |

| 36 | Jensen K F. Flow chemistry—microreaction technology comes of age[J]. AIChE Journal, 2017, 63(3): 858-869. |

| 37 | 骆广生, 王凯, 王玉军, 等. 微化工系统的原理和应用[J]. 化工进展, 2011, 30(8): 1637-1642. |

| Luo G S, Wang K, Wang Y J, et al. Principles and applications of micro-structured chemical system[J]. Chemical Industry and Engineering Progress, 2011, 30(8): 1637-1642. | |

| 38 | Zhang J, Wang K, Teixeira A R, et al. Design and scaling up of microchemical systems: a review[J]. Annual review of chemical biomolecular engineering, 2017, 8: 285-305. |

| 39 | Bedard A C, Adamo A, Aroh K C, et al. Reconfigurable system for automated optimization of diverse chemical reactions[J]. Science, 2018, 361(6408): 1220-1225. |

| 40 | Britton J, Raston C L. Multi-step continuous-flow synthesis[J]. Chemical Society Reviews, 2017, 46(5): 1250-1271. |

| 41 | Liu D, Jing Y, Wang K, et al. Reaction study of α-phase NaYF4:Yb,Er generation via a tubular microreactor: discovery of an efficient synthesis strategy[J]. Nanoscale, 2019, 11(17): 8363-8371. |

| 42 | Reis M H, Leibfarth F A, Pitet L M. Polymerizations in continuous flow: recent advances in the synthesis of diverse polymeric materials[J]. ACS Macro Letters, 2020, 9(1): 123-133. |

| 43 | Zaquen N, Rubens M, Corrigan N, et al. Polymer synthesis in continuous flow reactors[J]. Progress in Polymer Science, 2020, 107: 101256. |

| 44 | Tonhauser C, Nataello A, Lowe H, et al. Microflow technology in polymer synthesis[J]. Macromolecules, 2012, 45(24): 9551-9570. |

| 45 | Marre S, Adamo A, Basak S, et al. Design and packaging of microreactors for high pressure and high temperature applications[J]. Industrial & Engineering Chemistry Research, 2010, 49(22): 11310-11320. |

| 46 | Ehrfeld W, Hessel V, Löwe H. Microreactors: New Technology for Modern Chemistry[M]. Mainz: IMM Mainz GmbH, 2000. |

| 47 | Zhang J S, Wang K, Lu Y C, et al. Beckmann rearrangement in a microstructured chemical system for the preparation of ε-caprolactam[J]. AIChE Journal, 2012, 58(3): 925-931. |

| 48 | Wang K, Zhang H, Shen Y, et al. Thermoformed fluoropolymer tubing for in-line mixing[J]. Reaction Chemistry & Engineering, 2018, 3(5): 707-713. |

| 49 | Cambie D, Bottecchia C, Straathof N J W, et al. Applications of continuous-flow photochemistry in organic synthesis, material science, and water treatment[J]. Chemical Reviews, 2016, 116(17): 10276-10341. |

| 50 | Buglioni L, Raymenants F, Slattery A, et al. Technological innovations in photochemistry for organic synthesis: flow chemistry, high-throughput experimentation, scale-up, and photoelectrochemistry[J]. Chemical Reviews, 2022, 122(2): 2752-2906. |

| 51 | Campbell Z S, Abolhasani M. Facile synthesis of anhydrous microparticles using plug-and-play microfluidic reactors[J]. Reaction Chemistry & Engineering, 2020, 5(7): 1198-1211. |

| 52 | Bennett J A, Kristof A J, Vasudevan V, et al. Microfluidic synthesis of elastomeric microparticles: a case study in catalysis of palladium-mediated cross-coupling[J]. AIChE Journal, 2018, 64(8): 3188-3197. |

| 53 | Lebl R, Zhu Y, Ng D, et al. Scalable continuous flow hydrogenations using Pd/Al2O3-coated rectangular cross-section 3D-printed static mixers[J]. Catalysis Today, 2022, 383: 55-63. |

| 54 | Maier M C, Valotta A, Hiebler K, et al. 3D printed reactors for synthesis of active pharmaceutical ingredients in continuous flow[J]. Organic Process Research & Development, 2020, 24(10): 2197-2207. |

| 55 | Zhang H M, Kopfmüller T, Achermann R, et al. Accessing multidimensional mixing via 3D printing and showerhead micromixer design[J]. AIChE Journal, 2020, 66(4): e16873. |

| 56 | Feng Y R, Zhang H M, Wang J D, et al. Performance evaluation and scale-up behavior of an engineered in-line mixer for 3D printing[J]. Industrial & Engineering Chemistry Research, 2021, 60(30): 11568-11578. |

| 57 | Zhang H M, Ładosz A, Jensen K F. Design and operation of an enhanced pervaporation device with static mixers[J]. AIChE Journal, 2022, 68(2): e17455. |

| 58 | Feng Y R, Mu H F, Liu X, et al. Leveraging 3D printing for the design of high-performance Venturi microbubble generators[J]. Industrial & Engineering Chemistry Research, 2020, 59(17): 8447-8455. |

| 59 | Feng Y R, Wang J, Zhang H M, et al. A 3D-printed continuous flow platform for the synthesis of methylaluminoxane[J]. Green Chemistry, 2021, 23(11): 4087-4094. |

| 60 | Zhang M B, Feng Y R, Lou L J, et al. Flow toolkit for measuring reaction enthalpy and application to highly exothermic synthesis of alkylaluminoxanes[J]. Organic Process Research & Development, 2022, 26(5): 1506-1513. |

