化工学报 ›› 2025, Vol. 76 ›› Issue (5): 2348-2357.DOI: 10.11949/0438-1157.20241220

李紫鹃( ), 谭晓艳, 吴永盛, 杨陈怡, 陈红, 毕小刚, 刘捷(

), 谭晓艳, 吴永盛, 杨陈怡, 陈红, 毕小刚, 刘捷( ), 喻发全(

), 喻发全( )

)

收稿日期:2024-10-31

修回日期:2024-12-03

出版日期:2025-05-25

发布日期:2025-06-13

通讯作者:

刘捷,喻发全

作者简介:李紫鹃(2002—),女,硕士研究生,zijuan_wit@163.com

基金资助:

Zijuan LI( ), Xiaoyan TAN, Yongsheng WU, Chenyi YANG, Hong CHEN, Xiaogang BI, Jie LIU(

), Xiaoyan TAN, Yongsheng WU, Chenyi YANG, Hong CHEN, Xiaogang BI, Jie LIU( ), Faquan YU(

), Faquan YU( )

)

Received:2024-10-31

Revised:2024-12-03

Online:2025-05-25

Published:2025-06-13

Contact:

Jie LIU, Faquan YU

摘要:

膜分离技术是一种高效、节能的CO2分离技术。固有微孔梯形聚合物因其高孔隙率、高选择性、结构稳定等优点被视作CO2分离技术的优势材料。通过分子动力学模拟方法构建了三维扭曲催化芳烃-降冰片烯环化(CANAL)梯形聚合物膜(CANAL-Me-S5F膜)对CO2/N2混合气体的吸附和渗透模型,并对其CO2/N2分离性能进行研究。为了充分考虑聚合物链的柔性特征,在计算过程中,聚合物膜的大部分结构保持自由运动状态。结果表明,CO2在CANAL-Me-S5F膜中的吸附量(4.00 mmol/g)明显大于N2(0.30 mmol/g),这是由CANAL-Me-S5F与CO2分子之间更强的相互吸引作用决定的。CANAL-Me-S5F膜中CO2和N2的渗透率分别为22546.09 Barrer和1094.01 Barrer,渗透选择性

中图分类号:

李紫鹃, 谭晓艳, 吴永盛, 杨陈怡, 陈红, 毕小刚, 刘捷, 喻发全. 分子模拟研究三维扭曲催化芳烃-降冰片烯环化聚合物膜的CO2/N2分离机理[J]. 化工学报, 2025, 76(5): 2348-2357.

Zijuan LI, Xiaoyan TAN, Yongsheng WU, Chenyi YANG, Hong CHEN, Xiaogang BI, Jie LIU, Faquan YU. Molecular simulation study on CO2/N2 separation via 3D-contorted catalytic arene-norbornene annulation polymer membrane[J]. CIESC Journal, 2025, 76(5): 2348-2357.

