化工学报 ›› 2023, Vol. 74 ›› Issue (9): 3786-3796.DOI: 10.11949/0438-1157.20230544

收稿日期:2023-06-06

修回日期:2023-09-01

出版日期:2023-09-25

发布日期:2023-11-20

通讯作者:

文键

作者简介:李科(1992—),男,博士,助理教授,vincent_lee@xjtu.edu.cn

基金资助:

Ke LI( ), Jian WEN(

), Jian WEN( ), Biping XIN

), Biping XIN

Received:2023-06-06

Revised:2023-09-01

Online:2023-09-25

Published:2023-11-20

Contact:

Jian WEN

摘要:

基于MATLAB,构建了一种考虑氢储罐真空多层绝热结构、蒸气冷却屏和内部流体域的瞬态仿真模型。引入了无量纲的蒸气消耗因子

中图分类号:

李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796.

Ke LI, Jian WEN, Biping XIN. Study on influence mechanism of vacuum multi-layer insulation coupled with vapor-cooled shield on self-pressurization process of liquid hydrogen storage tank[J]. CIESC Journal, 2023, 74(9): 3786-3796.

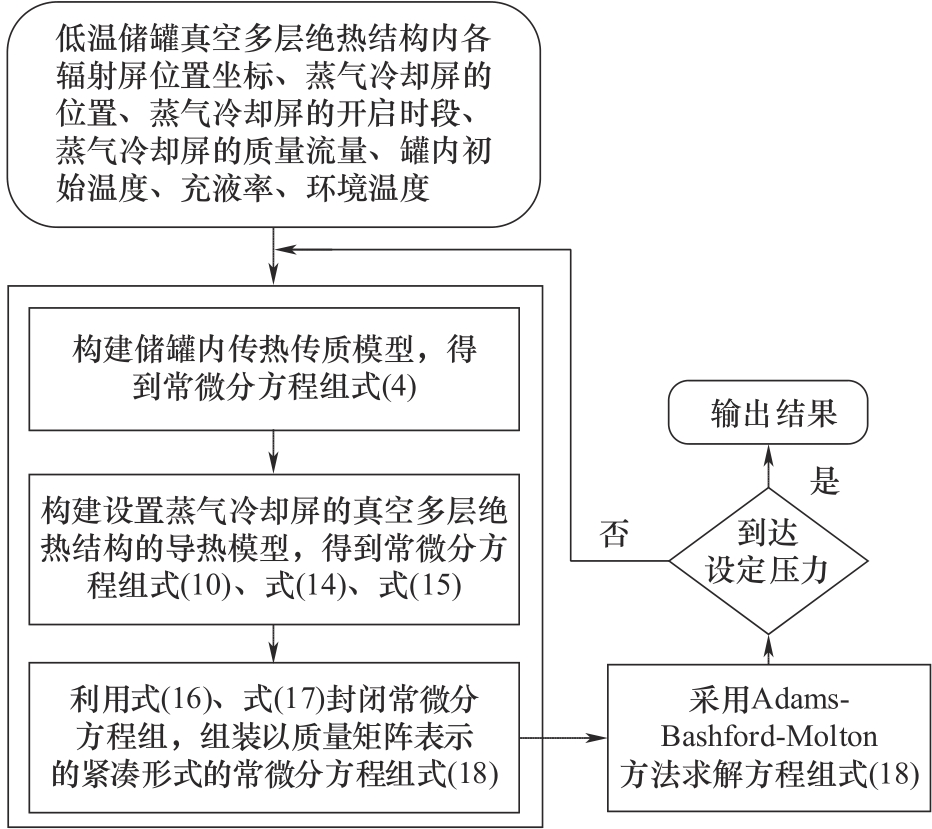

图 2 考虑真空多层绝热结构和蒸气冷却屏的液氢储罐的动态增压模型的计算流程图

Fig.2 Flow chart of dynamic pressurization model of liquid hydrogen storage tank considering vacuum multi-layer insulation and vapor-cooled shield

