化工学报 ›› 2025, Vol. 76 ›› Issue (8): 4052-4060.DOI: 10.11949/0438-1157.20250029

收稿日期:2025-01-07

修回日期:2025-02-18

出版日期:2025-08-25

发布日期:2025-09-17

通讯作者:

董鑫

作者简介:张建伟(1964—),男,博士,教授,zhangjianwei@syuct.edu.cn

基金资助:

Jianwei ZHANG( ), Yucheng LIU, Xin DONG(

), Yucheng LIU, Xin DONG( ), Ying FENG

), Ying FENG

Received:2025-01-07

Revised:2025-02-18

Online:2025-08-25

Published:2025-09-17

Contact:

Xin DONG

摘要:

为了探究气泡扰动强化撞击流反应器制备碳酸钙(CaCO3)粉体机制,通过撞击流共沉淀法,制备了具有不同晶体结构和含量的CaCO3粉体,考察了气泡扰动下反应温度对CaCO3晶体析出形式和转化过程的影响,研究了不同气液流量比下CaCO3晶体的晶相含量、成核速率及粒径尺寸。实验结果表明,反应温度是影响晶体形貌的关键因素,随着温度升高,CaCO3晶体析出形式依次为方解石、球霰石、文石。气泡扰动可有效调控CaCO3晶体含量和粒径尺寸。随着气液流量比增大,球霰石型CaCO3含量先降低后升高,成核速率先增大后减小,平均粒径先减小后增大。当气液流量比r=1.00时,产物中球霰石的含量达到最高水平,且平均粒径最小。为撞击流反应器可控制备CaCO3提供了参考。

中图分类号:

张建伟, 刘玉成, 董鑫, 冯颖. 气泡扰动强化撞击流共沉淀法合成碳酸钙粉体[J]. 化工学报, 2025, 76(8): 4052-4060.

Jianwei ZHANG, Yucheng LIU, Xin DONG, Ying FENG. Preparation of calcium carbonate by bubble disturbance enhanced impinging stream co-precipitation method[J]. CIESC Journal, 2025, 76(8): 4052-4060.

