CIESC Journal ›› 2021, Vol. 72 ›› Issue (10): 5183-5195.DOI: 10.11949/0438-1157.20210506

• Catalysis, kinetics and reactors • Previous Articles Next Articles

Xin HUANG( ),Yuxia LIN,Binghui YAN,Yueming LIU(

),Yuxia LIN,Binghui YAN,Yueming LIU( )

)

Received:2021-04-13

Revised:2021-07-04

Online:2021-10-05

Published:2021-10-05

Contact:

Yueming LIU

通讯作者:

刘月明

作者简介:黄鑫(1995—),男,硕士研究生,基金资助:CLC Number:

Xin HUANG,Yuxia LIN,Binghui YAN,Yueming LIU. Deactivated TS-1 as an efficient catalyst for catalytic cracking of butene to propene[J]. CIESC Journal, 2021, 72(10): 5183-5195.

黄鑫,林玉霞,阎炳会,刘月明. 失活TS-1高效催化

Add to citation manager EndNote|Ris|BibTeX

| Zeolite | Acidity① | Si/Ti② | Si/Al2② | Pore properties③ | Size④/ nm | |||||

|---|---|---|---|---|---|---|---|---|---|---|

WA/ (mmol/g) | MSA/ (mmol/g) | Total/ (mmol/g) | MSA/WA | ABET/ (m2/g) | Vtotal/ (cm3/g) | Vmic/ (cm3/g) | ||||

| MTS-1 | ~0 | ~0 | ~0 | – | 41 | 500 | 0.42 | 0.20 | ~250 | |

| De-TS-1 | 0.19 | 0.08 | 0.27 | 0.42 | 23 | 342 | 0.33 | 0.14 | <100 | |

| ZSM-5(70) | 0.32 | 0.45 | 0.77 | 1.41 | 63 | 428 | 0.70 | 0.15 | ~500 | |

Table 1 The comparison of acid properties and pore structure among MTS-1, De-TS-1 and ZSM-5(70)

| Zeolite | Acidity① | Si/Ti② | Si/Al2② | Pore properties③ | Size④/ nm | |||||

|---|---|---|---|---|---|---|---|---|---|---|

WA/ (mmol/g) | MSA/ (mmol/g) | Total/ (mmol/g) | MSA/WA | ABET/ (m2/g) | Vtotal/ (cm3/g) | Vmic/ (cm3/g) | ||||

| MTS-1 | ~0 | ~0 | ~0 | – | 41 | 500 | 0.42 | 0.20 | ~250 | |

| De-TS-1 | 0.19 | 0.08 | 0.27 | 0.42 | 23 | 342 | 0.33 | 0.14 | <100 | |

| ZSM-5(70) | 0.32 | 0.45 | 0.77 | 1.41 | 63 | 428 | 0.70 | 0.15 | ~500 | |

| Zeolite | Conversion( %(mol) | Selectivity/% (mol) | P/E/ (mol/mol) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| H2 | Arom. | |||||||||

| MTS-1 | ~0.50 | — | — | — | — | — | — | — | — | — |

| De-TS-1 | 42.19 | 4.22 | 47.87 | 34.29 | 5.69 | 0.19+0.05 | 6.84 | 0.29 | 0.47 | 11.34 |

| C-CAT | 46.41 | 4.74 | 49.71 | 31.42 | 6.03 | 0.13+0.03 | 7.23 | 0.21 | 0.39 | 10.48 |

Table 2 The result of butene conversion and product distribution produced from catalytic cracking of butene over MTS-1, De-TS-1 and C-CAT

| Zeolite | Conversion( %(mol) | Selectivity/% (mol) | P/E/ (mol/mol) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| H2 | Arom. | |||||||||

| MTS-1 | ~0.50 | — | — | — | — | — | — | — | — | — |

| De-TS-1 | 42.19 | 4.22 | 47.87 | 34.29 | 5.69 | 0.19+0.05 | 6.84 | 0.29 | 0.47 | 11.34 |

