• •

收稿日期:2025-11-20

修回日期:2026-01-13

出版日期:2026-01-14

通讯作者:

詹国武

作者简介:吴艺铃(1996—),女,博士研究生,274300970@qq.com

基金资助:

Yiling WU( ), Bin CHEN, Jian TIAN, Guowu ZHAN(

), Bin CHEN, Jian TIAN, Guowu ZHAN( )

)

Received:2025-11-20

Revised:2026-01-13

Online:2026-01-14

Contact:

Guowu ZHAN

摘要:

生物质催化热裂解是制备可再生烃类燃料与化学品的关键途径,其技术核心在于高效催化剂的设计与开发。本文系统综述了金属-分子筛集成催化剂在生物质热裂解中的最新研究进展,重点分析了贵金属、过渡金属、碱(土)金属及稀土金属等与ZSM-5、SAPO-11等典型分子筛结合所构建催化剂的性能特点及其应用效果。文中探讨了金属位点与分子筛酸中心之间的协同作用机制,特别是在调控脱氧路径、提高芳烃选择性以及增强催化剂抗积碳稳定性等方面的重要作用。最后,针对当前该技术仍面临的金属与酸中心平衡调控、活性位稳定性及工业放大可行性等挑战,对未来的研究方向与发展前景进行了展望。

中图分类号:

吴艺铃, 陈彬, 田间, 詹国武. 金属-分子筛集成催化剂调控生物质热裂解制高值化学品研究进展[J]. 化工学报, DOI: 10.11949/0438-1157.20251284.

Yiling WU, Bin CHEN, Jian TIAN, Guowu ZHAN. Research progress on metal-zeolite integrated catalysts for regulating biomass pyrolysis toward high-value chemicals[J]. CIESC Journal, DOI: 10.11949/0438-1157.20251284.

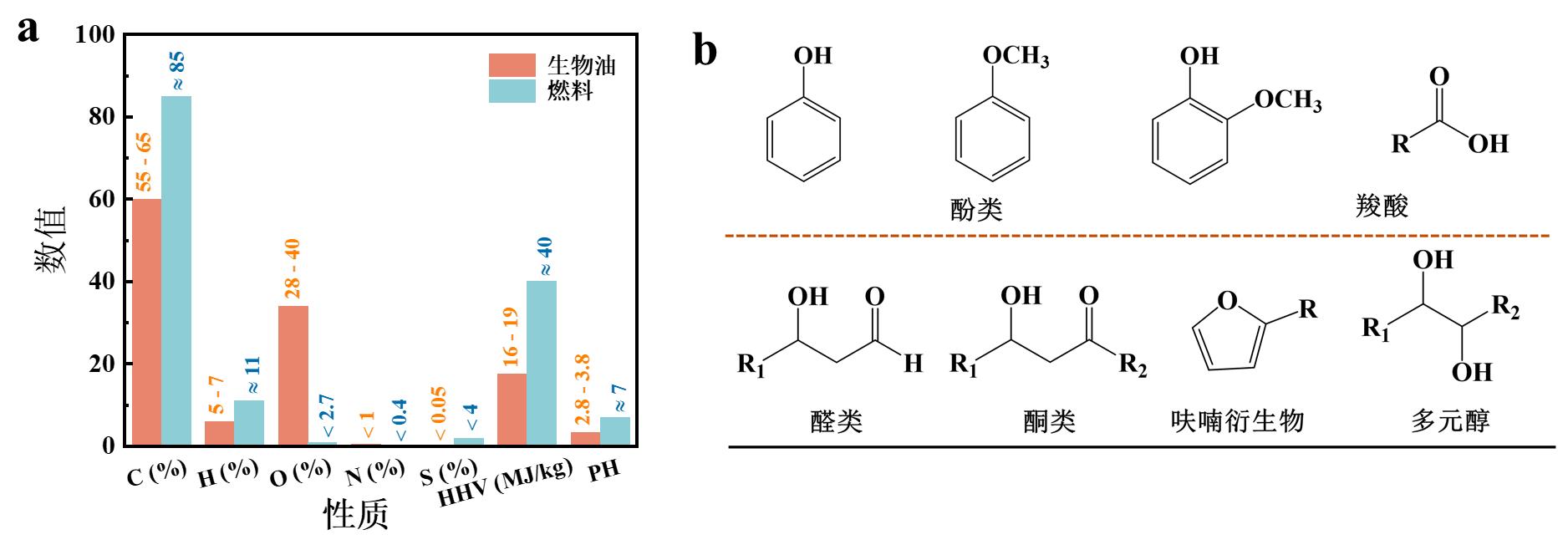

图1 (a)目标液体烃类燃料与生物油的关键性质对比;(b)生物油中典型含氧化合物的分子结构[12]

Fig. 1 (a) Comparison of key properties between target liquid hydrocarbon fuels and bio-oil; (b) Molecular structures of representative oxygenated compounds present in bio-oil

| 组分 | 起始温度/热稳定性 | 主要反应 | 关键中间体 | 产物分布与特征 | 主要副产物 |

|---|---|---|---|---|---|

| 纤维素 | 300-350 oC 热稳定性中等 | 糖苷键断裂、开环、环化 | 左旋葡聚糖、葡萄糖、呋喃环 | 产物多样性显著,以含氧化合物(如醛、酮)和轻质烯烃为主,是烯烃类的重要来源 | 反应路径复杂,易生成含氧小分子副产物,结焦适中 |

| 半纤维素 | 200-350 oC 热稳定性最低 | 解聚、脱水、支链断裂 | 木糖、乙酸、糠醛、小分子醛 | 气体产率最高,为主要不可凝气体来源,液体产物中含氧组分高 | 结焦量最低,但气体产物占比大 |

| 木质素 | 280-500 oC 热稳定性最高 | 醚键断裂、脱甲氧基、芳环缩合 | 酚类单体(如愈创木酚、苯酚等) | 芳香族产物主导,是酚类和轻质芳烃的最主要来源,但结焦率最高,易生成多环芳烃(如萘) | 结焦率最高,芳香缩合导致多环芳烃积累 |

