CIESC Journal ›› 2022, Vol. 73 ›› Issue (9): 4034-4044.DOI: 10.11949/0438-1157.20220340

• Energy and environmental engineering • Previous Articles Next Articles

Xinyi LUO1,2( ), Chao FENG1, Jing LIU1(

), Chao FENG1, Jing LIU1( ), Yu QIAO1(

), Yu QIAO1( )

)

Received:2022-03-07

Revised:2022-05-29

Online:2022-10-09

Published:2022-09-05

Contact:

Jing LIU, Yu QIAO

通讯作者:

刘晶,乔瑜

作者简介:罗欣宜(1996—),女,硕士研究生,luoxinyi@hust.edu.cn

基金资助:CLC Number:

Xinyi LUO, Chao FENG, Jing LIU, Yu QIAO. Phosphorus recovery from products of sewage sludge via different thermal treatment processes[J]. CIESC Journal, 2022, 73(9): 4034-4044.

罗欣宜, 冯超, 刘晶, 乔瑜. 污泥不同热处理工艺产物磷的浸出回收实验研究[J]. 化工学报, 2022, 73(9): 4034-4044.

Add to citation manager EndNote|Ris|BibTeX

| 工业分析①/%(质量) | 元素分析②/%(质量) | 高位热值/(MJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 水分③ | 挥发分 | 灰分 | 固定碳 | C | H | N | S | O④ | |

| 51.32 | 43.66 | 56.14 | 0.20 | 50.26 | 8.18 | 9.39 | 1.12 | 31.05 | 8.73 |

Table 1 Proximate analysis and ultimate analysis of sewage sludge

| 工业分析①/%(质量) | 元素分析②/%(质量) | 高位热值/(MJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 水分③ | 挥发分 | 灰分 | 固定碳 | C | H | N | S | O④ | |

| 51.32 | 43.66 | 56.14 | 0.20 | 50.26 | 8.18 | 9.39 | 1.12 | 31.05 | 8.73 |

| 样品 | 含量/%(质量) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | P2O5 | Fe2O3 | SO3 | CaO | K2O | MgO | C | |

| 污泥 | 24.69 | 8.26 | 5.96 | 3.68 | 3.18 | 1.92 | 1.74 | 1.55 | 21.24 |

| 阴燃灰 | 54.73 | 17.56 | 9.44 | 5.85 | 1.94 | 3.46 | 3.15 | 1.68 | 0.60 |

| 焚烧灰 | 51.37 | 18.18 | 9.60 | 7.21 | 0.33 | 4.15 | 2.98 | 2.25 | 0 |

| 热解焦 | 49.83 | 18.86 | 8.75 | 6.59 | 1.18 | 4.05 | 3.17 | 2.12 | 13.74 |

Table 2 Chemical composition and carbon content of sewage sludge (SS), smouldered ash (SA), incinerated ash (IA) and pyrolysis char (PC)

| 样品 | 含量/%(质量) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | P2O5 | Fe2O3 | SO3 | CaO | K2O | MgO | C | |

| 污泥 | 24.69 | 8.26 | 5.96 | 3.68 | 3.18 | 1.92 | 1.74 | 1.55 | 21.24 |

| 阴燃灰 | 54.73 | 17.56 | 9.44 | 5.85 | 1.94 | 3.46 | 3.15 | 1.68 | 0.60 |

| 焚烧灰 | 51.37 | 18.18 | 9.60 | 7.21 | 0.33 | 4.15 | 2.98 | 2.25 | 0 |

| 热解焦 | 49.83 | 18.86 | 8.75 | 6.59 | 1.18 | 4.05 | 3.17 | 2.12 | 13.74 |

| 样品 | Y/ (g/g) | P/ (mg P/g) | R/% |

|---|---|---|---|

| 阴燃灰 | 0.58 | 41.22 | 92.50 |

| 焚烧灰 | 0.54 | 41.93 | 87.02 |

| 热解焦 | 0.66 | 38.20 | 96.89 |

Table 3 Ash/char yield, P content and P retention rate of smouldered ash (SA), incinerated ash (IA) and pyrolysis char (PC)