| C-CAT | 46.41 | 4.74 | 49.71 | 31.42 | 6.03 | 0.13+0.03 | 7.23 | 0.21 | 0.39 | 10.48 |

| No. | Sample | Smicro①/ (m2/g) | Sexter①/ (m2/g) | Vmicro①/ (cm3/g) | Vmeso①/ (cm3/g) | Vtotal①/ (cm3/g) | Si/Ti② |

|---|---|---|---|---|---|---|---|

| 1 | De-TS-1 | 309 | 33 | 0.136 | 0.189 | 0.325 | 23 |

| 2 | AT-0.5 | 338 | 55 | 0.146 | 0.221 | 0.367 | 26 |

| 3 | AT-1.0 | 344 | 51 | 0.150 | 0.230 | 0.380 | 28 |

| 4 | AT-1.5 | 335 | 59 | 0.147 | 0.217 | 0.364 | 25 |

| 5 | AT-2.0 | 341 | 54 | 0.148 | 0.229 | 0.377 | 25 |

Table 3 The pore properties of De-TS-1 and the corresponding HNO3 modification samples

| No. | Sample | Smicro①/ (m2/g) | Sexter①/ (m2/g) | Vmicro①/ (cm3/g) | Vmeso①/ (cm3/g) | Vtotal①/ (cm3/g) | Si/Ti② |

|---|---|---|---|---|---|---|---|

| 1 | De-TS-1 | 309 | 33 | 0.136 | 0.189 | 0.325 | 23 |

| 2 | AT-0.5 | 338 | 55 | 0.146 | 0.221 | 0.367 | 26 |

| 3 | AT-1.0 | 344 | 51 | 0.150 | 0.230 | 0.380 | 28 |

| 4 | AT-1.5 | 335 | 59 | 0.147 | 0.217 | 0.364 | 25 |

| 5 | AT-2.0 | 341 | 54 | 0.148 | 0.229 | 0.377 | 25 |

| No. | Sample | 1540 cm-1/1880 cm-1 | 1447 cm-1/1880 cm-1 |

|---|---|---|---|

| 1 | De-TS-1 | 0.021 | 0.152 |

| 2 | AT-0.5 | 0.028 | 0.171 |

| 3 | AT-1.0 | 0.031 | 0.157 |

| 4 | AT-1.5 | 0.025 | 0.171 |

| 5 | AT-2.0 | 0.024 | 0.164 |

Table 4 The amount of Br?nsted and Lewis acid sites of De-TS-1 and the corresponding samples with HNO3 modification

| No. | Sample | 1540 cm-1/1880 cm-1 | 1447 cm-1/1880 cm-1 |

|---|---|---|---|

| 1 | De-TS-1 | 0.021 | 0.152 |

| 2 | AT-0.5 | 0.028 | 0.171 |

| 3 | AT-1.0 | 0.031 | 0.157 |

| 4 | AT-1.5 | 0.025 | 0.171 |

| 5 | AT-2.0 | 0.024 | 0.164 |

Fig.7 The relationship between butene conversion and product distribution produced from catalytic cracking of butene over samples and HNO3 concentration

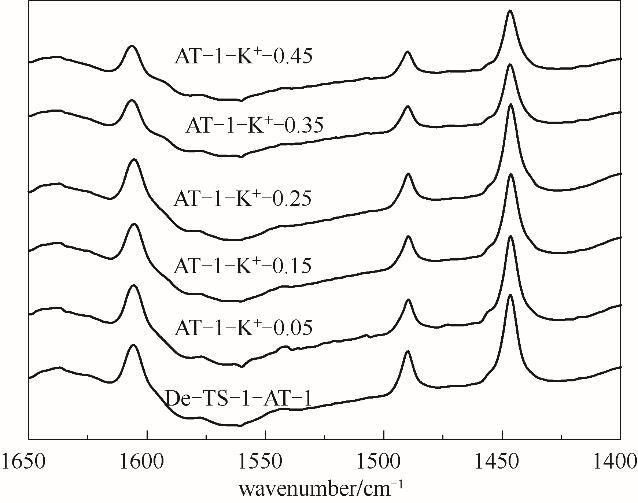

Fig.11 Py-IR spectra of De-TS-1-AT-1 and its potassium ionmodified samples under different K/Ti ratio (Desorption temperature was controlled at 373 K)