表1 木质纤维素生物质主要组分(木质素、半纤维素和纤维素)的热解途径[32]

Table 1 Pyrolysis pathways of the primary constituents of lignocellulosic biomass: lignin, hemicellulose, and cellulose

| 组分 | 起始温度/热稳定性 | 主要反应 | 关键中间体 | 产物分布与特征 | 主要副产物 |

|---|---|---|---|---|---|

| 纤维素 | 300-350 oC 热稳定性中等 | 糖苷键断裂、开环、环化 | 左旋葡聚糖、葡萄糖、呋喃环 | 产物多样性显著,以含氧化合物(如醛、酮)和轻质烯烃为主,是烯烃类的重要来源 | 反应路径复杂,易生成含氧小分子副产物,结焦适中 |

| 半纤维素 | 200-350 oC 热稳定性最低 | 解聚、脱水、支链断裂 | 木糖、乙酸、糠醛、小分子醛 | 气体产率最高,为主要不可凝气体来源,液体产物中含氧组分高 | 结焦量最低,但气体产物占比大 |

| 木质素 | 280-500 oC 热稳定性最高 | 醚键断裂、脱甲氧基、芳环缩合 | 酚类单体(如愈创木酚、苯酚等) | 芳香族产物主导,是酚类和轻质芳烃的最主要来源,但结焦率最高,易生成多环芳烃(如萘) | 结焦率最高,芳香缩合导致多环芳烃积累 |

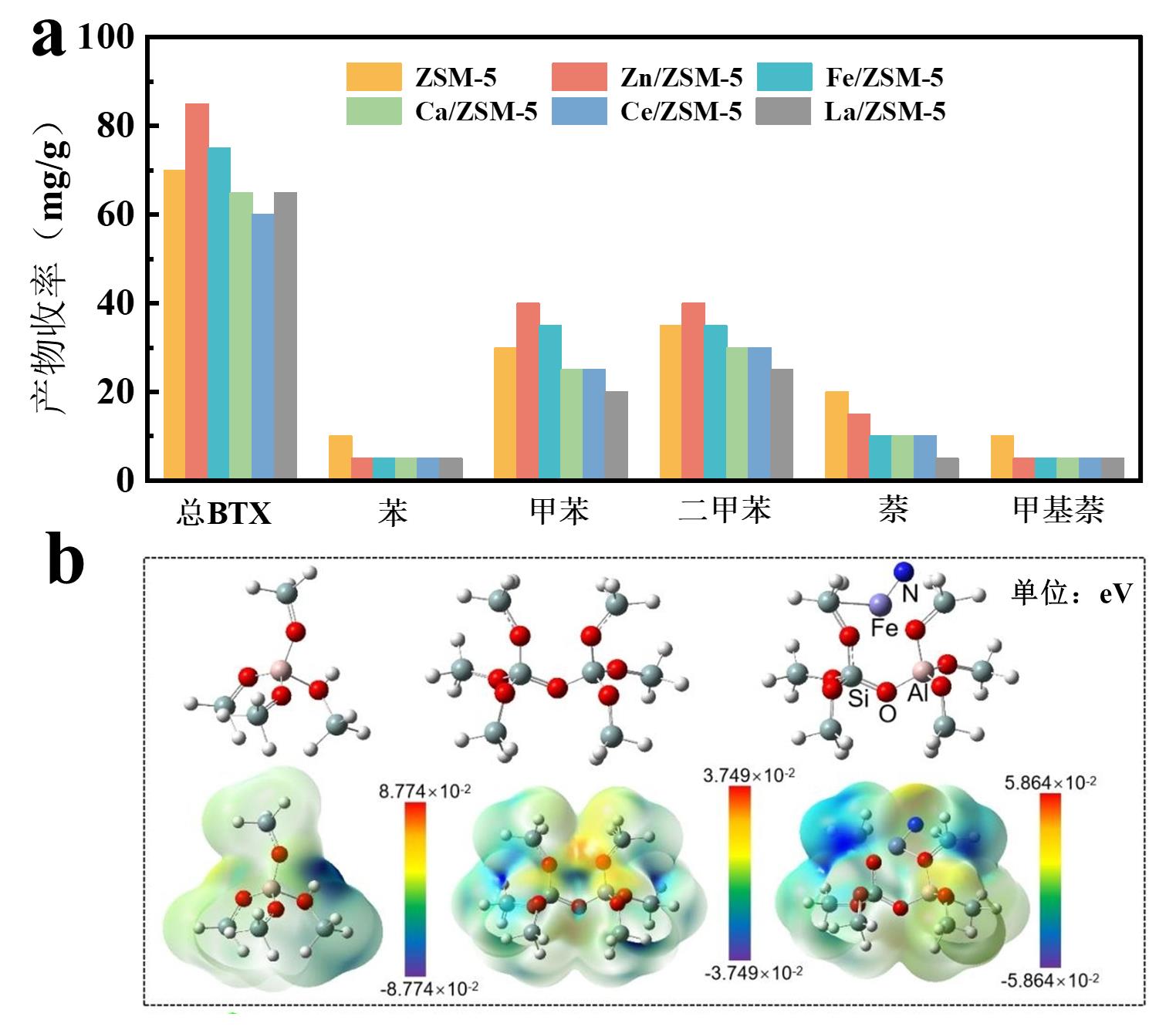

图4 (a)不同金属(Zn, Fe, Ca, Ce, La)改性ZSM-5催化剂对生物质催化热裂解生成单环芳烃产率的影响[49];(b)愈创木酚在三种催化剂模型表面吸附构型与静电势计算[50]

