化工学报 ›› 2024, Vol. 75 ›› Issue (7): 2556-2564.DOI: 10.11949/0438-1157.20240047

杨露1( ), 刘聪聪2, 孟彤彤1, 张博远1, 杨腾飞1(

), 刘聪聪2, 孟彤彤1, 张博远1, 杨腾飞1( ), 邓文安3, 王晓斌1(

), 邓文安3, 王晓斌1( )

)

收稿日期:2024-01-10

修回日期:2024-05-20

出版日期:2024-07-25

发布日期:2024-08-09

通讯作者:

杨腾飞,王晓斌

作者简介:杨露(1998—),女,硕士研究生,350641167@qq.com

基金资助:

Lu YANG1( ), Congcong LIU2, Tongtong MENG1, Boyuan ZHANG1, Tengfei YANG1(

), Congcong LIU2, Tongtong MENG1, Boyuan ZHANG1, Tengfei YANG1( ), Wen’an DENG3, Xiaobin WANG1(

), Wen’an DENG3, Xiaobin WANG1( )

)

Received:2024-01-10

Revised:2024-05-20

Online:2024-07-25

Published:2024-08-09

Contact:

Tengfei YANG, Xiaobin WANG

摘要:

采用马瑞常渣与印尼褐煤进行煤/重油加氢共炼反应,研究了马瑞常渣脱除沥青质和催化剂加量对共炼体系加氢转化深度的影响。利用XRD、XPS、TEM、TG、13C NMR和SEM对共炼反应后固体残渣进行表征。结果表明,沥青质的存在会促进生焦过程并显著降低共炼体系中煤的转化效率,达到同等转化深度时脱沥青油体系中所需催化剂加量大幅度降低。对于沥青质含量较高的马瑞常渣体系,催化剂反应后固体残渣中有机碳质组分芳香度降低,含氧组分比重下降,且残余有机碳也更易发生热解,表明催化剂对反应体系中碳质组分优异的氢解作用。固体残渣的微观形貌分析则显示出催化剂对生焦过程的良好抑制效果,有助于提高反应体系的加氢转化深度。

中图分类号:

杨露, 刘聪聪, 孟彤彤, 张博远, 杨腾飞, 邓文安, 王晓斌. 分散型催化剂在煤/重油共炼体系中的加氢抑焦作用[J]. 化工学报, 2024, 75(7): 2556-2564.

Lu YANG, Congcong LIU, Tongtong MENG, Boyuan ZHANG, Tengfei YANG, Wen’an DENG, Xiaobin WANG. Hydrogenation and coke-suppression performance of dispersed catalyst in coal/heavy oil co-processing reactions[J]. CIESC Journal, 2024, 75(7): 2556-2564.

