CIESC Journal ›› 2024, Vol. 75 ›› Issue (1): 120-137.DOI: 10.11949/0438-1157.20230845

• Reviews and monographs • Previous Articles Next Articles

Qi LIU( ), Zikang CHEN, Yu PIAO, Peng XIAO, Yafen GE, Yanjun GONG(

), Zikang CHEN, Yu PIAO, Peng XIAO, Yafen GE, Yanjun GONG( )

)

Received:2023-08-17

Revised:2023-12-16

Online:2024-03-11

Published:2024-01-25

Contact:

Yanjun GONG

通讯作者:

巩雁军

作者简介:刘琦(1994—),男,博士研究生,LiuQ0330@163.com

基金资助:CLC Number:

Qi LIU, Zikang CHEN, Yu PIAO, Peng XIAO, Yafen GE, Yanjun GONG. Zeolite catalysts for catalytic cracking of hydrocarbon to increase light olefins selectivity[J]. CIESC Journal, 2024, 75(1): 120-137.

刘琦, 陈子康, 朴宇, 肖鹏, 葛亚粉, 巩雁军. 烃类催化裂解高选择性制低碳烯烃的分子筛催化剂[J]. 化工学报, 2024, 75(1): 120-137.

Add to citation manager EndNote|Ris|BibTeX

| 分子筛 | 硅铝比 | 实验条件 | 转化率/% | 产物收率/% | 文献 | |||

|---|---|---|---|---|---|---|---|---|

| 低碳烯烃 | 乙烯 | 丙烯 | 丁烯 | |||||

| MCM-68 | 51 | 己烷, 550℃ | 45.0 | — | 12.0 | 50.0 | — | [ |

| 丝光沸石 | 45 | 己烷, 550℃ | 45.3 | — | 14.0 | 41.0 | — | [ |

| ZSM-5 | 45 | 己烷, 550℃ | 59.0 | — | 20.0 | 37.0 | — | [ |

| Beta | 41 | 己烷, 550℃ | 64.0 | — | 20.0 | 37.0 | — | [ |

| ZSM-5纳米片 | 54 | 正庚烷, 550℃ | 85.8 | — | — | 31.0 | — | [ |

| Y | 10.7 | 正辛烷, 460℃, 空速3.88 h-1 | 93.0 | — | — | — | — | [ |

| Beta | 40 | 十二烷, 550℃ | 98.0 | 49.7 | 7.8 | 25.5 | 16.4 | [ |

| ZSM-5(块状,500 nm) | 50 | 十二烷, 550℃ | 98.0 | 40.4 | 12.9 | 17.9 | 9.6 | [ |