Fig. 4 (a) Yields of monocyclic aromatic hydrocarbons from catalytic pyrolysis of biomass over ZSM-5 catalysts modified with different metals (Zn, Fe, Ca, Ce, La); (b) Adsorption configurations and electrostatic potential calculations for guaiacol on three catalyst models

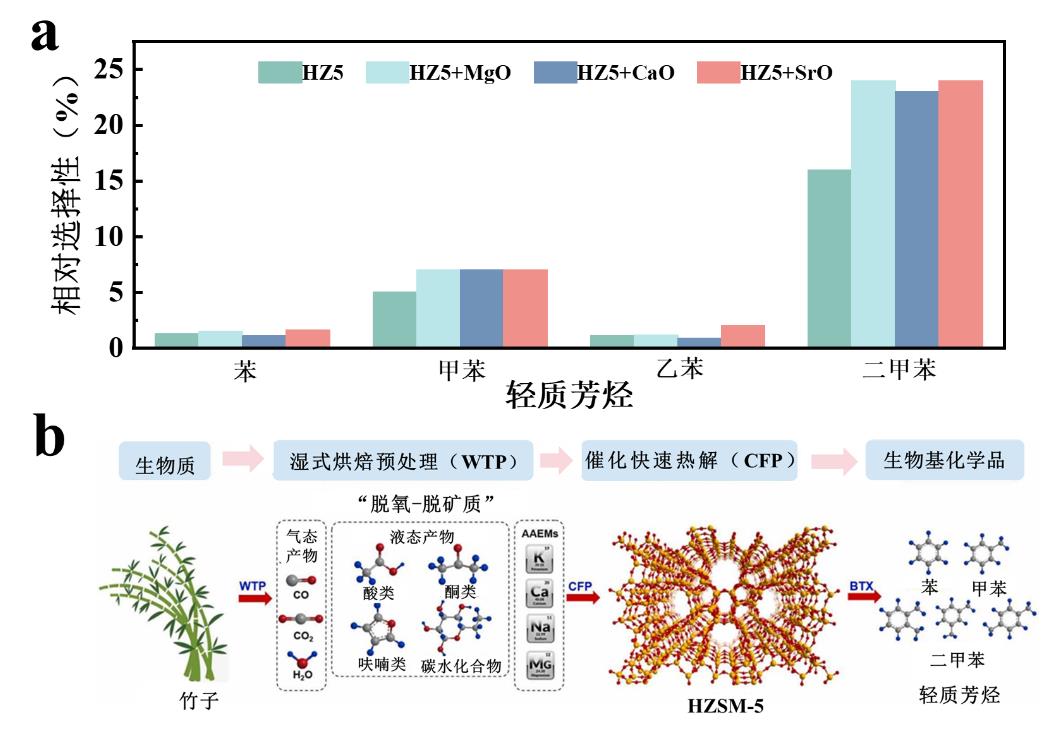

图5 (a)混合催化策略下竹屑催化热裂解产物中单环芳烃的相对选择性[55];(b)湿法焙烧预处理耦合催化快速热解提升竹子热解生物芳烃产量示意图[56]

Fig. 5 (a) Relative selectivity of monocyclic aromatic hydrocarbons from catalytic pyrolysis of bamboo sawdust using a mixed catalytic strategy; (b) Schematic of wet torrefaction pretreatment coupled with catalytic fast pyrolysis for enhancing bio-aromatics production from bamboo pyrolysis

| 催化剂 | 原料 | 生物质与催化剂的比例 | 热裂解温度/oC | 芳烃产率/% | 参考文献 |

|---|---|---|---|---|---|

| ZSM-5 | 牧草 | 10:1 | 600 | 24.5 | [ |

| Ga/ZSM-5 | 玉米秸秆 | 1∶1 | 500 | 49.4 | [ |

| Ca/ZSM-5 | 竹屑 | 3:10 | 550 | 31.3 | [ |

| Fe/ZSM-5 | 柳枝稷 | 1∶10 | 550 | 17.0 | [ |

| Pd/ZSM-5 | 麻疯树废弃物 | 1∶1 | 500 | 27.2 | [ |

| Sn/ZSM-5 | 木粉 | 1∶10 | 450 | 33.0 | [ |

表2 单金属负载分子筛催化生物质热解制备芳烃产率

Table 2 Research on the yield of aromatics prepared by catalytic pyrolysis of biomass over single - metal loaded zeolites

| 催化剂 | 原料 | 生物质与催化剂的比例 | 热裂解温度/oC | 芳烃产率/% | 参考文献 |

|---|---|---|---|---|---|

| ZSM-5 | 牧草 | 10:1 | 600 | 24.5 | [ |

| Ga/ZSM-5 | 玉米秸秆 | 1∶1 | 500 | 49.4 | [ |

| Ca/ZSM-5 | 竹屑 | 3:10 | 550 | 31.3 | [ |

| Fe/ZSM-5 | 柳枝稷 | 1∶10 | 550 | 17.0 | [ |

| Pd/ZSM-5 | 麻疯树废弃物 | 1∶1 | 500 | 27.2 | [ |

| Sn/ZSM-5 | 木粉 | 1∶10 | 450 | 33.0 | [ |

| 催化剂 | 原料 | 生物质与催化剂的比例 | 热裂解温度/oC | 芳烃产率/% | 参考文献 |

|---|---|---|---|---|---|

| Mo-Cu/ZSM-5 | 松木屑 | 1∶10 | 550 | 36.5 | [ |

| Co-Ni/ZSM-5/MCM-41 | 酶解木质素 | 1:2 | 550 | 19.0 | [ |

| Mo-Co/ZSM-5 | 褐煤 | 1:1 | 600 | 80.7 | [ |

| Ni-Ce/ZSM-5 | 甘蔗渣 | 1:1 | 500 | 13.8 | [ |

| Zn-Co/ZSM-5 | 松木粉 | 1:2 | 500 | 79.1 | [ |

表3 双金属负载分子筛催化生物质热解制备芳烃产率

Table 3 Yield of aromatics prepared by catalytic pyrolysis of biomass over bimetal-loaded zeolites. zeolites