| 性质 | 褐煤 | 常渣 |

|---|---|---|

| 挥发分含量/%(质量分数,daf) | 58.4 | / |

| 固定碳含量/%(质量分数,daf) | 41.6 | / |

| 灰分含量/%(质量分数,ad) | 4.5 | — |

| 密度(20℃)/(g·cm-3) | 1.475 | 0.998 |

| 黏度(100℃)/(mm2·s-1) | / | 294.3 |

| 硫含量/%(质量分数) | 0.61 | 2.38 |

| 氮含量/%(质量分数) | 0.66 | 0.62 |

| 氢/碳摩尔比 | 0.912 | 1.526 |

| 初馏点~360℃馏分/%(质量分数) | / | 1.8 |

| 360~480℃馏分/%(质量分数) | / | 85.5 |

| >480℃馏分/%(质量分数) | / | 12.7 |

| 正庚烷沥青质含量/%(质量分数) | / | 10.2 |

| 甲苯不溶物含量/%(质量分数) | / | — |

表1 印尼褐煤与马瑞常渣的基本性质

Table 1 Main properties of Indonesia lignite and MRAR

| 性质 | 褐煤 | 常渣 |

|---|---|---|

| 挥发分含量/%(质量分数,daf) | 58.4 | / |

| 固定碳含量/%(质量分数,daf) | 41.6 | / |

| 灰分含量/%(质量分数,ad) | 4.5 | — |

| 密度(20℃)/(g·cm-3) | 1.475 | 0.998 |

| 黏度(100℃)/(mm2·s-1) | / | 294.3 |

| 硫含量/%(质量分数) | 0.61 | 2.38 |

| 氮含量/%(质量分数) | 0.66 | 0.62 |

| 氢/碳摩尔比 | 0.912 | 1.526 |

| 初馏点~360℃馏分/%(质量分数) | / | 1.8 |

| 360~480℃馏分/%(质量分数) | / | 85.5 |

| >480℃馏分/%(质量分数) | / | 12.7 |

| 正庚烷沥青质含量/%(质量分数) | / | 10.2 |

| 甲苯不溶物含量/%(质量分数) | / | — |

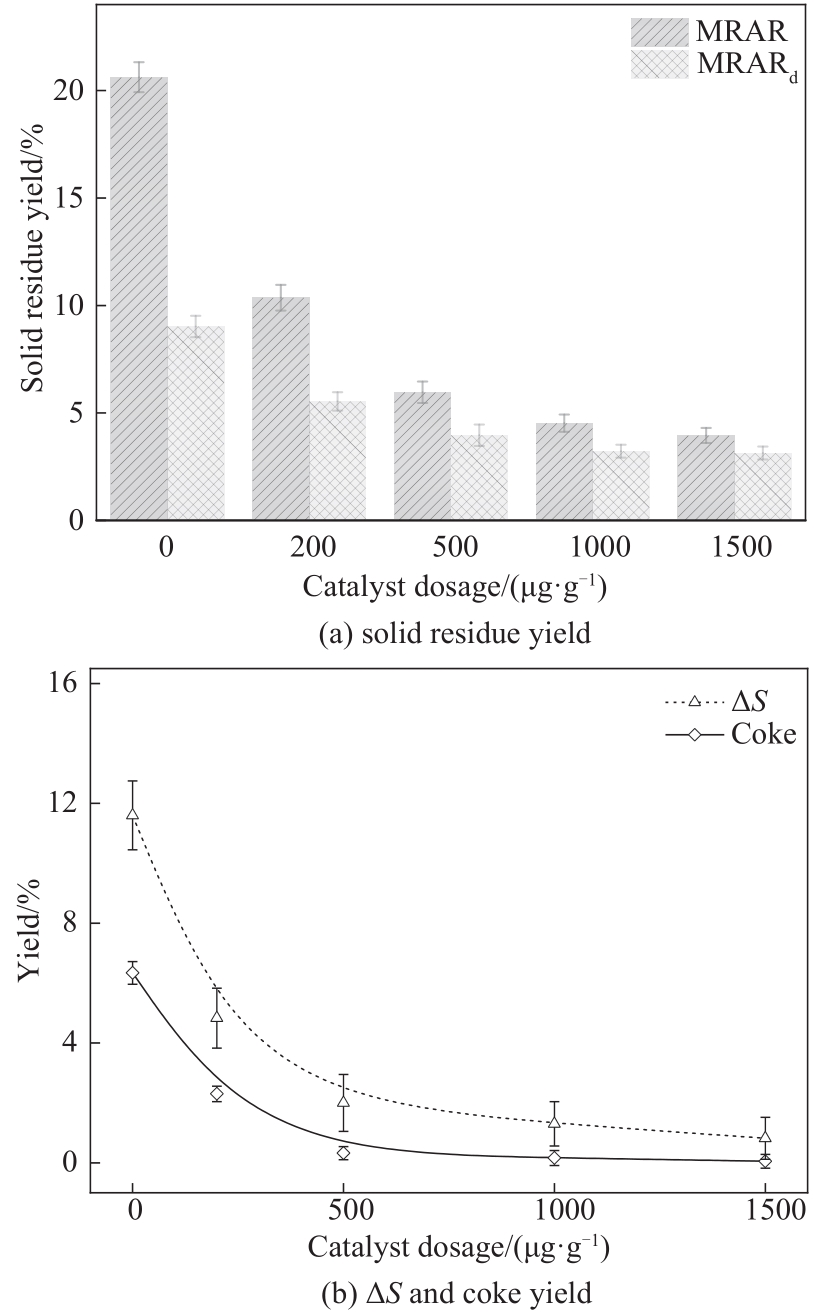

图2 不同催化剂加量下共炼体系反应后固体残渣收率及马瑞常渣单独反应的生焦量变化

Fig.2 Variations of the solid residue yield in co-processing system and the coke yield in reacted MRAR alone with different catalyst dosage

