化工学报 ›› 2025, Vol. 76 ›› Issue (3): 1288-1296.DOI: 10.11949/0438-1157.20240943

贾文龙1( ), 肖欢1, 冷翔宇2, 黄巧竞1, 刘程玮3, 吴瑕1

), 肖欢1, 冷翔宇2, 黄巧竞1, 刘程玮3, 吴瑕1

收稿日期:2024-08-21

修回日期:2024-11-05

出版日期:2025-03-25

发布日期:2025-03-28

通讯作者:

贾文龙

作者简介:贾文龙(1986—),男,博士,教授,jiawenlong08@126.com

基金资助:

Wenlong JIA1( ), Huan XIAO1, Xiangyu LENG2, Qiaojing HUANG1, Chengwei LIU3, Xia WU1

), Huan XIAO1, Xiangyu LENG2, Qiaojing HUANG1, Chengwei LIU3, Xia WU1

Received:2024-08-21

Revised:2024-11-05

Online:2025-03-25

Published:2025-03-28

Contact:

Wenlong JIA

摘要:

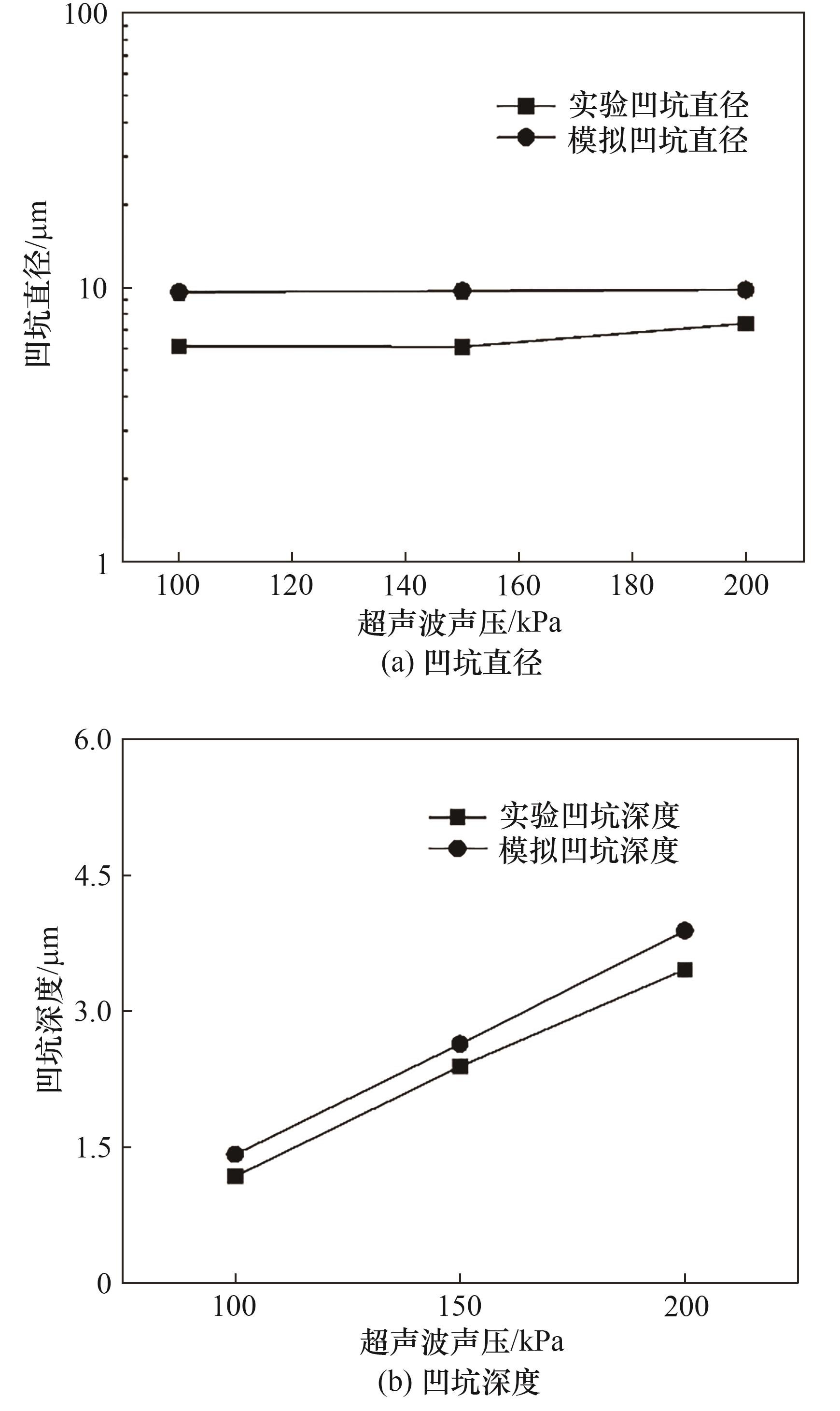

针对原油重质沉积物超声波空化微射流清洗作用机理不明确、微射流对沉积物的冲击作用缺乏定量表征等问题,建立了超声波空化微射流冲击清洗重质沉积物的仿真模型,通过数值仿真和实验研究了超声波空化微射流对沉积物的清洗机理及规律。结果表明:超声波空化微射流存在高度随机性,导致沉积物表面形成大量不均匀凹坑,凹坑直径近似呈GEVⅡ分布;沉积物内部及壁面黏结处出现扩展性裂纹,促使沉积物剥离;沉积物表面凹坑直径和深度与超声波声压呈线性增大规律,超声波对凹坑深度的影响大于直径的影响。超声波功率从100 W增大到300 W,声压从100 kPa增加至200 kPa,超声波作用60 s,实验得到凹坑平均直径从6.10 μm增大至7.38 μm,平均深度从1.18 μm增加至3.46 μm;数值仿真计算凹坑直径从9.60 μm增大至9.80 μm,平均深度从1.42 μm增加至3.89 μm。

中图分类号:

贾文龙, 肖欢, 冷翔宇, 黄巧竞, 刘程玮, 吴瑕. 原油储罐重质沉积物超声波空化微射流清洗实验及数值模拟[J]. 化工学报, 2025, 76(3): 1288-1296.

Wenlong JIA, Huan XIAO, Xiangyu LENG, Qiaojing HUANG, Chengwei LIU, Xia WU. Experimental and numerical simulation of ultrasonic cavitation microjet cleaning of heavy deposition in crude oil storage tank[J]. CIESC Journal, 2025, 76(3): 1288-1296.

