CIESC Journal ›› 2020, Vol. 71 ›› Issue (10): 4792-4799.DOI: 10.11949/0438-1157.20200672

• Energy and environmental engineering • Previous Articles Next Articles

Changyuan TAO1,2( ),Xiuxiu WANG1,2,Zuohua LIU1,2,Renlong LIU1,2,Jinhua LUAN3

),Xiuxiu WANG1,2,Zuohua LIU1,2,Renlong LIU1,2,Jinhua LUAN3

Received:2020-06-03

Revised:2020-07-14

Online:2020-10-05

Published:2020-10-05

Contact:

Changyuan TAO

陶长元1,2( ),王秀秀1,2,刘作华1,2,刘仁龙1,2,栾进华3

),王秀秀1,2,刘作华1,2,刘仁龙1,2,栾进华3

通讯作者:

陶长元

作者简介:陶长元(1963—),男,博士,教授,基金资助:CLC Number:

Changyuan TAO, Xiuxiu WANG, Zuohua LIU, Renlong LIU, Jinhua LUAN. Research on leaching rate enhancement and organic matter removal in wet-process phosphoric acid[J]. CIESC Journal, 2020, 71(10): 4792-4799.

陶长元, 王秀秀, 刘作华, 刘仁龙, 栾进华. 湿法磷酸浸出强化及有机质去除研究[J]. 化工学报, 2020, 71(10): 4792-4799.

Add to citation manager EndNote|Ris|BibTeX

| 成分 | 含量/%(mass) |

|---|---|

| Ca | 60.98 |

| P | 20.36 |

| Si | 7.19 |

| F | 4.29 |

| Mg | 2.83 |

| Fe | 2.01 |

| Al | 0.78 |

| K | 0.43 |

| S | 0.37 |

Table1 Composition of phosphate rock

| 成分 | 含量/%(mass) |

|---|---|

| Ca | 60.98 |

| P | 20.36 |

| Si | 7.19 |

| F | 4.29 |

| Mg | 2.83 |

| Fe | 2.01 |

| Al | 0.78 |

| K | 0.43 |

| S | 0.37 |

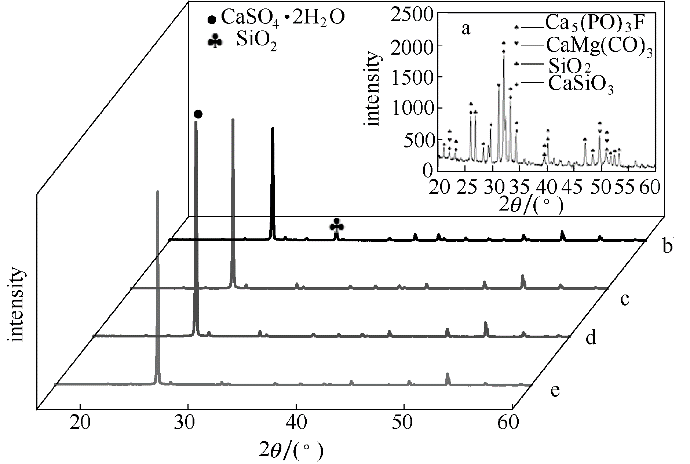

Fig.8 XRD patterns of phosphate rock under different extraction conditions a—original phosphate rock; b—direct acid extraction; c—H2O2 extraction; d—MnO2 extraction; e—H2O2with MnO2 extraction

| 1 | Arisht S N, Abdul P M, Liu C M, et al. Biotoxicity assessment and lignocellulosic structural changes of phosphoric acid pre-treated young coconut husk hydrolysate for biohydrogen production[J]. International Journal of Hydrogen Energy, 2019, 44(1): 5830-5843. |

| 2 | Matta S, Stephan K, Stephan J, et al. Phosphoric acid production by attacking phosphate rock with recycled hexafluosilicic acid[J]. International Journal of Mineral Processing, 2017, 161(10): 21-27. |

| 3 | Ma H, Feng X, Zeng B. Self-anticorrosion for the combustion tower of heat recovered thermal process phosphoric acid production[J]. Process Safety and Environmental Protection, 2018, 118(8): 330-347. |

| 4 | 孟详东, 黄群星, 严建华, 等. 磷在污泥热解过程中的迁移转化[J]. 化工学报, 2018, 69(7): 3208-3215. |

| Meng X D, Huang Q X, Yan J H, et al. Migration and transformation of phosphorus during pyrolysis process of sewage sludge[J]. CIESC Journal, 2018, 69(7): 3208-3215. | |