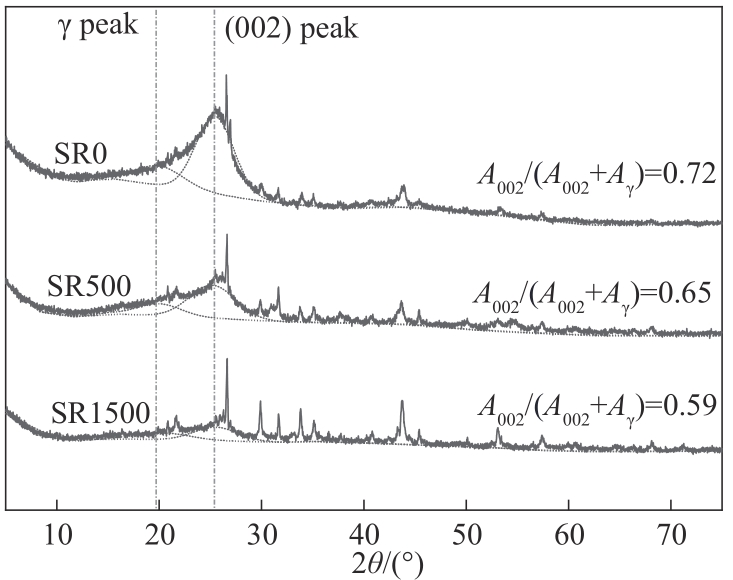

图6 不同催化剂加量下反应后固体残渣的XRD谱图及无定形碳区域的分峰拟合

Fig.6 XRD patterns and the peak-fittings for amorphous carbon regions of solid residues with different catalyst dosage

| 固体残渣 样品 | 相对含量/% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 芳香碳 | 烷基碳 | 羰/羧基碳 | 桥联碳 | 质子化芳香碳 | 氧连芳香碳 | 烷基侧链芳香碳 | 甲(氧)基碳 | 亚/次甲基碳 | 氧连烷基碳 | |

| SR0 | 71.6 | 28.4 | 17.8 | 10.9 | 26.2 | 6.3 | 10.4 | 15.6 | 12.8 | 8.8 |

| SR500 | 62.5 | 37.5 | 13.9 | 9.5 | 22.7 | 5.8 | 10.6 | 16.4 | 21.1 | 8.2 |

| SR1500 | 62.3 | 37.7 | 13.2 | 9.0 | 24.6 | 5.3 | 10.2 | 18.1 | 19.6 | 7.4 |

表2 固体残渣中不同类型有机碳的相对含量

Table 2 Relative proportions of different organic carbons in solid residues

| 固体残渣 样品 | 相对含量/% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 芳香碳 | 烷基碳 | 羰/羧基碳 | 桥联碳 | 质子化芳香碳 | 氧连芳香碳 | 烷基侧链芳香碳 | 甲(氧)基碳 | 亚/次甲基碳 | 氧连烷基碳 | |

| SR0 | 71.6 | 28.4 | 17.8 | 10.9 | 26.2 | 6.3 | 10.4 | 15.6 | 12.8 | 8.8 |

| SR500 | 62.5 | 37.5 | 13.9 | 9.5 | 22.7 | 5.8 | 10.6 | 16.4 | 21.1 | 8.2 |

| SR1500 | 62.3 | 37.7 | 13.2 | 9.0 | 24.6 | 5.3 | 10.2 | 18.1 | 19.6 | 7.4 |

| 固体残渣 样品 | 最高热解 温度Tm/℃ | 活化能Ea/ (kJ·mol-1) | 指前因子A/s-1 | 拟合度R2 |

|---|---|---|---|---|

| SR0 | 479.5 | 49.9 | 18.89 | 0.992 |

| SR500 | 468.2 | 41.8 | 5.14 | 0.998 |

| SR1500 | 455.3 | 36.1 | 2.83 | 0.997 |

表3 固体残渣最高热解温度处的热解动力学参数

Table 3 Pyrolysis kinetic parameters for solid residues at the maximum pyrolysis temperature

| 固体残渣 样品 | 最高热解 温度Tm/℃ | 活化能Ea/ (kJ·mol-1) | 指前因子A/s-1 | 拟合度R2 |

|---|---|---|---|---|

| SR0 | 479.5 | 49.9 | 18.89 | 0.992 |

| SR500 | 468.2 | 41.8 | 5.14 | 0.998 |

| SR1500 | 455.3 | 36.1 | 2.83 | 0.997 |

| 1 | 张宏文, 张乾, 涂椿滟, 等. 低变质烟煤与不同类型油共炼反应特性[J]. 煤炭学报, 2023, 48(10): 3920-3927. |

| Zhang H W, Zhang Q, Tu C Y, et al. Co-processing behavior of a sub-bituminous coal with different types of oil[J]. Journal of China Coal Society, 2023, 48(10): 3920-3927. | |