| No. | Sample | 1540 cm-1/1880 cm-1 | 1446 cm-1/1880 cm-1 |

|---|---|---|---|

| 1 | De-TS-1-AT-1 | 0.031 | 0.157 |

| 2 | AT-1-K+-0.05 | 0.023 | 0.158 |

| 3 | AT-1-K+-0.15 | 0.019 | 0.153 |

| 4 | AT-1-K+-0.25 | 0.017 | 0.155 |

| 5 | AT-1-K+-0.35 | 0.014 | 0.153 |

| 6 | AT-1-K+-0.45 | 0.011 | 0.155 |

Table 5 The amount of Br?nsted and Lewis acid sites of De-TS-1-AT-1 and its potassium ionmodified samples under different K/Ti ratio

| No. | Sample | 1540 cm-1/1880 cm-1 | 1446 cm-1/1880 cm-1 |

|---|---|---|---|

| 1 | De-TS-1-AT-1 | 0.031 | 0.157 |

| 2 | AT-1-K+-0.05 | 0.023 | 0.158 |

| 3 | AT-1-K+-0.15 | 0.019 | 0.153 |

| 4 | AT-1-K+-0.25 | 0.017 | 0.155 |

| 5 | AT-1-K+-0.35 | 0.014 | 0.153 |

| 6 | AT-1-K+-0.45 | 0.011 | 0.155 |

| No. | Sample | Cracking of | Oxidation of 1-hexene② | Alcoholysis of PO③ | ||||

|---|---|---|---|---|---|---|---|---|

| Conv.( | Yield.( % | Conv.(1-hex.)/% | Sel.(epo.)/ % | Conv.(PO)/ % | Sel.(PPM)/ % | Sel.(SPM)/ % | ||

| 1 | De-TS-1 | 42.19 | 20.20 | 12.1 | 97.0 | 77.5 | 24.9 | 75.1 |

| 2 | De-TS-1-AT-1 | 59.37 | 31.82 | 16.6 | 82.9 | 88.7 | 19.7 | 80.3 |

| 3 | AT-1-K+-0.05 | 40.40 | 18.31 | 16.9 | 86.0 | 72.5 | 20.5 | 79.5 |

| 4 | AT-1-K+-0.15 | 33.09 | 14.38 | 17.5 | 85.5 | 67.7 | 19.9 | 80.1 |

| 5 | AT-1-K+-0.25 | 26.81 | 11.20 | 17.8 | 83.0 | 55.1 | 17.6 | 82.4 |

| 6 | AT-1-K+-0.35 | 21.38 | 8.43 | 17.9 | 83.9 | 49.0 | 17.0 | 83.0 |

| 7 | AT-1-K+-0.45 | 16.89 | 6.67 | 17.7 | 82.9 | 38.7 | 16.3 | 83.7 |

Table 6 The activities in catalytic cracking of C4=, oxidation of 1-hexene and alcoholysis of PO over De-TS-1, De-TS-1-AT-1 and its potassium ion modified samples under different K/Ti ratio

| No. | Sample | Cracking of | Oxidation of 1-hexene② | Alcoholysis of PO③ | ||||

|---|---|---|---|---|---|---|---|---|

| Conv.( | Yield.( % | Conv.(1-hex.)/% | Sel.(epo.)/ % | Conv.(PO)/ % | Sel.(PPM)/ % | Sel.(SPM)/ % | ||