| 样品 | Y/ (g/g) | P/ (mg P/g) | R/% |

|---|---|---|---|

| 阴燃灰 | 0.58 | 41.22 | 92.50 |

| 焚烧灰 | 0.54 | 41.93 | 87.02 |

| 热解焦 | 0.66 | 38.20 | 96.89 |

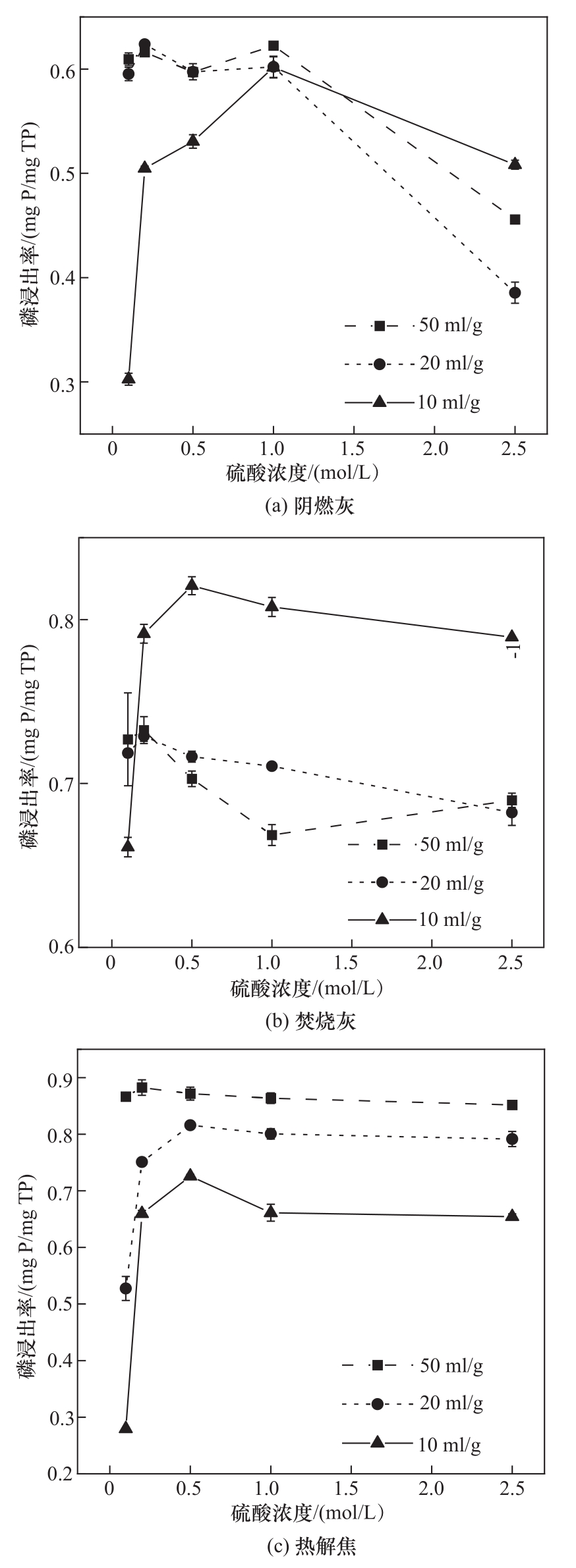

Fig.6 Phosphorus leaching proportion of smouldered ash (SA), incineration ash (IA) and pyrolysis char (PC) under different H2SO4 concentrations and liquid/solid ratios