| 催化剂 | 原料 | 生物质与催化剂的比例 | 热裂解温度/oC | 芳烃产率/% | 参考文献 |

|---|---|---|---|---|---|

| Mo-Cu/ZSM-5 | 松木屑 | 1∶10 | 550 | 36.5 | [ |

| Co-Ni/ZSM-5/MCM-41 | 酶解木质素 | 1:2 | 550 | 19.0 | [ |

| Mo-Co/ZSM-5 | 褐煤 | 1:1 | 600 | 80.7 | [ |

| Ni-Ce/ZSM-5 | 甘蔗渣 | 1:1 | 500 | 13.8 | [ |

| Zn-Co/ZSM-5 | 松木粉 | 1:2 | 500 | 79.1 | [ |

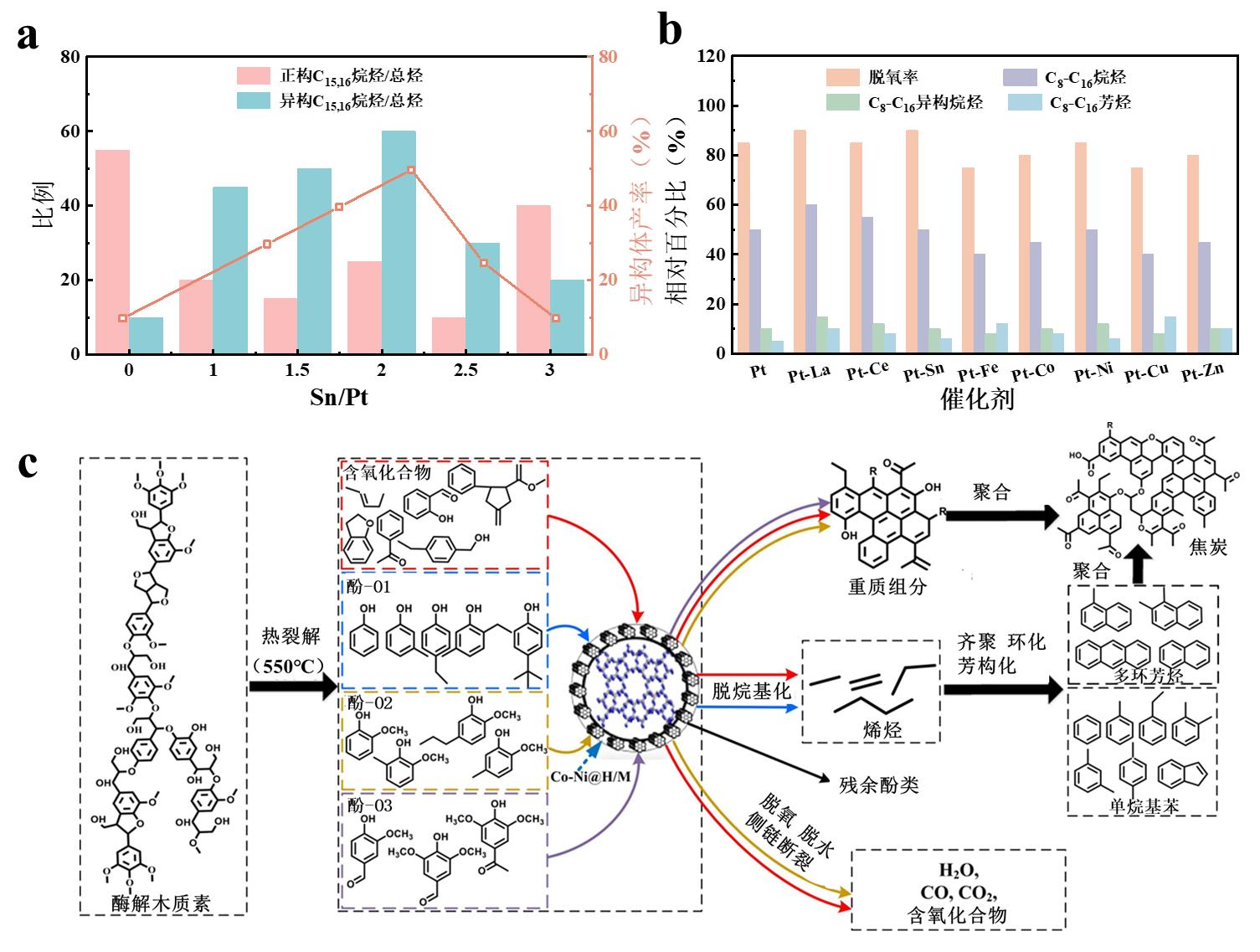

图6 (a)Sn添加量对催化剂异构化活性的影响[70];(b)不同金属助剂对Pt/SAPO-11催化剂性能的影响[71];(c)酶解木质素在Co-Ni@HZSM-5/MCM-41催化剂上热解转化为单环芳烃等产物的可能路径[66]