| 2 | Li C, Gan Z, Yang T F, et al. Enhanced conversion of heavy feedstock through the circulation of catalytic components in tail oil derived from coal liquefaction[J]. Applied Catalysis A: General, 2024, 679: 119755. |

| 3 | 黄格省, 李顶杰, 乔明, 等. 煤油共炼技术发展现状及产业化前景分析[J]. 石化技术与应用, 2020, 38(1): 1-8. |

| Huang G S, Li D J, Qiao M, et al. Development status and industrialization prospect analysis on coal-oil co-refining technology[J]. Petrochemical Technology & Application, 2020, 38(1): 1-8. | |

| 4 | 孙昱东, 赵凌云, 韩忠祥, 等. 临氢缓和条件下温度对煤-油共炼反应的影响[J]. 石油炼制与化工, 2020, 51(10): 28-31. |

| Sun Y D, Zhao L Y, Han Z X, et al. Effect of reaction temperature on coal-oil co-processing under mild condition in hydrogen[J]. Petroleum Processing and Petrochemicals, 2020, 51(10): 28-31. | |

| 5 | Xie J, Lu H F, Shu G P, et al. The relationship between the microstructures and catalytic behaviors of iron-oxygen precursors during direct coal liquefaction[J]. Chinese Journal of Catalysis, 2018, 39(4): 857-866. |

| 6 | 邓文安, 刘聪聪, 杨腾飞, 等. 煤/重油加氢共炼中沥青质的转化规律[J]. 煤炭转化, 2019, 42(5): 37-46. |

| Deng W A, Liu C C, Yang T F, et al. Conversion of asphaltenes in hydro-coprocessing of coal and heavy oil[J]. Coal Conversion, 2019, 42(5): 37-46. | |

| 7 | 金建, 程相林, 毕秦岭, 等. 纳米α-FeOOH的制备及在煤-油共炼中的催化性能[J]. 石油学报(石油加工), 2020, 36(1): 63-69. |

| Jin J, Cheng X L, Bi Q L, et al. Preparation of nano-α-FeOOH and its catalytic performance in coal-oil co-processing[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2020, 36(1): 63-69. | |

| 8 | 王光耀, 王熺乾, 赵渊. 煤油共炼有机钼催化剂制备及加氢性能研究[J]. 煤炭转化, 2022, 45(4): 55-63. |

| Wang G Y, Wang X Q, Zhao Y. Study on preparation and hydrogenation performance of organo molybdenum catalyst for coal-oil co-processing[J]. Coal Conversion, 2022, 45(4): 55-63. | |

| 9 | 吴孟德, 李广慈, 李明时, 等. 重质油悬浮床加氢技术和相关催化剂的研究进展[J]. 工业催化, 2020, 28(12): 1-11. |

| Wu M D, Li G C, Li M S, et al. Research progress on residue slurry-bed hydrogenation technology and related catalysts[J]. Industrial Catalysis, 2020, 28(12): 1-11. | |

| 10 | Yang T F, Liu C C, Li C, et al. Promotion effect with dispersed Fe-Ni-S catalyst to facilitate hydrogenolysis of lignite and heavy residue[J]. Fuel, 2020, 259: 116303. |

| 11 | Sun Z Q, Ma F Y, Liu X J, et al. Large-scale synthesis and catalysis of oleic acid-coated Fe2O3 for co-liquefaction of coal and petroleum vacuum residues[J]. Fuel Processing Technology, 2015, 139: 173-177. |

| 12 | Li C, Han Y P, Yang T F, et al. Preliminary study on the influence of catalyst dosage on coke formation of heavy oil slurry-bed hydrocracking[J]. Fuel, 2020, 270: 117489. |

| 13 | 李海军, 张小彬, 王兴宝, 等. 煤直接液化溶剂研究述评[J]. 煤炭学报, 2022, 47(10): 3791-3804. |

| Li H J, Zhang X B, Wang X B, et al. Research progress and prospects of coal direct liquefaction solvents[J]. Journal of China Coal Society, 2022, 47(10): 3791-3804. | |