| 1 | De-TS-1 | 42.19 | 20.20 | 12.1 | 97.0 | 77.5 | 24.9 | 75.1 |

| 2 | De-TS-1-AT-1 | 59.37 | 31.82 | 16.6 | 82.9 | 88.7 | 19.7 | 80.3 |

| 3 | AT-1-K+-0.05 | 40.40 | 18.31 | 16.9 | 86.0 | 72.5 | 20.5 | 79.5 |

| 4 | AT-1-K+-0.15 | 33.09 | 14.38 | 17.5 | 85.5 | 67.7 | 19.9 | 80.1 |

| 5 | AT-1-K+-0.25 | 26.81 | 11.20 | 17.8 | 83.0 | 55.1 | 17.6 | 82.4 |

| 6 | AT-1-K+-0.35 | 21.38 | 8.43 | 17.9 | 83.9 | 49.0 | 17.0 | 83.0 |

| 7 | AT-1-K+-0.45 | 16.89 | 6.67 | 17.7 | 82.9 | 38.7 | 16.3 | 83.7 |

| 1 | 陈硕, 王定博, 吉媛媛, 等. 丙烯为目的产物的技术进展[J]. 石油化工, 2011, 40(2): 217-224. |

| Chen S, Wang D B, Ji Y Y, et al. Development in on-purpose propylene technology[J]. Petrochemical Technology, 2011, 40(2): 217-224. | |

| 2 | 白尔铮, 胡云光. 四种增产丙烯催化工艺的技术经济比较[J]. 工业催化, 2003, 11(5): 7-12. |

| Bai E Z, Hu Y G. Techno-economics of four types of propylene promotion catalytic processes[J]. Industrial Catalysis, 2003, 11(5): 7-12. | |

| 3 | Sekiguchi M, Takamatsu Y. Process for producing propylene and aromatic hydrocarbons, and producing apparatus therefor: US8034987[P]. 2011-10-11. |

| 4 | Voskoboynikov T V, Pelekh A Y, Senetar J J. OCP catalyst with improved steam tolerance: US8609567[P]. 2013-12-17. |

| 5 | 滕加伟, 谢在库. 无黏结剂复合孔分子筛催化烯烃裂解制丙烯技术[J]. 中国科学: 化学, 2015, 45(5): 533-540. |

| Teng J W, Xie Z K. Novel binder-less hierarchical ZSM-5 catalyst for olefins catalytic cracking to produce propylene[J]. Science China Chemistry, 2015, 45(5): 533-540. | |

| 6 | 马会霞, 周峰, 武光, 等. 多级孔HZSM-5分子筛催化快速热解生物质制芳烃[J]. 化工学报, 2020, 71(11): 5200-5207. |

| Ma H X, Zhou F, Wu G, et al. Catalytic fast pyrolysis of biomass to aromatics over hierarchical HZSM-5[J]. CIESC Journal, 2020, 71(11): 5200-5207. | |

| 7 | 金放, 刘铁良, 王先桥, 等. 工业氟硅酸合成钛硅介孔分子筛催化环己烯环氧化[J]. 化工学报, 2016, 67(10): 4176-4186. |

| Jin F, Liu T L, Wang X Q, et al. Synthesis of mesoporous titanosilicates from industrial by-product hexafluosilicic acid and application for catalytic cyclohexene epoxidation[J]. CIESC Journal, 2016, 67(10): 4176-4186. | |

| 8 | 冯利利, 卢书培, 齐兴义, 等. Me-OMS-1s分子筛催化叔丁基过氧化氢分解制备叔丁醇[J]. 化工学报, 2015, 66(10): 3965-3970. |

| Feng L L, Lu S P, Qi X Y, et al. Catalytic decomposition of tert-butyl hydroperoxide into tert-butyl alcohol over Me-OMS-1s molecular sieves[J]. CIESC Journal, 2015, 66(10): 3965-3970. | |

