化工学报 ›› 2023, Vol. 74 ›› Issue (6): 2668-2679.DOI: 10.11949/0438-1157.20230296

朱风1( ), 陈凯琳1, 黄小凤1,2(

), 陈凯琳1, 黄小凤1,2( ), 鲍银珠1, 李文斌1, 刘嘉鑫1, 吴玮强1, 高王伟1

), 鲍银珠1, 李文斌1, 刘嘉鑫1, 吴玮强1, 高王伟1

收稿日期:2023-03-27

修回日期:2023-06-05

出版日期:2023-06-05

发布日期:2023-07-27

通讯作者:

黄小凤

作者简介:朱风(1999—),女,硕士研究生,1311019104@qq.com

基金资助:

Feng ZHU1( ), Kailin CHEN1, Xiaofeng HUANG1,2(

), Kailin CHEN1, Xiaofeng HUANG1,2( ), Yinzhu BAO1, Wenbin LI1, Jiaxin LIU1, Weiqiang WU1, Wangwei GAO1

), Yinzhu BAO1, Wenbin LI1, Jiaxin LIU1, Weiqiang WU1, Wangwei GAO1

Received:2023-03-27

Revised:2023-06-05

Online:2023-06-05

Published:2023-07-27

Contact:

Xiaofeng HUANG

摘要:

以电石渣为原料,采用过体积浸渍法制备KOH改性电石渣,考察了不同制备条件及工艺条件对脱除羰基硫(COS)的影响,并通过N2-BET、SEM-EDS、XPS、FTIR等方法进行表征,初步探究了改性电石渣的脱硫性能及反应过程,发现KOH改性电石渣脱除COS的过程中主要发生催化水解、氧化反应及酸碱吸附。结果表明,最佳制备条件为焙烧温度800℃、焙烧时间6 h,KOH最适添加量为25%;在此条件下,当入口浓度、反应温度和空速分别为600 mg/m3、25℃和5733 h-1时,KOH改性电石渣脱除COS效果最佳,穿透吸附量为43.70 mg/g。

中图分类号:

朱风, 陈凯琳, 黄小凤, 鲍银珠, 李文斌, 刘嘉鑫, 吴玮强, 高王伟. KOH改性电石渣脱除羰基硫的性能研究[J]. 化工学报, 2023, 74(6): 2668-2679.

Feng ZHU, Kailin CHEN, Xiaofeng HUANG, Yinzhu BAO, Wenbin LI, Jiaxin LIU, Weiqiang WU, Wangwei GAO. Performance study of KOH modified carbide slag for removal of carbonyl sulfide[J]. CIESC Journal, 2023, 74(6): 2668-2679.

