化工学报 ›› 2025, Vol. 76 ›› Issue (12): 6614-6625.DOI: 10.11949/0438-1157.20250503

尹胜强1( ), 钟湘宇1, 龚漫雨1, 李露1, 刘远征2, 周寿斌3, 肖俊兵1,3(

), 钟湘宇1, 龚漫雨1, 李露1, 刘远征2, 周寿斌3, 肖俊兵1,3( ), 刘昌会2(

), 刘昌会2( ), 贾传坤1

), 贾传坤1

收稿日期:2025-05-08

修回日期:2025-06-23

出版日期:2025-12-31

发布日期:2026-01-23

通讯作者:

肖俊兵,刘昌会

作者简介:尹胜强(2004—),男,本科生,yin_sq310@163.com

基金资助:

Shengqiang YIN1( ), Xiangyu ZHONG1, Manyu GONG1, Lu LI1, Yuanzheng LIU2, Shoubin ZHOU3, Junbing XIAO1,3(

), Xiangyu ZHONG1, Manyu GONG1, Lu LI1, Yuanzheng LIU2, Shoubin ZHOU3, Junbing XIAO1,3( ), Changhui LIU2(

), Changhui LIU2( ), Chuankun JIA1

), Chuankun JIA1

Received:2025-05-08

Revised:2025-06-23

Online:2025-12-31

Published:2026-01-23

Contact:

Junbing XIAO, Changhui LIU

摘要:

为改善相变材料的导热性能,以桃胶为碳源、氢氧化钾(KOH)为活化剂,采用一步化学活化法制备了活化桃胶碳。在棕榈酸(PA)-硬脂酸(SA)二元混合物中分别加入KOH活化桃胶碳(CPGK)和未经活化的桃胶碳(CPG),研究了活化处理对提高二元混合物热性能的影响机制。结果表明,添加剂与相变材料之间仅为物理结合。当添加剂质量分数为5%时,CPGK对复合相变材料导热性能的提升更为明显,PA-SA/CPGK热导率为0.3528 W·m-1·K-1,分别较PA-SA/CPG及PA-SA提高0.92%、22.46%,这是由于CPGK的孔隙结构能提供更多热传导路径。相比于PA-SA混合物,PA-SA/CPGK的熔化时间最大缩短了53.64%,凝固时间最大缩短了11.39%。PA-SA/CPGK较PA-SA/CPG具有更好的热稳定性及形状稳定性,相同测试条件下,PA-SA/CPGK的质量损失比PA-SA/CPG减小2.37%,PA-SA/CPGK的完全泄漏时间较PA-SA/CPG延长5.26%。所制备的复合相变材料具有良好的热性能,在太阳能热利用和热能储存等领域具有广阔应用前景。

中图分类号:

尹胜强, 钟湘宇, 龚漫雨, 李露, 刘远征, 周寿斌, 肖俊兵, 刘昌会, 贾传坤. 活化桃胶碳基复合相变材料性能表征及导热增强研究[J]. 化工学报, 2025, 76(12): 6614-6625.

Shengqiang YIN, Xiangyu ZHONG, Manyu GONG, Lu LI, Yuanzheng LIU, Shoubin ZHOU, Junbing XIAO, Changhui LIU, Chuankun JIA. Characterization of properties and thermal conductivity enhancement of activated carbonized peach gum-based composite phase change materials[J]. CIESC Journal, 2025, 76(12): 6614-6625.

| 材料 | 密度/(g⋅cm-3) | 纯度/% | 熔化温度/℃ |

|---|---|---|---|

| 棕榈酸 | 0.85 | 98.00 | 62.50 |

| 硬脂酸 | 0.84 | 98.37 | 71.70 |

| 氢氧化钾 | 2.04 | AR | — |

表1 部分材料的主要物性参数

Table 1 The main physical properties of used materials

| 材料 | 密度/(g⋅cm-3) | 纯度/% | 熔化温度/℃ |

|---|---|---|---|

| 棕榈酸 | 0.85 | 98.00 | 62.50 |

| 硬脂酸 | 0.84 | 98.37 | 71.70 |

| 氢氧化钾 | 2.04 | AR | — |

| CPG质量分数 | 熔化过程 | 凝固过程 | CPGK质量分数 | 熔化过程 | 凝固过程 | ||||

|---|---|---|---|---|---|---|---|---|---|

| ΔTm/℃ | hm/(J·g-1) | ΔTc/℃ | hc/(J·g-1) | ΔTm/℃ | hm/(J·g-1) | ΔTc/℃ | hc/(J·g-1) | ||

