化工学报 ›› 2024, Vol. 75 ›› Issue (7): 2533-2543.DOI: 10.11949/0438-1157.20240181

王寅( ), 初鹏飞, 刘虎, 吕静, 黄守莹(

), 初鹏飞, 刘虎, 吕静, 黄守莹( ), 王胜平, 马新宾

), 王胜平, 马新宾

收稿日期:2024-02-18

修回日期:2024-04-25

出版日期:2024-07-25

发布日期:2024-08-09

通讯作者:

黄守莹

作者简介:王寅(1999—),男,硕士研究生,wangyin@tju.edu.cn

基金资助:

Yin WANG( ), Pengfei CHU, Hu LIU, Jing LYU, Shouying HUANG(

), Pengfei CHU, Hu LIU, Jing LYU, Shouying HUANG( ), Shengping WANG, Xinbin MA

), Shengping WANG, Xinbin MA

Received:2024-02-18

Revised:2024-04-25

Online:2024-07-25

Published:2024-08-09

Contact:

Shouying HUANG

摘要:

由合成气生产二甲醚(DME),然后DME羰基化生产乙酸甲酯(MA),MA加氢生成乙醇是一条转化率和选择性高、反应条件温和、分离能耗低的绿色工艺路线。其中二甲醚羰基化反应作为重要的中间反应已经受到了广大学者的高度关注。本文主要针对DME羰基化制MA反应,使用具有高活性和高稳定性的丝光沸石(MOR)制备成型催化剂,为进一步工业化奠定基础。通过使用不同pH的铝溶胶作黏结剂制备一系列丝光沸石成型催化剂,并与使用拟薄水铝石作黏结剂的成型催化剂进行比较。通过强度测试以及Weibull函数统计分析,探究了黏结剂对成型MOR的强度以及强度可靠性的影响;X射线衍射、N2物理吸附、29Si MAS NMR、吡啶吸附原位红外等表征结合活性评价,探究了黏结剂对MOR的物理结构、酸性以及催化性能的作用。结果表明,铝溶胶的pH对丝光沸石成型催化剂的孔道结构、力学性能和催化性能都有十分重要的影响。铝溶胶的pH在4.9时,成型催化剂介孔比表面积和体积最大(70 m2/g和0.20 cm3/g),机械强度最高(110.7 N/cm),单位分子筛上Brønsted酸量下降幅度最小。因此,单位分子筛上DME转化率和时空收率最高。

中图分类号:

王寅, 初鹏飞, 刘虎, 吕静, 黄守莹, 王胜平, 马新宾. 不同pH铝溶胶对二甲醚羰基化成型丝光沸石催化剂性能的影响[J]. 化工学报, 2024, 75(7): 2533-2543.

Yin WANG, Pengfei CHU, Hu LIU, Jing LYU, Shouying HUANG, Shengping WANG, Xinbin MA. Influence of aluminum sol with different pH on performance of shaped mordenite catalyst for dimethyl ether carbonylation[J]. CIESC Journal, 2024, 75(7): 2533-2543.

| 样品 | SBET/ (m2/g) | SMicropore/ (m2/g) | SMesopore/ (m2/g) | VTotalpore/ (cm3/g) | VMicropore/ (cm3/g) | VMesopore/ (cm3/g) |

|---|---|---|---|---|---|---|

| MOR | 561 | 538 | 23 | 0.33 | 0.21 | 0.12 |

| MOR-BH | 511 | 435 | 76 | 0.36 | 0.17 | 0.19 |

| MOR-3.7 | 507 | 454 | 53 | 0.35 | 0.17 | 0.17 |

| MOR-4.1 | 493 | 437 | 56 | 0.36 | 0.17 | 0.18 |

| MOR-4.9 | 487 | 418 | 70 | 0.36 | 0.16 | 0.20 |

| MOR-7.7 | 451 | 401 | 50 | 0.33 | 0.17 | 0.17 |

表1 未成型MOR与成型催化剂的物理结构性质

Table 1 Textural properties of parent and shaped catalyet

| 样品 | SBET/ (m2/g) | SMicropore/ (m2/g) | SMesopore/ (m2/g) | VTotalpore/ (cm3/g) | VMicropore/ (cm3/g) | VMesopore/ (cm3/g) |