| 化学组成/%(质量) | |||||||

|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | Cl | SO3 |

| 93.278 | 3.006 | 1.864 | 0.245 | 0.093 | 0.38 | 0.093 | 0.502 |

表1 电石渣化学组成

Table 1 Chemical composition of carbide slag

| 化学组成/%(质量) | |||||||

|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | Cl | SO3 |

| 93.278 | 3.006 | 1.864 | 0.245 | 0.093 | 0.38 | 0.093 | 0.502 |

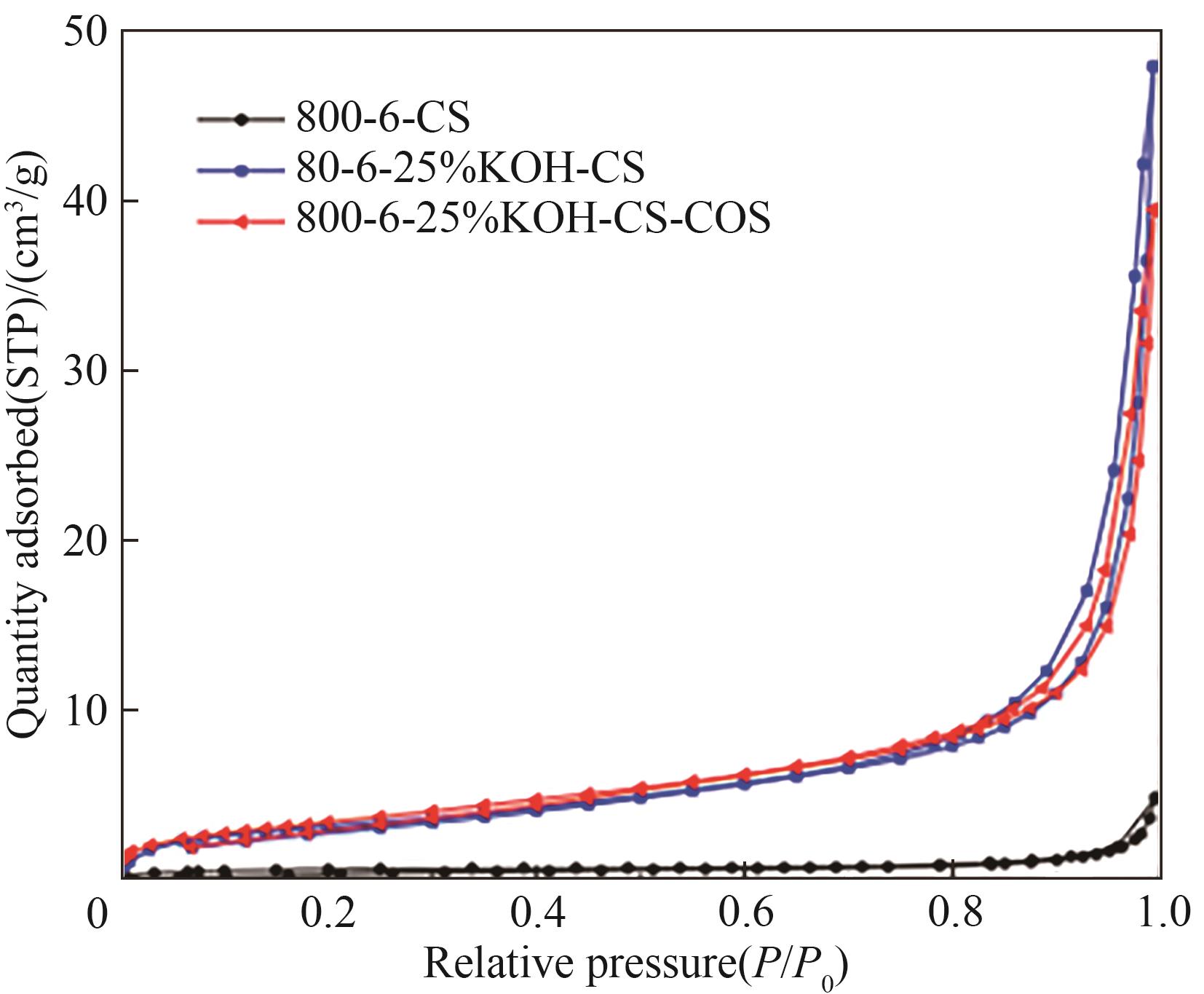

| 样品 | 比表面积/(m2/g) | 总孔体积/(cm3/g) | 平均孔径/nm |

|---|---|---|---|

| 800-6-CS | 1.8618 | 0.007424 | 7.8737 |

| 800-6-25%KOH-CS | 7.5073 | 0.042714 | 25.6445 |

| 800-6-25%KOH-CS-COS | 5.5664 | 0.043636 | 19.3113 |

表2 800-6-CS、800-6-25%KOH-CS、800-6-25%KOH-CS-COS的孔结构特征

Table 2 Pore structure characteristics of 800-6-CS, 800-6-25%KOH-CS, and 800-6-25%KOH-CS-COS

| 样品 | 比表面积/(m2/g) | 总孔体积/(cm3/g) | 平均孔径/nm |

|---|---|---|---|

| 800-6-CS | 1.8618 | 0.007424 | 7.8737 |

| 800-6-25%KOH-CS | 7.5073 | 0.042714 | 25.6445 |

| 800-6-25%KOH-CS-COS | 5.5664 | 0.043636 | 19.3113 |

图10 800-6-CS、800-6-25%KOH-CS、800-6-25%KOH-CS-COS的吸附-脱附等温线

Fig.10 Nitrogen adsorption-desorption isotherms of 800-6-CS, 800-6-25%KOH-CS, and 800-6-25%KOH-CS-COS