| 0 | [56.10,60.68] | 186.4 | [45.13,52.29] | 186.1 | 0 | [56.10,60.68] | 186.4 | [45.13,52.29] | 186.1 |

| 0.01 | [56.60,62.34] | 183.1 | [43.53,51.73] | 181.6 | 0.01 | [55.30,62.63] | 180.8 | [43.07,52.04] | 175.4 |

| 0.02 | [55.68,60.56] | 171.6 | [44.74,52.02] | 169.8 | 0.02 | [55.52,60.88] | 175.4 | [44.17,51.56] | 172.7 |

| 0.03 | [56.31,62.25] | 170.0 | [43.45,52.33] | 168.8 | 0.03 | [54.78,61.76] | 170.3 | [43.24,51.90] | 169.9 |

| 0.04 | [55.65,62.97] | 169.0 | [43.67,53.23] | 168.2 | 0.04 | [55.38,62.21] | 169.4 | [43.31,52.27] | 169.1 |

| 0.05 | [55.83,59.04] | 166.0 | [46.51,53.24] | 164.2 | 0.05 | [55.02,62.76] | 165.5 | [42.67,51.23] | 165.2 |

表2 复合相变材料的相变潜热及相变温度

Table 2 The latent heat of phase change and phase change temperature of composites

| CPG质量分数 | 熔化过程 | 凝固过程 | CPGK质量分数 | 熔化过程 | 凝固过程 | ||||

|---|---|---|---|---|---|---|---|---|---|

| ΔTm/℃ | hm/(J·g-1) | ΔTc/℃ | hc/(J·g-1) | ΔTm/℃ | hm/(J·g-1) | ΔTc/℃ | hc/(J·g-1) | ||

| 0 | [56.10,60.68] | 186.4 | [45.13,52.29] | 186.1 | 0 | [56.10,60.68] | 186.4 | [45.13,52.29] | 186.1 |

| 0.01 | [56.60,62.34] | 183.1 | [43.53,51.73] | 181.6 | 0.01 | [55.30,62.63] | 180.8 | [43.07,52.04] | 175.4 |

| 0.02 | [55.68,60.56] | 171.6 | [44.74,52.02] | 169.8 | 0.02 | [55.52,60.88] | 175.4 | [44.17,51.56] | 172.7 |

| 0.03 | [56.31,62.25] | 170.0 | [43.45,52.33] | 168.8 | 0.03 | [54.78,61.76] | 170.3 | [43.24,51.90] | 169.9 |

| 0.04 | [55.65,62.97] | 169.0 | [43.67,53.23] | 168.2 | 0.04 | [55.38,62.21] | 169.4 | [43.31,52.27] | 169.1 |

| 0.05 | [55.83,59.04] | 166.0 | [46.51,53.24] | 164.2 | 0.05 | [55.02,62.76] | 165.5 | [42.67,51.23] | 165.2 |