|---|---|---|---|---|---|---|

| MOR | 561 | 538 | 23 | 0.33 | 0.21 | 0.12 |

| MOR-BH | 511 | 435 | 76 | 0.36 | 0.17 | 0.19 |

| MOR-3.7 | 507 | 454 | 53 | 0.35 | 0.17 | 0.17 |

| MOR-4.1 | 493 | 437 | 56 | 0.36 | 0.17 | 0.18 |

| MOR-4.9 | 487 | 418 | 70 | 0.36 | 0.16 | 0.20 |

| MOR-7.7 | 451 | 401 | 50 | 0.33 | 0.17 | 0.17 |

| 样品 | F/(N/cm) | m | R2 | F10%/(N/cm) |

|---|---|---|---|---|

| MOR-BH | 128.6±24.4 | 5.2 | 0.87 | 114.4 |

| MOR-3.7 | 82.1±11.8 | 4.8 | 0.94 | 74.2 |

| MOR-4.1 | 87.5±14.6 | 4.8 | 0.82 | 77.5 |

| MOR-4.9 | 110.7±14.8 | 5.3 | 0.87 | 102.9 |

| MOR-7.7 | 80.8±14.6 | 4.2 | 0.87 | 67.9 |

表2 成型MOR催化剂的强度数据统计

Table 2 Statistics of strength data for the shaped MOR

| 样品 | F/(N/cm) | m | R2 | F10%/(N/cm) |

|---|---|---|---|---|

| MOR-BH | 128.6±24.4 | 5.2 | 0.87 | 114.4 |

| MOR-3.7 | 82.1±11.8 | 4.8 | 0.94 | 74.2 |

| MOR-4.1 | 87.5±14.6 | 4.8 | 0.82 | 77.5 |

| MOR-4.9 | 110.7±14.8 | 5.3 | 0.87 | 102.9 |

| MOR-7.7 | 80.8±14.6 | 4.2 | 0.87 | 67.9 |

| 样品 | Si(0Al)/% | Si(0Al)/% | Si(1Al)/% | Si(2Al)/% | Si/Al① |

|---|---|---|---|---|---|

| MOR | 2.2 | 66.2 | 28.8 | 2.8 | 11.6 |

| MOR-BH | 2.5 | 69.7 | 25.8 | 2.0 | 13.4 |

| MOR-3.7 | 3.0 | 68.9 | 26.1 | 2.1 | 13.2 |

| MOR-4.1 | 3.2 | 68.6 | 26.1 | 2.1 | 13.2 |

| MOR-4.9 | 2.8 | 67.3 | 26.2 | 3.8 | 11.8 |

| MOR-7.7 | 2.2 | 67.6 | 27.3 | 2.9 | 12.1 |

表3 29Si MAS NMR测试及分峰结果

Table 3 The de-convolution results of 29Si MAS NMR profiles

| 样品 | Si(0Al)/% | Si(0Al)/% | Si(1Al)/% | Si(2Al)/% | Si/Al① |

|---|---|---|---|---|---|

| MOR | 2.2 | 66.2 | 28.8 | 2.8 | 11.6 |

| MOR-BH | 2.5 | 69.7 | 25.8 | 2.0 | 13.4 |

| MOR-3.7 | 3.0 | 68.9 | 26.1 | 2.1 | 13.2 |

| MOR-4.1 | 3.2 | 68.6 | 26.1 | 2.1 | 13.2 |

| MOR-4.9 | 2.8 | 67.3 | 26.2 | 3.8 | 11.8 |

| MOR-7.7 | 2.2 | 67.6 | 27.3 | 2.9 | 12.1 |

| 样品 | Btotal/ (μmol/g) | B12-MR/ (μmol/g) | B8-MR/ (μmol/g) | B8-MR/ B12-MR① | B8-MR/ B12-MR② |