| 动力学模型 | 阴燃灰 | 焚烧灰 | 热解焦 | ||||

|---|---|---|---|---|---|---|---|

| R2 | K/s-1 | R2 | K/s-1 | R2 | K/s-1 | ||

| Ⅰ | 0.9587 | 0.0086 | 0.9100 | 0.0296 | 0.9120 | 0.0077 | |

| Ⅱ | 0.9706 | 0.0030 | 0.9195 | 0.0125 | 0.9177 | 0.0036 | |

| Ⅲ | 0.9812 | 0.0033 | 0.9415 | 0.0192 | 0.9393 | 0.0073 | |

| Ⅳ | 0.9893 | 0.0095 | 0.9655 | 0.0875 | 0.9616 | 0.0474 | |

Table 4 R2and K of the kinetic models

| 动力学模型 | 阴燃灰 | 焚烧灰 | 热解焦 | ||||

|---|---|---|---|---|---|---|---|

| R2 | K/s-1 | R2 | K/s-1 | R2 | K/s-1 | ||

| Ⅰ | 0.9587 | 0.0086 | 0.9100 | 0.0296 | 0.9120 | 0.0077 | |

| Ⅱ | 0.9706 | 0.0030 | 0.9195 | 0.0125 | 0.9177 | 0.0036 | |

| Ⅲ | 0.9812 | 0.0033 | 0.9415 | 0.0192 | 0.9393 | 0.0073 | |

| Ⅳ | 0.9893 | 0.0095 | 0.9655 | 0.0875 | 0.9616 | 0.0474 | |

| 样品 | 最高磷浸出工况 | 优选工况 | |||||

|---|---|---|---|---|---|---|---|

| 磷回收率①/%(质量) | 磷浸出量/(mg P/g) | 硫酸单位消耗量/mmol | 磷回收率①/%(质量) | 磷浸出量/(mg P/g) | 硫酸单位消耗量/mmol | ||

| 阴燃灰 | 59.30 | 25.72 | 0.16 | 56.58 | 24.54 | 0.082 | |

| 焚烧灰 | 70.10 | 34.42 | 0.15 | 67.59 | 33.19 | 0.060 | |

| 热解焦 | 84.21 | 33.71 | 0.30 | 62.96 | 25.20 | 0.079 | |

Table 5 P recovery capability and leaching agent consumption of smouldered ash (SA), incinerated ash (IA) and pyrolysis char (PC)

| 样品 | 最高磷浸出工况 | 优选工况 | |||||

|---|---|---|---|---|---|---|---|

| 磷回收率①/%(质量) | 磷浸出量/(mg P/g) | 硫酸单位消耗量/mmol | 磷回收率①/%(质量) | 磷浸出量/(mg P/g) | 硫酸单位消耗量/mmol | ||

| 阴燃灰 | 59.30 | 25.72 | 0.16 | 56.58 | 24.54 | 0.082 | |

| 焚烧灰 | 70.10 | 34.42 | 0.15 | 67.59 | 33.19 | 0.060 | |

| 热解焦 | 84.21 | 33.71 | 0.30 | 62.96 | 25.20 | 0.079 | |

| 1 | Fang L, Wang Q M, Li J S, et al. Feasibility of wet-extraction of phosphorus from incinerated sewage sludge ash (ISSA) for phosphate fertilizer production: a critical review[J]. Critical Reviews in Environmental Science and Technology, 2021, 51(9): 939-971. |

| 2 | 旦增, 王旭彤, 颜蓓蓓, 等. 西藏生活垃圾掺烧市政污泥的焚烧特性研究[J]. 化工学报, 2019, 70(8): 3151-3159. |

| Dan Z, Wang X T, Yan B B, et al. Study on incineration characteristics of Tibetan municipal solid wastes mixed with sewage sludge[J]. CIESC Journal, 2019, 70(8): 3151-3159. | |

| 3 | Syed-Hassan S S A, Wang Y, Hu S, et al. Thermochemical processing of sewage sludge to energy and fuel: fundamentals, challenges and considerations[J]. Renewable and Sustainable Energy Reviews, 2017, 80: 888-913. |

| 4 | Schnell M, Horst T, Quicker P. Thermal treatment of sewage sludge in Germany: a review[J]. Journal of Environmental Management, 2020, 263: 110367. |

| 5 | Wyn H K, Konarova M, Beltramini J, et al. Self-sustaining smouldering combustion of waste: a review on applications, key parameters and potential resource recovery[J]. Fuel Processing Technology, 2020, 205: 106425. |