| 样品 | 质量分数/% | 原子分数/% | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | O | Ca | Al | Si | K | S | C | O | Ca | Al | Si | K | S | |

| 800-6-CS | 2.73 | 33.23 | 60.17 | 0.99 | 2.11 | 0.03 | 0.07 | 5.77 | 52.66 | 38.21 | 0.93 | 1.90 | 0.04 | 0.06 |

| 800-6-25%KOH-CS | 7.50 | 39.00 | 43.70 | 1.00 | 1.40 | 7.06 | 0 | 14.00 | 55.10 | 24.70 | 0.80 | 1.10 | 4.10 | 0.03 |

| 800-6-25%KOH-CS-COS | 9.30 | 40.60 | 41.60 | 0.80 | 1.00 | 5.10 | 1.60 | 16.80 | 55.30 | 22.60 | 0.70 | 0.70 | 2.80 | 1.20 |

表3 800-6-CS、800-6-25%KOH-CS、800-6-25%KOH-CS-COS的EDS元素分析

Table 3 EDS elemental analysis of 800-6-CS, 800-6-25%KOH-CS, and 800-6-25%KOH-CS-COS

| 样品 | 质量分数/% | 原子分数/% | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | O | Ca | Al | Si | K | S | C | O | Ca | Al | Si | K | S | |

| 800-6-CS | 2.73 | 33.23 | 60.17 | 0.99 | 2.11 | 0.03 | 0.07 | 5.77 | 52.66 | 38.21 | 0.93 | 1.90 | 0.04 | 0.06 |

| 800-6-25%KOH-CS | 7.50 | 39.00 | 43.70 | 1.00 | 1.40 | 7.06 | 0 | 14.00 | 55.10 | 24.70 | 0.80 | 1.10 | 4.10 | 0.03 |

| 800-6-25%KOH-CS-COS | 9.30 | 40.60 | 41.60 | 0.80 | 1.00 | 5.10 | 1.60 | 16.80 | 55.30 | 22.60 | 0.70 | 0.70 | 2.80 | 1.20 |

| 1 | 牟秀娟, 朱干宇, 颜坤, 等. 干法电石渣性质分析及乙炔气逸出行为研究[J]. 化工学报, 2021, 72(2): 1107-1115. |

| Mu X J, Zhu G Y, Yan K, et al. Properties analysis of dry-process calcium carbide slag and study on acetylene gas escape behavior[J]. CIESC Journal, 2021, 72(2): 1107-1115. | |

| 2 | Yang J, Liu S Y, Ma L P. Thermodynamic analysis of hydrogen production from carbide slag used as oxygen carrier, hydrogen carrier and in-situ carbon capture agent during the gasification of lignite[J]. Energy Conversion and Management, 2021, 244: 114456. |

| 3 | 马晓彤, 李英杰, 王文静, 等. 间歇氯化对电石渣循环捕集CO2性能的影响[J]. 化工学报, 2016, 67(12): 5268-5275. |

| Ma X T, Li Y J, Wang W J, et al. Effect of indirect chlorination on cyclic CO2 capture performance of carbide slag[J]. CIESC Journal, 2016, 67(12): 5268-5275. | |

| 4 | Hu Y P, Wu S M, Li Y J, et al. H2S removal performance of Ca3Al2O6-stabilized carbide slag from CO2 capture cycles using calcium looping[J]. Fuel Processing Technology, 2021, 218: 106845. |

| 5 | 李锐, 王博涛, 贾丽娟, 等. 改性电石渣干法催化净化工业废气中的NO[J]. 环境工程学报, 2021, 15(5): 1599-1605. |

| Li R, Wang B T, Jia L J, et al. Dry catalytic purification of NO by modified calcium carbide slag[J]. Chinese Journal of Environmental Engineering, 2021, 15(5): 1599-1605. | |