| 介质 | 饱和烃/% | 芳香烃/% | 胶质/% | 沥青质/% |

|---|---|---|---|---|

| 原油 | 30.23 | 24.18 | 26.14 | 19.45 |

| 沉积物油相 | 27.29 | 21.67 | 19.43 | 31.61 |

表1 原油及沉积物油相组分

Table 1 Crude oil and deposition oil phase fractions

| 介质 | 饱和烃/% | 芳香烃/% | 胶质/% | 沥青质/% |

|---|---|---|---|---|

| 原油 | 30.23 | 24.18 | 26.14 | 19.45 |

| 沉积物油相 | 27.29 | 21.67 | 19.43 | 31.61 |

| 介质 | 声速/(m/s) | 直径/μm | 厚度/μm | 50℃黏度/(mPa·s) | 密度/(kg/m3) | 泊松比 | 剪切模量/MPa | 屈服强度/MPa |

|---|---|---|---|---|---|---|---|---|

| 原油 | 1300.0 | 140.0 | 70.0 | 260 | 840.0 | — | — | — |

| 重质沉积物 | 2300.0 | 140.0 | 10.0 | — | 2000.0 | 0.35 | 413.6 | 1.6 |

表2 原油沉积物物性及模型参数

Table 2 Crude oil deposition physical properties and model parameters

| 介质 | 声速/(m/s) | 直径/μm | 厚度/μm | 50℃黏度/(mPa·s) | 密度/(kg/m3) | 泊松比 | 剪切模量/MPa | 屈服强度/MPa |

|---|---|---|---|---|---|---|---|---|

| 原油 | 1300.0 | 140.0 | 70.0 | 260 | 840.0 | — | — | — |

| 重质沉积物 | 2300.0 | 140.0 | 10.0 | — | 2000.0 | 0.35 | 413.6 | 1.6 |

图11 实验和数值计算不同超声波声压在沉积物表面产生的凹坑尺寸

Fig.11 Experimental and numerical calculation results of cavitation pits sizes on the surface of depositions produced by different ultrasonic pressures