| 6 | Rashwan T L, Gerhard J I, Grant G P. Application of self-sustaining smouldering combustion for the destruction of wastewater biosolids[J]. Waste Management, 2016, 50: 201-212. |

| 7 | Fabris I, Cormier D, Gerhard J I, et al. Continuous, self-sustaining smouldering destruction of simulated faeces[J]. Fuel, 2017, 190: 58-66. |

| 8 | Meng X D, Huang Q X, Gao H P, et al. Improved utilization of phosphorous from sewage sludge (as fertilizer) after treatment by low-temperature combustion[J]. Waste Management, 2018, 80: 349-358. |

| 9 | Fang L, Li J S, Guo M Z, et al. Phosphorus recovery and leaching of trace elements from incinerated sewage sludge ash (ISSA)[J]. Chemosphere, 2018, 193: 278-287. |

| 10 | Kleemann R, Chenoweth J, Clift R, et al. Comparison of phosphorus recovery from incinerated sewage sludge ash (ISSA) and pyrolysed sewage sludge char (PSSC)[J]. Waste Management, 2017, 60: 201-210. |

| 11 | Donatello S, Cheeseman C R. Recycling and recovery routes for incinerated sewage sludge ash (ISSA): a review[J]. Waste Management, 2013, 33(11): 2328-2340. |

| 12 | Adam C, Peplinski B, Michaelis M, et al. Thermochemical treatment of sewage sludge ashes for phosphorus recovery[J]. Waste Management, 2009, 29(3): 1122-1128. |

| 43 | Fu X, Liu M, Chen Y. Research progresses on recovery of phosphorus from sewage sludge ash by wet chemical method[J]. Environmental Protection of Chemical Industry, 2017, 37(3): 276-281. |

| 44 | Zhang P Z, Zhang X X, Li Y F, et al. Influence of pyrolysis temperature on chemical speciation, leaching ability, and environmental risk of heavy metals in biochar derived from cow manure[J]. Bioresource Technology, 2020, 302: 122850. |

| 45 | Baba A A, Adekola F A. A study of dissolution kinetics of a Nigerian galena ore in hydrochloric acid[J]. Journal of Saudi Chemical Society, 2012, 16(4): 377-386. |

| 46 | Dickinson C F, Heal G R. Solid-liquid diffusion controlled rate equations[J]. Thermochimica Acta, 1999, 340/341: 89-103. |

| 47 | Ottosen L M, Kirkelund G M, Jensen P E. Extracting phosphorous from incinerated sewage sludge ash rich in iron or aluminum[J]. Chemosphere, 2013, 91(7): 963-969. |

| 48 | 李伟新. 浸提时间对城市污泥重金属浸出特性的影响[J]. 水科学与工程技术, 2012(2): 43-45. |

| Li W X. Experimental study on the effects of extraction time on the leachability of heavy metals in sewage sludge[J]. Water Sciences and Engineering Technology, 2012(2): 43-45. | |

| 13 | 郝晓地, 于晶伦, 刘然彬, 等. 剩余污泥焚烧灰分磷回收及其技术进展[J]. 环境科学学报, 2020, 40(4): 1149-1159. |

| Hao X D, Yu J L, Liu R B, et al. Advances of phosphorus recovery from the incineration ashes of excess sludge and its associated technologies[J]. Acta Scientiae Circumstantiae, 2020, 40(4): 1149-1159. | |

| 14 | Zhu Y, Zhai Y B, Li S H, et al. Thermal treatment of sewage sludge: a comparative review of the conversion principle, recovery methods and bioavailability-predicting of phosphorus[J]. Chemosphere, 2022, 291: 133053. |

| 15 | Fahimi A, Federici S, Depero L E, et al. Evaluation of the sustainability of technologies to recover phosphorus from sewage sludge ash based on embodied energy and CO2 footprint[J]. Journal of Cleaner Production, 2021, 289: 125762. |