| 5 | 张海燕, 邹密, 杨劲, 等. 中低品位磷矿直接制湿法磷酸技术研究[J]. 化工矿物与加工, 2015, 44(1): 17-20. |

| Zhang H Y, Zhou M, Yang J, et al.Study on the direct preparation of wet phosphoric acid from medium and low grade phosphate[J]. Industrial Minerals and Processing, 2015, 44(1): 17-20. | |

| 6 | Han Y, Cui X, Lv X, et al. Preparation and characterization of geopolymers based on a phosphoric-acid-activated electrolytic manganese dioxide residue[J]. Journal of Cleaner Production, 2018, 205(20): 488-498. |

| 7 | Li G, Zhou Q, Zhu Z, et al. Selective leaching of nickel and cobalt from limonitic laterite using phosphoric acid: an alternative for value-added processing of laterite[J]. Journal of Cleaner Production, 2018, 189(10): 620-626. |

| 8 | Chen H, Li W, Wang J, et al. Adsorption of cadmium and lead ions by phosphoric acid-modified biochar generated from chicken feather: selective adsorption and influence of dissolved organic matter[J]. Bioresource Technology, 2019, 292: 12-19. |

| 9 | Khoualdia B, Loungou M, Elaloui E. Adsorption of organic matter from industrial phosphoric acid (H3PO4) onto activated bentonite[J]. Arabian Journal of Chemistry, 2017, 10: S1073-S1080. |

| 10 | Zermane S, Meniai A H. Experimental study of competitive adsorption of heavy metals and organic matter for the phosphoric acid purification[J]. Energy Procedia, 2012, 18: 888-895. |

| 11 | 李天祥, 李白玉, 刘飞, 等. 湿法磷酸中有机物的脱除方法[J]. 无机盐工业, 2008, 40(12): 44-46. |

| Li T X, Li B Y, Liu F, et al. Method for removal of organic matter from wet phosphoric acid[J]. Inorganic Chemicals Industry, 2008, 40(12): 44-46. | |

| 12 | 李燕凤, 李军, 任永胜, 等. 预分散溶剂萃取用于浓缩湿法磷酸脱色[J]. 无机盐工业, 2007,5 (7): 33-35. |

| Li Y F, Li J, Ren Y S, et al. Predispersed solvent extraction is used to concentrate wet phosphoric acid for decolorization[J]. Inorganic Chemicals Industry, 2007,5 (7): 33-35. | |

| 13 | 林倩, 耿建铭, 江燕斌, 等. 超纯过氧化氢制备中有机杂质的吸附净化技术进展 [J]. 化工进展, 2006, 67(9): 1031-1035. |

| Lin Q, Geng J M, Jiang Y B, et al. Advances in the adsorption and purification of organic impurities in the preparation of ultrapure hydrogen peroxide[J]. Chemical industry and Engineering Progress, 2006, 67(9): 1031-1035. | |

| 14 | Ulu F, Gengec E, Kobya M. Removal of natural organic matter from Lake Terkos by EC process: studying on removal mechanism by floc size and zeta potential measurement and characterization by HPSEC method[J]. Journal of Water Process Engineering, 2019, 17: 31-35. |

| 15 | Särkkä H, Vepsäläinen M, Sillanpää M. Natural organic matter (NOM) removal by electrochemical methods — a review[J]. Journal of Electroanalytical Chemistry, 2015, 755(1): 100-108. |

| 16 | Vepsäläinen M, Ghiasvand M, Selin J, et al. Investigations of the effects of temperature and initial sample pH on natural organic matter (NOM) removal with electrocoagulation using response surface method (RSM)[J]. Separation and Purification Technology, 2009, 69(15): 255-261. |

| 17 | Ma L, He M, Fu P, et al. Adsorption of volatile organic compounds on modified spherical activated carbon in a new cyclonic fluidized bed[J]. Separation and Purification Technology, 2020, 235: 116146. |

| 18 | 李兵, 杨义, 刘作华, 等. 湿法磷酸固-液体系混沌混合与浸出强化行为[J]. 化工学报, 2019, 70(5): 1742-1749. |

| Li B, Yang Y, Liu Z H, et al. Olid-liquid chaotic mixing and leaching enhancement performance in phosphoric acid leaching process[J]. CIESC Journal, 2019, 70(5): 1742-1749. | |

| 19 | Guillossou R, Le Roux J, Mailler R, et al. Influence of dissolved organic matter on the removal of 12 organic micropollutants from wastewater effluent by powdered activated carbon adsorption[J]. Water Research, 2020, 172: 115487. |

| 20 | 陈亮, 李军, 钟本和. 浓缩湿法磷酸脱色研究 [J]. 无机盐工业, 2005, 37(7): 21-22. |

| Chen L, Li J, Zhong B H. Study on decolorization of concentrated wet phosphoric acid[J]. Inorganic Chemicals Industry, 2005, 37(7): 21-22. | |