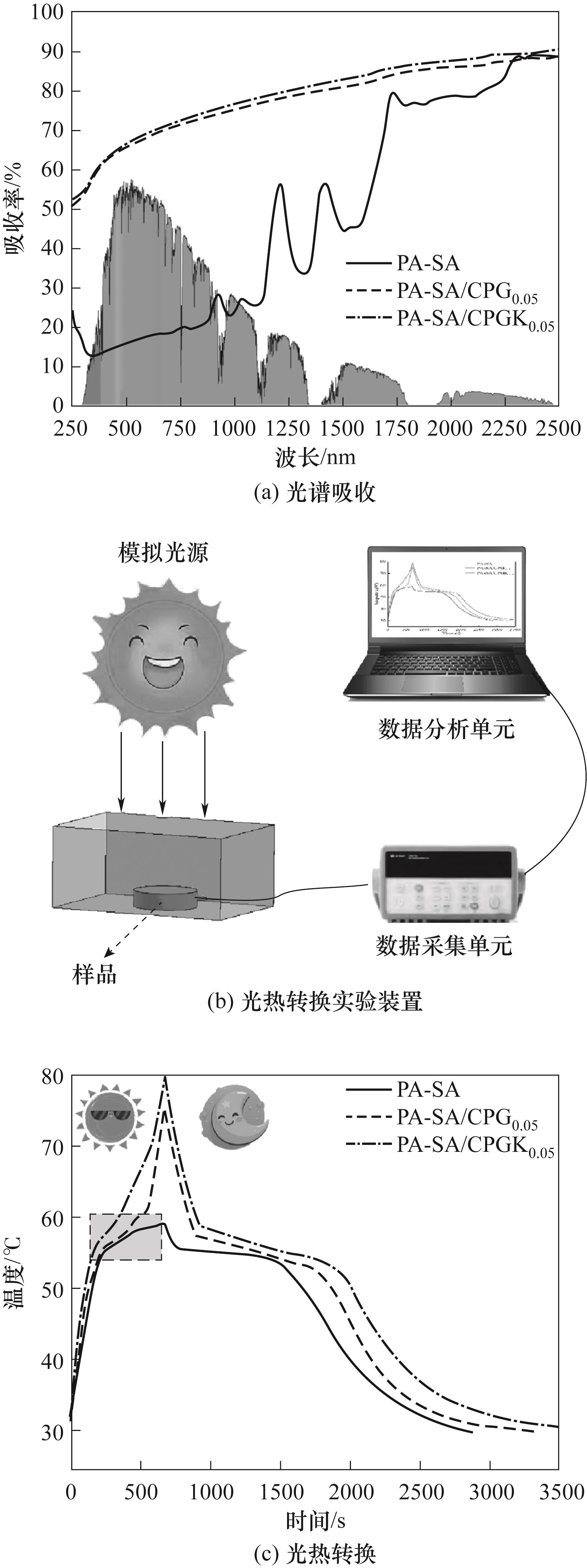

图8 复合相变材料的光热转换实验装置示意图和光热转换曲线

Fig.8 Experimental setup of photothermal conversion and photothermal conversion curves of composite phase change materials

| [1] | Yang S, Shao X F, Luo J H, et al. A novel cascade latent heat thermal energy storage system consisting of erythritol and paraffin wax for deep recovery of medium-temperature industrial waste heat[J]. Energy, 2023, 265: 126359. |

| [2] | Wang K, Li Y, Wang B L, et al. Study on the integrated battery thermal management system based on magnetic fields and nano-enhanced phase change materials coupled with electrothermal films[J]. International Journal of Heat and Mass Transfer, 2025, 240: 126665. |

| [3] | 邹瀚影, 冯妍卉, 邱琳, 等. 十八烷酸热传导机制的尺度效应研究[J]. 化工学报, 2019, 70(S2): 155-160, 377. |

| Zou H Y, Feng Y H, Qiu L, et al. Size effect of heat conduction mechanism on stearic acid[J]. CIESC Journal, 2019, 70(S2): 155-160, 377. | |

| [4] | Xu T, He R H, Fan G, et al. Hexadecanol-palmitic acid/expanded graphite eutectic composite phase change material and its application in photovoltaic panel[J]. Solar Energy Materials and Solar Cells, 2024, 273: 112934. |

| [5] | 朱郑洋, 李小姗, 罗聪, 等. 基于二元双峰相变储热材料的电池热管理系统及其热适应性研究[J/OL]. 洁净煤技术, 2025. . |

| Zhu Z Y, Li X S, Luo C, et al. Investigations on thermal adaptability of battery thermal management system based on binary double-peak phase change materials[J/OL]. Clean Coal Technology, 2025.. | |