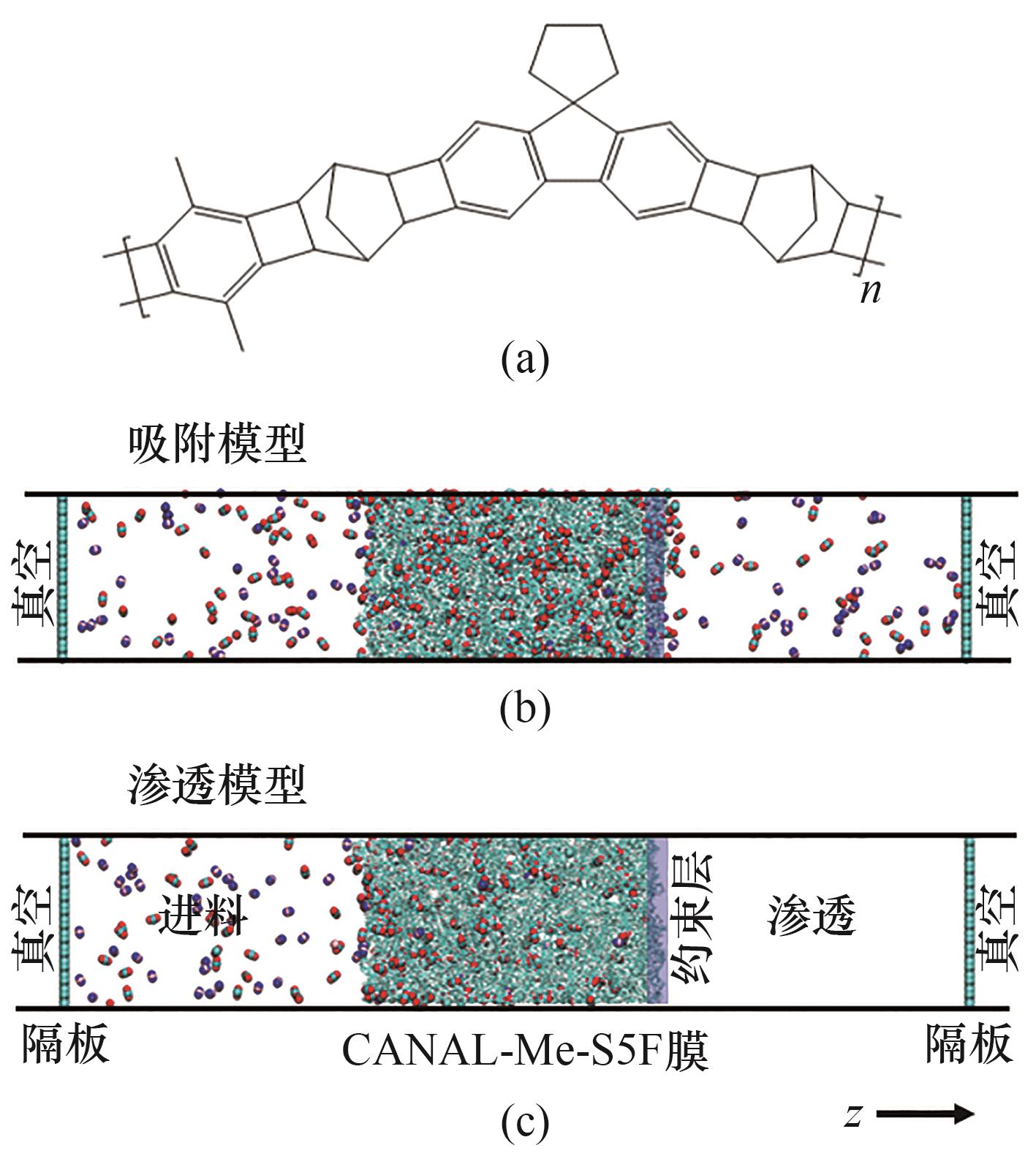

图1 CANAL-Me-S5F聚合物的结构(a)以及CO2/N2混合气体的吸附过程(b)和渗透过程(c)(膜中的紫色区域是CANAL-Me-S5F聚合物膜的位置约束层)

Fig.1 Structure of CANAL-Me-S5F polymer (a) and sorption (b) and permeation(c) processes of CO2/N2 mixture (purple area in membrane refers to restrained layer)