| 21 | Ike I A, Karanfil T, Cho J, et al. Oxidation byproducts from the degradation of dissolved organic matter by advanced oxidation processes — a critical review[J]. Water Research, 2019, 164: 114929. |

| 22 | Wang H, Quan B, Bo G, et al. Advanced oxidation treatment of dissolved organic matter from wastewater treatment plant secondary effluent using scattering electrical reactor[J]. Journal of Cleaner Production, 2020, 267: 122258. |

| 23 | Fu L, Wu C, Zhou Y, et al. Ozonation reactivity characteristics of dissolved organic matter in secondary petrochemical wastewater by single ozone, ozone/H2O2, and ozone/catalyst[J]. Chemosphere, 2019, 233: 34-43. |

| 24 | Razaviarani V, Zazo J A, Casas J A, et al. Coupled fenton-denitrification process for the removal of organic matter and total nitrogen from coke plant wastewater[J]. Chemosphere, 2019, 224: 653-657. |

| 25 | Zhang Y, Liu H, Dai X, et al. The release of organic matter, nitrogen, phosphorus and heavy metals from erythromycin fermentation residue under heat-activated persulfate oxidation conditioning[J]. Science of the Total Environment, 2020, 724: 138349. |

| 26 | Ernst M, Lurot F, Schrotter J C. Catalytic ozonation of refractory organic model compounds in aqueous solution by aluminum oxide[J]. Applied Catalysis B: Environmental, 2004, 47(8): 15-25. |

| 27 | Tang Y, Zheng S, Xu Y, et al. Advanced batteries based on manganese dioxide and its composites[J]. Energy Storage Materials, 2018, 12: 284-309. |

| 28 | 国家技术监督局, 化工部化工矿山设计研究院. 磷矿石和磷精矿中五氧化二磷含量的测定磷钼酸喹啉重量法和容量法: GB/T 1871.1—1995[S]. 北京: 中国标准出版社, 1995. |

| The State Bureau of Quality and Technical Supervision, Chemical Mine Design and Research Institute, Ministry of Chemical Industry, Standardization Administration of The People's Republic of China. Phosphate rock and concentrate—determination of phosphrous pentoxide content—quinoline phosphomolybdate gravimetric and volumetric methods: GB/T 1871.1—1995[S]. Beijing: Standards Press of China, 1995. | |

| 29 | 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 循环冷却水中总有机碳(TOC)的测定: GB/T 32116—2015[S]. 北京: 中国标准出版社, 2015. |

| General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Determination of total organic carbon (TOC) in industrial circulating cooling water: GB/T 32116-2015 [S]. Beijing: Standards Press of China, 2015. | |

| 30 | Shu J, Liu R, Liu Z, et al. Enhanced extraction of manganese from electrolytic manganese residue by electrochemical[J]. Journal of Electroanalytical Chemistry, 2016, 780(1): 32-37. |

| 31 | Vega E, Valdés H. New evidence of the effect of the chemical structure of activated carbon on the activity to promote radical generation in an advanced oxidation process using hydrogen peroxide[J]. Microporous and Mesoporous Materials, 2018, 259(15): 1-8. |

| 32 | Hao Z, Wang J, Yin Y, et al. Abiotic formation of organoiodine compounds by manganese dioxide induced iodination of dissolved organic matter[J]. Environment Pollution, 2018, 236: 672-679. |

| 33 | Shu J, Liu R, Liu Z, et al. Manganese recovery and ammonia nitrogen removal from simulation wastewater by pulse electrolysis[J]. Separation and Purification Technology, 2016, 168(10): 107-113. |

| 34 | Zhang X, Wang J, Dong X X, et al. Functionalized metal-organic frameworks for photocatalytic degradation of organic pollutants in environment[J]. Chemosphere, 2019, 242: 125144. |

| 35 | Filipovic M R, Koppenol W H. The Haber-Weiss reaction — the latest revival[J]. Free Radical Biology Medicine, 2019, 145: 221-222. |

| 36 | Baldikova E, Pospiskova K, Safarikova M, et al. Non-woven fabric supported manganese dioxide microparticles as a low-cost, easily recoverable catalyst for hydrogen peroxide decomposition[J]. Materials Chemistry and Physics, 2018, 203(1): 280-283. |

| 37 | Zhang Y, Wang F, Ou P, et al. High efficiency and rapid degradation of bisphenol A by the synergy between adsorption and oxidization on the MnO2@nano hollow carbon sphere[J]. Journal of Hazardous Materials, 2018, 360(15): 223-232. |