| 9 | Zhu X X, Liu S L, Song Y Q, et al. Catalytic cracking of C4 alkenes to propene and ethene: influences of zeolites pore structures and Si/Al2 ratios[J]. Applied Catalysis A: General, 2005, 288(1/2): 134-142. |

| 10 | Zeng P H, Liang Y, Ji S F, et al. Preparation of phosphorus-modified PITQ-13 catalysts and their performance in 1-butene catalytic cracking[J]. Journal of Energy Chemistry, 2014, 23(2): 193-200. |

| 11 | Meusinger J, Corma A. Influence of zeolite composition and structure on hydrogen transfer reactions from hydrocarbons and from hydrogen[J]. Journal of Catalysis, 1996, 159(2): 353-360. |

| 12 | Shen K X, Huang X, Wang J, et al. Synthesis of FER/MFI composite zeolite using isopropylamine as a structure-directing agent[J]. Microporous and Mesoporous Materials, 2020, 297: 110027. |

| 13 | Lin L F, Qiu C F, Zhuo Z X, et al. Acid strength controlled reaction pathways for the catalytic cracking of 1-butene to propene over ZSM-5[J]. Journal of Catalysis, 2014, 309: 136-145. |

| 14 | Lin L F, Zhao S F, Zhang D W, et al. Acid strength controlled reaction pathways for the catalytic cracking of 1-pentene to propene over ZSM-5[J]. ACS Catalysis, 2015, 5(7): 4048-4059. |

| 15 | Zhao S F, Yang D, Zhang X W, et al. ZSM-5 with controllable acidity as an efficient catalyst for a highly adjustable propene/ethene ratio in the 1-butene cracking[J]. Chemical Communications, 2016, 52(75): 11191-11194. |

| 16 | Iwase Y, Sakamoto Y, Shiga A, et al. Shape-selective catalysis determined by the volume of a zeolite cavity and the reaction mechanism for propylene production by the conversion of butene using a proton-exchanged zeolite[J]. The Journal of Physical Chemistry C, 2012, 116(8): 5182-5196. |

| 17 | Epelde E, Ibañez M, Aguayo A T, et al. Differences among the deactivation pathway of HZSM-5 zeolite and SAPO-34 in the transformation of ethylene or 1-butene to propylene[J]. Microporous and Mesoporous Materials, 2014, 195: 284-293. |

| 18 | Arudra P, Bhuiyan T I, Akhtar M N, et al. Silicalite-1 as efficient catalyst for production of propene from 1-butene[J]. ACS Catalysis, 2014, 4(11): 4205-4214. |

| 19 | Hattori H, Arudra P, Abdalla A, et al. Infrared study of silanol groups on dealuminated high silica MFI zeolite to correlate different types of silanol groups with activity for conversion of 1-butene to propene[J]. Catalysis Letters, 2020, 150(3): 771-780. |

| 20 | Zhao G L, Teng J W, Xie Z K, et al. Effect of phosphorus on HZSM-5 catalyst for C4-olefin cracking reactions to produce propylene[J]. Journal of Catalysis, 2007, 248(1): 29-37. |

| 21 | Xue N H, Chen X K, Nie L, et al. Understanding the enhancement of catalytic performance for olefin cracking: hydrothermally stable acids in P/HZSM-5[J]. Journal of Catalysis, 2007, 248(1): 20-28. |

| 22 | Epelde E, Santos J I, Florian P, et al. Controlling coke deactivation and cracking selectivity of MFI zeolite by H3PO4 or KOH modification[J]. Applied Catalysis A: General, 2015, 505: 105-115. |

| 23 | Xu R F, Liu J X, Liang C C, et al. Effect of alkali metal ion modification on the catalytic performance of nano-HZSM-5 zeolite in butene cracking[J]. Journal of Fuel Chemistry and Technology, 2011, 39(6): 449-454. |

