化工学报 ›› 2024, Vol. 75 ›› Issue (10): 3477-3487.DOI: 10.11949/0438-1157.20240470

收稿日期:2024-04-28

修回日期:2024-06-22

出版日期:2024-10-25

发布日期:2024-11-04

通讯作者:

于源

作者简介:刘克润(1998—),男,硕士研究生,2021200640@buct.edu.cn

基金资助:Received:2024-04-28

Revised:2024-06-22

Online:2024-10-25

Published:2024-11-04

Contact:

Yuan YU

摘要:

为探究颗粒团聚体在分级机流场内的破碎规律,基于软球模型研究了涡流空气分级流场中团聚体破碎行为及组成团聚体的单颗粒粒径、单颗粒数和团聚体形状对团聚体破碎的影响。结果表明:团聚体进入分级流场后在流体曳力的作用下先发生变形随后破碎;颗粒越小,其组成的团聚体团聚性越强;球形团聚体团聚性最强,圆柱体团聚体次之,立方体团聚体团聚性最弱;组成团聚体的单颗粒数越多,其在分级流场中完全解团所需时间越长,当团聚体大到一定程度时可能无法完全解团则被收集为粗粉,导致“鱼钩效应”。因此,通过优化流场延缓团聚体沉降或对粉体原料预分散处理有利于团聚体解团。

中图分类号:

刘克润, 于源. 涡流空气分级流场中团聚体破碎规律研究[J]. 化工学报, 2024, 75(10): 3477-3487.

Kerun LIU, Yuan YU. Study of aggregate fragmentation laws in turbo air classification flow field[J]. CIESC Journal, 2024, 75(10): 3477-3487.