| 参数 | 气体 | 模拟值 | 现有文献结果 [ |

|---|---|---|---|

| S/(mmol/g) | CO2 | 4.00 | — |

| N2 | 0.30 | — | |

| 13.33 | — | ||

| P/Barrer | CO2 | 22546.09 | 4000±100 |

| N2 | 1094.01 | 220±8 | |

| 20.61 |

表1 CANAL-Me-S5F膜的气体分离性能

Table 1 Results of gas separation through CANAL-Me-S5F membrane

| 参数 | 气体 | 模拟值 | 现有文献结果 [ |

|---|---|---|---|

| S/(mmol/g) | CO2 | 4.00 | — |

| N2 | 0.30 | — | |

| 13.33 | — | ||

| P/Barrer | CO2 | 22546.09 | 4000±100 |

| N2 | 1094.01 | 220±8 | |

| 20.61 |

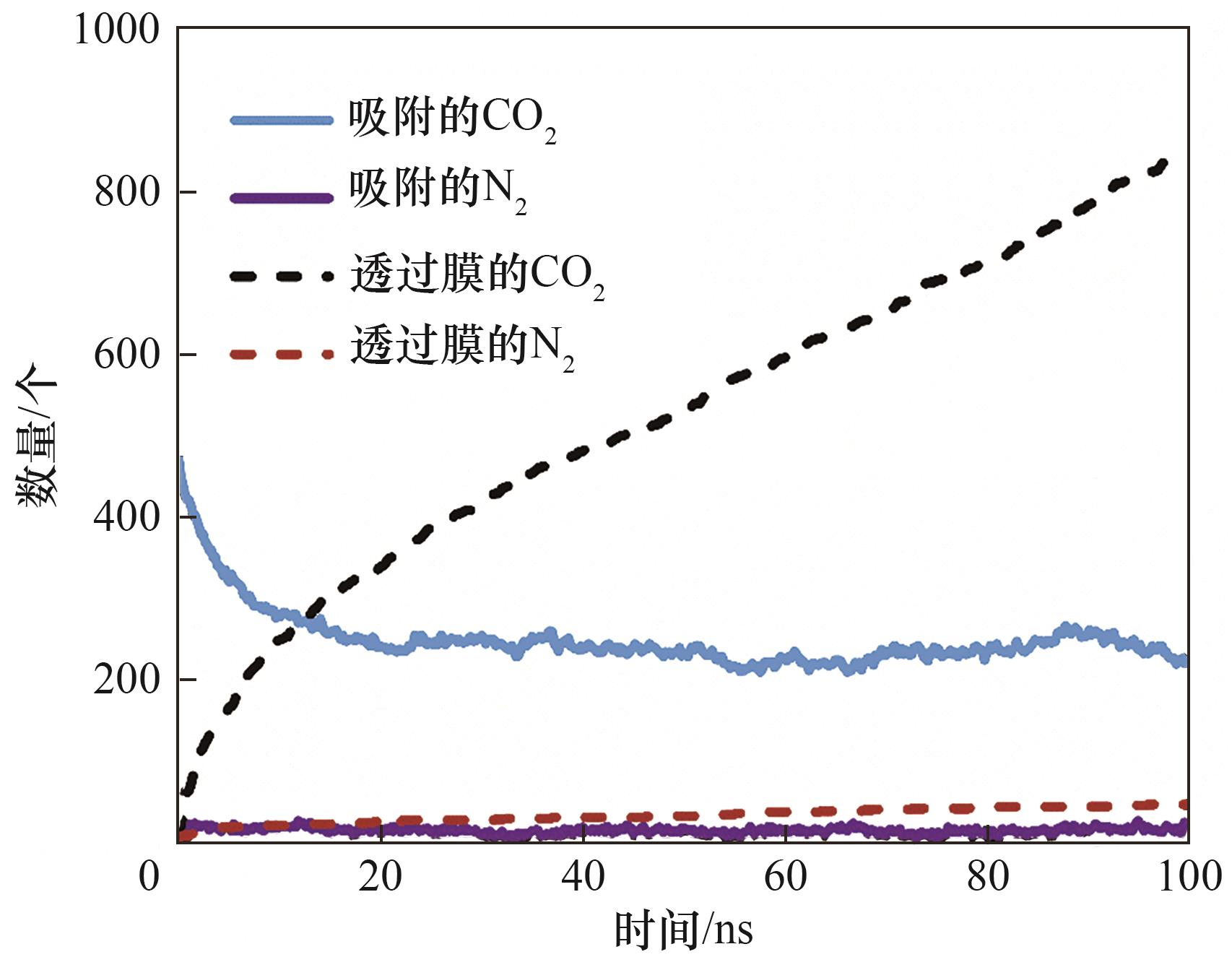

图6 渗透过程中吸附在CANAL-Me-S5F膜内和渗透过CANAL-Me-S5F膜的气体分子数随时间的变化

Fig.6 Variation of number of gas molecules sorbed in CANAL-Me-S5F membrane and permeated through CANAL-Me-S5F membrane versus time during permeation