| 1 | Wang Q X, Zhang W, Wang C, et al. Microstructure of heavy oil components and mechanism of influence on viscosity of heavy oil[J]. ACS Omega, 2023, 8(12): 10980-10990. |

| 2 | 温燕军, 蒋驰, 李文轩, 等. 含油污泥各组分热解相互作用的反应力场模拟研究[J]. 化工学报, 2021, 72(2): 1100-1106. |

| Wen Y J, Jiang C, Li W X, et al. Study on reaction force field simulation of pyrolysis interaction among components of oily sludge[J]. CIESC Journal, 2021, 72(2): 1100-1106. | |

| 3 | Kang C H, Guo J X, Kiyingi W, et al. Sustainable treatment and recycling of oily sludge: incorporation into gel-system to improve oil recovery[J]. Journal of Cleaner Production, 2024, 436: 140640. |

| 4 | 赵健, 董航, 付小明, 等. 浮顶罐内含蜡原油静态储存中的冷却胶凝规律[J]. 化工学报, 2017, 68(12): 4882-4891. |

| Zhao J, Dong H, Fu X M, et al. Cooling and gelatinization rule of waxy crude oil during static storage in floating roof tank[J]. CIESC Journal, 2017, 68(12): 4882-4891. | |

| 5 | Gao Y X, Ding R, Chen X, et al. Ultrasonic washing for oily sludge treatment in pilot scale[J]. Ultrasonics, 2018, 90: 1-4. |

| 6 | 吴馨, 龚建英, 靳龙, 等. 超声波激励下铝板表面液滴群输运特性的研究[J]. 化工学报, 2023, 74(S1): 104-112. |

| Wu X, Gong J Y, Jin L, et al. Study on the transportation characteristics of droplets on the aluminium surface under ultrasonic excitation[J]. CIESC Journal, 2023, 74(S1): 104-112. | |

| 7 | Abadshapouri R A, Amani H, Hajimohammadi R, et al. Heavy oil storage tanks clean-up using biosurfactants and investigation of the synergistic effect with silica nanoparticles[J]. Tenside Surfactants Detergents, 2021, 58(4): 259-264. |

| 8 | Brujan E A, Ikeda T, Yoshinaka K, et al. The final stage of the collapse of a cloud of bubbles close to a rigid boundary[J]. Ultrasonics Sonochemistry, 2011, 18(1): 59-64. |

| 9 | Brujan E A, Ikeda T, Matsumoto Y. Shock wave emission from a cloud of bubbles[J]. Soft Matter, 2012, 8(21): 5777-5783. |

| 10 | 叶林征, 祝锡晶, 王建青, 等. 基于CEL不同角度超声空化微射流冲击的仿真分析[J]. 振动与冲击, 2016, 35(16): 130-134, 157. |

| Ye L Z, Zhu X J, Wang J Q, et al. Simulations of ultrasonic cavitation micro-jet impact with different angles based on CEL[J]. Journal of Vibration and Shock, 2016, 35(16): 130-134, 157. | |

| 11 | Zhao F, Yan Q Q, Cheng D L. Numerical study on the desorption processes of oil droplets inside oil-contaminated sand under cavitation micro-jets[J]. Ultrasonics Sonochemistry, 2021, 78: 105745. |

| 12 | Song H X, Ye Y, Zheng W R, et al. Synthesis of nano-β-CD@Fe3O4 magnetic material and its application in ultrasonic treatment of oily sludge[J]. Ultrasonics Sonochemistry, 2023, 92: 106256. |

| 13 | Zhang P, Luo X M, Gong H Y, et al. Desorption characteristic of oil from sludge surfaces under low-frequency ultrasound[J]. Chemical Engineering and Processing, 2023, 189: 109400. |

| 14 | Mullakaev M S, Vexler G B, Mullakaev R M. Sonochemical technology for separating oil sludge and oil-contaminated soil[J]. Petroleum Science and Technology, 2018, 36(8): 604-608. |

| 15 | Tzanakis I, Eskin D G, Georgoulas A, et al. Incubation pit analysis and calculation of the hydrodynamic impact pressure from the implosion of an acoustic cavitation bubble[J]. Ultrasonics Sonochemistry, 2014, 21(2): 866-878. |

| 16 | 方伟锋, 沈本贤, 仝玉军, 等. LM-S沥青改性剂提高沥青混合料黏附性能的分子模拟计算及路用性能考察[J]. 化工进展, 2018, 37(10): 3949-3957. |