| 16 | Liang S, Chen H M, Zeng X H, et al. A comparison between sulfuric acid and oxalic acid leaching with subsequent purification and precipitation for phosphorus recovery from sewage sludge incineration ash[J]. Water Research, 2019, 159: 242-251. |

| 17 | Zhang F S, Yamasaki S I, Nanzyo M. Application of waste ashes to agricultural land—effect of incineration temperature on chemical characteristics[J]. Science of the Total Environment, 2001, 264(3): 205-214. |

| 18 | Reuna S, Väisänen A. To incinerate or not?—Effects of incineration on the concentrations of heavy metals and leaching efficiency of post-precipitated sewage sludge (RAVITATM)[J]. Waste Management, 2020, 118: 241-246. |

| 19 | 何天澄, 朱学良, 范浩然, 等. 城市固废自维持阴燃处理的调控因素实验研究[J]. 工程热物理学报, 2020, 41(9): 2333-2344. |

| He T C, Zhu X L, Fan H R, et al. Self-sustaining smoldering treatment of municipal solid wastes: controlling parameters[J]. Journal of Engineering Thermophysics, 2020, 41(9): 2333-2344. | |

| 20 | 邓文义, 严建华, 李晓东, 等. 流化床内干化污泥燃烧污染物排放特性研究[J]. 浙江大学学报(工学版), 2008, 42(10): 1805-1811. |

| Deng W Y, Yan J H, Li X D, et al. Emission characteristics of pollutants during fluidized-bed incineration of pre-dried sewage sludge[J]. Journal of Zhejiang University (Engineering Science), 2008, 42(10): 1805-1811. | |

| 21 | 廖艳芬, 漆雅庆, 马晓茜.城市污水污泥焚烧处理环境影响分析[J]. 环境科学学报, 2009, 29(11): 2359-2365. |

| Liao Y F, Qi Y Q, Ma X Q. Environmental impact assessment of sewage sludge incineration treatments[J]. Acta Scientiae Circumstantiae, 2009, 29(11): 2359-2365. | |

| 22 | Shao J G, Lee D H, Yan R, et al. Agglomeration characteristics of sludge combustion in a bench-scale fluidized bed combustor[J]. Energy & Fuels, 2007, 21(5): 2608-2614. |

| 23 | Wang L, Skjevrak G, Hustad J E, et al. Sintering characteristics of sewage sludge ashes at elevated temperatures[J]. Fuel Processing Technology, 2012, 96: 88-97. |

| 24 | 金正宇, 张国臣, 王凯军. 热解技术资源化处理城市污泥的研究进展[J]. 化工进展, 2012, 31(1): 1-9. |

| Jin Z Y, Zhang G C, Wang K J. Research advance in resource recovery treatment of sewage sludge by pyrolysis[J]. Chemical Industry and Engineering Progress, 2012, 31(1): 1-9. | |

| 25 | Shiba N C, Ntuli F. Extraction and precipitation of phosphorus from sewage sludge[J]. Waste Management, 2017, 60: 191-200. |

| 26 | 国家环境保护总局. 水和废水监测分析方法[M]. 4版. 北京: 中国环境科学出版社,2008. |

| China Environmental Protection Administration. Monitoring and Determination Methods for Water and Wastewater[M]. 4th ed. Beijing: China Environmental Science Press, 2008. | |

| 27 | Yang F, Chen J Y, Yang M, et al. Phosphorus recovery from sewage sludge via incineration with chlorine-based additives[J]. Waste Management, 2019, 95: 644-651. |

| 28 | de Figueiredo C C, de Souza Prado Junqueira Reis A, de Araujo A S, et al. Assessing the potential of sewage sludge-derived biochar as a novel phosphorus fertilizer: influence of extractant solutions and pyrolysis temperatures[J]. Waste Management, 2021, 124: 144-153. |

| 29 | Falayi T. Alkaline recovery of phosphorous from sewage sludge and stabilisation of sewage sludge residue[J]. Waste Management, 2019, 84: 166-172. |