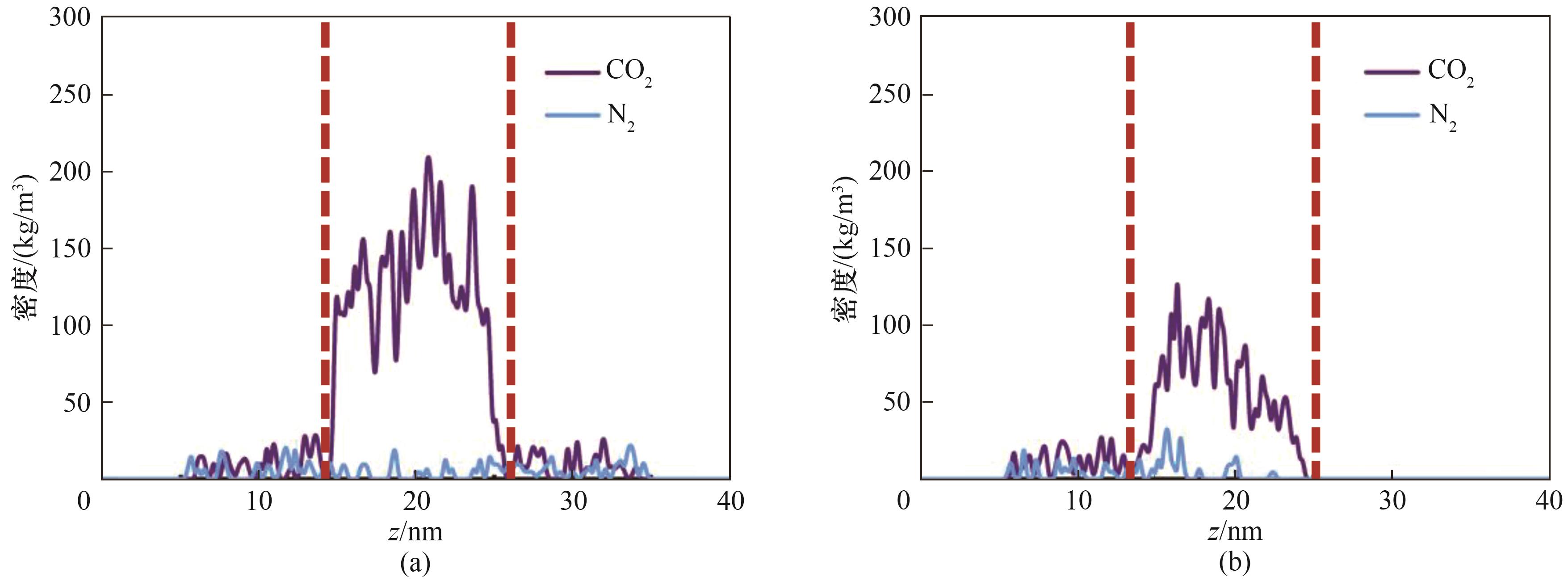

图7 CO2和N2在吸附过程(a)和渗透过程(b)中沿z方向的密度分布(膜位于两条虚线之间)

Fig.7 Density profiles of CO2 and N2 along z direction during sorption (a) and permeation (b) processes (membrane is between the two dashed lines)

| 1 | Kamio E, Yoshioka T, Matsuyama H. Recent advances in carbon dioxide separation membranes: a review[J]. Journal of Chemical Engineering of Japan, 2023, 56(1): 2222000. |

| 2 | Bredesen R, Kumakiri I, Peters T. CO2 capture with membrane systems[M]//Drioli E, Giorno L. Membrane Operations. Weinheim: Wiley-VCH, 2009: 195-220. |

| 3 | Wang S F, Li X Q, Wu H, et al. Advances in high permeability polymer-based membrane materials for CO2 separations[J]. Energy & Environmental Science, 2016, 9(6): 1863-1890. |

| 4 | Kamiya Y, Naito Y, Mizoguchi K, et al. Thermodynamic interactions in rubbery polymer/gas systems[J]. Journal of Polymer Science Part B: Polymer Physics, 1997, 35(7): 1049-1053. |

| 5 | Dai Z D, Deng L Y. Membranes for CO2 capture and separation: progress in research and development for industrial applications[J]. Separation and Purification Technology, 2024, 335: 126022. |

| 6 | Figueroa J D, Fout T, Plasynski S, et al. Advances in CO2 capture technology—the U.S. Department of Energy's carbon sequestration program[J]. International Journal of Greenhouse Gas Control, 2008, 2(1): 9-20. |