| 14 | Niu B, Jin L J, Li Y, et al. Mechanism of hydrogen transfer and role of solvent during heating-up stage of direct coal liquefaction[J]. Fuel Processing Technology, 2017, 160: 130-135. |

| 15 | 邓文安, 王磊, 李传, 等. 马瑞常压渣油悬浮床加氢裂化反应生焦过程[J]. 石油学报(石油加工), 2017, 33(2): 291-302. |

| Deng W A, Wang L, Li C, et al. The coke formation process during slurry-bed hydrocracking of merey atmospheric residue[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2017, 33(2): 291-302. | |

| 16 | Nguyen M T, Le Tri Nguyen D, Xia C L, et al. Recent advances in asphaltene transformation in heavy oil hydroprocessing: progress, challenges, and future perspectives[J]. Fuel Processing Technology, 2021, 213: 106681. |

| 17 | Yang T F, Liu C C, Deng W A, et al. Influence of the iron proportion on the efficiency of an oil-soluble Ni-Fe catalyst applied in the co-liquefaction of lignite and heavy residue[J]. Industrial & Engineering Chemistry Research, 2019, 58(41): 19072-19081. |

| 18 | 刘聪聪, 杨腾飞, 邓文安, 等. 煤担载高分散铁镍催化剂在煤/重油加氢共炼中的活性研究[J]. 石油炼制与化工, 2019, 50(6): 57-63. |

| Liu C C, Yang T F, Deng W A, et al. Study of activity of high dispersed Fe-Ni catalyst supported on coal in co-processing of coal and heavy oil[J]. Petroleum Processing and Petrochemicals, 2019, 50(6): 57-63. | |

| 19 | Yang T F, Qin Y, Meng H S, et al. Structure and morphology variation of solid residue from co-liquefaction of lignite and Merey atmospheric residue[J]. Fuel, 2018, 232: 215-224. |

| 20 | Du J T, Deng W A, Li C, et al. Multi-metal catalysts for slurry-phase hydrocracking of coal-tar vacuum residue: impact of inherent inorganic minerals[J]. Fuel, 2018, 215: 370-377. |

| 21 | 杨绍旗, 赵淑蘅, 陈伦刚, 等. Raney镍-质子型离子液体体系催化木质素平台分子加氢脱氧制备烷烃[J]. 化工学报, 2023, 74(9): 3697-3707. |

| Yang S Q, Zhao S H, Chen L G, et al. Hydrodeoxygenation of lignin-derived compounds to alkanes in Raney Ni-protic ionic liquid system[J]. CIESC Journal, 2023, 74(9): 3697-3707. | |

| 22 | 白翔, 郭润, 曾招朋, 等. 沥青质含量对重油中氢气溶解度影响的研究[J]. 化工学报, 2019, 70(10): 4012-4020. |

| Bai X, Guo R, Zeng Z P, et al. Effect of asphaltene contents on hydrogen solubility in heavy oils[J]. CIESC Journal, 2019, 70(10): 4012-4020. | |

| 23 | Yang T F, Zheng J, Liu C C, et al. Utilization of coal liquefaction solid residue waste as an effective additive for enhanced catalytic performance[J]. Fuel, 2022, 329: 125454. |

| 24 | Wu D, Liu G J, Sun R Y, et al. Investigation of structural characteristics of thermally metamorphosed coal by FTIR spectroscopy and X-ray diffraction[J]. Energy & Fuels, 2013, 27(10): 5823-5830. |

| 25 | Liu J X, Luo L, Ma J F, et al. Chemical properties of superfine pulverized coal particles (Ⅲ): Nuclear magnetic resonance analysis of carbon structural features[J]. Energy & Fuels, 2016, 30(8): 6321-6329. |

| 26 | Shi L, Liu Q Y, Guo X J, et al. Pyrolysis behavior and bonding information of coal—a TGA study[J]. Fuel Processing Technology, 2013, 108: 125-132. |

| 27 | 马金凤, 曾玺, 王芳, 等. 煤红外快速热解过程中床层对二次反应的影响[J]. 化工学报, 2020, 71(2): 736-745. |

| Ma J F, Zeng X, Wang F, et al. Effect of coal layer thickness on secondary reaction during its infrared rapid pyrolysis[J]. CIESC Journal, 2020, 71(2): 736-745. | |