| 30 | Lim B H, Kim D J. Selective acidic elution of Ca from sewage sludge ash for phosphorus recovery under pH control[J]. Journal of Industrial and Engineering Chemistry, 2017, 46: 62-67. |

| 31 | 许劲, 朱杰东, 李卷利, 等. 湿化学法回收污泥水热炭中磷的潜能研究[J]. 化工学报, 2021, 72(11): 5779-5789. |

| Xu J, Zhu J D, Li J L, et al. Potential of phosphorus recovery from sludge-based hydrochar by wet chemical method[J]. CIESC Journal, 2021, 72(11): 5779-5789. | |

| 32 | Feng C, Huang J C, Yang C H, et al. Smouldering combustion of sewage sludge: volumetric scale-up, product characterization, and economic analysis[J]. Fuel, 2021, 305: 121485. |

| 33 | Yermán L, Cormier D, Fabris I, et al. Potential bio-oil production from smouldering combustion of faeces[J]. Waste and Biomass Valorization, 2017, 8(2): 329-338. |

| 34 | Feng C, Cheng M K, Gao X P, et al. Occurrence forms and leachability of inorganic species in ash residues from self-sustaining smouldering combustion of sewage sludge[J]. Proceedings of the Combustion Institute, 2021, 38(3): 4327-4334. |

| 35 | Atienza-Martínez M, Gea G, Arauzo J, et al. Phosphorus recovery from sewage sludge char ash[J]. Biomass and Bioenergy, 2014, 65(2): 42-50. |

| 36 | Wu H, Castro M, Jensen P A, et al. Release and transformation of inorganic elements in combustion of a high-phosphorus fuel[J]. Energy & Fuels, 2011, 25(7): 2874-2886. |

| 37 | 沈雪莲, 周振, 任伟超, 等. 城镇污水处理厂污泥中磷的形态分布及生物可利用性分析[J]. 环境工程学报, 2016, 10(3): 1200-1204. |

| Shen X L, Zhou Z, Ren W C, et al. Fractionation and bioavailability of phosphorus in sludge from municipal wastewater treatment plants[J]. Chinese Journal of Environmental Engineering, 2016, 10(3): 1200-1204. | |

| 38 | 王超, 刘清伟, 职音, 等. 中国市政污泥中磷的含量与形态分布[J]. 环境科学, 2019, 40(4): 1922-1930. |

| Wang C, Liu Q W, Zhi Y, et al. Contents and forms of phosphorous in the municipal sewage sludge of China[J]. Environmental Science, 2019, 40(4): 1922-1930. | |

| 39 | Sevim F, Saraç H, Kocakerim M M, et al. Dissolution kinetics of phosphate ore in H2SO4 solutions[J]. Industrial & Engineering Chemistry Research, 2003, 42(10): 2052-2057. |

| 40 | Lee M S, Kim D J. Identification of phosphorus forms in sewage sludge ash during acid pre-treatment for phosphorus recovery by chemical fractionation and spectroscopy[J]. Journal of Industrial and Engineering Chemistry, 2017, 51: 64-70. |

| 41 | 王贤华, 鞠付栋, 陈汉平, 等. 污泥热解过程中焦的表面孔隙结构分形生长[J]. 燃料化学学报, 2010, 38(3): 374-379. |

| Wang X H, Ju F D, Chen H P, et al. Fractal growth of char surface pore structure during sewage sluge pyrolysis[J]. Journal of Fuel Chemistry and Technology, 2010, 38(3): 374-379. | |

| 42 | Robinson J S, Baumann K, Hu Y F, et al. Phosphorus transformations in plant-based and bio-waste materials induced by pyrolysis[J]. Ambio, 2018, 47(): 73-82. |

| 43 | 付雄, 刘敏, 陈滢. 污泥灰中磷的湿化学法回收技术研究进展[J]. 化工环保, 2017, 37(3): 276-281. |

| [1] | Cheng CHENG, Zhongdi DUAN, Haoran SUN, Haitao HU, Hongxiang XUE. Lattice Boltzmann simulation of surface microstructure effect on crystallization fouling [J]. CIESC Journal, 2023, 74(S1): 74-86. |