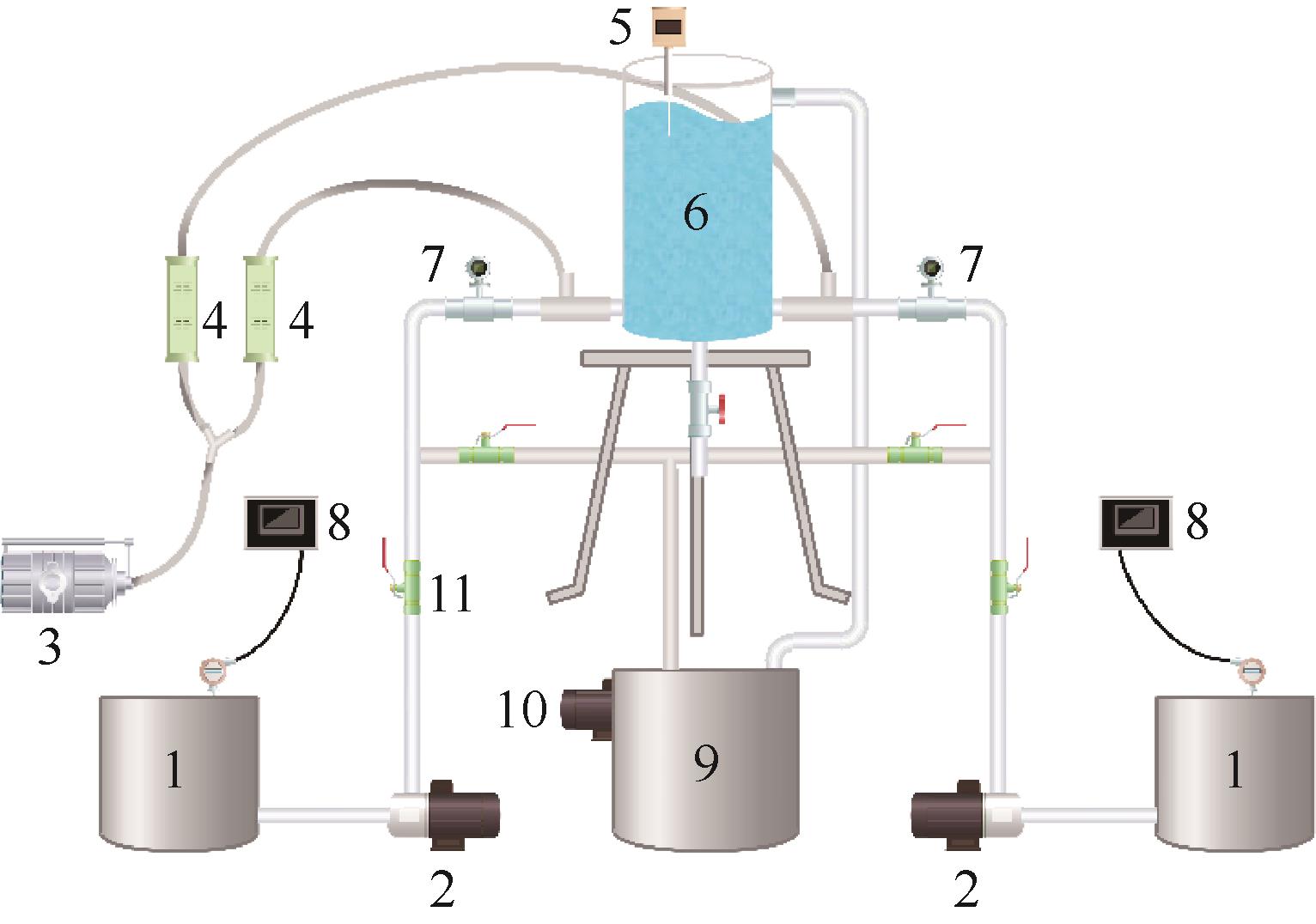

图1 撞击流反应器实验系统图1—feed bucket; 2—charge pump; 3—air pump; 4—gas flowmeter; 5—thermometer; 6—impinging stream reactor; 7—electromagnetic flowmeter; 8—intelligent temperature regulator; 9—discharge bucket; 10—circulating pump; 11—valve

Fig.1 Experimental system diagram of impinging stream reactor

| 组别 | 反应温度T/℃ | 气液 流量比r | 组别 | 反应温度T/℃ | 气液 流量比r |

|---|---|---|---|---|---|

| 1 | 20 | 1.00 | 10 | 30 | 0.75 |

| 2 | 30 | 1.00 | 11 | 30 | 1.00 |

| 3 | 40 | 1.00 | 12 | 30 | 1.25 |

| 4 | 50 | 1.00 | 13 | 50 | 0 |

| 5 | 60 | 1.00 | 14 | 50 | 0.25 |

| 6 | 70 | 1.00 | 15 | 50 | 0.50 |

| 7 | 30 | 0 | 16 | 50 | 0.75 |

| 8 | 30 | 0.25 | 17 | 50 | 1.00 |

| 9 | 30 | 0.50 | 18 | 50 | 1.25 |

表1 实验参数

Table 1 Experimental parameter

| 组别 | 反应温度T/℃ | 气液 流量比r | 组别 | 反应温度T/℃ | 气液 流量比r |

|---|---|---|---|---|---|

| 1 | 20 | 1.00 | 10 | 30 | 0.75 |

| 2 | 30 | 1.00 | 11 | 30 | 1.00 |

| 3 | 40 | 1.00 | 12 | 30 | 1.25 |

| 4 | 50 | 1.00 | 13 | 50 | 0 |

| 5 | 60 | 1.00 | 14 | 50 | 0.25 |

| 6 | 70 | 1.00 | 15 | 50 | 0.50 |

| 7 | 30 | 0 | 16 | 50 | 0.75 |

| 8 | 30 | 0.25 | 17 | 50 | 1.00 |

| 9 | 30 | 0.50 | 18 | 50 | 1.25 |

| 流量比 | 晶核粒数密度n0/(109 μm-1·ml-1) | 生长速率G/(μm/min) | 成核速率B0/ (108 ml-1·min-1) | 悬浮密度MT/(g/ml) |

|---|---|---|---|---|

| 0 | 4.995 | 0.0432 | 2.159 | 0.0114 |

| 0.25 | 15.037 | 0.0386 | 5.810 | 0.0115 |

| 0.50 | 25.693 | 0.0322 | 8.265 | 0.0122 |

| 0.75 | 23.595 | 0.0332 | 7.843 | 0.0119 |

| 1.00 | 3.287 | 0.0581 | 1.910 | 0.0127 |

| 1.25 | 4.825 | 0.0497 | 2.397 | 0.0115 |

表2 不同气液流量比下结晶动力学参数

Table 2 Crystallization kinetics parameters under different gas-liquid flow ratio