| 工况 | 蒸气冷却屏中 蒸气流量/(kg/h) | 蒸气冷却屏 开启时刻 | 蒸气冷却屏 关闭时刻 | 蒸气冷却屏所在 辐射屏的编号 |

|---|---|---|---|---|

| 基准 | 未设置蒸气冷却屏,或虽设置未开启 | |||

| 1 | 0.108 | 第10000 s | 第510000 s | 15 |

| 2 | 0.0108 | 第10000 s | 第5010000 s | 15 |

| 3 | 0.0108 | 第10000 s | 第5010000 s | 5, 21 |

表1 守恒验证所采用的参数

Table 1 Parameters used for conservation verification

| 工况 | 蒸气冷却屏中 蒸气流量/(kg/h) | 蒸气冷却屏 开启时刻 | 蒸气冷却屏 关闭时刻 | 蒸气冷却屏所在 辐射屏的编号 |

|---|---|---|---|---|

| 基准 | 未设置蒸气冷却屏,或虽设置未开启 | |||

| 1 | 0.108 | 第10000 s | 第510000 s | 15 |

| 2 | 0.0108 | 第10000 s | 第5010000 s | 15 |

| 3 | 0.0108 | 第10000 s | 第5010000 s | 5, 21 |

| 工况 | 初始储罐内 流体内能 Uini/J | 从储罐进入 蒸气冷却屏的蒸气的焓hvcs/J | 真空多层绝热结构进入 流体域的漏热Qin/J | 计算终止时 储罐内流体 内能Uter/J | (Uini+Qin-hvcs)/J | 外界进入真空多层绝热结构的热量Qe/J | 真空多层绝热结构温度上升吸收的热量Qvcs/J | 蒸气冷却屏 吸收的 热量bi /J | (Qe-Qin-bi )/J |

|---|---|---|---|---|---|---|---|---|---|

| 基准 | 2.3352×105 | 0 | 4.3003×107 | 4.3236×107 | 4.3236×107 | 1.4315×108 | 1.0040×108 | 0 | 1.0015×108 |

| 1 | 2.3352×105 | 6.6375×106 | 4.9272×107 | 4.2856×107 | 4.2867×107 | 1.6115×108 | 1.0296×108 | 9.2265×106 | 1.0265×108 |

| 2 | 2.3352×105 | 6.7047×106 | 4.9329×107 | 4.2856×107 | 4.2858×107 | 1.6685×108 | 1.0105×108 | 1.6532×107 | 1.0098×108 |

| 3 | 2.3352×105 | 6.6995×106 | 4.9324×107 | 4.2856×107 | 4.2858×107 | 1.7561×108 | 1.0069×108 | 2.5889×107 | 1.0040×108 |

表2 能量守恒核算结果

Table 2 Verification results of energy conservation

| 工况 | 初始储罐内 流体内能 Uini/J | 从储罐进入 蒸气冷却屏的蒸气的焓hvcs/J | 真空多层绝热结构进入 流体域的漏热Qin/J | 计算终止时 储罐内流体 内能Uter/J | (Uini+Qin-hvcs)/J | 外界进入真空多层绝热结构的热量Qe/J | 真空多层绝热结构温度上升吸收的热量Qvcs/J | 蒸气冷却屏 吸收的 热量bi /J | (Qe-Qin-bi )/J |

|---|---|---|---|---|---|---|---|---|---|

| 基准 | 2.3352×105 | 0 | 4.3003×107 | 4.3236×107 | 4.3236×107 | 1.4315×108 | 1.0040×108 | 0 | 1.0015×108 |

| 1 | 2.3352×105 | 6.6375×106 | 4.9272×107 | 4.2856×107 | 4.2867×107 | 1.6115×108 | 1.0296×108 | 9.2265×106 | 1.0265×108 |

| 2 | 2.3352×105 | 6.7047×106 | 4.9329×107 | 4.2856×107 | 4.2858×107 | 1.6685×108 | 1.0105×108 | 1.6532×107 | 1.0098×108 |