|---|---|---|---|---|---|

| MOR | 1320 | 641 | 678 | 1.1 | 1.1 |

| MOR-BH | 1156 | 571 | 584 | 1.0 | 1.1 |

| MOR-3.7 | 1173 | 584 | 588 | 1.0 | 1.1 |

| MOR-4.1 | 1174 | 585 | 589 | 1.0 | 1.1 |

| MOR-4.9 | 1297 | 633 | 664 | 1.1 | 1.1 |

| MOR-7.7 | 1274 | 618 | 666 | 1.1 | 1.1 |

表4 未成型MOR及成型催化剂酸量

Table 4 The amounts of acid for parent and shaped MOR

| 样品 | Btotal/ (μmol/g) | B12-MR/ (μmol/g) | B8-MR/ (μmol/g) | B8-MR/ B12-MR① | B8-MR/ B12-MR② |

|---|---|---|---|---|---|

| MOR | 1320 | 641 | 678 | 1.1 | 1.1 |

| MOR-BH | 1156 | 571 | 584 | 1.0 | 1.1 |

| MOR-3.7 | 1173 | 584 | 588 | 1.0 | 1.1 |

| MOR-4.1 | 1174 | 585 | 589 | 1.0 | 1.1 |

| MOR-4.9 | 1297 | 633 | 664 | 1.1 | 1.1 |

| MOR-7.7 | 1274 | 618 | 666 | 1.1 | 1.1 |

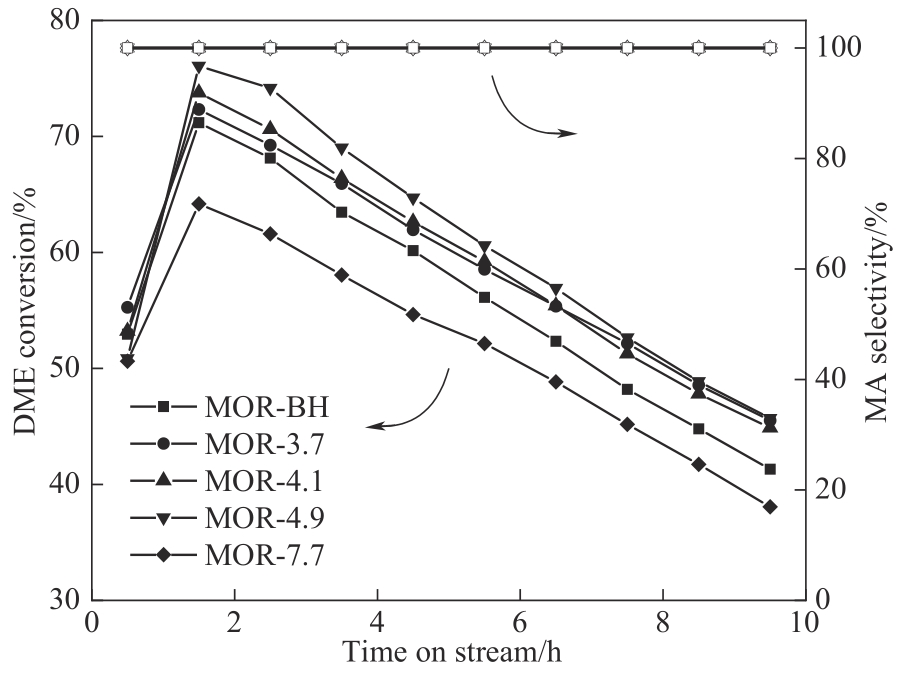

图15 MOR和不同成型催化剂上的DME转化率和MA选择性(反应条件:温度200℃,总压1.5 MPa,混合气DME/CO摩尔比1/49,空速9000 h-1)

Fig.15 Conversion of DME and selectivity to MA of the parent and shaped catalysts (reaction conditions: 200℃, 1.5 MPa, DME/CO molar ratio 1/49, 9000 h-1)

| 1 | Boronat M, Martínez-Sánchez C, Law D, et al. Enzyme-like specificity in zeolites: a unique site position in mordenite for selective carbonylation of methanol and dimethyl ether with CO[J]. Journal of the American Chemical Society, 2008, 130(48): 16316-16323. |

| 2 | Rasmussen D B, Christensen J M, Temel B, et al. Ketene as a reaction intermediate in the carbonylation of dimethyl ether to methyl acetate over mordenite[J]. Angewandte Chemie International Edition, 2015, 54(25): 7261-7264. |