| 参数 | 数值 |

|---|---|

| 空气动力黏度μ/(Pa·s) | 1.83×10-5 |

| 空气密度 | 1.205 |

| 颗粒密度 | 2700 |

| 杨氏模量E/GPa | 2 |

| 泊松比 | 0.2 |

| 时间步长δt/s | 10-8 |

| Hamaker常数A/J | 5×10-19[ |

| 颗粒表面能 | 0.0826[ |

| 进口风速/(m·s-1) | 12 |

| 转笼转速/(r·min-1) | 1200 |

表1 数值模拟参数设置

Table 1 Parameter settings in the numerical simulation

| 参数 | 数值 |

|---|---|

| 空气动力黏度μ/(Pa·s) | 1.83×10-5 |

| 空气密度 | 1.205 |

| 颗粒密度 | 2700 |

| 杨氏模量E/GPa | 2 |

| 泊松比 | 0.2 |

| 时间步长δt/s | 10-8 |

| Hamaker常数A/J | 5×10-19[ |

| 颗粒表面能 | 0.0826[ |

| 进口风速/(m·s-1) | 12 |

| 转笼转速/(r·min-1) | 1200 |

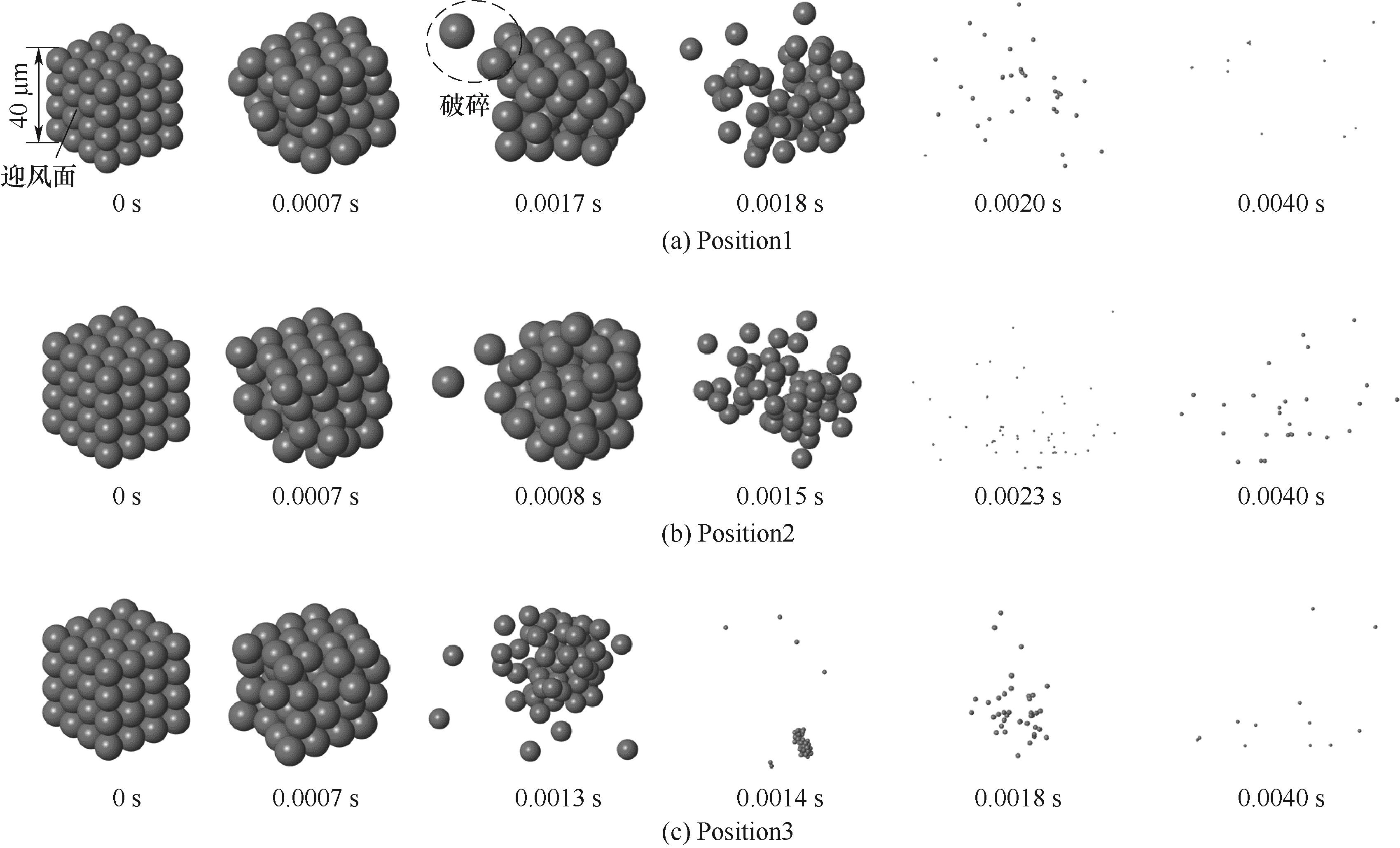

图3 三个不同位置释放的团聚体在分级流场中不同时刻的形态变化

Fig.3 The morphological changes of aggregates released in different locations at different time in classification flow field