| 3 | 2.3352×105 | 6.6995×106 | 4.9324×107 | 4.2856×107 | 4.2858×107 | 1.7561×108 | 1.0069×108 | 2.5889×107 | 1.0040×108 |

| 工况 | 初始储罐内 气相质量 | 初始储罐内 液相质量 | 计算终止时储罐内气相质量 | 计算终止时储罐内 液相质量 | 蒸气冷却屏 带走的质量mvcs/kg | |

|---|---|---|---|---|---|---|

| 基准 | 9.0014 | 772.1027 | 23.7368 | 757.3673 | 0 | 757.3673 |

| 1 | 9.0014 | 772.1027 | 24.6337 | 741.4437 | 15 | 741.4704 |

| 2 | 9.0014 | 772.1027 | 24.6323 | 741.4689 | 15 | 741.4718 |

| 3 | 9.0014 | 772.1027 | 24.6324 | 741.4681 | 15 | 741.4717 |

表3 质量守恒核算结果

Table 3 Verification results of mass conservation

| 工况 | 初始储罐内 气相质量 | 初始储罐内 液相质量 | 计算终止时储罐内气相质量 | 计算终止时储罐内 液相质量 | 蒸气冷却屏 带走的质量mvcs/kg | |

|---|---|---|---|---|---|---|

| 基准 | 9.0014 | 772.1027 | 23.7368 | 757.3673 | 0 | 757.3673 |

| 1 | 9.0014 | 772.1027 | 24.6337 | 741.4437 | 15 | 741.4704 |

| 2 | 9.0014 | 772.1027 | 24.6323 | 741.4689 | 15 | 741.4718 |

| 3 | 9.0014 | 772.1027 | 24.6324 | 741.4681 | 15 | 741.4717 |

| 1 | 周淑慧, 王军, 梁严. 碳中和背景下中国“十四五”天然气行业发展[J]. 天然气工业, 2021, 41(2): 171-182. |

| Zhou S H, Wang J, Liang Y. Development of China’s natural gas industry during the 14th Five-Year Plan in the background of carbon neutrality[J]. Natural Gas Industry, 2021, 41(2): 171-182. | |

| 2 | Ratnakar R R, Gupta N, Zhang K, et al. Hydrogen supply chain and challenges in large-scale LH2 storage and transportation[J]. International Journal of Hydrogen Energy, 2021, 46(47): 24149-24168. |

| 3 | 邹才能, 李建明, 张茜, 等. 氢能工业现状、技术进展、挑战及前景[J]. 天然气工业, 2022, 42(4): 1-20. |

| Zou C N, Li J M, Zhang X, et al. Industrial status, technological progress, challenges and prospects of hydrogen energy[J]. Natural Gas Industry, 2022, 42(4): 1-20. | |

| 4 | Ratnakar R R, Dindoruk B, Harvey A. Thermodynamic modeling of hydrogen-water system for high-pressure storage and mobility applications[J]. Journal of Natural Gas Science and Engineering, 2020, 81(15): 103463. |

| 5 | 陈晓露, 刘小敏, 王娟, 等. 液氢储运技术及标准化[J]. 化工进展, 2021, 40(9): 4806-4814. |

| Chen X L, Liu X M, Wang J, et al. Technology and standardization of liquid hydrogen storage and transportation[J]. Chemical Industry and Engineering Progress, 2021, 40(9): 4806-4814. | |

| 6 | 曹军文, 覃祥富, 耿嘎, 等. 氢气储运技术的发展现状与展望[J]. 石油学报(石油加工), 2021, 37(6): 1461-1478. |

| Cao J W, Qin X F, Geng G, et al. Current status and prospects of hydrogen storage and transportation technology[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2021, 37(6): 1461-1478. | |