| 6 | Li K, Song X, Ning P, et al. Energy utilization of yellow phosphorus tail gas: simultaneous catalytic hydrolysis of carbonyl sulfide and carbon disulfide at low temperature[J]. Energy Technology, 2015, 3(2): 136-144. |

| 7 | 张礼树, 张杰, 韦光建. 电石炉气净化技术研究进展[J]. 广东化工, 2019, 46(5): 160-162. |

| Zhang L S, Zhang J, Wei G J. Research progress of carbide furnace vent gas purification technology[J]. Guangdong Chemical Industry, 2019, 46(5): 160-162. | |

| 8 | 王学谦, 程晨, 马懿星, 等. 直流电晕放电净化羰基硫以及其产物分析[J]. 材料导报, 2017, 31(1): 149-154. |

| Wang X Q, Cheng C, Ma Y X, et al. Removal of carbonyl sulfide by DC corona discharge and analysis of the product[J]. Materials Review, 2017, 31(1): 149-154. | |

| 9 | Pendyala V R R, Jacobs G, Ma W P, et al. Fischer-Tropsch synthesis: effect of carbonyl sulfide poison over a Pt promoted Co/alumina catalyst[J]. Catalysis Today, 2018, 299: 14-19. |

| 10 | Whelan M E, Min D H, Rhew R C. Salt marsh vegetation as a carbonyl sulfide (COS) source to the atmosphere[J]. Atmospheric Environment, 2013, 73: 131-137. |

| 11 | Zhao S Z, Yi H H, Tang X L, et al. Adsorptive removal of carbonyl sulfide by Fe-modified activated carbon: experiments and DFT calculations[J]. Adsorption, 2017, 23(7): 1013-1022. |

| 12 | Li K L, Wang C, Ning P, et al. Surface characterization of metal oxides-supported activated carbon fiber catalysts for simultaneous catalytic hydrolysis of carbonyl sulfide and carbon disulfide[J]. Journal of Environmental Sciences, 2020, 96: 44-54. |

| 13 | 刘雪珂, 张丽, 刘芬, 等. NHD/MDEA/H2O复合脱硫液催化水解羰基硫[J]. 化工学报, 2020, 71(11): 5286-5293. |

| Liu X K, Zhang L, Liu F, et al. Catalytic hydrolysis of carbonyl sulfide with application of NHD/MDEA/H2O[J]. CIESC Journal, 2020, 71(11): 5286-5293. | |

| 14 | Yang L, Wang X Z, Liu Y, et al. Layer-dependent catalysis of MoS2/graphene nanoribbon composites for efficient hydrodesulfurization[J]. Catalysis Science & Technology, 2017, 7(3): 693-702. |

| 15 | 王海沛, 陈绍云, 张永春. KOH改性活性炭吸附羰基硫及再生性能的研究[J]. 现代化工, 2019, 39(1): 128-132. |

| Wang H P, Chen S Y, Zhang Y C. Study on adsorption of carbonyl sulfide by KOH modified activated carbon and regeneration performance[J]. Modern Chemical Industry, 2019, 39(1): 128-132. | |

| 16 | Wang X Q, Ma Y X, Ning P, et al. Adsorption of carbonyl sulfide on modified activated carbon under low-oxygen content conditions[J]. Adsorption, 2014, 20(4): 623-630. |

| 17 | Kim J, Do J Y, Nahm K, et al. Capturing ability for COS gas by a strong bridge bonding of a pair of potassium anchored on carbonate of activated carbon at low temperatures[J]. Separation and Purification Technology, 2019, 211: 421-429. |

| 18 | Zhao S Z, Tang X L, He M, et al. The potential mechanism of potassium promoting effect in the removal of COS over K/NiAlO mixed oxides[J]. Separation and Purification Technology, 2018, 194: 33-39. |

| 19 | Bandosz T J. Effect of pore structure and surface chemistry of virgin activated carbons on removal of hydrogen sulfide[J]. Carbon, 1999, 37(3): 483-491. |