Fig. 6 (a) Effect of Sn loading on the isomerization activity of the catalysts; (b) Influence of different metal promoters on the performance of Pt/SAPO-11 catalyst; (c) Proposed reaction pathway for the conversion of enzymatic hydrolysis lignin to monocyclic aromatic hydrocarbons and other products via pyrolysis over a Co-Ni@HZSM-5/MCM-41 catalyst

| [1] | 郝泽光, 张乾, 高增林, 等. 生物质与催化裂化油浆共热解协同作用研究[J]. 化工学报, 2022, 73(9): 4070-4078. |

| Hao Z G, Zhang Q, Gao Z L, et al. Study on synergistic effect of biomass and FCC slurry co-pyrolysis[J]. CIESC Journal, 2022, 73(9): 4070-4078. | |

| [2] | Pang S S. Advances in thermochemical conversion of woody biomass to energy, fuels and chemicals[J]. Biotechnology Advances, 2019, 37(4): 589-597. |

| [3] | Lynd L R, Beckham G T, Guss A M, et al. Toward low-cost biological and hybrid biological/catalytic conversion of cellulosic biomass to fuels[J]. Energy & Environmental Science, 2022, 15(3): 938-990. |

| [4] | Stöcker M. Perspectives for thermochemical conversions of lignocellulosic biomass[J]. Small, 2024, 20(39): 2302495. |

| [5] | Boddula R, Lee Y Y, Masimukku S, et al. Sustainable hydrogen production: solar-powered biomass conversion explored through (photo)electrochemical advancements[J]. Process Safety and Environmental Protection, 2024, 186: 1149-1168. |

| [6] | Xia Q, Gao X, Wu J, et al. Efficient synthesis of organosulfur compounds via electrochemical biomass conversion[J]. Nature Synthesis, 2025, 4(6): 765-775. |

| [7] | 杨峥豪, 何臻, 常玉龙, 等. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| Yang Z H, He Z, Chang Y L, et al. Research progress in downer fluidized bed reactor for biomass fast pyrolysis[J]. CIESC Journal, 2023, 74(6): 2249-2263. | |

| [8] | Poopisut P, Boonyanan P, Boontawan P, et al. Oleaginous yeast, Rhodotorula paludigena CM33, platform for bio-oil and biochar productions via fast pyrolysis[J]. Biotechnology for Biofuels and Bioproducts, 2023, 16(1): 17. |

| [9] | 余娅洁, 李静茹, 周树锋, 等. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74 (7): 2735-2752. |

| Yu Y J, Li J R, Zhou S F, et al. Construction of nanomaterial and integrated catalyst based on biological template: a review[J]. CIESC Journal, 2023, 74 (7): 2735-2752. | |

| [10] | Tian J, Tan K B, Li Y X, et al. Engineering hierarchical zeolites via bio-inspired routes: from synthesis to application[J]. Coordination Chemistry Reviews, 2026, 549: 217349. |

| [11] | Mishra R K, Chistie S M, Naika S U, et al. Catalytic pyrolysis of biomass over zeolites for bio-oil and chemical production: a review on their structure, porosity and acidity co-relation[J]. Bioresource Technology, 2022, 366: 128189. |

| [12] | Shi Y C, Xing E H, Wu K J, et al. Recent progress on upgrading of bio-oil to hydrocarbons over metal/zeolite bifunctional catalysts[J]. Catalysis Science & Technology, 2017, 7(12): 2385-2415. |

| [13] | Wu K J, Wu Y L, Chen Y, et al. Heterogeneous catalytic conversion of biobased chemicals into liquid fuels in the aqueous phase[J]. ChemSusChem, 2016, 9(12): 1355-1385. |

| [14] | 仉利, 姚宗路, 赵立欣, 等. 生物质热化学转化提质及其催化剂研究进展[J]. 化工学报, 2020, 71(8): 3416-3427. |

| Zhang L, Yao Z L, Zhao L X, et al. Research progress on thermochemical conversion of biomass to enhance quality and catalyst[J]. CIESC Journal, 2020, 71(8): 3416-3427. | |

| [15] | Iyodo Mohammed H, Garba K, Isa Ahmed S, et al. Recent advances on strategies for upgrading biomass pyrolysis vapour to value-added bio-oils for bioenergy and chemicals[J]. Sustainable Energy Technologies and Assessments, 2023, 55: 102984. |

| [16] | 陈彬, 吴艺铃, 黄加乐, 等. 油脂催化热裂解制备液体燃料和化学品研究进展[J]. 中国科学: 化学, 2023, 53(8): 1494-1509. |

| Chen B, Wu Y L, Huang J L, et al. Recent advances in the conversion of lipids to liquid fuels and chemicals via catalytic pyrolysis[J]. Scientia Sinica Chimica, 2023, 53(8): 1494-1509. | |

| [17] | Keller T C, Desai K, Mitchell S, et al. Design of base zeolite catalysts by alkali-metal grafting in alcoholic media[J]. ACS Catalysis, 2015, 5(9): 5388-5396. |

| [18] | Hilten R, Weber J, Kastner J R. Continuous upgrading of fast pyrolysis oil by simultaneous esterification and hydrogenation[J]. Energy & Fuels, 2016, 30(10): 8357-8368. |

| [19] | Bhurse R, Gautam N, Singh N, et al. Study on catalytic pyrolysis of rice straw for bio-oil production[J]. BioEnergy Research, 2025, 18(1): 49. |

| [20] | Valle B, Palos R, Bilbao J, et al. Role of zeolite properties in bio-oil deoxygenation and hydrocarbons production by catalytic cracking[J]. Fuel Processing Technology, 2022, 227: 107130. |

| [21] | Vuppaladadiyam A K, Vuppaladadiyam S S V, Awasthi A, et al. Biomass pyrolysis: a review on recent advancements and green hydrogen production[J]. Bioresource Technology, 2022, 364: 128087. |

| [22] | Xu T, Chen L Y, Chen J, et al. Evolution in functional groups of agricultural straw during pyrolysis at elevated temperature: in situ synchrotron radiation infrared spectroscopy[J]. Bioresource Technology, 2025, 437: 133125. |