| 7 | Merkel T C, Lin H Q, Wei X T, et al. Power plant post-combustion carbon dioxide capture: an opportunity for membranes[J]. Journal of Membrane Science, 2010, 359(1/2): 126-139. |

| 8 | Keairns D, Newby R, Shah V. Current and future technologies for power generation with post-combustion carbon capture[R]. United States, 2012. |

| 9 | Sanders D F, Smith Z P, Guo R L, et al. Energy-efficient polymeric gas separation membranes for a sustainable future: a review[J]. Polymer, 2013, 54(18): 4729-4761. |

| 10 | Lee Y C, Chuah C Y, Lee J, et al. Effective functionalization of porous polymer fillers to enhance CO2/N2 separation performance of mixed-matrix membranes[J]. Journal of Membrane Science, 2022, 647: 120309. |

| 11 | Wang Y H, Zhou Y, Zhang X R, et al. SPEEK membranes by incorporation of NaY zeolite for CO2/N2 separation[J]. Separation and Purification Technology, 2021, 275: 119189. |

| 12 | Li X X, Jiao C L, Zhang X Q, et al. A general strategy for fabricating polymer/nanofiller composite membranes with enhanced CO2/N2 separation performance[J]. Journal of Cleaner Production, 2022, 350: 131468. |

| 13 | Liu J Y, Hou X D, Park H B, et al. High-performance polymers for membrane CO2/N2 separation[J]. Chemistry, 2016, 22(45): 15980-15990. |

| 14 | Ding X L, Wang W J, Cheng X Y, et al. Composite membranes based on ether oxygen-rich polyimide with superior CO2/N2 separation properties prepared by interfacial polymerization[J]. Journal of Membrane Science, 2024, 693: 122355. |

| 15 | Zhao B W, Wong J W, Liang C Z, et al. Inner-selective polyethersulfone-polydimethylsiloxane (PES-PDMS) thin film composite hollow fiber membrane for CO2/N2 separation at high pressures[J]. Separation and Purification Technology, 2023, 323: 124439. |

| 16 | Pang R Z, Chen K K, Han Y, et al. Highly permeable polyethersulfone substrates with bicontinuous structure for composite membranes in CO2/N2 separation[J]. Journal of Membrane Science, 2020, 612: 118443. |

| 17 | Sandru M, Sandru E M, Ingram W F, et al. An integrated materials approach to ultrapermeable and ultraselective CO2 polymer membranes[J]. Science, 2022, 376(6588): 90-94. |

| 18 | Xu X Z, Wang J J, Zhou A W, et al. High-efficiency CO2 separation using hybrid LDH-polymer membranes[J]. Nature Communications, 2021, 12(1): 3069. |

| 19 | Barnett J W, Bilchak C R, Wang Y W, et al. Designing exceptional gas-separation polymer membranes using machine learning[J]. Science Advances, 2020, 6(20): eaaz4301. |

| 20 | Chen L D, Su P C, Liu J D, et al. Post-synthesis amination of polymer of intrinsic microporosity membranes for CO2 separation[J]. AIChE Journal, 2023, 69(6): e18050. |

| 21 | McKeown N B. The structure-property relationships of polymers of intrinsic microporosity (PIMs)[J]. Current Opinion in Chemical Engineering, 2022, 36: 100785. |

| 22 | Lai H W H, Benedetti F M, Jin Z X, et al. Tuning the molecular weights, chain packing, and gas-transport properties of CANAL ladder polymers by short alkyl substitutions[J]. Macromolecules, 2019, 52(16): 6294-6302. |

| 23 | Lai H W H, Benedetti F M, Ahn J M, et al. Hydrocarbon ladder polymers with ultrahigh permselectivity for membrane gas separations[J]. Science, 2022, 375(6587): 1390-1392. |

| 24 | Robinson A M, Xia Y. Regioisomeric spirobifluorene CANAL ladder polymers and their gas separation performance[J]. ACS Macro Letters, 2024: 118-123. |

| 25 | Ma X H, Lai H W H, Wang Y G, et al. Facile synthesis and study of microporous catalytic arene-norbornene annulation-Tröger’s base ladder polymers for membrane air separation[J]. ACS Macro Letters, 2020, 9(5): 680-685. |