| 20 | 邱娟. 矿冶废气中低浓度羰基硫吸附剂开发及机理研究[D]. 昆明: 昆明理工大学, 2013. |

| Qiu J. Development and mechanism study of low concentration carbonyl sulfur adsorbent in mining and metallurgy waste gas[D]. Kunming: Kunming University of Science and Technology, 2013. | |

| 21 | 马铭宇, 王超, 李运甲, 等. 高炉煤气中羰基硫水解吸附催化剂的制备及性能研究[J]. 化工学报, 2022, 73(1): 275-283. |

| Ma M Y, Wang C, Li Y J, et al. Preparation and performance study of catalyst for COS hydrolysis and adsorption in blast furnace gas[J]. CIESC Journal, 2022, 73(1): 275-283. | |

| 22 | Niu S L, Liu M Q, Lu C M, et al. Thermogravimetric analysis of carbide slag[J]. Journal of Thermal Analysis and Calorimetry, 2014, 115(1): 73-79. |

| 23 | 何胜平, 孙国玉. 电石渣制水泥的烧成技术研究与实践[J]. 水泥技术, 2018(2): 91-93. |

| He S P, Sun G Y. Study and practice of cement burning technology with carbide slag[J]. Cement Technology, 2018(2): 91-93. | |

| 24 | 马林凤. 利用电石渣制备高活性氧化钙的研究[D]. 北京: 中国石油大学(北京), 2018. |

| Ma L F. Study on preparation of high activated calcium oxide from carbide slag[D]. Beijing: China University of Petroleum, 2018. | |

| 25 | 李宇杰. 分子筛吸附剂脱除高炉煤气中COS和H2S性能及操作参数优化[D]. 太原: 太原理工大学, 2021. |

| Li Y J. Performance of molecular sieve adsorbent for removing COS and H2S from blast furnace gas optimization of operating parameters[D]. Taiyuan: Taiyuan University of Technology, 2021. | |

| 26 | 魏征, 张鑫, 张凤莲, 等. 镁铝水滑石衍生复合氧化物的COS水解性能[J]. 环境科学, 2019, 40(10): 4423-4430. |

| Wei Z, Zhang X, Zhang F L, et al. Hydrolysis of COS over MgAl mixed oxides derived from hydrotalcites[J]. Environmental Science, 2019, 40(10): 4423-4430. | |

| 27 | 刘霜, 齐天勤机, 张永春. KOH改性活性炭及其对微量乙烷的吸附性能[J]. 现代化工, 2019, 39(3): 176-180. |

| Liu S, Qi T, Zhang Y C. KOH modified activated carbon and its adsorption performance to trace ethane[J]. Modern Chemical Industry, 2019, 39(3): 176-180. | |

| 28 | 武越,赵婷,金彦任, 等. 氢氧化锆改性对NH3和SO2吸附性能的影响[J]. 现代化工, 2021, 41(1): 154-158. |

| Wu Y, Zhao T, Jin Y R, et al. Effect of zirconium hydroxide modification on its adsorption performance for NH3 and SO2 [J]. Modern Chemical Industry, 2021, 41(1): 154-158. | |

| 29 | Tanpure S, Ghanwat V, Shinde B, et al. The eggshell waste transformed green and efficient synthesis of K-Ca(OH)2 catalyst for room temperature synthesis of chalcones[J]. Polycyclic Aromatic Compounds, 2022, 42(4): 1322-1340. |

| 30 | 翁诗甫. 傅里叶变换红外光谱分析[M]. 2版. 北京: 化学工业出版社, 2010: 78-92. |

| Weng S F. Fourier Transform Infrared Spectrum Analysis[M]. 2nd ed. Beijing: Chemical Industry Press, 2010: 78-92. | |

| 31 | George Z M. Effect of catalyst basicity for COS-SO2 and COS hydrolysis reactions[J]. Journal of Catalysis, 1974, 35(2): 218-224. |

| 32 | Li X, Wang X Q, Wang L L, et al. Efficient removal of carbonyl sulfur and hydrogen sulfide from blast furnace gas by one-step catalytic process with modified activated carbon[J]. Applied Surface Science, 2022, 579: 152189. |