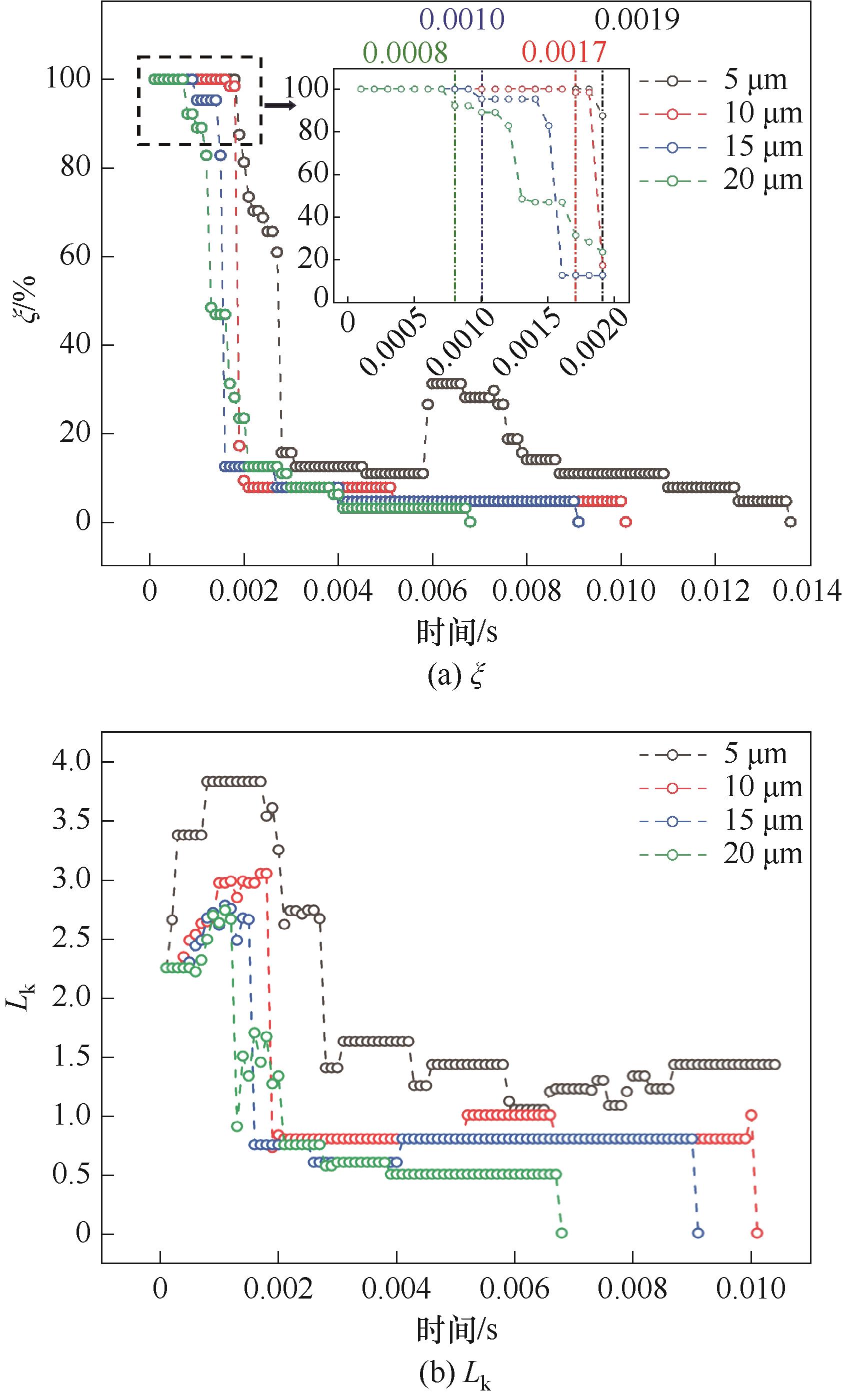

图11 不同粒径单颗粒组成的团聚体的团聚率ξ和接触率Lk随时间变化情况

Fig.11 The changes of the aggregation rate ξ and contact rate Lk of aggregates with different single particle sizes

| 1 | Banjac V, Pezo L, Pezo M, et al. Optimization of the classification process in the zigzag air classifier for obtaining a high protein sunflower meal—chemometric and CFD approach[J]. Advanced Powder Technology, 2017, 28(3): 1069-1078. |

| 2 | 林亮. 涡流空气分级机的发展与应用[J]. 化学工程与装备, 2014(10): 164-166. |

| Lin L. The development and application of vortex air classifier[J]. Chemical Engineering & Equipment, 2014(10): 164-166. | |

| 3 | Huang L, Yuan J L, Pan M, et al. CFD simulation and parameter optimization of the internal flow field of a disturbed air cyclone centrifugal classifier[J]. Separation and Purification Technology, 2023, 307: 122760. |

| 4 | Yu Y, Li X S, Zhang Y, et al. The influence of air inlet layout on the inner flow field for a vertical turbo air classifier[J]. Physicochemical Problems of Mineral Processing, 2023, 59(6): 175859. |

| 5 | 卢道铭, 范怡平, 卢春喜. 颗粒空气分级技术研究进展[J]. 中国粉体技术, 2020, 26(6): 11-24. |

| Lu D M, Fan Y P, Lu C X. Advances in research on granular air classification[J]. China Powder Science and Technology, 2020, 26(6): 11-24. | |

| 6 | Wang Z Y, Yang H D, Sun Z P, et al. Structure optimization of rotor cage blades for turbo air classifier based on entropy production analysis[J]. Advanced Powder Technology, 2023, 34(8): 104103. |

| 7 | Yu Y, Kong X, Ren C, et al. Effect of the rotor cage chassis on inner flow field of a turbo air classifier[J]. Materialwissenschaft Und Werkstofftechnik, 2021, 52(7): 772-780. |

| 8 | Izquierdo J, Sukunza X, Espinazo P, et al. Quantitative assessment of the prominence of fish hooks in hydrocyclones over different operation and geometrical parameters[J]. Powder Technology, 2024, 431: 119079. |

| 9 | Betz M, Nirschl H, Gleiss M. Development of a new solver to model the fish-hook effect in a centrifugal classifier[J]. Minerals, 2021, 11(7): 663. |

| 10 | Guimarães A A, Klein T S, de Andrade Medronho R. Fish-hook effect in granulometric efficiency curves of hydrocyclones: a misuse of laser diffraction particle size analysers[J]. Powder Technology, 2020, 374: 185-189. |

| 11 | Nageswararao K, Karri B. Fish hook in classifier efficiency curves: an update[J]. Separation and Purification Technology, 2016, 158: 31-38. |