| [6] | Zhang H Q, Sun Q R, Yuan Y P, et al. A novel form-stable phase change composite with excellent thermal and electrical conductivities[J]. Chemical Engineering Journal, 2018, 336: 342-351. |

| [7] | Niu J Y, Yuan W H, Zhang Z G, et al. A pourable, thermally conductive and electronic insulated phase change material for thermal management of lithium-ion battery[J]. Chemical Engineering Journal, 2024, 489: 151310. |

| [8] | Ali Bhutto Y, Pandey A K, Saidur R, et al. Hybrid silver-graphene nanoparticles enhanced Lauric acid phase change material for photovoltaic and thermoelectric generator applications: experimental and simulation analysis[J]. Journal of Energy Storage, 2024, 93: 112320. |

| [9] | Bian Z, Hou F, Bai Y, et al. Composited phase change material with hierarchical metal foam for efficient thermal energy management[J]. Applied Thermal Engineering, 2024, 236: 121745. |

| [10] | Bin Shahid U, Abdala A. A critical review of phase change material composite performance through figure-of-merit analysis: graphene vs boron nitride[J]. Energy Storage Materials, 2021, 34: 365-387. |

| [11] | Xiao J B, Zou B, Liu C H, et al. Carbonized loofah sponge fragments enhanced phase change thermal energy storage: preparation and thermophysical property analysis[J]. Applied Thermal Engineering, 2024, 242: 122505. |

| [12] | Zhang Y, Yan J J, Xie H W, et al. Preparation and performance study of porous biochar-based shape-stabilized phase change materials for thermal energy storage[J]. Biomass Conversion and Biorefinery, 2025, 15(7): 11065-11081. |

| [13] | Atinafu D G, Yun B Y, Yang S, et al. Encapsulation of dodecane in gasification biochar for its prolonged thermal/shape stability, reliability, and ambient enthalpy storage[J]. Chemical Engineering Journal, 2022, 437: 135407. |

| [14] | Li C C, Xie B S, He Z X, et al. 3D structure fungi-derived carbon stabilized stearic acid as a composite phase change material for thermal energy storage[J]. Renewable Energy, 2019, 140: 862-873. |

| [15] | Gao N, Du J L, Yang W B, et al. Biomass-based shape-stabilized composite phase-change materials with high solar-thermal conversion efficiency for thermal energy storage[J]. Polymers, 2023, 15(18): 3747. |

| [16] | Liu X X, Zhang Y H, Yu C Y, et al. N-doped porous carbon with directional oriented channel structure derived from biomass peach gum/poly(o-phenylenediamine) composite for high-performance supercapacitors[J]. Journal of Energy Storage, 2024, 84: 110860. |

| [17] | Lin Y, Chen Z Y, Yu C Y, et al. Heteroatom-doped sheet-like and hierarchical porous carbon based on natural biomass small molecule peach gum for high-performance supercapacitors[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(3): 3389-3403. |

| [18] | Zhao D, Zhao Q, Feng L, et al. Honey-comb carbon nanostructure derived from peach gum to yield high microwave absorption[J]. Journal of Materials Science: Materials in Electronics, 2021, 32(21): 25829-25839. |

| [19] | Dai J S, Ma F, Fu Z, et al. Applicability assessment of stearic acid/palmitic acid binary eutectic phase change material in cooling pavement[J]. Renewable Energy, 2021, 175: 748-759. |

| [20] | Kumar P, Thomas S, Sobhan C B, et al. Activated carbon foam composite derived from PEG400/Terminalia Catappa as form stable PCM for sub-zero cold energy storage[J]. Journal of Cleaner Production, 2024, 434: 139993. |

| [21] | Dai Z F, Zhang G L, Xiao Y F, et al. High-directional thermally conductive stearic acid/expanded graphite-graphene films for efficient photothermal energy storage[J]. Chemical Engineering Journal, 2024, 484: 149203. |

| [22] | 肖俊兵, 钟湘宇, 任建地, 等. 基于生物碳材料强化的硬脂酸相变材料储热性能研究[J]. 化工学报, 2025, 76(3): 1312-1322. |