| [23] | Zheng Y W, Tao L, Yang X Q, et al. Insights into pyrolysis and catalytic co-pyrolysis upgrading of biomass and waste rubber seed oil to promote the formation of aromatics hydrocarbon[J]. International Journal of Hydrogen Energy, 2018, 43(34): 16479-16496. |

| [24] | Premchand P, Demichelis F, Chiaramonti D, et al. Biochar production from slow pyrolysis of biomass under CO2 atmosphere: a review on the effect of CO2 medium on biochar production, characterisation, and environmental applications[J]. Journal of Environmental Chemical Engineering, 2023, 11(3): 110009. |

| [25] | Yang C Y, Li R, Zhang B, et al. Pyrolysis of microalgae: a critical review[J]. Fuel Processing Technology, 2019, 186: 53-72. |

| [26] | Yang Y, Zhang Y Q, Omairey E, et al. Intermediate pyrolysis of organic fraction of municipal solid waste and rheological study of the pyrolysis oil for potential use as bio-bitumen[J]. Journal of Cleaner Production, 2018, 187: 390-399. |

| [27] | Adelawon B O, Latinwo G K, Eboibi B E, et al. Comparison of the slow, fast, and flash pyrolysis of recycled maize-cob biomass waste, box-benhken process optimization and characterization studies for the thermal fast pyrolysis production of bio-energy[J]. Chemical Engineering Communications, 2022, 209(9): 1246-1276. |

| [28] | Ighalo J O, Iwuchukwu F U, Eyankware O E, et al. Flash pyrolysis of biomass: a review of recent advances[J]. Clean Technologies and Environmental Policy, 2022, 24(8): 2349-2363. |

| [29] | Garcìa-Pérez M, Chaala A, Pakdel H, et al. Vacuum pyrolysis of softwood and hardwood biomass: comparison between product yields and bio-oil properties[J]. Journal of Analytical and Applied Pyrolysis, 2007, 78(1): 104-116. |

| [30] | Kan T, Strezov V, Evans T J, et al. Lignocellulosic biomass pyrolysis: a review of product properties and effects of pyrolysis parameters[J]. Renewable and Sustainable Energy Reviews, 2016, 57: 1126-1140. |

| [31] | Zhang C T, Chao L, Zhang Z M, et al. Pyrolysis of cellulose: evolution of functionalities and structure of bio-char versus temperature[J]. Renewable and Sustainable Energy Reviews, 2021, 135: 110416. |

| [32] | Chen D Y, Cen K H, Zhuang X Z, et al. Insight into biomass pyrolysis mechanism based on cellulose, hemicellulose, and lignin: evolution of volatiles and kinetics, elucidation of reaction pathways, and characterization of gas, biochar and bio-oil[J]. Combustion and Flame, 2022, 242: 112142. |

| [33] | Leng E W, Guo Y L, Chen J W, et al. A comprehensive review on lignin pyrolysis: mechanism, modeling and the effects of inherent metals in biomass[J]. Fuel, 2022, 309: 122102. |

| [34] | Dada T K, Sheehan M, Murugavelh S, et al. A review on catalytic pyrolysis for high-quality bio-oil production from biomass[J]. Biomass Conversion and Biorefinery, 2023, 13(4): 2595-2614. |

| [35] | Yang S S, Gu J X, Dai B Q, et al. A critical review of the synthesis and applications of spinel-derived catalysts to bio-oil upgrading[J]. ChemSusChem, 2025, 18(4): e202401115. |

| [36] | Wang S R, Ru B, Lin H Z, et al. Pyrolysis mechanism of hemicellulose monosaccharides in different catalytic processes[J]. Chemical Research in Chinese Universities, 2014, 30(5): 848-854. |

| [37] | Wang K G, Johnston P A, Brown R C. Comparison of in-situ and ex-situ catalytic pyrolysis in a micro-reactor system[J]. Bioresource Technology, 2014, 173: 124-131. |

| [38] | Sankaranarayanan S, Won W. Catalytic pyrolysis of biomass to produce bio-oil using layered double hydroxides (LDH)-derived materials[J]. GCB Bioenergy, 2024, 16(3): e13124. |

| [39] | Patel M, Zhang X L, Kumar A. Techno-economic and life cycle assessment on lignocellulosic biomass thermochemical conversion technologies: a review[J]. Renewable and Sustainable Energy Reviews, 2016, 53: 1486-1499. |

| [40] | Huang D X, Song G X, Li R C, et al. Investigation on in-situ and ex-situ catalysis of metal salt in biomass photo-thermal pyrolysis: effects on decoupled primary and secondary reactions[J]. Fuel, 2026, 405: 136638. |

| [41] | 卢欣欣, 蔡东仁, 詹国武. 基于固体前体构建集成催化剂及CO2加氢研究进展[J]. 化工进展, 2024, 43(5): 2786-2802. |

| Lu X X, Cai D R, Zhan G W. Research progress in the construction of integrated catalysts based on solid precursors and their application in CO2 hydrogenation[J]. Chemical Industry and Engineering Progress, 2024, 43(5): 2786-2802. | |

| [42] | Iliopoulou E F, Stefanidis S D, Kalogiannis K G, et al. Catalytic upgrading of biomass pyrolysis vapors using transition metal-modified ZSM-5 zeolite[J]. Applied Catalysis B: Environmental, 2012, 127: 281-290. |

| [43] | Fermoso J, Hernando H, Jana P, et al. Lamellar and pillared ZSM-5 zeolites modified with MgO and ZnO for catalytic fast-pyrolysis of eucalyptus woodchips[J]. Catalysis Today, 2016, 277: 171-181. |

| [44] | 聂懿宸, 李帅哲, Phidsavard Keomeesay, 等. 贵金属(Pt/Pd/Ru)/分子筛在油脂加氢脱氧制备高品质烃类液体燃料中的研究进展[J]. 材料导报, 2025, 39(11): 261-274. |