| 24 | Li J W, Ma H F, Sun Q W, et al. Effect of iron and phosphorus on HZSM-5 in catalytic cracking of 1-butene[J]. Fuel Processing Technology, 2015, 134: 32-38. |

| 25 | 姚旭婷, 黄鑫, 林玉霞, 等. 失活TS-1高效催化环己烯水合生成环己醇的研究[J]. 化学学报, 2020, 78(10): 1111-1119. |

| Yao X T, Huang X, Lin Y X, et al. Deactivated TS-1 as efficient catalyst for hydration of cyclohexene to cyclohexanol[J]. Acta Chimica Sinica, 2020, 78(10): 1111-1119. | |

| 26 | 卓佐西, 林龙飞, 邓秀娟, 等. 钛硅分子筛催化环己酮液相氨肟化固定床工艺[J]. 催化学报,2013, 34(3): 604-611. |

| Zhuo Z X, Lin L F, Deng X J, et al. Fixed-bed process of liquid-phase ammoximation of cyclohexanone over titanosilicates[J]. Chinese Journal of Catalysis, 2013, 34(3): 604-611. | |

| 27 | Taramasso M, Perego G, Notari B. Preparation of porous crystalline synthetic material comprised of silicon and titanium oxides: US4410501[P]. 1983-10-18. |

| 28 | Nijhuis T A, Huizinga B J, Makkee M, et al. Direct epoxidation of propene using gold dispersed on TS-1 and other titanium-containing supports[J]. Industrial & Engineering Chemistry Research, 1999, 38(3): 884-891. |

| 29 | 孙斌. 环己酮氨肟化反应过程中钛硅分子筛的溶解流失研究[J]. 石油炼制与化工, 2005, 36(11): 54-58. |

| Sun B. Study on dissolution erosion of titanium silicalite zeolite in cyclohehanone ammoximation[J]. Petroleum Processing and Petrochemicals, 2005, 36(11): 54-58. | |

| 30 | Su J, Xiong G, Zhou J C, et al. Amorphous Ti species in titanium silicalite-1: structural features, chemical properties, and inactivation with sulfosalt[J]. Journal of Catalysis, 2012, 288: 1-7. |

| 31 | Fang X Q, Wang Q, Zheng A M, et al. Fluorine-planted titanosilicate with enhanced catalytic activity in alkene epoxidation with hydrogen peroxide[J]. Catalysis Science & Technology, 2012, 2(12): 2433. |

| 32 | Wang Y, Liu Y M, Li X H, et al. Intermolecular condensation of ethylenediamine to 1, 4-diazabicyclo[2, 2, 2]octane over TS-1 catalysts[J]. Journal of Catalysis, 2009, 266(2): 258-267. |

| 33 | Vayssilov G N. Structural and physicochemical features of titanium silicalites[J]. Catalysis Reviews, 1997, 39(3): 209-251. |

| 34 | Blasco T, Camblor M A, Corma A, et al. The state of Ti in titanoaluminosilicates isomorphous with zeolite.beta[J]. Journal of the American Chemical Society, 1993, 115(25): 11806-11813. |

| 35 | Notari B. Titanium silicalites[J]. Catalysis Today, 1993, 18(2): 163-172. |

| 36 | Liu Z F, Davis R J. Investigation of the structure of microporous Ti-Si mixed oxides by X-ray, UV reflectance, FT-Raman, and FT-IR spectroscopies[J]. The Journal of Physical Chemistry, 1994, 98(4): 1253-1261. |

| 37 | 刘银乾, 李永祥, 吴巍, 等. 环己酮氨肟化反应体系中TS-1分子筛失活原因的研究[J]. 石油炼制与化工, 2002, 33(5): 41-45. |

| Liu Y Q, Li Y X, Wu W, et al. Study on deactivation behavior of ts-1 molecular sieve in cyclohexanone ammoximation[J]. Petroleum Processing and Petrochemicals, 2002, 33(5): 41-45. | |