| Xiao J B, Zhong X Y, Ren J D, et al. Research on the heat storage properties of stearic acid phase change materials enhanced by bio-carbon materials[J]. CIESC Journal, 2025, 76(3): 1312-1322. | |

| [23] | Yadav A, Pandey A K, Samykano M, et al. Wheat husk derived microparticle infused organic phase change material for efficient heat transfer and sustainable thermal energy storage[J]. Journal of Energy Storage, 2024, 86: 111204. |

| [24] | Wang C M, Chen K, Huang J, et al. Thermal behavior of polyethylene glycol based phase change materials for thermal energy storage with multiwall carbon nanotubes additives[J]. Energy, 2019, 180: 873-880. |

| [25] | Liu S X, Zhang X, Zhu X Z, et al. A low-temperature phase change material based on capric-stearic acid/expanded graphite for thermal energy storage[J]. ACS Omega, 2021, 6(28): 17988-17998. |

| [26] | Li W, Dong Y, Zhang X, et al. Preparation and performance analysis of graphite additive/paraffin composite phase change materials[J]. Processes, 2019, 7(7): 447. |

| [27] | Agrawal R, Singh K D P, Sharma R K. Experimental investigations on the phase change and thermal properties of nano enhanced binary eutectic phase change material of palmitic acid‐stearic acid/CuO nanoparticles for thermal energy storage[J]. International Journal of Energy Research, 2022, 46(5): 6562-6576. |

| [28] | Bing N C, Wu G Z, Yang J, et al. Thermally induced flexible phase change composites with enhanced thermal conductivity for solar thermal conversion and storage[J]. Solar Energy Materials and Solar Cells, 2022, 240: 111684. |

| [29] | Bai K H, Li C C, Xie B S, et al. Emerging PEG/VO2 dual phase change materials for thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2022, 239: 111686. |

| [30] | Wu X H, Wang C X, Wang Y L, et al. Experimental study of thermo-physical properties and application of paraffin-carbon nanotubes composite phase change materials[J]. International Journal of Heat and Mass Transfer, 2019, 140: 671-677. |

| [31] | 陈莎, 陈岳浩, 孙小琴, 等. 碳基纳米石蜡复合相变储能材料制备与性能研究[J]. 储能科学与技术, 2024, 13(12): 4349-4356. |

| Chen S, Chen Y H, Sun X Q, et al. Preparation and properties of nano-carbon-based composite paraffin phase-change materials[J]. Energy Storage Science and Technology, 2024, 13(12): 4349-4356. | |

| [32] | Lu Y, Hu R P, Chen X P, et al. A strategy for constructing 3D ordered boron nitride aerogels-based thermally conductive phase change composites for battery thermal management[J]. Journal of Materials Science & Technology, 2023, 160: 248-257. |

| [33] | Wang C M, Chen K, Huang Z, et al. Effect of polymer-derived silicon carbonitride on thermal performances of polyethylene glycol based composite phase change materials[J]. Solar Energy, 2020, 208: 282-288. |

| [34] | Xiong T, Ok Y S, Dissanayake P D, et al. Preparation and thermal conductivity enhancement of a paraffin wax-based composite phase change material doped with garlic stem biochar microparticles[J]. Science of the Total Environment, 2022, 827: 154341. |

| [35] | Ji W, Cheng X M, Chen S H, et al. Self-assembly fabrication of GO/TiO2@paraffin microcapsules for enhancement of thermal energy storage[J]. Powder Technology, 2021, 385: 546-556. |

| [36] | Ali Bhutto Y, Pandey A K, Saidur R, et al. Analyzing the thermal potential of binary 2D(h-BN/Gr)nanoparticles enhanced lauric acid phase change material for photovoltaic thermal system application[J]. Journal of Energy Storage, 2023, 73: 109116. |

| [37] | Zhang Y A, Wang J S, Qiu J J, et al. Ag-graphene/PEG composite phase change materials for enhancing solar-thermal energy conversion and storage capacity[J]. Applied Energy, 2019, 237: 83-90. |