| 3 | Li X J, Liu X H, Liu S L, et al. Activity enhancement of ZSM-35 in dimethyl ether carbonylation reaction through alkaline modifications[J]. RSC Advances, 2013, 3(37): 16549-16557. |

| 4 | Zhou H, Zhu W L, Shi L, et al. Promotion effect of Fe in mordenite zeolite on carbonylation of dimethyl ether to methyl acetate[J]. Catalysis Science & Technology, 2015, 5(3): 1961-1968. |

| 5 | Goldemberg J. Ethanol for a sustainable energy future[J]. Science, 2007, 315(5813): 808-810. |

| 6 | 宋庆锋, 张勇, 曾清湖. 合成气直接转化制乙醇工艺路线的技术经济分析[J]. 工业催化, 2013, 21(6): 17-21. |

| Song Q F, Zhang Y, Zeng Q H. Techno-economic analysis of production process of syngas to ethanol[J]. Industrial Catalysis, 2013, 21(6): 17-21. | |

| 7 | 王辉, 吴志连, 邰志军, 等. 合成气经二甲醚羰基化及乙酸甲酯加氢制无水乙醇的研究进展[J]. 化工进展, 2019, 38(10): 4497-4503. |

| Wang H, Wu Z L, Tai Z J, et al. Advances in synthesis of anhydrous ethanol from syngas via carbonylation of dimethyl ether and hydrogenation of methyl acetate[J]. Chemical Industry and Engineering Progress, 2019, 38(10): 4497-4503. | |

| 8 | Li Y, Huang S Y, Cheng Z Z, et al. Promoting the activity of Ce-incorporated MOR in dimethyl ether carbonylation through tailoring the distribution of Brønsted acids[J]. Applied Catalysis B: Environmental, 2019, 256: 117777. |

| 9 | 黄守莹, 王悦, 吕静, 等. 合成气经二甲醚/乙酸甲酯制无水乙醇的研究进展[J]. 化工学报, 2016, 67(1): 240-247. |

| Huang S Y, Wang Y, Lü J, et al. Advances in indirect synthesis of ethanol from syngas via dimethyl ether/methyl acetate[J]. CIESC Journal, 2016, 67(1): 240-247. | |

| 10 | Yang G H, San X G, Jiang N, et al. A new method of ethanol synthesis from dimethyl ether and syngas in a sequential dual bed reactor with the modified zeolite and Cu/ZnO catalysts[J]. Catalysis Today, 2011, 164(1): 425-428. |

| 11 | Fujimoto K, Shikada T, Omata K, et al. Vapor phase carbonylation of methanol with solid acid catalysts[J]. Chemistry Letters, 1984, 13(12): 2047-2050. |

| 12 | Cheung P, Bhan A, Sunley G J, et al. Selective carbonylation of dimethyl ether to methyl acetate catalyzed by acidic zeolites[J]. Angewandte Chemie International Edition, 2006, 45(10): 1617-1620. |

| 13 | He T, Liu X C, Xu S T, et al. Role of 12-ring channels of mordenite in DME carbonylation investigated by solid-state NMR[J]. The Journal of Physical Chemistry C, 2016, 120(39): 22526-22531. |

| 14 | Liu Z Q, Yi X F, Wang G R, et al. Roles of 8-ring and 12-ring channels in mordenite for carbonylation reaction: from the perspective of molecular adsorption and diffusion[J]. Journal of Catalysis, 2019, 369: 335-344. |

| 15 | Li B J, Xu J, Han B, et al. Insight into dimethyl ether carbonylation reaction over mordenite zeolite from in situ solid-state NMR spectroscopy[J]. The Journal of Physical Chemistry C, 2013, 117(11): 5840-5847. |

| 16 | Cheung P, Bhan A, Sunley G J, et al. Site requirements and elementary steps in dimethyl ether carbonylation catalyzed by acidic zeolites[J]. Journal of Catalysis, 2007, 245(1): 110-123. |

| 17 | Cheng Z Z, Huang S Y, Li Y, et al. Carbonylation of dimethyl ether over MOR and Cu/H-MOR catalysts: comparative investigation of deactivation behavior[J]. Applied Catalysis A: General, 2019, 576: 1-10. |