| 28 | 凌开成, 盛清涛. 煤高温快速液化[M]. 北京: 化学工业出版社, 2017. |

| Ling K C, Sheng Q T. Quick Coal Liquefaction at High Temperature[M]. Beijing: Chemical Industry Press, 2017. | |

| 29 | Xu L, Tang M C, Duan L E, et al. Pyrolysis characteristics and kinetics of residue from China Shenhua industrial direct coal liquefaction plant[J]. Thermochimica Acta, 2014, 589: 1-10. |

| 30 | Rezaei H, Liu X B, Ardakani S J, et al. A study of Cold Lake vacuum residue hydroconversion in batch and semi-batch reactors using unsupported MoS2 catalysts[J]. Catalysis Today, 2010, 150(3/4): 244-254. |

| [1] | 刘旭升, 李泽洋, 杨宇森, 卫敏. 电催化二氧化碳还原制备气态产物的研究进展[J]. 化工学报, 2024, 75(7): 2385-2408. |

| [2] | 罗莉, 陈文尧, 张晶, 钱刚, 周兴贵, 段学志. 氧化铝结构与表面性质调控及其催化甲醇脱水制二甲醚性能研究[J]. 化工学报, 2024, 75(7): 2522-2532. |

| [3] | 王寅, 初鹏飞, 刘虎, 吕静, 黄守莹, 王胜平, 马新宾. 不同pH铝溶胶对二甲醚羰基化成型丝光沸石催化剂性能的影响[J]. 化工学报, 2024, 75(7): 2533-2543. |

| [4] | 王天闻, 闫肃, 赵梦园, 杨天让, 刘建国. 固体氧化物电池空气电极铬中毒机理及抗铬性能研究进展[J]. 化工学报, 2024, 75(6): 2091-2108. |

| [5] | 赵亭亭, 鄢立祥, 唐福利, 肖敏之, 谭烨, 宋刘斌, 肖忠良, 李灵均. 光辅助锂-二氧化碳电池催化剂的设计策略与反应机理研究进展[J]. 化工学报, 2024, 75(5): 1750-1764. |

| [6] | 莫锦洪, 韩雪, 朱毅翔, 李菁, 王旭裕, 纪红兵. Pt-Ga/CeO2-ZrO2-Al2O3脱氢裂解双功能催化剂用于正丁烷催化制烯烃研究[J]. 化工学报, 2024, 75(5): 1855-1869. |

| [7] | 丁禹, 杨昌泽, 李军, 孙会东, 商辉. 原子尺度钼系加氢脱硫催化剂的研究进展与展望[J]. 化工学报, 2024, 75(5): 1735-1749. |

| [8] | 黄志鸿, 周利, 柴士阳, 吉旭. 耦合加氢装置优化的多周期氢网络集成[J]. 化工学报, 2024, 75(5): 1951-1965. |

| [9] | 申州洋, 薛康, 刘青, 史成香, 邹吉军, 张香文, 潘伦. 吸热型纳米流体燃料研究进展[J]. 化工学报, 2024, 75(4): 1167-1182. |

| [10] | 程骁恺, 历伟, 王靖岱, 阳永荣. 镍催化可控/活性自由基聚合反应研究进展[J]. 化工学报, 2024, 75(4): 1105-1117. |

| [11] | 范以薇, 刘威, 李盈盈, 王培霞, 张吉松. 有机液体储氢中全氢化乙基咔唑催化脱氢研究进展[J]. 化工学报, 2024, 75(4): 1198-1208. |

| [12] | 贾旭东, 杨博龙, 程前, 李雪丽, 向中华. 分步负载金属法制备铁钴双金属位点高效氧还原电催化剂[J]. 化工学报, 2024, 75(4): 1578-1593. |

| [13] | 严孝清, 赵瑛, 张宇哲, 欧鸿辉, 黄起中, 胡华贵, 杨贵东. 五重孪晶铜纳米线@聚吡咯制备及其电催化硝酸盐还原制氨[J]. 化工学报, 2024, 75(4): 1519-1532. |

| [14] | 刘梦绮, 王凯, 骆广生. 基于人工智能的微分散基础研究[J]. 化工学报, 2024, 75(4): 1096-1104. |

| [15] | 李昂, 赵振宇, 李洪, 高鑫. 微波诱导高分散Pd/FeP催化剂构筑及其电催化性能研究[J]. 化工学报, 2024, 75(4): 1594-1606. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号