| [38] | Xiao S K, Hu X W, Jiang L, et al. Nano-Ag modified bio-based loofah foam/polyethylene glycol composite phase change materials with higher photo-thermal conversion efficiency and thermal conductivity[J]. Journal of Energy Storage, 2022, 54: 105238. |

| [1] | 廖兵, 祝鑫宇, 黄倩倩, 胥雯, 寇梦瑶, 郭娜. 盐酸羟胺强化芬顿体系在近中性条件下去除2,4-DCP的性能及机理研究[J]. 化工学报, 2025, 76(8): 4273-4283. |

| [2] | 吴雷, 胡紫璇, 高渊, 刘长波, 曹虎生, 刘田田, 朱瑞玉, 周军. 微波联合生物炭活化过硫酸盐氧化修复多环芳烃污染土壤研究[J]. 化工学报, 2025, 76(7): 3659-3670. |

| [3] | 刘纹佳, 杜如雪, 王思齐, 李廷贤. 电-热转换功能型相变储热材料的研究进展及应用[J]. 化工学报, 2025, 76(7): 3185-3196. |

| [4] | 何军, 李勇, 赵楠, 何孝军. 碳负载硒掺杂硫化钴在锂硫电池中的性能研究[J]. 化工学报, 2025, 76(6): 2995-3008. |

| [5] | 赵清萍, 张敏, 赵辉, 王刚, 邱永福. 乙烯氢甲酯化合成丙酸甲酯的氢键作用机制及反应动力学研究[J]. 化工学报, 2025, 76(6): 2701-2713. |

| [6] | 范佳媛, 曾文慧, 任志超, 张文涛, 吕霜. 多熔点相变乳液的制备及性能强化研究[J]. 化工学报, 2025, 76(4): 1863-1874. |

| [7] | 肖俊兵, 钟湘宇, 任建地, 钟芳芳, 刘昌会, 贾传坤. 基于生物碳材料强化的硬脂酸相变材料储热性能研究[J]. 化工学报, 2025, 76(3): 1312-1322. |

| [8] | 肖俊兵, 邹博, 任建地, 刘昌会, 贾传坤. 基于相图分析的氯化物复合熔盐储热性能研究[J]. 化工学报, 2025, 76(3): 963-974. |

| [9] | 陈仲卿, 刘家旭, 王艳语, 井红权, 侯翠红, 屈凌波. K-B-Al体系对磷矿熔融特性及玻璃结构的影响[J]. 化工学报, 2025, 76(3): 1323-1333. |

| [10] | 高越, 李丁, 高玉苗. 有机污染场地土壤催化氧化修复技术研究[J]. 化工学报, 2025, 76(3): 1297-1304. |

| [11] | 杨田, 郭惠霞, 孙梦慈. CoFe2O4/CeO2复合材料活化PMS降解盐酸四环素[J]. 化工学报, 2025, 76(12): 6680-6695. |

| [12] | 王煜晨, 王万宗, 张鑫, 郭茂强, 周晓明, 盛利志. 高负载梓树豆荚壳衍生多孔碳材料的电化学性能研究[J]. 化工学报, 2025, 76(12): 6748-6760. |

| [13] | 陈欣妍, 陈依玲, 彭馨博, 胡靖杰, 江学良, 游峰. 隔热材料的制备、结构及应用研究进展[J]. 化工学报, 2025, 76(12): 6179-6195. |

| [14] | 彭郅众, 郎学磊, 房强, 井慧芳, 钟达忠, 李晋平, 赵强. Ag-Sn间电子结构调控在酸性环境中实现1 A/cm2下高效CO2还原[J]. 化工学报, 2025, 76(12): 6376-6386. |

| [15] | 邱家齐, 杨仲卿, 张志刚, 甘海龙, 霍春秀, 窦志帅, 冉景煜. Mn/Ce共掺杂强化氧物种转化与稀薄甲烷催化燃烧机制研究[J]. 化工学报, 2025, 76(11): 5604-5616. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号