| 18 | He T, Ren P J, Liu X C, et al. Direct observation of DME carbonylation in the different channels of H-MOR zeolite by continuous-flow solid-state NMR spectroscopy[J]. Chemical Communications, 2015, 51(94): 16868-16870. |

| 19 | Wang M X, Huang S Y, Lv J, et al. Modifying the acidity of H-MOR and its catalytic carbonylation of dimethyl ether[J]. Chinese Journal of Catalysis, 2016, 37(9): 1530-1537. |

| 20 | Li Y, Yu M, Qi G D, et al. Designing a mordenite catalyst with enhanced acidity for dimethyl ether carbonylation by engineering open Sn sites[J]. Engineering, DOI: 10.1016/j.eng.2023.01.020 . |

| 21 | Cai K, Huang S Y, Li Y, et al. Influence of acid strength on the reactivity of dimethyl ether carbonylation over H-MOR[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(2): 2027-2034. |

| 22 | Li Y, Yu M, Cai K, et al. Template-induced Al distribution in MOR and enhanced activity in dimethyl ether carbonylation[J]. Physical Chemistry Chemical Physics, 2020, 22(20): 11374-11381. |

| 23 | Blasco T, Boronat M, Concepción P, et al. Carbonylation of methanol on metal-acid zeolites: evidence for a mechanism involving a multisite active center[J]. Angewandte Chemie International Edition, 2007, 46(21): 3938-3941. |

| 24 | Li Y, Huang S Y, Cheng Z Z, et al. Synergy between Cu and Brønsted acid sites in carbonylation of dimethyl ether over Cu/H-MOR[J]. Journal of Catalysis, 2018, 365: 440-449. |

| 25 | He P, Li Y, Cai K, et al. Nano-assembled mordenite zeolite with tunable morphology for carbonylation of dimethyl ether[J]. ACS Applied Nano Materials, 2020, 3(7): 6460-6468. |

| 26 | Xue H F, Huang X M, Ditzel E, et al. Dimethyl ether carbonylation to methyl acetate over nanosized mordenites[J]. Industrial & Engineering Chemistry Research, 2013, 52(33): 11510-11515. |

| 27 | Liu S P, Cheng Z Z, Li Y, et al. Improved catalytic performance in dimethyl ether carbonylation over hierarchical mordenite by enhancing mass transfer[J]. Industrial & Engineering Chemistry Research, 2020, 59(31): 13861-13869. |

| 28 | Wang X S, Li R J, Yu C C, et al. Dimethyl ether carbonylation over nanosheet-assembled hierarchical mordenite[J]. Microporous and Mesoporous Materials, 2019, 274: 227-235. |

| 29 | Liu Y H, Zhao N, Xian H, et al. Facilely synthesized H-mordenite nanosheet assembly for carbonylation of dimethyl ether[J]. ACS Applied Materials & Interfaces, 2015, 7(16): 8398-8403. |

| 30 | Ma M, Huang X M, Zhan E S, et al. Synthesis of mordenite nanosheets with shortened channel lengths and enhanced catalytic activity[J]. Journal of Materials Chemistry A, 2017, 5(19): 8887-8891. |

| 31 | Li Y, Sun Q, Huang S Y, et al. Dimethyl ether carbonylation over pyridine-modified MOR: enhanced stability influenced by acidity[J]. Catalysis Today, 2018, 311: 81-88. |

| 32 | Wu D F, Zhou J C, Li Y D. Distribution of the mechanical strength of solid catalysts[J]. Chemical Engineering Research and Design, 2006, 84(12): 1152-1157. |

| 33 | Wu D F, Tang M L. Effects of process factors on extrusion of hierarchically porous ZSM-5 zeolite[J]. Powder Technology, 2019, 352: 79-90. |

| 34 | Vajglov Z, Kumar N, Mäki-Arvela P, et al. Synthesis and physicochemical characterization of shaped catalysts of β and Y zeolites for cyclization of citronellal[J]. Industrial & Engineering Chemistry Research, 2019, 58(39): 18084-18096. |