| 流量比 | 晶核粒数密度n0/(109 μm-1·ml-1) | 生长速率G/(μm/min) | 成核速率B0/ (108 ml-1·min-1) | 悬浮密度MT/(g/ml) |

|---|---|---|---|---|

| 0 | 4.995 | 0.0432 | 2.159 | 0.0114 |

| 0.25 | 15.037 | 0.0386 | 5.810 | 0.0115 |

| 0.50 | 25.693 | 0.0322 | 8.265 | 0.0122 |

| 0.75 | 23.595 | 0.0332 | 7.843 | 0.0119 |

| 1.00 | 3.287 | 0.0581 | 1.910 | 0.0127 |

| 1.25 | 4.825 | 0.0497 | 2.397 | 0.0115 |

| [9] | Yu H, Wang M, Zhou J, et al. Microreactor-assisted synthesis of α-alumina nanoparticles[J]. Ceramics International, 2020, 46(9): 13272-13281. |

| [10] | 姚瀚植, 游攀, 张俊杰, 等. 微型Y型撞击流混合器强化快速沉淀反应可控制备碳酸锶微球[J]. 无机化学学报, 2022, 38(10): 2103-2110. |

| Yao H Z, You P, Zhang J J, et al. Controllable preparation of strontium carbonate microspheres by fast precipitation reaction in a miniature Y-jet mixer[J]. Chinese Journal of Inorganic Chemistry, 2022, 38(10): 2103-2110. | |

| [11] | Lin X Y, Wang K, Zhang J S, et al. Liquid-liquid mixing enhancement rules by microbubbles in three typical micro-mixers[J]. Chemical Engineering Science, 2015, 127: 60-71. |

| [12] | Zhang J W, Zhang J, Dong X, et al. Flow regime transition and bubble behavior in gas-liquid two-phase impinging jet reactor[J]. Chemical Engineering Research & Design, 2024, 201: 275-285. |

| [13] | Schlickmann K P, Howarth J L L, Silva D A K, et al. Effect of the incorporation of micro and nanoparticles of calcium carbonate in poly(vinyl chloride) matrix for industrial application[J]. Materials Research, 2019, 22: e20180870. |

| [14] | Chen P, Liu Y, Di M W. The effect of nano-filler on the damping properties of polyacrylic damping paint[J]. Advanced Materials Research, 2011, 1154(183/184/185): 2154-2157. |

| [15] | Svenskaya Y I, Fattah H, Inozemtseva O A, et al. Key parameters for size- and shape-controlled synthesis of vaterite particles[J]. Crystal Growth & Design, 2018, 18(1): 331-337. |

| [16] | Trushina D B, Bukreeva T V, Kovalchuk M V, et al. CaCO3 vaterite microparticles for biomedical and personal care applications[J]. Materials Science and Engineering C, 2014, 45: 644-658. |

| [17] | Kawano J, Shimobayashi N, Miyake A, et al. Precipitation diagram of calcium carbonate polymorphs: its construction and significance[J]. Journal of Physics: Condensed Matter, 2009, 21(42): 425102. |

| [18] | Ma M G, Sun R C. Biomineralization and biomimetic synthesis of biomineral and nanomaterials[M]//Cavrak M. Advances in Biomimetics. Rijeka, Croatia: InTech, 2011. DOI:10.5772/13838 . |

| [19] | Ohgushi H, Okumura M, Yoshikawa T, et al. Bone formation process in porous calcium carbonate and hydroxyapatite[J]. Biomedical Materials, 1992, 26: 885-895. |

| [20] | Diego J R, Samuel S, G B L. The kinetics and mechanisms of amorphous calcium carbonate (ACC) crystallization to calcite, via vaterite[J]. Nanoscale, 2011, 3(1): 265-271. |

| [21] | Liendo F, Arduino M, Deorsola F A, et al. Optimization of CaCO3 synthesis through the carbonation route in a packed bed reactor[J]. Powder Technology, 2021, 377: 868-881. |

| [22] | Bots P, Benning L G, Rodriguez-Blanco J D, et al. Mechanistic insights into the crystallization of amorphous calcium carbonate (ACC)[J]. Crystal Growth & Design, 2012, 12(7): 3806-3814. |

| [23] | Declet A, Reyes E, Suárez O M. Calcium carbonate precipitation: a review of the carbonate crystallization process and applications in bioinspired composites[J]. Nanoscale, 2016, 44: 87-107. |