| 12 | Sun Z P, Liang L L, Liu C Y, et al. Structural optimization of vortex finder for a centrifugal air classifier[J]. Chemical Engineering Research and Design, 2021, 166: 220-226. |

| 13 | Guizani R, Mokni I, Mhiri H, et al. CFD modeling and analysis of the fish-hook effect on the rotor separator's efficiency[J]. Powder Technology, 2014, 264: 149-157. |

| 14 | Ruan X, Chen S, Li S Q. Structural evolution and breakage of dense agglomerates in shear flow and Taylor-Green vortex[J]. Chemical Engineering Science, 2020, 211: 115261. |

| 15 | Knoop C, Todorova Z, Tomas J, et al. Agglomerate fragmentation in high-intensity acoustic standing wave fields[J]. Powder Technology, 2016, 291: 214-222. |

| 16 | Frungieri G, Bäbler M U, Biferale L, et al. Heavy and light inertial particle aggregates in homogeneous isotropic turbulence: a study on breakup and stress statistics[J]. Computers & Fluids, 2023, 263: 105944. |

| 17 | van Wachem B, Thalberg K, Nguyen D, et al. Analysis, modelling and simulation of the fragmentation of agglomerates[J]. Chemical Engineering Science, 2020, 227: 115944. |

| 18 | Yu Y, Li X S, Ren J S, et al. Influence of guide vane on dispersion of aggregates near the guide vane in a turbo air classifier[J]. Powder Technology, 2024, 434: 119344. |

| 19 | 麻向军, 吴哲浩. 颗粒团聚体在流场中的分散过程及力链演变[J]. 华南理工大学学报(自然科学版), 2016, 44(6): 65-69, 76. |

| Ma X J, Wu Z H. Breakup process and force chain evolution of particle aggregates in flow field[J]. Journal of South China University of Technology (Natural Science Edition), 2016, 44(6): 65-69, 76. | |

| 20 | Yu Y, Chen W, Kong X, et al. Design of the new guide vane for the turbo air classifier[J]. Materialwissenschaft Und Werkstofftechnik, 2023, 54(2): 196-206. |

| 21 | Siqueira F C S, Farias I S, Moraes D, et al. CFD simulation of annular oil flow wrapped with water[J]. The Canadian Journal of Chemical Engineering, 2019, 97(2): 444-451. |

| 22 | Jarrin N, Benhamadouche S, Laurence D, et al. A synthetic-eddy-method for generating inflow conditions for large-eddy simulations[J]. International Journal of Heat and Fluid Flow, 2006, 27(4): 585-593. |

| 23 | Lai A C K, Chen F Z. Modeling particle deposition and distribution in a chamber with a two-equation Reynolds-averaged Navier-Stokes model[J]. Journal of Aerosol Science, 2006, 37(12): 1770-1780. |

| 24 | Mihajlovic M, Roghair I, van Sint Annaland M. On the numerical implementation of the van der Waals force in soft-sphere discrete element models for gas-solid fluidization[J]. Chemical Engineering Science, 2020, 226: 115794. |

| 25 | 于源, 刘克润, 李兴帅, 等. 涡流空气分级流场中颗粒运动及分布规律研究[J]. 化工学报, 2023, 74(10): 4074-4086. |

| Yu Y, Liu K R, Li X S, et al. Study of particle motion and distribution laws in the turbo air classification flow field[J]. CIESC Journal, 2023, 74(10): 4074-4086. | |

| 26 | 任成. 涡流空气分级机流场分布规律及结构对比研究[D]. 北京: 北京化工大学, 2019. |

| Ren C. Study on flow field distribution and structure comparison of turbo air classifier[D]. Beijing: Beijing University of Chemical Technology, 2019. | |

| 27 | Yu Y, Wang L, Liu J. Analysis of numerical simulation models for the turbo air classifier[J]. Materialwissenschaft Und Werkstofftechnik, 2022, 53(5): 644-657. |

| 28 | Mirzaei M, Jensen P A, Nakhaei M, et al. A hybrid multiphase model accounting for particle agglomeration for coarse-grid simulation of dense solid flow inside large-scale cyclones[J]. Powder Technology, 2022, 399: 117186. |

| 29 | Dollimore D, Pearce J. Changes in surface free energy for the adsorption of nitrogen on porous powders of alumina and silica coated with manganese oxides[J]. Surface Technology, 1980, 10(2): 123-131. |

| 30 | 王铮. 纳米颗粒聚团破碎、重组和凝并的数值模拟研究[D]. 南京: 东南大学, 2018. |

| Wang Z. Numerical simulation of nanoparticle agglomerate breakage, restructuring, and coagulation[D]. Nanjing: Southeast University, 2018. | |