| 35 | 黄守莹, 熊雄, 贺培, 等. 二甲醚羰基化丝光沸石成型催化剂黏结剂的研究[J]. 化工学报, 2020, 71(10): 4642-4651. |

| Huang S Y, Xiong X, He P, et al. Study on binder of extruded mordenite catalyst for dimethyl ether carbonylation[J]. CIESC Journal, 2020, 71(10): 4642-4651. | |

| 36 | Chu P F, Liu H, Cai K, et al. Influence of pseudoboehmite on the performance of shaped mordenite catalyst for dimethyl ether carbonylation[J]. Chemical Engineering Science, 2023, 272: 118607. |

| 37 | Zhang L N, Liu H Y, Yue Y Y, et al. Design and in situ synthesis of hierarchical SAPO-34@kaolin composites as catalysts for methanol to olefins[J]. Catalysis Science & Technology, 2019, 9(22): 6438-6451. |

| 38 | Lakiss L, Gilson J P, Valtchev V, et al. Zeolites in a good shape: catalyst forming by extrusion modifies their performances[J]. Microporous and Mesoporous Materials, 2020, 299: 110114. |

| 39 | Michels N L, Mitchell S, Pérez-Ramírez J. Effects of binders on the performance of shaped hierarchical MFI zeolites in methanol-to-hydrocarbons[J]. ACS Catalysis, 2014, 4(8): 2409-2417. |

| 40 | Liu B N, Zhu X C, Zhao J, et al. A study into the γ-Al2O3 binder influence on nano-H-ZSM-5 via scaled-up laboratory methanol-to-hydrocarbon reaction[J]. Catalysts, 2021, 11(10): 1140. |

| 41 | Eschenbacher A, Jensen P A, Henriksen U B, et al. Deoxygenation of wheat straw fast pyrolysis vapors using HZSM-5, Al2O3, HZSM-5/Al2O3 extrudates, and desilicated HZSM-5/Al2O3 extrudates[J]. Energy & Fuels, 2019, 33(7): 6405-6420. |

| 42 | Ebrahimi A, Haghighi M, Aghamohammadi S. Single vs. dual-binder surface design of spray-dried Si-Al-sol-bound Kaolin-matrixed SAPO-34 nanocatalyst for conversion of methanol to light-olefins in fluidized bed reactor[J]. Microporous and Mesoporous Materials, 2022, 332: 111714. |

| 43 | Zhang Y W, Zhou Y M, Qiu A D, et al. Effect of alumina binder on catalytic performance of PtSnNa/ZSM-5 catalyst for propane dehydrogenation[J]. Industrial & Engineering Chemistry Research, 2006, 45(7): 2213-2219. |

| 44 | Lee Y J, Kim Y W, Viswanadham N, et al. Novel aluminophosphate (AlPO) bound ZSM-5 extrudates with improved catalytic properties for methanol to propylene (MTP) reaction[J]. Applied Catalysis A: General, 2010, 374(1/2): 18-25. |

| 45 | Devyatkov S Y, Zinnurova A A, Aho A, et al. Shaping of sulfated zirconia catalysts by extrusion: understanding the role of binders[J]. Industrial & Engineering Chemistry Research, 2016, 55(23): 6595-6606. |

| 46 | Li Y, Li Z H, Huang S Y, et al. Morphology-dependent catalytic performance of mordenite in carbonylation of dimethyl ether: enhanced activity with high c/b ratio[J]. ACS Applied Materials & Interfaces, 2019, 11(27): 24000-24005. |

| 47 | Emeis C A. Determination of integrated molar extinction coefficients for infrared absorption bands of pyridine adsorbed on solid acid catalysts[J]. Journal of Catalysis, 1993, 141(2): 347-354. |

| 48 | Dib E, Costa I M, Vayssilov G N, et al. Complex H-bonded silanol network in zeolites revealed by IR and NMR spectroscopy combined with DFT calculations[J]. Journal of Materials Chemistry A, 2021, 9(48): 27347-27352. |

| 49 | Barbera K, Bonino F, Bordiga S, et al. Structuredeactivation relationship for ZSM-5 catalysts governed by framework defects[J]. Journal of Catalysis, 2011, 280(2): 196-205. |