| [2] | Manzheng ZHANG, Meng XIAO, Peiwei YAN, Zheng MIAO, Jinliang XU, Xianbing JI. Working fluid screening and thermodynamic optimization of hazardous waste incineration coupled organic Rankine cycle system [J]. CIESC Journal, 2023, 74(8): 3502-3512. |

| [3] | Linzheng WANG, Yubing LU, Ruizhi ZHANG, Yonghao LUO. Analysis on thermal oxidation characteristics of VOCs based on molecular dynamics simulation [J]. CIESC Journal, 2023, 74(8): 3242-3255. |

| [4] | Chen HAN, Youmin SITU, Bin ZHU, Jianliang XU, Xiaolei GUO, Haifeng LIU. Study of reaction and flow characteristics in multi-nozzle pulverized coal gasifier with co-processing of wastewater [J]. CIESC Journal, 2023, 74(8): 3266-3278. |

| [5] | Mengmeng ZHANG, Dong YAN, Yongfeng SHEN, Wencui LI. Effect of electrolyte types on the storage behaviors of anions and cations for dual-ion batteries [J]. CIESC Journal, 2023, 74(7): 3116-3126. |

| [6] | Yuanhao QU, Wenyi DENG, Xiaodan XIE, Yaxin SU. Study on electro-osmotic dewatering of sludge assisted by activated carbon/graphite [J]. CIESC Journal, 2023, 74(7): 3038-3050. |

| [7] | Chao KANG, Jinpeng QIAO, Shengchao YANG, Chao PENG, Yuanpeng FU, Bin LIU, Jianrong LIU, Aleksandrova TATIANA, Chenlong DUAN. Research progress on activation extraction of valuable metals in coal gangue [J]. CIESC Journal, 2023, 74(7): 2783-2799. |

| [8] | Jipeng ZHOU, Wenjun HE, Tao LI. Reaction engineering calculation of deactivation kinetics for ethylene catalytic oxidation over irregular-shaped catalysts [J]. CIESC Journal, 2023, 74(6): 2416-2426. |

| [9] | Guangyu WANG, Kai ZHANG, Kaihua ZHANG, Dongke ZHANG. Heat and mass transfer and energy consumption for microwave drying of coal slime [J]. CIESC Journal, 2023, 74(6): 2382-2390. |

| [10] | Zhaoguang CHEN, Yuxiang JIA, Meng WANG. Modeling neutralization dialysis desalination driven by low concentration waste acid and its validation [J]. CIESC Journal, 2023, 74(6): 2486-2494. |

| [11] | Quanbi ZHANG, Yijin YANG, Xujing GUO. Catalytic degradation of dissolved organic matter in rifampicin pharmaceutical wastewater by Fenton oxidation process [J]. CIESC Journal, 2023, 74(5): 2217-2227. |

| [12] | Simin YI, Yali MA, Weiqiang LIU, Jinshuai ZHANG, Yan YUE, Qiang ZHENG, Songyan JIA, Xue LI. Study on ammonia evaporation and hydration kinetics of microcrystalline magnesite [J]. CIESC Journal, 2023, 74(4): 1578-1586. |

| [13] | Jin YU, Binbin YU, Xinsheng JIANG. Study on quantification methodology and analysis of chemical effects of combustion control based on fictitious species [J]. CIESC Journal, 2023, 74(3): 1303-1312. |

| [14] | Qingyun YANG, Qingsong LI, Zeming CHEN, Jing DENG, Yuying LI, Fan YANG, Guoyuan CHEN, Guoxin LI. Degradation of methylparaben by UV/PMS, UV/PDS and UV/SPC process [J]. CIESC Journal, 2023, 74(3): 1322-1331. |

| [15] | Hao CHEN, Yijuan TIAN, Xuejun QUAN, Ziwen JIANG, Gang LI. Decomposition behaviour of chromite in the HCl-HF system [J]. CIESC Journal, 2023, 74(3): 1161-1174. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||