| 31 | 张文斌, 祁海鹰, 由长福, 等. 碰撞诱发颗粒团聚及破碎的力学分析[J]. 清华大学学报(自然科学版), 2002, 42(12): 1639-1643. |

| Zhang W B, Qi H Y, You C F, et al. Mechanical analysis of agglomeration and fragmentation of particles during collisions[J]. Journal of Tsinghua University (Science and Technology), 2002, 42(12): 1639-1643. | |

| 32 | 王庆功. 扰流场内增黏微粒湍流团聚特性研究[D]. 东营: 中国石油大学(华东), 2020. |

| Wang Q G. Investigation on agglomeration characteristics of cohesive particles in turbulence flow[D]. Dongying: China University of Petroleum, 2020. | |

| 33 | 由长福, 祁海鹰, 徐旭常. 气固两相流动中非球形颗粒所受曳力的数值研究[J]. 化工学报, 2003, 54(2): 188-191. |

| You C F, Qi H Y, Xu X C. Numerical simulation of drag force on non-spherical particle in gas-particle two-phase flow[J]. Journal of Chemical Industry and Engineering (China), 2003, 54(2): 188-191. |

| [1] | 祝赫, 张仪, 齐娜娜, 张锴. 欧拉-欧拉双流体模型中颗粒黏性对液固散式流态化的影响[J]. 化工学报, 2024, 75(9): 3103-3112. |

| [2] | 陈巨辉, 苏潼, 李丹, 陈立伟, 吕文生, 孟凡奇. 翅形扰流片作用下的微通道换热特性[J]. 化工学报, 2024, 75(9): 3122-3132. |

| [3] | 李舒月, 王欢, 周少强, 毛志宏, 张永民, 王军武, 吴秀花. 基于CPFD方法的U3O8氢还原流化床反应器数值模拟[J]. 化工学报, 2024, 75(9): 3133-3151. |

| [4] | 豆少军, 郝亮. PEMFC催化层耦合气体电荷传输过程的介观模拟[J]. 化工学报, 2024, 75(8): 3002-3010. |

| [5] | 钱啸宇, 阮璇, 李水清. 外加电场下电介质颗粒层结构重构与悬浮[J]. 化工学报, 2024, 75(8): 2756-2762. |

| [6] | 朱子良, 王爽, 姜宇昂, 林梅, 王秋旺. 欧拉-拉格朗日迭代固-液相变算法[J]. 化工学报, 2024, 75(8): 2763-2776. |

| [7] | 邓爱明, 何玉荣, 唐天琪, 胡彦伟. 导流板对喷雾流化床内颗粒生长过程影响的模拟[J]. 化工学报, 2024, 75(8): 2787-2799. |

| [8] | 罗正航, 李敬宇, 陈伟雄, 种道彤, 严俊杰. 摇摆运动下低流率蒸汽冷凝换热特性和气泡受力数值模拟[J]. 化工学报, 2024, 75(8): 2800-2811. |

| [9] | 李倩, 张蓉民, 林子杰, 战琪, 蔡伟华. 基于机器学习的印刷电路板式换热器流动换热预测与仿真[J]. 化工学报, 2024, 75(8): 2852-2864. |

| [10] | 曹佳蕾, 孙立岩, 曾德望, 尹凡, 高子翔, 肖睿. 双流化床化学链制氢反应器的数值模拟[J]. 化工学报, 2024, 75(8): 2865-2874. |

| [11] | 金虎, 杨帆, 戴梦瑶. 基于格子Boltzmann方法的液滴在圆柱壁面上运动过程研究[J]. 化工学报, 2024, 75(8): 2897-2908. |

| [12] | 吕方明, 包志铭, 王博文, 焦魁. 气体扩散层侵入流道对燃料电池水管理影响研究[J]. 化工学报, 2024, 75(8): 2929-2938. |

| [13] | 方立昌, 李梓龙, 陈博, 苏政, 贾莉斯, 王智彬, 陈颖. 基于相变微胶囊悬浮液的芯片阵列冷却特性研究[J]. 化工学报, 2024, 75(7): 2455-2464. |

| [14] | 周文轩, 刘珍, 张福建, 张忠强. 高通量-高截留率时间维度膜法水处理机理研究[J]. 化工学报, 2024, 75(7): 2583-2593. |

| [15] | 张香港, 常玉龙, 汪华林, 江霞. 废弃秸秆等生物质低能耗非相变秒级干燥[J]. 化工学报, 2024, 75(7): 2433-2445. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号