| 33 | Liu F D, He H. Structure-activity relationship of iron titanate catalysts in the selective catalytic reduction of NO x with NH3 [J]. The Journal of Physical Chemistry C, 2010, 114(40): 16929-16936. |

| 34 | Li Y, Gao L H, Zhang J H, et al. Synergetic utilization of microwave-assisted fly ash and carbide slag for simultaneous desulfurization and denitrification: high efficiency, low cost and catalytic mechanism[J]. Chemical Engineering Journal, 2022, 437: 135488. |

| 35 | Song X, Ning P, Wang C, et al. Research on the low temperature catalytic hydrolysis of COS and CS2 over walnut shell biochar modified by Fe-Cu mixed metal oxides and basic functional groups[J]. Chemical Engineering Journal, 2017, 314: 418-433. |

| 36 | 钱红辉, 曾丹林, 王光辉, 等. 改性氧化铁脱硫剂脱除羰基硫性能的研究[J]. 化学与生物工程, 2008, 25(9): 16-19. |

| Qian H H, Zeng D L, Wang G H, et al. Study on carbonyl sulfide removal performance of modified iron oxide desulfurizer[J]. Chemistry & Bioengineering, 2008, 25(9): 16-19. |

| [1] | 常明慧, 王林, 苑佳佳, 曹艺飞. 盐溶液蓄能型热泵循环特性研究[J]. 化工学报, 2023, 74(S1): 329-337. |

| [2] | 吴延鹏, 李晓宇, 钟乔洋. 静电纺丝纳米纤维双疏膜油性细颗粒物过滤性能实验分析[J]. 化工学报, 2023, 74(S1): 259-264. |

| [3] | 杨天阳, 邹慧明, 周晖, 王春磊, 田长青. -30℃电动汽车补气式CO2热泵制热性能实验研究[J]. 化工学报, 2023, 74(S1): 272-279. |

| [4] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [5] | 王阳, 戴永强, 曾炜. 2,5-二羟基苯磺酸增强离子水凝胶材料热电性能的研究[J]. 化工学报, 2023, 74(9): 3946-3955. |

| [6] | 徐文杰, 贾献峰, 王际童, 乔文明, 凌立成, 王任平, 余子舰, 张寅旭. 有机硅/酚醛杂化气凝胶的制备和性能研究[J]. 化工学报, 2023, 74(8): 3572-3583. |

| [7] | 陈国泽, 卫东, 郭倩, 向志平. 负载跟踪状态下的铝空气电池堆最优功率点优化方法[J]. 化工学报, 2023, 74(8): 3533-3542. |

| [8] | 盛冰纯, 于建国, 林森. 铝基锂吸附剂分离高钠型地下卤水锂资源过程研究[J]. 化工学报, 2023, 74(8): 3375-3385. |

| [9] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [10] | 李凯旋, 谭伟, 张曼玉, 徐志豪, 王旭裕, 纪红兵. 富含零价钴活性位点的钴氮碳/活性炭设计及甲醛催化氧化应用研究[J]. 化工学报, 2023, 74(8): 3342-3352. |

| [11] | 史方哲, 甘云华. 超薄热管启动特性和传热性能数值模拟[J]. 化工学报, 2023, 74(7): 2814-2823. |

| [12] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [13] | 王志龙, 杨烨, 赵真真, 田涛, 赵桐, 崔亚辉. 搅拌时间和混合顺序对锂离子电池正极浆料分散特性的影响[J]. 化工学报, 2023, 74(7): 3127-3138. |

| [14] | 刘杰, 吴立盛, 李锦锦, 罗正鸿, 周寅宁. 含乙烯基胺酯键聚醚类可逆交联聚合物的制备及性能研究[J]. 化工学报, 2023, 74(7): 3051-3057. |

| [15] | 张谭, 刘光, 李晋平, 孙予罕. Ru基氮还原电催化剂性能调控策略[J]. 化工学报, 2023, 74(6): 2264-2280. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号