| Fang W F, Shen B X, Tong Y J, et al. Molecular simulation of LM-S asphalt modifier to improve the adhesion of asphalt mixture and investigation of road performance[J]. Chemical Industry and Engineering Progress, 2018, 37(10): 3949-3957. | |

| 17 | 时浩天, 郭力. 模拟流体冲击致结构破坏问题的SPH-PD耦合方法[J]. 振动与冲击, 2022, 41(17): 170-176, 203. |

| Shi H T, Guo L. SPH-PD coupled method for simulation of structure failure impacted by fluid[J]. Journal of Vibration and Shock, 2022, 41(17): 170-176, 203. | |

| 18 | Hedayati E, Vahedi M. Evaluating impact resistance of aluminum 6061-T651 plate using smoothed particle hydrodynamics method[J]. Defence Science Journal, 2018, 68(3): 251-259. |

| 19 | Zhang C, Zhu Y J, Wu D, et al. Smoothed particle hydrodynamics: methodology development and recent achievement[J]. Journal of Hydrodynamics, 2022, 34(5): 767-805. |

| 20 | Leng J, Ye G L, Ye B, et al. Laboratory test and empirical model for shear modulus degradation of soft marine clays[J]. Ocean Engineering, 2017, 146: 101-114. |

| 21 | 邱薛, 刘晓辉, 胡安奎, 等. 煤岩动态RHT本构模型数值模拟研究[J]. 煤炭学报, 2024, 49(S1): 261-273. |

| Qiu X, Liu X H, Hu A K, et al. Research on numerical simulation of coal dynamic RHT constitutive model[J]. Journal of China Coal Society, 2024, 49(S1): 261-273. | |

| 22 | Chen C, Tu Y L, Chen J L, et al. Dynamic constitutive relationship of TiZrHfCu0.5 high entropy alloy based on Johnson-Cook model[J]. Journal of Materials Research and Technology, 2023, 27: 3729-3740. |

| 23 | Wu H, Zhou C, Pu Z H, et al. Effect of low-frequency ultrasonic field at different power on the dynamics of a single bubble near a rigid wall[J]. Ultrasonics Sonochemistry, 2019, 58: 104704. |

| 24 | 叶永. 沥青混合料黏弹塑性本构模型的实验研究[D]. 武汉: 华中科技大学, 2009. |

| Ye Y. Experimental researches on visco-elastoplastic constitutive model of asphalt mixture[D]. Wuhan: Huazhong University of Science and Technology, 2009. | |

| 25 | 毕玉峰, 孙立军. 沥青混合料抗剪试验方法研究[J]. 同济大学学报(自然科学版), 2005, 33(8): 1036-1040. |

| Bi Y F, Sun L J. Research on test method of asphalt mixture’s shearing properties[J]. Journal of Tongji University, 2005, 33(8): 1036-1040. | |

| 26 | 陈刚, 苏慧君, 栗菁, 等. 延长管输原油的组分特征及其析蜡行为[J]. 石油学报(石油加工), 2015, 31(1): 104-111. |

| Chen G, Su H J, Li J, et al. Characteristics of Yanchang pipeline crude oil components and its wax deposition behavior[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2015, 31(1): 104-111. | |

| 27 | Ye L Z, Zhu X J, Wei X M, et al. Damage characteristics and surface description of near-wall materials subjected to ultrasonic cavitation[J]. Ultrasonics Sonochemistry, 2020, 67: 105175. |

| 28 | Luo J, Xu W L, Luo M, et al. Study on the mesoscale causes of the influence of surface tension on material erosion in a cavitation field[J]. Journal of Hydraulic Research, 2022, 60(1): 82-93. |

| 29 | 张自健, 赵军, 唐贤康, 等. 基于EDEM-Fluent耦合的挖藕机喷水系统仿真优化[J]. 山东大学学报(工学版), 2022, 52(3): 86-93, 99. |

| Zhang Z J, Zhao J, Tang X K, et al. Simulation and optimization of lotus root digging machine sprinkler system based on EDEM-Fluent[J]. Journal of Shandong University (Engineering Science), 2022, 52(3): 86-93, 99. | |

| 30 | Zhang A M, Wang S P, Wu G X. Simulation of bubble motion in a compressible liquid based the three dimensional wave equation[J]. Engineering Analysis with Boundary Elements, 2013, 37(9):1179-1188. |