| Nie Y C, Li S Z, Phidsavard K, et al. Research progress on noble metals(Pt/Pd/Ru)/molecular sieve in the preparation of high-quality hydrocarbon liquid fuels through hydrodeoxygenation of fats and oils[J]. Materials Reports, 2025, 39(11): 261-274. | |

| [45] | Jeon M J, Jeon J K, Suh D J, et al. Catalytic pyrolysis of biomass components over mesoporous catalysts using Py-GC/MS[J]. Catalysis Today, 2013, 204: 170-178. |

| [46] | Zong R, Li H, Ding W T, et al. Highly dispersed Pd on zeolite/carbon nanocomposites for selective hydrodeoxygenation of biomass-derived molecules under mild conditions[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(29): 9891-9902. |

| [47] | Ren X Y, Cao J P, Ma M W, et al. Reactivity and stability of Ni encapsulated hierarchical HZSM-5 for lignite-to-aromatics via catalytic pyrolysis[J]. Fuel, 2025, 381: 133446. |

| [48] | Chen B, Yang S, Shang L M, et al. Catalytic pyrolysis of biomass to aromatics over bifunctional Ni/ZSM-5 catalysts assembled on rice husk-derived silica platform[J]. Chem Catalysis, 2024, 4(4): 100958. |

| [49] | Che Q F, Yang M J, Wang X H, et al. Influence of physicochemical properties of metal modified ZSM-5 catalyst on benzene, toluene and xylene production from biomass catalytic pyrolysis[J]. Bioresource Technology, 2019, 278: 248-254. |

| [50] | Wang Y, Cao K Q, Sun W L, et al. HZSM-5 supported with N-doped Fe for microwave catalytic pyrolysis of lignin[J]. Chemical Engineering Journal, 2024, 500: 156809. |

| [51] | Xu J, Wen Y X, Li D K, et al. Catalytic upgrading of biomass pyrolysis volatiles over Y zeolites modified with different metal oxides[J]. Fuel, 2024, 371: 131936. |

| [52] | Wu L, Xin J J, Wang Y G, et al. Hollow ZSM-5 encapsulated with single Ga-atoms for the catalytic fast pyrolysis of biomass waste[J]. Journal of Energy Chemistry, 2023, 84: 363-373. |

| [53] | Williams P T, Horne P A. The influence of catalyst type on the composition of upgraded biomass pyrolysis oils[J]. Journal of Analytical and Applied Pyrolysis, 1995, 31: 39-61. |

| [54] | Balasundram V, Ibrahim N, Kasmani R M, et al. Catalytic pyrolysis of willow wood with Me/HZSM-5 (Me = Mg, K, Fe, Ga, Ni) to produce aromatics and olefins[J]. BioResources, 2013, 8: 5612-5621. |

| [55] | Wang J, Zhong Z P, Ding K, et al. Catalytic fast pyrolysis of bamboo sawdust via a two-step bench scale bubbling fluidized bed/fixed bed reactor: study on synergistic effect of alkali metal oxides and HZSM-5[J]. Energy Conversion and Management, 2018, 176: 287-298. |

| [56] | Hu Z Y, Zhu L, Cai H Y, et al. Enhancement of the production of bio-aromatics from bamboo pyrolysis: wet torrefaction pretreatment coupled with catalytic fast pyrolysis[J]. Journal of Analytical and Applied Pyrolysis, 2023, 169: 105818. |

| [57] | Momayez F, Towfighi Darian J, Teimouri Sendesi S M. Synthesis of zirconium and cerium over HZSM-5 catalysts for light olefins production from naphtha[J]. Journal of Analytical and Applied Pyrolysis, 2015, 112: 135-140 |

| [58] | Bi J D, Liu M, Song C S, et al. C2–C4 light olefins from bioethanol catalyzed by Ce-modified nanocrystalline HZSM-5 zeolite catalysts[J]. Applied Catalysis B: Environmental, 2011, 107(1/2): 68-76. |

| [59] | Doronin V P, Sorokina T P, Lipin P V, et al. Development and introduction of zeolite containing catalysts for cracking with controlled contents of rare earth elements[J]. Catalysis in Industry, 2015, 7(1): 12-16. |

| [60] | Veses A, Puértolas B, López J M, et al. Promoting deoxygenation of bio-oil by metal-loaded hierarchical ZSM-5 zeolites[J]. ACS Sustainable Chemistry & Engineering, 2016, 4(3): 1653-1660. |

| [61] | Cheng S Y, Wei L, Zhao X H, et al. Conversion of prairie cordgrass to hydrocarbon biofuel over Co-Mo/HZSM-5 using a two-stage reactor system[J]. Energy Technology, 2016, 4(6): 706-713. |

| [62] | Mullen C A, Boateng A A. Production of aromatic hydrocarbons via catalytic pyrolysis of biomass over Fe-modified HZSM-5 zeolites[J]. ACS Sustainable Chemistry & Engineering, 2015, 3(7): 1623-1631. |

| [63] | Vichaphund S, Aht-ong D, Sricharoenchaikul V, et al. Production of aromatic compounds from catalytic fast pyrolysis of Jatropha residues using metal/HZSM-5 prepared by ion-exchange and impregnation methods[J]. Renewable Energy, 2015, 79: 28-37. |

| [64] | Veses A, Puértolas B, Callén M S, et al. Catalytic upgrading of biomass derived pyrolysis vapors over metal-loaded ZSM-5 zeolites: effect of different metal cations on the bio-oil final properties[J]. Microporous and Mesoporous Materials, 2015, 209: 189-196. |

| [65] | Huang Y B, Wei L, Crandall Z, et al. Combining Mo–Cu/HZSM-5 with a two-stage catalytic pyrolysis system for pine sawdust thermal conversion[J]. Fuel, 2015, 150: 656-663. |