| 26 | Hazazi K, Wang Y G, Srivatsa Bettahalli N M, et al. Catalytic arene-norbornene annulation (CANAL) ladder polymer derived carbon membranes with unparalleled hydrogen/carbon dioxide size-sieving capability[J]. Journal of Membrane Science, 2022, 654: 120548. |

| 27 | Xu Q B, Xin B R, Wei J, et al. Tröger’s base polymeric membranes for CO2 separation: a review[J]. Journal of Materials Chemistry A, 2023, 11(29): 15600-15634. |

| 28 | Yuan P, Zhang M R, Pang Y Y, et al. Intrinsically microporous polyimides from norbornyl bis-benzocyclobutene-containing diamines and rigid dianhydrides for membrane-based gas separation[J]. ACS Applied Polymer Materials, 2023, 5(2): 1420-1429. |

| 29 | Liu B, Smit B. Molecular simulation studies of separation of CO2/N2, CO2/CH4, and CH4/N2 by ZIFs[J]. The Journal of Physical Chemistry C, 2010, 114(18): 8515-8522. |

| 30 | Meng X S, Fang T M, Zhou G H, et al. Molecular simulation study on CO2 separation performance of GO/ionic liquid membrane[J]. International Journal of Heat and Mass Transfer, 2022, 197: 123360. |

| 31 | Xu P, Zhang X C, Zhao L L, et al. Prominently improved CO2/N2 separation efficiency by ultrathin-ionic-liquid-covered MXene membrane[J]. Separation and Purification Technology, 2023, 311: 123296. |

| 32 | Neyertz S, Brown D, Salimi S, et al. Molecular characterization of membrane gas separation under very high temperatures and pressure: single-and mixed-gas CO2/CH4 and CO2/N2 permselectivities in hybrid networks[J]. Membranes, 2022, 12(5): 526. |

| 33 | Apriliyanto Y B, Faginas-Lago N, Evangelisti S, et al. Multilayer graphtriyne membranes for separation and storage of CO2: molecular dynamics simulations of post-combustion model mixtures[J]. Molecules, 2022, 27(18): 5958. |

| 34 | Kojabad M E, Babaluo A, Tavakoli A. A novel semi-mobile carrier facilitated transport membrane containing aniline/poly (ether-block-amide) for CO2/N2 separation: molecular simulation and experimental study[J]. Separation and Purification Technology, 2021, 266: 118494. |

| 35 | Ozcan A, Semino R, Maurin G, et al. Modeling of gas transport through polymer/MOF interfaces: a microsecond-scale concentration gradient-driven molecular dynamics study[J]. Chemistry of Materials, 2020, 32(3): 1288-1296. |

| 36 | Ozcan A, Fan D, Datta S J, et al. Tuning MOF/polymer interfacial pore geometry in mixed matrix membrane for upgrading CO2 separation performance[J]. Science Advances, 2024, 10(28): eadk5846. |

| 37 | Asif K, Lock S S M, Ali Ammar Taqvi S, et al. A molecular simulation study on amine-functionalized silica/polysulfone mixed matrix membrane for mixed gas separation[J]. Chemosphere, 2023, 311: 136936. |

| 38 | Daglar H, Keskin S. Combining machine learning and molecular simulations to unlock gas separation potentials of MOF membranes and MOF/polymer MMMs[J]. ACS Applied Materials & Interfaces, 2022, 14(28): 32134-32148. |

| 39 | Heuchel M, Fritsch D, Budd P M, et al. Atomistic packing model and free volume distribution of a polymer with intrinsic microporosity (PIM-1)[J]. Journal of Membrane Science, 2008, 318(1/2): 84-99. |

| 40 | Fang W J, Zhang L L, Jiang J W. Polymers of intrinsic microporosity for gas permeation: a molecular simulation study[J]. Molecular Simulation, 2010, 36(12): 992-1003. |

| 41 | Zhou J H, Zhu X, Hu J, et al. Mechanistic insight into highly efficient gas permeation and separation in a shape-persistent ladder polymer membrane[J]. Physical Chemistry Chemical Physics, 2014, 16(13): 6075-6083. |