| 7 | 丁镠, 唐涛, 王耀萱, 等. 氢储运技术研究进展与发展趋势[J]. 天然气化工—C1化学与化工, 2022, 47(2): 35-40. |

| Ding L, Tang T, Wang Y X, et al. Research progress and development trend of hydrogen storage and transportation technology[J]. Natural Gas Chemical Industry, 2022, 47(2): 35-40. | |

| 8 | Wang B, Huang Y H, Li P, et al. Optimization of variable density multilayer insulation for cryogenic application and experimental validation[J]. Cryogenics, 2016, 80: 154-163. |

| 9 | 高云飞, 王博, 王浩任, 等. 液氢温区真空多层绝热材料研究进展[J]. 低温工程, 2021(6): 12-21. |

| Gao Y F, Wang B, Wang H R, et al. Progress of vacuum multilayer insulation materials at liquid hydrogen temperatures[J]. Cryogenics, 2021(6): 12-21. | |

| 10 | Folkman N R, Lee T G. Thermodynamic design fundamentals of high-performance insulation[J]. Journal of Spacecraft and Rockets, 1968, 5(8): 954-959. |

| 11 | Krishnaprakas C K, Badari N K, Dutta P. Heat transfer correlations for multilayer insulation systems[J]. Cryogenics, 2000, 40(7): 431-435. |

| 12 | Martin J J, Hastings L. Large-scale liquid hydrogen testing of variable density multilayer insulation with a foam substrate[R]. NASA Marshell Space Flight Center, 2001:26-37 |

| 13 | Tien C L, Cunnington G R. Cryogenic insulation heat transfer[M]//Advances in Heat Transfer. Amsterdam: Elsevier, 1973: 349-417. |

| 14 | Matsuda A, Yoshikiyo H. Simple structure insulating material properties for multilayer insulation[J]. Cryogenics, 1980, 20(3): 135-138. |

| 15 | Scott R B. Thermal design of large storage vessels for liquid hydrogen and helium[J]. Journal of Research of the National Bureau of Standards, 1957, 58(6): 317-325. |

| 16 | Jiang W B, Yang Y L, Hu C, et al. Experimental study on composite insulation with foam, multilayer and vapor cooled shield for cryogen storage under different vacuum conditions[J]. Cryogenics, 2023, 129: 103604. |

| 17 | Jiang W B, Zuo Z Q, Sun P J, et al. Thermal analysis of coupled vapor-cooling-shield insulation for liquid hydrogen-oxygen pair storage[J]. International Journal of Hydrogen Energy, 2022, 47(12): 8000-8014. |

| 18 | Zheng J P, Chen L B, Wang J, et al. Thermodynamic analysis and comparison of four insulation schemes for liquid hydrogen storage tank[J]. Energy Conversion and Management, 2019, 186: 526-534. |

| 19 | Xu X F, Xu H, Yang B A, et al. A novel composite insulation system of hollow glass microspheres and multilayer insulation with self-evaporating vapor cooled shield for liquid hydrogen storage[J]. Energy Technology, 2020, 8(9): 2000591. |

| 20 | 孟垂举, 张亮, 黄永华. 蒸气冷却屏内仲-正氢转化释冷效应分析[J]. 真空与低温, 2022, 28(3): 279-284. |

| Meng C J, Zhang L, Huang Y H. Analysis of cooling effect of para-ortho hydrogen conversion in vapor cooling shield[J]. Vacuum and Cryogenics, 2022, 28(3): 279-284. | |

| 21 | Jiang Y B, Yu Y S, Wang Z, et al. CFD simulation of heat transfer and phase change characteristics of the cryogenic liquid hydrogen tank under microgravity conditions[J]. International Journal of Hydrogen Energy, 2023, 48(19): 7026-7037. |

| 22 | 李佳超, 梁国柱. 液氮贮箱自增压实验与数值仿真[J]. 宇航学报, 2018, 39(4): 426-434. |

| Li J C, Liang G Z. Experiment and numerical simulation of liquid nitrogen tank self-pressurization[J]. Journal of Astronautics, 2018, 39(4): 426-434. | |