| [66] | Zheng X, Zhong Z P, Zhang B, et al. Catalytic pyrolysis of enzymatic hydrolysis lignin by transition-metal modified HZSM-5/MCM-41 core–shell catalyst for the enhancement of monocyclic aromatic hydrocarbons[J]. Journal of Analytical and Applied Pyrolysis, 2023, 169: 105849. |

| [67] | Ren X Y, Cao J P, Zhao X Y, et al. Catalytic upgrading of pyrolysis vapors from lignite over mono/bimetal-loaded mesoporous HZSM-5[J]. Fuel, 2018, 218: 33-40. |

| [68] | Balasundram V, Zaman K K, Ibrahim N, et al. Catalytic upgrading of pyrolysis vapours over metal modified HZSM-5 via in-situ pyrolysis of sugarcane bagasse: effect of nickel to cerium ratio on HZSM-5[J]. Journal of Analytical and Applied Pyrolysis, 2018, 134: 309-325. |

| [69] | Zheng Y W, Wang F, Yang X Q, et al. Study on aromatics production via the catalytic pyrolysis vapor upgrading of biomass using metal-loaded modified H-ZSM-5[J]. Journal of Analytical and Applied Pyrolysis, 2017, 126: 169-179. |

| [70] | Chen N, Ren Y X, Qian E W. Elucidation of the active phase in PtSn/SAPO-11 for hydrodeoxygenation of methyl palmitate[J]. Journal of Catalysis, 2016, 334: 79-88. |

| [71] | Chen Y B, Li X Y, Liu S J, et al. Effects of metal promoters on one-step Pt/SAPO-11 catalytic hydrotreatment of castor oil to C8-C16 alkanes[J]. Industrial Crops and Products, 2020, 146: 112182. |

| [72] | Persson H, Duman I, Wang S, et al. Catalytic pyrolysis over transition metal-modified zeolites: a comparative study between catalyst activity and deactivation[J]. Journal of Analytical and Applied Pyrolysis, 2019, 138: 54-61. |

| [1] | 钱慧慧, 王文婕, 陈文尧, 周兴贵, 张晶, 段学志. 聚丙烯定向转化制芳烃:金属-分子筛协同催化机制[J]. 化工学报, 2025, 76(9): 4838-4849. |

| [2] | 李泽权, 蔡天宇, 刘家骏, 陈奇志, 肖沛文, 徐小飞, 赵双良. 木质素基絮凝剂的合成与应用[J]. 化工学报, 2025, 76(9): 4709-4722. |

| [3] | 周媚, 曾浩桀, 蒋火炎, 蒲婷, 曾星星, 刘宝玉. 二次晶化法改性合成MTW分子筛及其在苯和环己烯烷基化反应中的催化性能[J]. 化工学报, 2025, 76(8): 4071-4080. |

| [4] | 刘沁雯, 叶恒冰, 张逸伟, 朱法华, 钟文琪. 煤与禽类粪便混合燃料的加压富氧燃烧特性研究[J]. 化工学报, 2025, 76(7): 3487-3497. |

| [5] | 陆昕晟, 郭晓镭, 王世丞, 陆海峰, 刘海峰. 秸秆类生物质的粉碎特性研究[J]. 化工学报, 2025, 76(7): 3539-3551. |

| [6] | 吴天灏, 叶霆威, 林延, 黄振. 生物质化学链气化原位补氢制H2/CO可控合成气[J]. 化工学报, 2025, 76(7): 3498-3508. |

| [7] | 张畅, 解强, 沙雨桐, 王炳杰, 梁鼎成, 刘金昌. 低灰低硅竹炭的制备及衍生硬炭的电化学性能[J]. 化工学报, 2025, 76(6): 3073-3083. |

| [8] | 姬海燕, 刘家印, 吴海军, 何璟琳, 靳紫恒, 魏钿航, 江霞. 低温等离子体在生物质气化制氢中的应用研究进展[J]. 化工学报, 2025, 76(6): 2419-2433. |

| [9] | 戴文智, 沈雄健, 宋晓博, 杨新乐. 生物质双级蒸发双回热有机朗肯循环系统环境分析[J]. 化工学报, 2025, 76(3): 1230-1242. |

| [10] | 严珅, 席悦, 张盛宇, 陈晓东, 吴铎. 基于IGC-ZLC法测定有机蒸气在ZSM-5中的晶内扩散系数[J]. 化工学报, 2025, 76(3): 1076-1083. |

| [11] | 翟紫航, 蒋杰, 李锦锦, 赵玲, 奚桢浩. 基于2,5-呋喃二甲酸的三元无规共聚酯PBSF的制备与性能[J]. 化工学报, 2025, 76(2): 868-878. |

| [12] | 邹立, 马砺, 张鹏宇, 魏高明, 郭睿智, 赵钦新. 煅烧电石渣强化生物质气化制氢特性及其反应动力学研究[J]. 化工学报, 2025, 76(11): 6040-6057. |

| [13] | 张盼兮, 田大勇, 次东辉, 王帅, 罗坤, 樊建人. 流化床生物质与煤掺混燃烧的全三维数值模拟研究[J]. 化工学报, 2025, 76(11): 6027-6039. |

| [14] | 金雨昕, 吴文莉, 童婳, 叶代启, 陈礼敏. 高分散双位点Co物种协同催化CO2氧化乙烷脱氢制乙烯的研究[J]. 化工学报, 2025, 76(10): 5128-5140. |

| [15] | 曹文轩, 吴泊洋, 李俊, 刘天冀, 曾阔, 杨海平, 陈汉平. 熔融盐辅助生物质热化学高值化转化研究进展[J]. 化工学报, 2025, 76(10): 4976-4987. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号