| 38 | Itoh M, Hattori H, Tanabe K. The acidic properties of TiO2-SiO2 and its catalytic activities for the amination of phenol, the hydration of ethylene and the isomerization of butene[J]. Journal of Catalysis, 1974, 35(2): 225-231. |

| 39 | Post J G, van Hooff J H C. Acidity and activity of H-ZSM-5 measured with NH3-t.p.d. and n-hexane cracking[J]. Zeolites, 1984, 4(1): 9-14. |

| 40 | Farneth W E, Gorte R J. Methods for characterizing zeolite acidity[J]. Chemical Reviews, 1995, 95(3): 615-635. |

| 41 | Al-Dughaither A S, de Lasa H. HZSM-5 zeolites with different SiO2/Al2O3 ratios. Characterization and NH3 desorption kinetics[J]. Industrial & Engineering Chemistry Research, 2014, 53(40): 15303-15316. |

| 42 | Corma A, Orchillés A V. Current views on the mechanism of catalytic cracking[J]. Microporous and Mesoporous Materials, 2000, 35/36: 21-30. |

| 43 | Emeis C A. Determination of integrated molar extinction coefficients for infrared absorption bands of pyridine adsorbed on solid acid catalysts[J]. Journal of Catalysis, 1993, 141(2): 347-354. |

| 44 | Barzetti T, Selli E, Moscotti D, et al. Pyridine and ammonia as probes for FTIR analysis of solid acid catalysts[J]. Journal of the Chemical Society, Faraday Transactions, 1996, 92(8): 1401. |

| 45 | den Hollander M A, Wissink M, Makkee M, et al. Gasoline conversion: reactivity towards cracking with equilibrated FCC and ZSM-5 catalysts[J]. Applied Catalysis A: General, 2002, 223(1/2): 85-102. |

| 46 | Wu P, Tatsumi T, Komatsu T, et al. A novel titanosilicate with MWW structure(Ⅰ): Hydrothermal synthesis, elimination of extraframework titanium, and characterizations[J]. The Journal of Physical Chemistry B, 2001, 105(15): 2897-2905. |

| 47 | Liu H, Lu G Z, Guo Y L, et al. Effect of pretreatment on properties of TS-1/diatomite catalyst for hydroxylation of phenol by H2O2 in fixed-bed reactor[J]. Catalysis Today, 2004, 93/94/95: 353-357. |

| 48 | Qi Y Y, Ye C B, Zhuang Z, et al. Preparation and evaluation of titanium silicalite-1 utilizing pretreated titanium dioxide as a titanium source[J]. Microporous and Mesoporous Materials, 2011, 142(2/3): 661-665. |

| 49 | 阎炳会. C4=/C5=催化裂解C2=/C3=导向生成反应路径的研究[D]. 上海: 华东师范大学, 2019. |

| Yan B H. Study on the reaction pathway of C4=/C5= catalytic cracking to C2=/C3= [D]. Shanghai: East China Normal University, 2019. | |

| 50 | Wu L Z, Zhao S F, Lin L F, et al. In-depth understanding of acid catalysis of solvolysis of propene oxide over titanosilicates and titanosilicate/H2O2 systems[J]. Journal of Catalysis, 2016, 337: 248-259. |

| [1] | Jie CHEN, Yongsheng LIN, Kai XIAO, Chen YANG, Ting QIU. Study on catalytic synthesis of sec-butanol by tunable choline-based basic ionic liquids [J]. CIESC Journal, 2023, 74(9): 3716-3730. |

| [2] | Xuejin YANG, Jintao YANG, Ping NING, Fang WANG, Xiaoshuang SONG, Lijuan JIA, Jiayu FENG. Research progress in dry purification technology of highly toxic gas PH3 [J]. CIESC Journal, 2023, 74(9): 3742-3755. |