| 38 | Qu F, Yan Z, Liu W, et al. Effects of manganese dioxides on the ultrafiltration membrane fouling by algal extracellular organic matter[J]. Separation and Purification Technology, 2015, 153(16): 29-36. |

| [1] | Pan LI, Junyang MA, Zhihao CHEN, Li WANG, Yun GUO. Effect of the morphology of Ru/α-MnO2 on NH3-SCO performance [J]. CIESC Journal, 2023, 74(7): 2908-2918. |

| [2] | Yuming TU, Gaoyan SHAO, Jianjie CHEN, Feng LIU, Shichao TIAN, Zhiyong ZHOU, Zhongqi REN. Advances in the design, synthesis and application of calcium-based catalysts [J]. CIESC Journal, 2023, 74(7): 2717-2734. |

| [3] | Chen WANG, Xiufeng SHI, Xianfeng WU, Fangjia WEI, Haohong ZHANG, Yin CHE, Xu WU. Preparation of Mn3O4 catalyst by redox method and study on its catalytic oxidation performance and mechanism of toluene [J]. CIESC Journal, 2023, 74(6): 2447-2457. |

| [4] | Jian JIAN, Jiaming ZHANG, Xiang SHE, Hu ZHOU, Kuiyi YOU, Hean LUO. Correlation with the redox V4+/V5+ ratio in VPO catalysts for oxidation of cyclohexane by NO2 [J]. CIESC Journal, 2023, 74(4): 1570-1577. |

| [5] | YE Kai, LIU Xianghua, JIANG Yue, YU Ying, ZHAO Yafei, ZHUANG Ye, ZHENG Jinbao, CHEN Binghui. Combing low-temperature plasma with CeO2/13X for toluene degradation [J]. CIESC Journal, 2021, 72(7): 3706-3715. |

| [6] | SUN Jing, DONG Yilin, LI Faqi, LI Wenxiang, MA Xiaoling, WANG Wenlong. Study on adsorption and catalytic oxidation characteristics of toluene on Co3O4 modified USY molecular sieve [J]. CIESC Journal, 2021, 72(6): 3306-3315. |

| [7] | Wenjun LIANG, Yuxue ZHU, Xiujuan SHI, Huipin SUN, Sida REN. Effect of Ce doping on catalytic chlorobenzene performance of Ru/TiO2 catalysts [J]. CIESC Journal, 2020, 71(8): 3585-3593. |

| [8] | Bing LI, Yi YANG, Zuohua LIU, Changyuan TAO, Deyin GU, Chuanlin XU, Yundong WANG. Solid-liquid chaotic mixing and leaching enhancement performance in phosphoric acid leaching process [J]. CIESC Journal, 2019, 70(5): 1742-1749. |

| [9] | Shuai HE, Feng GUO, Guojun KANG, Jian YU, Xuefeng REN, Guangwen XU. Preparation of palladium-based catalysts by complexing-solvothermal method and catalytic oxidation of m-xylene [J]. CIESC Journal, 2019, 70(3): 937-943. |

| [10] | RUI Zebao, YANG Xiaoqing, CHEN Junfei, JI Hongbing. Photo-thermal synergistic catalysis for VOCs purification: current status and future perspectives [J]. CIESC Journal, 2018, 69(12): 4947-4958. |

| [11] | ZHANG Juan, HU Yanhui, REN Tengjie, LI Weikang, ZHAO Dishun. Photocatalytic oxidation desulfurization by iron phthalocyanine supported on Ti-MCM-41 [J]. CIESC Journal, 2015, 66(9): 3437-3443. |

| [12] | XU Xihua, FEI Zhaoyang, CHEN Xian, TANG Jihai, CUI Mifen, QIAO Xu. CeO2 nanoclusters stabilized in aerogel matrix as catalysts for Cl2 production from HCl oxidation [J]. CIESC Journal, 2015, 66(9): 3421-3427. |

| [13] | LUO Lei, DAI Chengyi, ZHANG Anfeng, SONG Chunshan, GUO Xinwen. Review on catalytic wet peroxide oxidation process [J]. CIESC Journal, 2015, 66(9): 3319-3323. |

| [14] | CHEN Yanguang, HE Feng, DAGA Shivalik, LI Fanxing. Redox conversion of methane with Fe2O3-CaTixM1-xO3 composite oxides for hydrogen and liquid fuel co-production [J]. CIESC Journal, 2014, 65(7): 2741-2750. |

| [15] | ZHANG Haiyan,CAI Lei,ZHOU Huanyu. Properties of the catalytic oxidative desulfurization of model oil using phosphotungstic acid alkyl betaine [J]. Chemical Industry and Engineering Progree, 2014, 33(07): 1769-1772. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||