| [24] | Nehrke G, Cappellen V P. Framboidal vaterite aggregates and their transformation into calcite: a morphological study[J]. Journal of Crystal Growth, 2005, 287(2): 528-530. |

| [25] | Han Y S, Hadiko G, Fuji M, et al. Effect of flow rate and CO2 content on the phase and morphology of CaCO3 prepared by bubbling method[J]. Journal of Crystal Growth, 2005, 276(3/4): 541-548. |

| [26] | Hu Z S, Shao M H, Cai Q, et al. Synthesis of needle-like aragonite from limestone in the presence of magnesium chloride[J]. Journal of Materials Processing Technology, 2008, 209(3): 1607-1611. |

| [27] | Chang R, Choi D, Kim M H, et al. Tuning crystal polymorphisms and structural investigation of precipitated calcium carbonates for CO2 mineralization[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(2): 1659-1667. |

| [28] | Udrea I, Capat C, Olaru E A, et al. Vaterite synthesis via gas-liquid route under controlled pH conditions[J]. Industrial & Engineering Chemistry Research, 2012, 51(24): 8185-8193. |

| [29] | Hu Q, Zhang J M, Teng H, et al. Growth process and crystallographic properties of ammonia-induced vaterite[J]. American Mineralogist, 2015, 97(8/9): 1437-1445. |

| [30] | Dai Y Z, Zou H F, Zhu H, et al. Controlled synthesis of calcite/vaterite/aragonite and their applications as red phosphors doped with Eu3+ ions[J]. CrystEngComm, 2017, 19(20): 2758-2767. |

| [31] | Flaten E M, Seiersten M, Andreassen J P. Polymorphism and morphology of calcium carbonate precipitated in mixed solvents of ethylene glycol and water[J]. Journal of Crystal Growth, 2009, 311(13): 3533-3538. |

| [32] | Hussein A I, Ab-Ghani Z, Mat A N C, et al. Synthesis and characterization of spherical calcium carbonate nanoparticles derived from cockle shells[J]. Applied Sciences, 2020, 10(20): 7170. |

| [33] | Huang Z Q, Huang Y Z, Yang A, et al. Formation and breakage of chain-like in preparation of nano-sized precipitated calcium carbonate[J]. Journal of Crystal Growth, 2025, 652: 128010. |

| [1] | 伍沅. 撞击流性质及其应用[J]. 化工进展, 2001(11): 8-13. |

| Wu Y. Properties and application of impinging streams[J]. Chemical Industry and Engineering Progress, 2001(11): 8-13. | |

| [2] | Yue S, Liu X Q. Study of the drying characteristics in an asymmetric impinging stream reactor[J]. Chemical Papers, 2021, 8(75): 4355-4370. |

| [3] | 方书起, 张欣悦, 李思齐, 等. 撞击流式反应器内水合物法分离沼气中CO2研究[J]. 化工学报, 2020, 71(5): 2099-2108. |

| Fang S Q, Zhang X Y, Li S Q . et al. Investigation on separation of CO2 from biogas by hydrate method in impinging stream reactor[J]. CIESC Journal, 2020, 71(5): 2099-2108. | |

| [4] | Chen L M, Dong B, Guo Y Q, et al. CFD modelling of the effects of local turbulence intensification on synthesis of LiFePO4 particles in an impinging jet reactor[J]. Chemical Engineering and Processing-Process Intensification, 2020, 155: 11. |

| [5] | Dong B, Qian H L, Xue C Y, et al. Controllable synthesis of hierarchical micro/nano structured FePO4 particles under synergistic effects of ultrasound irradiation and impinging stream[J]. Advanced Powder Technology, 2020, 10(31): 4292-4300. |

| [6] | Sahoo K, Kumar S. Green synthesis of sub 10 nm silver nanoparticles in gram scale using free impinging jet reactor[J]. Chemical Engineering and Processing-Process Intensification, 2021, 165: 12. |

| [7] | Zhang J W, Zhang J, Dong X, et al. Preparation of Ca(OH)2 nanoparticles by impinging stream reaction precipitation method[J]. The Canadian Journal of Chemical Engineering, 2023, 101(12): 7251-7262. |

| [8] | Jiao W, Qin Y, Luo S, et al. Continuous preparation of nanoscale zero-valent iron using impinging stream-rotating packed bed reactor and their application in reduction of nitrobenzene[J]. Journal of Nanoparticle Research, 2017, 19(2): 52. |