| 42 | Shi Q, Zhang K, Lu R F, et al. Water desalination and biofuel dehydration through a thin membrane of polymer of intrinsic microporosity: atomistic simulation study[J]. Journal of Membrane Science, 2018, 545: 49-56. |

| 43 | Cabrales-Navarro F A, Gómez-Ballesteros J L, Balbuena P B. Molecular dynamics simulations of metal-organic frameworks as membranes for gas mixtures separation[J]. Journal of Membrane Science, 2013, 428: 241-250. |

| 44 | Zhang N, Luo Y, Li Z W, et al. Molecular investigation on the mechanism of permselective transport of CO2/N2 mixture through graphene slit[J]. Separation and Purification Technology, 2022, 282: 119986. |

| 45 | Li W, Zheng X, Dong Z H, et al. Molecular dynamics simulations of CO2/N2 separation through two-dimensional graphene oxide membranes[J]. The Journal of Physical Chemistry C, 2016, 120(45): 26061-26066. |

| 46 | Shan M X, Xue Q Z, Jing N N, et al. Influence of chemical functionalization on the CO2/N2 separation performance of porous graphene membranes[J]. Nanoscale, 2012, 4(17): 5477-5482. |

| 47 | Liu J, Jiang J W. Molecular design of microporous polymer membranes for the upgrading of natural gas[J]. The Journal of Physical Chemistry C, 2019, 123(11): 6607-6615. |

| 48 | Tong M M, Yang Q Y, Ma Q T, et al. Few-layered ultrathin covalent organic framework membranes for gas separation: a computational study[J]. Journal of Materials Chemistry A, 2016, 4(1): 124-131. |

| 49 | Abraham M J, Murtola T, Schulz R, et al. GROMACS: high performance molecular simulations through multi-level parallelism from laptops to supercomputers[J]. SoftwareX, 2015, 1: 19-25. |

| 50 | Jorgensen W L, Maxwell D S, Tirado-Rives J. Development and testing of the OPLS all-atom force field on conformational energetics and properties of organic liquids[J]. Journal of the American Chemical Society, 1996, 118(45): 11225-11236. |

| 51 | Zhao Z Y, Liu J, Jiang J W. Dipeptide membranes for CO2 separation: a molecular simulation study[J]. Fluid Phase Equilibria, 2020, 515: 112570. |

| 52 | Kong X, Liu J. An atomistic simulation study on POC/PIM mixed-matrix membranes for gas separation[J]. The Journal of Physical Chemistry C, 2019, 123(24): 15113-15121. |

| 53 | Harris J G, Yung K H. Carbon dioxide's liquid-vapor coexistence curve and critical properties as predicted by a simple molecular model[J]. The Journal of Physical Chemistry, 1995, 99(31): 12021-12024. |

| 54 | Nosé S. A molecular dynamics method for simulations in the canonical ensemble[J]. Molecular Physics, 1984, 52(2): 255-268. |

| 55 | Parrinello M, Rahman A. Polymorphic transitions in single crystals: a new molecular dynamics method[J]. Journal of Applied Physics, 1981, 52(12): 7182-7190. |

| 56 | Golzar K, Modarress H, Amjad-Iranagh S. Separation of gases by using pristine, composite and nanocomposite polymeric membranes: a molecular dynamics simulation study[J]. Journal of Membrane Science, 2017, 539: 238-256. |

| 57 | Low Z X, Budd P M, McKeown N B, et al. Gas permeation properties, physical aging, and its mitigation in high free volume glassy polymers[J]. Chemical Reviews, 2018, 118(12): 5871-5911. |

| 58 | Lin H Q, Van Wagner E, Freeman B D, et al. Plasticization-enhanced hydrogen purification using polymeric membranes[J]. Science, 2006, 311(5761): 639-642. |

| 59 | Tiwari R R, Jin J Y, Freeman B D, et al. Physical aging, CO2 sorption and plasticization in thin films of polymer with intrinsic microporosity (PIM-1)[J]. Journal of Membrane Science, 2017, 537: 362-371. |

| 60 | Zhang L L, Xiao Y C, Chung T S, et al. Mechanistic understanding of CO2-induced plasticization of a polyimide membrane: a combination of experiment and simulation study[J]. Polymer, 2010, 51(19): 4439-4447. |