| 61 | Pédeutour J-N, Radhakrishnan K, Cramail H, et al. Reactivity of metallocene catalysts for olefin polymerization: influence of activator nature and structure[J]. Macromolecular Rapid Communications, 2001, 22(14): 1095-1123. |

| 62 | Kissin Y V, Brandolini A J. An alternative route to methylalumoxane: synthesis, structure, and the use of model methylalumoxanes as cocatalysts for transition metal complexes in polymerization reactions[J]. Macromolecules, 2003, 36(1): 18-26. |

| 63 | Kaminsky W, Strubel C. Hydrogen transfer reactions of supported metallocene catalysts[J]. Journal of Molecular Catalysis A-Chemical, 1998, 128(1/2/3): 191-200. |

| 64 | Kaminsky W, Bark A, Steiger R. Stereospecific polymerization by metallocene aluminoxane catalysts[J]. Journal of Molecular Catalysis, 1992, 74(1/2/3): 109-119. |

| 65 | Chen E Y, Marks T J. Cocatalysts for metal-catalyzed olefin polymerization: activators, activation processes, and structure-activity relationships[J]. Chemical Reviews, 2000, 100(4): 1391-1434. |

| 66 | Velthoen M E Z, Boereboom J M, Bulo R E, et al. Insights into the activation of silica-supported metallocene olefin polymerization catalysts by methylaluminoxane[J]. Catalysis Today, 2019, 334: 223-230. |

| 67 | Baier M C, Zuideveld M A, Mecking S. Post-metallocenes in the industrial production of polyolefins[J]. Angewandte Chemie International Edition, 2014, 53(37): 9722-9744. |

| 68 | Stellbrink J, Niu A, Allgaier J, et al. Analysis of polymeric methylaluminoxane (MAO) via small angle neutron scattering[J]. Macromolecules, 2007, 40(14): 4972-4981. |

| 69 | Feng Y R, Zhang M B, Zhang H M, et al. Continuous synthesis of isobutylaluminoxanes in a compact and integrated approach[J]. Chemical Engineering Journal, 2021, 425: 131750. |

| 70 | Bravaya N M, Panin A N, Faingol'd E E, et al. Isobutylalumoxanes as high-performance activators of rac-Et(2-MeInd)2ZrMe2 in copolymerization of ethylene with propylene and ternary copolymerization of ethylene, propylene, and 5-ethylidene-2-norbornene[J]. Polymer Bulletin, 2015, 73(2): 473-491. |

| 71 | Zhang M B, Lou L J, Zheng Y T, et al. A two-stage flow strategy for the synthesis of isobutyl-modified methylaluminoxane[J]. Reaction Chemistry & Engineering, 2023, DOI:10.1039/D2RE00595F . |

| [1] | 王琪, 张斌, 张晓昕, 武虎建, 战海涛, 王涛. 氯铝酸-三乙胺离子液体/P2O5催化合成伊索克酸和2-乙基蒽醌[J]. 化工学报, 2023, 74(S1): 245-249. |

| [2] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [3] | 李彬, 徐正虎, 姜爽, 张天永. 双氧水催化氧化法清洁高效合成促进剂CBS[J]. 化工学报, 2023, 74(7): 2919-2925. |

| [4] | 葛加丽, 管图祥, 邱新民, 吴健, 沈丽明, 暴宁钟. 垂直多孔碳包覆的FeF3正极的构筑及储锂性能研究[J]. 化工学报, 2023, 74(7): 3058-3067. |

| [5] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| [6] | 张谭, 刘光, 李晋平, 孙予罕. Ru基氮还原电催化剂性能调控策略[J]. 化工学报, 2023, 74(6): 2264-2280. |

| [7] | 董茂林, 陈李栋, 黄六莲, 吴伟兵, 戴红旗, 卞辉洋. 酸性助水溶剂制备木质纳米纤维素及功能应用研究进展[J]. 化工学报, 2023, 74(6): 2281-2295. |

| [8] | 何汉兵, 刘真, 陈勇, 王小锋, 曾婧. 直写成型电极锰氧化物粉末的合成与浆料调控[J]. 化工学报, 2023, 74(5): 2239-2247. |

| [9] | 葛泽峰, 吴雨青, 曾名迅, 查振婷, 马宇娜, 侯增辉, 张会岩. 灰化学成分对生物质气化特性的影响规律[J]. 化工学报, 2023, 74(5): 2136-2146. |

| [10] | 王锋, 陈钰, 裴鸿艳, 刘东东, 张静, 张立新. 1,2,4-𫫇二唑类衍生物的设计、合成及抗菌活性[J]. 化工学报, 2023, 74(3): 1390-1398. |

| [11] | 刘定平, 陈爱桦, 张向阳, 何文浩, 王海. 铝灰半干法水解脱氮研究[J]. 化工学报, 2023, 74(3): 1294-1302. |

| [12] | 刘润竹, 储甜甜, 张孝阿, 王成忠, 张军营. α,ω-端羟基亚苯基氟硅聚合物的合成及性能[J]. 化工学报, 2023, 74(3): 1360-1369. |

| [13] | 袁海鸥, 叶方俊, 张硕, 罗祎青, 袁希钢. 考虑中间换热器的能量集成精馏序列合成[J]. 化工学报, 2023, 74(2): 796-806. |

| [14] | 李鑫, 曾少娟, 彭奎霖, 袁磊, 张香平. CO2电催化还原制合成气研究进展及趋势[J]. 化工学报, 2023, 74(1): 313-329. |

| [15] | 刘昕, 戈钧, 李春. 光驱动微生物杂合系统提高生物制造水平[J]. 化工学报, 2023, 74(1): 330-341. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号