| 50 | Bhan A, Allian A D, Sunley G J, et al. Specificity of sites within eight-membered ring zeolite channels for carbonylation of methyls to acetyls[J]. Journal of the American Chemical Society, 2007, 129(16): 4919-4924. |

| [1] | 黄静茹, 陈佳轩, 张群锋, 阮晋, 朱来, 叶光华, 周兴贵. ZSM-5分子筛结构对苯烷基化反应性能影响的数值模拟研究[J]. 化工学报, 2024, 75(7): 2544-2555. |

| [2] | 刘旭升, 李泽洋, 杨宇森, 卫敏. 电催化二氧化碳还原制备气态产物的研究进展[J]. 化工学报, 2024, 75(7): 2385-2408. |

| [3] | 罗莉, 陈文尧, 张晶, 钱刚, 周兴贵, 段学志. 氧化铝结构与表面性质调控及其催化甲醇脱水制二甲醚性能研究[J]. 化工学报, 2024, 75(7): 2522-2532. |

| [4] | 杨露, 刘聪聪, 孟彤彤, 张博远, 杨腾飞, 邓文安, 王晓斌. 分散型催化剂在煤/重油共炼体系中的加氢抑焦作用[J]. 化工学报, 2024, 75(7): 2556-2564. |

| [5] | 王天闻, 闫肃, 赵梦园, 杨天让, 刘建国. 固体氧化物电池空气电极铬中毒机理及抗铬性能研究进展[J]. 化工学报, 2024, 75(6): 2091-2108. |

| [6] | 冀钟, 赵彦玲, 陈雨濛, 高林霞, 王翼鹏, 刘欢. ZSM-5分子筛对典型涂装VOCs的吸附性能及机理研究[J]. 化工学报, 2024, 75(6): 2332-2343. |

| [7] | 秦晗淞, 李国梁, 闫昊, 冯翔, 刘熠斌, 陈小博, 杨朝合. 多级孔ZSM-5分子筛中油酸甲酯催化裂解吸附和扩散行为模拟研究[J]. 化工学报, 2024, 75(5): 1870-1881. |

| [8] | 赵亭亭, 鄢立祥, 唐福利, 肖敏之, 谭烨, 宋刘斌, 肖忠良, 李灵均. 光辅助锂-二氧化碳电池催化剂的设计策略与反应机理研究进展[J]. 化工学报, 2024, 75(5): 1750-1764. |

| [9] | 莫锦洪, 韩雪, 朱毅翔, 李菁, 王旭裕, 纪红兵. Pt-Ga/CeO2-ZrO2-Al2O3脱氢裂解双功能催化剂用于正丁烷催化制烯烃研究[J]. 化工学报, 2024, 75(5): 1855-1869. |

| [10] | 丁禹, 杨昌泽, 李军, 孙会东, 商辉. 原子尺度钼系加氢脱硫催化剂的研究进展与展望[J]. 化工学报, 2024, 75(5): 1735-1749. |

| [11] | 李昂, 赵振宇, 李洪, 高鑫. 微波诱导高分散Pd/FeP催化剂构筑及其电催化性能研究[J]. 化工学报, 2024, 75(4): 1594-1606. |

| [12] | 范以薇, 刘威, 李盈盈, 王培霞, 张吉松. 有机液体储氢中全氢化乙基咔唑催化脱氢研究进展[J]. 化工学报, 2024, 75(4): 1198-1208. |

| [13] | 贾旭东, 杨博龙, 程前, 李雪丽, 向中华. 分步负载金属法制备铁钴双金属位点高效氧还原电催化剂[J]. 化工学报, 2024, 75(4): 1578-1593. |

| [14] | 严孝清, 赵瑛, 张宇哲, 欧鸿辉, 黄起中, 胡华贵, 杨贵东. 五重孪晶铜纳米线@聚吡咯制备及其电催化硝酸盐还原制氨[J]. 化工学报, 2024, 75(4): 1519-1532. |

| [15] | 韩宇, 周乐, 张鑫, 罗勇, 孙宝昌, 邹海魁, 陈建峰. 高黏附性Pd/SiO2/NF整体式催化剂的制备及加氢性能研究[J]. 化工学报, 2024, 75(4): 1533-1542. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号