| [3] | Yitong LI, Hang GUO, Hao CHEN, Fang YE. Study on operating conditions of proton exchange membrane fuel cells with non-uniform catalyst distributions [J]. CIESC Journal, 2023, 74(9): 3831-3840. |

| [4] | Feifei YANG, Shixi ZHAO, Wei ZHOU, Zhonghai NI. Sn doped In2O3 catalyst for selective hydrogenation of CO2 to methanol [J]. CIESC Journal, 2023, 74(8): 3366-3374. |

| [5] | Kaixuan LI, Wei TAN, Manyu ZHANG, Zhihao XU, Xuyu WANG, Hongbing JI. Design of cobalt-nitrogen-carbon/activated carbon rich in zero valent cobalt active site and application of catalytic oxidation of formaldehyde [J]. CIESC Journal, 2023, 74(8): 3342-3352. |

| [6] | Xin YANG, Xiao PENG, Kairu XUE, Mengwei SU, Yan WU. Preparation of molecularly imprinted-TiO2 and its properties of photoelectrocatalytic degradation of solubilized PHE [J]. CIESC Journal, 2023, 74(8): 3564-3571. |

| [7] | Yajie YU, Jingru LI, Shufeng ZHOU, Qingbiao LI, Guowu ZHAN. Construction of nanomaterial and integrated catalyst based on biological template: a review [J]. CIESC Journal, 2023, 74(7): 2735-2752. |

| [8] | Pan LI, Junyang MA, Zhihao CHEN, Li WANG, Yun GUO. Effect of the morphology of Ru/α-MnO2 on NH3-SCO performance [J]. CIESC Journal, 2023, 74(7): 2908-2918. |

| [9] | Yuming TU, Gaoyan SHAO, Jianjie CHEN, Feng LIU, Shichao TIAN, Zhiyong ZHOU, Zhongqi REN. Advances in the design, synthesis and application of calcium-based catalysts [J]. CIESC Journal, 2023, 74(7): 2717-2734. |

| [10] | Qiyu ZHANG, Lijun GAO, Yuhang SU, Xiaobo MA, Yicheng WANG, Yating ZHANG, Chao HU. Recent advances in carbon-based catalysts for electrochemical reduction of carbon dioxide [J]. CIESC Journal, 2023, 74(7): 2753-2772. |

| [11] | Jipeng ZHOU, Wenjun HE, Tao LI. Reaction engineering calculation of deactivation kinetics for ethylene catalytic oxidation over irregular-shaped catalysts [J]. CIESC Journal, 2023, 74(6): 2416-2426. |

| [12] | Tan ZHANG, Guang LIU, Jinping LI, Yuhan SUN. Performance regulation strategies of Ru-based nitrogen reduction electrocatalysts [J]. CIESC Journal, 2023, 74(6): 2264-2280. |

| [13] | Chen WANG, Xiufeng SHI, Xianfeng WU, Fangjia WEI, Haohong ZHANG, Yin CHE, Xu WU. Preparation of Mn3O4 catalyst by redox method and study on its catalytic oxidation performance and mechanism of toluene [J]. CIESC Journal, 2023, 74(6): 2447-2457. |

| [14] | Yong LI, Jiaqi GAO, Chao DU, Yali ZHAO, Boqiong LI, Qianqian SHEN, Husheng JIA, Jinbo XUE. Construction of Ni@C@TiO2 core-shell dual-heterojunctions for advanced photo-thermal catalytic hydrogen generation [J]. CIESC Journal, 2023, 74(6): 2458-2467. |

| [15] | Xiqing ZHANG, Yanting WANG, Yanhong XU, Shuling CHANG, Tingting SUN, Ding XUE, Lihong ZHANG. Effect of Mg content on isobutane dehydrogenation properties over nanosheets supported Pt-In catalysts [J]. CIESC Journal, 2023, 74(6): 2427-2435. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||