| [34] | Kontoyannis C G, Vagenas N V. Calcium carbonate phase analysis using XRD and FT-Raman spectroscopy[J]. Analyst, 2000, 125(2): 251-255. |

| [35] | Shu Y D, Liu J J, Zhang Y, et al. Considering nucleation, breakage and aggregation in morphological population balance models for crystallization processes[J]. Computers & Chemical Engineering, 2020, 136: 106781-106781. |

| [36] | Khoshkhoo S, Anwar J. Crystallization of polymorphs: the effect of solvent[J]. Journal of Physics D: Applied Physics, 1993, 26: B90-B93. |

| [37] | Masayoshi T. Zeta potential of microbubbles in aqueous solutions: electrical properties of the gas-water interface[J]. The Journal of Physical Chemistry. B, 2005, 109(46): 21858-21864. |

| [1] | 戴元燊, 邵之江, 陈伟锋, 陈宁. 基于粒数衡算方程的三元前体结晶过程粒度分布动态预测方法[J]. 化工学报, 2025, 76(8): 4119-4128. |

| [2] | 苏国庆, 田学梅, 李彦, 张建文, 张志军. 气力输送系统弯管三通的冲蚀分析及改进[J]. 化工学报, 2025, 76(8): 3894-3904. |

| [3] | 王涛, 李光明, 胡秋霞, 徐静. 基于时序演变粒子群算法的双色注射产品翘曲工艺优化[J]. 化工学报, 2025, 76(7): 3403-3415. |

| [4] | 胡家玮, 王聪, 刘美婧. 一种抑制隧道排水管道中结晶体形成的双层阻垢疏水涂层[J]. 化工学报, 2025, 76(6): 3053-3072. |

| [5] | 梁碧麟, 余倩, 贾思琦, 李芳, 李其明. Ni-MOF-74金属有机框架膜的结构调变及气体分离性能研究[J]. 化工学报, 2025, 76(6): 2714-2721. |

| [6] | 刘晗, 崔家馨, 殷梦凡, 郑涛, 张睿, 孟祥海, 刘植昌, 刘海燕, 徐春明. CuAlCl4-二甲苯络合物晶体结构及二元固液相平衡测定[J]. 化工学报, 2025, 76(5): 2241-2250. |

| [7] | 张玮杰, 何甲文, 张一鸣, 李德立, 胡光亚, 蔡骁, 王金华, 黄佐华. 燃料分层对多级旋流甲烷燃烧流场和火焰结构影响研究[J]. 化工学报, 2025, 76(4): 1754-1764. |

| [8] | 蔡本安, 张建新, 龙城君, 杜乔琛, 车勋建, 张义迎, 蔡伟华. 喷雾闪蒸制备微纳米颗粒[J]. 化工学报, 2025, 76(3): 1334-1345. |

| [9] | 侯亚祺, 张玮, 张鸿, 高飞雨, 胡嘉华. 基于机器学习与粒子群算法的LBM多相流模型优化[J]. 化工学报, 2025, 76(3): 1120-1132. |

| [10] | 董举, 余留洋, 贾晟哲, 史连军, 王诗瀚, 胡国涛, 汤伟伟, 王静康, 龚俊波. 电子级磷酸的结晶精制技术发展现状与研究进展[J]. 化工学报, 2025, 76(2): 438-453. |

| [11] | 李文宝, 胡锦鹏, 杜淼, 潘鹏举, 单国荣. 强韧P(SBMA-co-AAc)/SiO2复合水凝胶海洋防污减阻涂层[J]. 化工学报, 2025, 76(2): 787-796. |

| [12] | 张思文, 顾海明, 赵善辉. 纳米氧化铁对纤维素化学链气化的分子反应机理[J]. 化工学报, 2025, 76(1): 363-373. |

| [13] | 董沛洲, 喻慧文, 谈灵操, 徐百平, 杨芳. 基于移动粒子半隐式方法的非充满折流板双螺杆流道内混合[J]. 化工学报, 2025, 76(1): 198-207. |

| [14] | 孙娜娜, 董红妹, 郭文豪, 柳健, 胡建波, 靳爽. 改性磁性纳米粒子稳定的稠油O/W型乳状液的流变性影响因素及管输压降预测模型[J]. 化工学报, 2024, 75(S1): 143-157. |

| [15] | 韩志敏, 李江, 陈则齐, 刘威, 徐志明. 脉动流通道内不同纵向涡发生器的颗粒污垢特性[J]. 化工学报, 2024, 75(7): 2486-2496. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号