| 23 | 陈既东, 朱建炳, 赵积鹏, 等. 低温推进剂贮箱内自增压过程仿真分析研究[J]. 真空与低温, 2023, 29(2): 163-170. |

| Chen J D, Zhu J B, Zhao J P, et al. Simulation and analysis of self-pressurization process in cryogenic propellant tank[J]. Vacuum and Cryogenics, 2023, 29(2): 163-170. | |

| 24 | 陈亮, 梁国柱, 邓新宇, 等. 贮箱内低温推进剂汽化过程的CFD数值仿真[J]. 北京航空航天大学学报, 2013, 39(2): 264-268. |

| Chen L, Liang G Z, Deng X Y, et al. CFD numerical simulation of cryogenic propellant vaporization in tank[J]. Journal of Beijing University of Aeronautics and Astronautics, 2013, 39(2): 264-268. | |

| 25 | 王磊, 厉彦忠, 李翠, 等. 液体火箭贮箱增压排液过程温度场数值研究[J]. 航空动力学报, 2011, 26(8): 1893-1899. |

| Wang L, Li Y Z, Li C, et al. Numerical study on temperature distribution of tank pressurization process of liquid rocket during outflow[J]. Journal of Aerospace Power, 2011, 26(8): 1893-1899. | |

| 26 | 胡正根, 湛利华, 朱文俐, 等. 短壳绝热面积对液氢贮箱绝热性能影响[J]. 航空动力学报, 2020, 35(8): 1786-1792. |

| Hu Z G, Zhan L H, Zhu W L, et al. Effect of short-shell insulated area on thermal insulation performance of liquid hydrogen tank[J]. Journal of Aerospace Power, 2020, 35(8): 1786-1792. | |

| 27 | 李文, 陈叔平, 赵高逸, 等. 飞行器用液氢贮箱低温推进剂晃动热力学响应分析[J]. 载人航天, 2022, 28(6): 771-778. |

| Li W, Chen S P, Zhao G Y, et al. Thermodynamic response analysis of cryogenic propellant sloshing in liquid hydrogen tank for aircraft[J]. Manned Spaceflight, 2022, 28(6): 771-778. | |

| 28 | Kinefuchi K, Umemura Y. Numerical study of effect of pressurant gas species on thermal behavior in cryogenic tank[J]. Journal of Spacecraft and Rockets, 2022, 59(4): 1262-1275. |

| 29 | 王舜浩, 朱文俐, 胡正根, 等. 液氢缩比贮箱蒸发特性数值模拟及实验验证[J]. 化工学报, 2019, 70(3): 840-849. |

| Wang S H, Zhu W L, Hu Z G, et al. Numerical simulation and experimental validation of evaporation characteristics of scaled liquid hydrogen tank[J]. CIESC Journal, 2019, 70(3): 840-849. | |

| 30 | Ahluwalia R K, Peng J K. Dynamics of cryogenic hydrogen storage in insulated pressure vessels for automotive applications[J]. International Journal of Hydrogen Energy, 2008, 33(17): 4622-4633. |

| 31 | Peng J K, Ahluwalia R K. Enhanced dormancy due to para-to-ortho hydrogen conversion in insulated cryogenic pressure vessels for automotive applications[J]. International Journal of Hydrogen Energy, 2013, 38(31): 13664-13672. |

| 32 | Chen L, Xiao R F, Cheng C, et al. Thermodynamic analysis of the para-to-ortho hydrogen conversion in cryo-compressed hydrogen vessels for automotive applications[J]. International Journal of Hydrogen Energy, 2020, 45(46): 24928-24937. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [3] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [4] | 连梦雅, 谈莹莹, 王林, 陈枫, 曹艺飞. 地下水预热新风一体化热泵空调系统制热性能研究[J]. 化工学报, 2023, 74(S1): 311-319. |

| [5] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [6] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [7] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [8] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [9] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [10] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [11] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [12] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [13] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [14] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [15] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号