| 61 | 李辰鑫, 潘艳秋, 何流, 等. 基于碳微晶结构的炭膜模型及其气体分离模拟[J]. 化工学报, 2023, 74(5): 2057-2066. |

| Li C X, Pan Y Q, He L, et al. Carbon membrane model based on carbon microcrystal structure and its gas separation simulation[J]. CIESC Journal, 2023, 74(5): 2057-2066. |

| [1] | 郭彭涛, 王婷, 薛波, 应允攀, 刘大欢. 用于CH4/N2分离的多吸附位点超微孔MOF[J]. 化工学报, 2025, 76(5): 2304-2312. |

| [2] | 花敬贤, 罗宇荣, 顾亚伟, 吴婷婷, 潘宜昌, 邢卫红. 超薄取向ZIF-8膜的制备及乙烯/乙烷高效分离[J]. 化工学报, 2025, 76(5): 2209-2218. |

| [3] | 李艳, 雷美丽, 李鑫钢. 基于分离性能的顺序式模拟移动床结构调控策略[J]. 化工学报, 2025, 76(5): 2219-2229. |

| [4] | 刘鑫, 郑皓仁, 陈强, 丁静怡, 黄康, 徐至. 全钒液流电池用纤维素纳米晶掺杂混合基质膜[J]. 化工学报, 2025, 76(5): 2294-2303. |

| [5] | 巴雅琪, 吴涛, 邸安頔, 陆安慧. 多孔炭材料用于低碳烃分离的研究进展[J]. 化工学报, 2025, 76(5): 2136-2157. |

| [6] | 谈朋, 李雪梅, 刘晓勤, 孙林兵. 基于柔性MOFs的磁响应复合材料及其丙烯吸附性能研究[J]. 化工学报, 2025, 76(5): 2230-2240. |

| [7] | 向昕辰, 鲁丹, 赵影, 姚之侃, 寇瑞强, 郑丹军, 周志军, 张林. 聚酰胺纳滤膜表面季铵化提高荷正电性及其锂镁分离性能[J]. 化工学报, 2025, 76(5): 2377-2386. |

| [8] | 茅雨洁, 路晓飞, 锁显, 杨立峰, 崔希利, 邢华斌. 工业气体中微量氧深度脱除催化剂研究进展[J]. 化工学报, 2025, 76(5): 1997-2010. |

| [9] | 时任泽, 丁秋燕, 袁振军, 那健, 刘见华, 郭树虎, 赵雄, 李洪, 高鑫. 4N电子级二乙氧基甲基硅烷的纯化技术研究[J]. 化工学报, 2025, 76(5): 2186-2197. |

| [10] | 郭明钢, 杨晓航, 代岩, 米盼盼, 马世鑫, 贺高红, 肖武, 崔福军. 贫氦管输天然气提氦多元化产品耦合工艺优化设计[J]. 化工学报, 2025, 76(5): 2251-2261. |

| [11] | 程刘惠美, 闫军营, 刘慧情, 王治澎, 王报英, 徐铜文, 汪耀明. 双极膜电渗析在醇水体系的应用研究进展[J]. 化工学报, 2025, 76(5): 1960-1972. |

| [12] | 顾栋, 皮行健, 张叠, 张瑛. 不同粒径CAU-1/PI混合基质膜的构建与H2/CO2分离性能研究[J]. 化工学报, 2025, 76(5): 2410-2418. |

| [13] | 张耀辉, 班宇杰, 杨维慎. 以蒸气加工法制备和修饰金属-有机框架膜[J]. 化工学报, 2025, 76(5): 2070-2086. |

| [14] | 杨雅南, 常胜然, 薛松林, 潘建明, 邢卫红. 基于光、电驱动促进海水中铀和锂提取的研究进展[J]. 化工学报, 2025, 76(5): 1927-1942. |

| [15] | 杨紫博, 王有发, 岳寒松, 远双杰, 耿付江, 李晴晴, 奥德, 李斌, 叶茂, 顾振杰, 乔志华. MOF玻璃基气体分离膜的研究进展[J]. 化工学报, 2025, 76(5): 2158-2168. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号