| 31 | Huang G H, Zhang M D, Ma X J, et al. Dynamic behavior of a single bubble between the free surface and rigid wall[J]. Ultrasonics Sonochemistry, 2020, 67: 105147. |

| 32 | 王青祥, 王通, 唐佳旭, 等. 矸石磨料射流冲击煤体的破碎行为及其力学特性研究[J]. 采矿与安全工程学报, 2024, 41(3): 623-633. |

| Wang Q X, Wang T, Tang J X, et al. Study on the crushing behavior and mechanical properties of gangue abrasive jet impacting coal[J]. Journal of Mining & Safety Engineering, 2024, 41(3): 623-633. |

| [1] | 贾晶宇, 孔德齐, 沈圆辉, 张东辉, 李文彬, 唐忠利. 合成氨反应器尾气变压吸附氨分离工艺的模拟与分析[J]. 化工学报, 2025, 76(2): 718-730. |

| [2] | 肖志华, 房浩楠, 郑方植, 孙冬, 陶丽达, 李永峰, 徐春明, 马新龙. NaCl辅助构筑高性能沥青基硬炭负极材料[J]. 化工学报, 2025, 76(2): 846-857. |

| [3] | 李舒月, 王欢, 周少强, 毛志宏, 张永民, 王军武, 吴秀花. 重质颗粒流态化研究现状与展望[J]. 化工学报, 2025, 76(2): 466-483. |

| [4] | 何传超, 周静红, 曹约强, 施尧, 周兴贵. Ag/SiO2催化草酸酯加氢制乙醇酸甲酯的床层-颗粒双尺度耦合模拟研究[J]. 化工学报, 2025, 76(2): 654-666. |

| [5] | 张珂, 任维杰, 王梦娜, 范凯锋, 常丽萍, 李佳斌, 马涛, 田晋平. Bunsen反应产物在微通道中的液-液两相混合特性[J]. 化工学报, 2025, 76(2): 623-636. |

| [6] | 张泽雨, 王平, 戴凯论, 钱伟佳, Roy Subhajit, 帅瑞洋, Ferrante Antonio. 轴向双级氨/甲烷湍流预混火焰燃烧特性及NO生成[J]. 化工学报, 2025, 76(2): 835-845. |

| [7] | 常斐, 师人博, 刘士花, 高文倩, 王一飞, 郑镔, 焦怡萱, 蓝兴英, 徐春明, 韩晔华. 石化行业产品生命周期碳足迹评价研究现状及展望[J]. 化工学报, 2025, 76(2): 419-437. |

| [8] | 姚佳逸, 张东辉, 唐忠利, 李文彬. 基于二级双回流的变压吸附捕碳工艺研究[J]. 化工学报, 2025, 76(2): 744-754. |

| [9] | 王瀚彬, 胡帅, 毕丰雷, 李隽森, 贺来宾. 新型波纹翅片金属氢化物反应器的放氢性能有限元分析[J]. 化工学报, 2025, 76(1): 221-230. |

| [10] | 高羡明, 杨汶轩, 卢少辉, 任晓松, 卢方财. 双槽道结构对超疏水表面液滴合并弹跳的影响[J]. 化工学报, 2025, 76(1): 208-220. |

| [11] | 韩启沃, 刘永峰, 裴普成, 张璐, 姚圣卓. 工作温度对PEMFC水分布、质子传输及性能影响分析[J]. 化工学报, 2025, 76(1): 374-384. |

| [12] | 邓志诚, 杨欢, 王斯民, 王家瑞. 微混燃烧器中微管结构对氢燃料掺混效果与燃烧性能影响[J]. 化工学报, 2025, 76(1): 335-347. |

| [13] | 刘萍, 邱雨生, 李世婧, 孙瑞奇, 申晨. 微通道内纳米流体传热流动特性[J]. 化工学报, 2025, 76(1): 184-197. |

| [14] | 韩志敏, 周相宇, 张宏宇, 徐志明. 不同粗糙元结构下CaCO3污垢局部沉积特性[J]. 化工学报, 2025, 76(1): 151-160. |

| [15] | 董新宇, 边龙飞, 杨怡怡, 张宇轩, 刘璐, 王腾. 冷却条件下倾斜上升管S-CO2流动与传热特性研究[J]. 化工学报, 2024, 75(S1): 195-205. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号