| MCM-22 | 52 | 1-丁烯, 550℃, 空速5 h-1 | 83.0 | — | 12.0 | 29.5 | — | [ |

Table 1 The catalytic cracking performance of different zeolite catalysts

| 分子筛 | 硅铝比 | 实验条件 | 转化率/% | 产物收率/% | 文献 | |||

|---|---|---|---|---|---|---|---|---|

| 低碳烯烃 | 乙烯 | 丙烯 | 丁烯 | |||||

| MCM-68 | 51 | 己烷, 550℃ | 45.0 | — | 12.0 | 50.0 | — | [ |

| 丝光沸石 | 45 | 己烷, 550℃ | 45.3 | — | 14.0 | 41.0 | — | [ |

| ZSM-5 | 45 | 己烷, 550℃ | 59.0 | — | 20.0 | 37.0 | — | [ |

| Beta | 41 | 己烷, 550℃ | 64.0 | — | 20.0 | 37.0 | — | [ |

| ZSM-5纳米片 | 54 | 正庚烷, 550℃ | 85.8 | — | — | 31.0 | — | [ |

| Y | 10.7 | 正辛烷, 460℃, 空速3.88 h-1 | 93.0 | — | — | — | — | [ |

| Beta | 40 | 十二烷, 550℃ | 98.0 | 49.7 | 7.8 | 25.5 | 16.4 | [ |

| ZSM-5(块状,500 nm) | 50 | 十二烷, 550℃ | 98.0 | 40.4 | 12.9 | 17.9 | 9.6 | [ |

| MCM-22 | 52 | 1-丁烯, 550℃, 空速5 h-1 | 83.0 | — | 12.0 | 29.5 | — | [ |

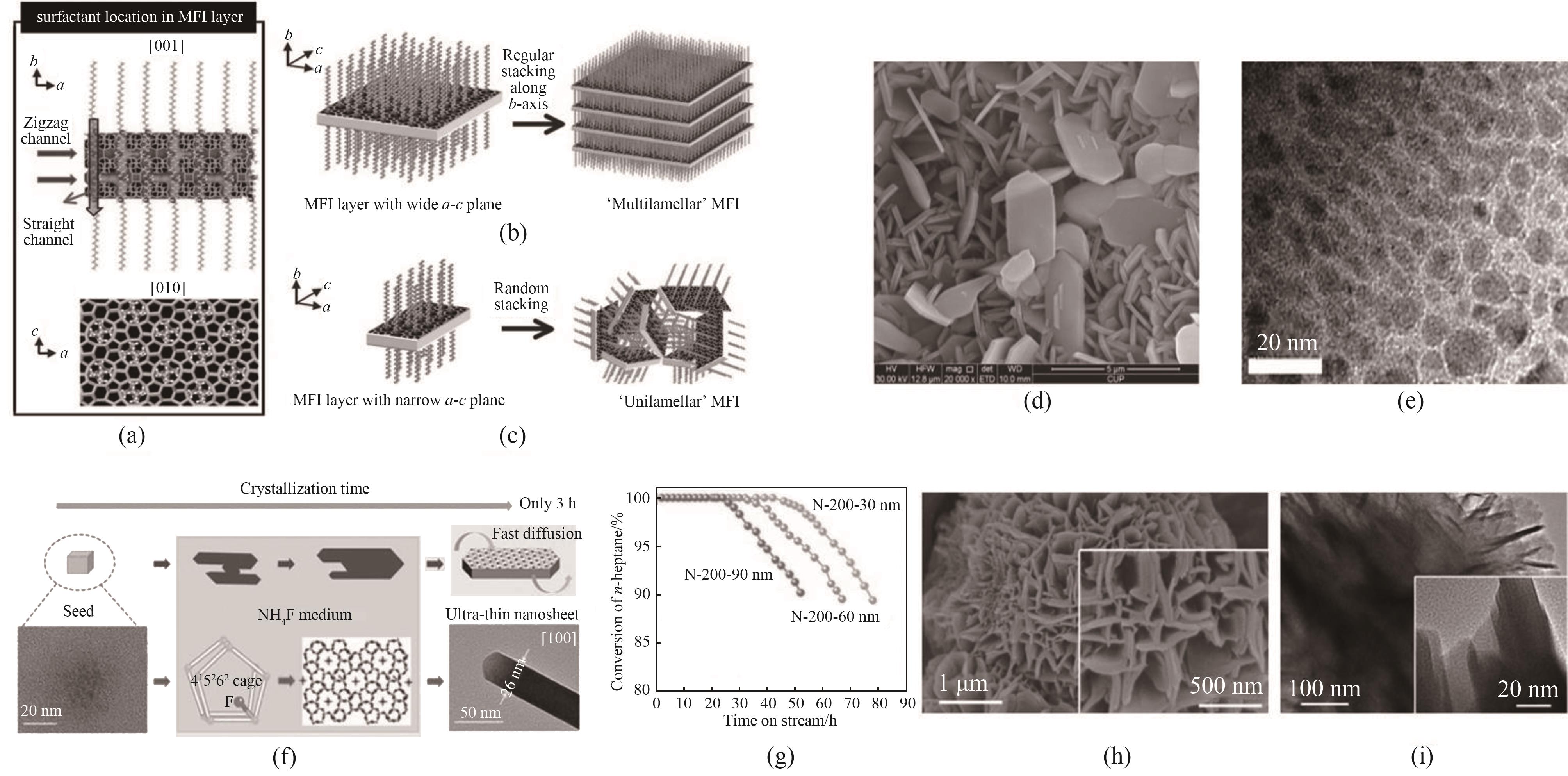

Fig.2 (a) Structure model for the single MFI nanosheet; (b) Many MFI nanosheets form either multilamellar stacking along the b-axis; (c) A random assembly of unilamellar structure[57]; (d), (e) The SEM and HRTEM images of ZSM-5 zeolite with a sheet-like structure combined in our group[59]; (f), (g) Schematic diagram of the synthesis of ZSM-5 nanosheets using template and fluoride and their catalytic cracking performance[63]; (h), (i) SEM and HRTEM images of the pillared HZSM-5 nanosheet zeolite[65]

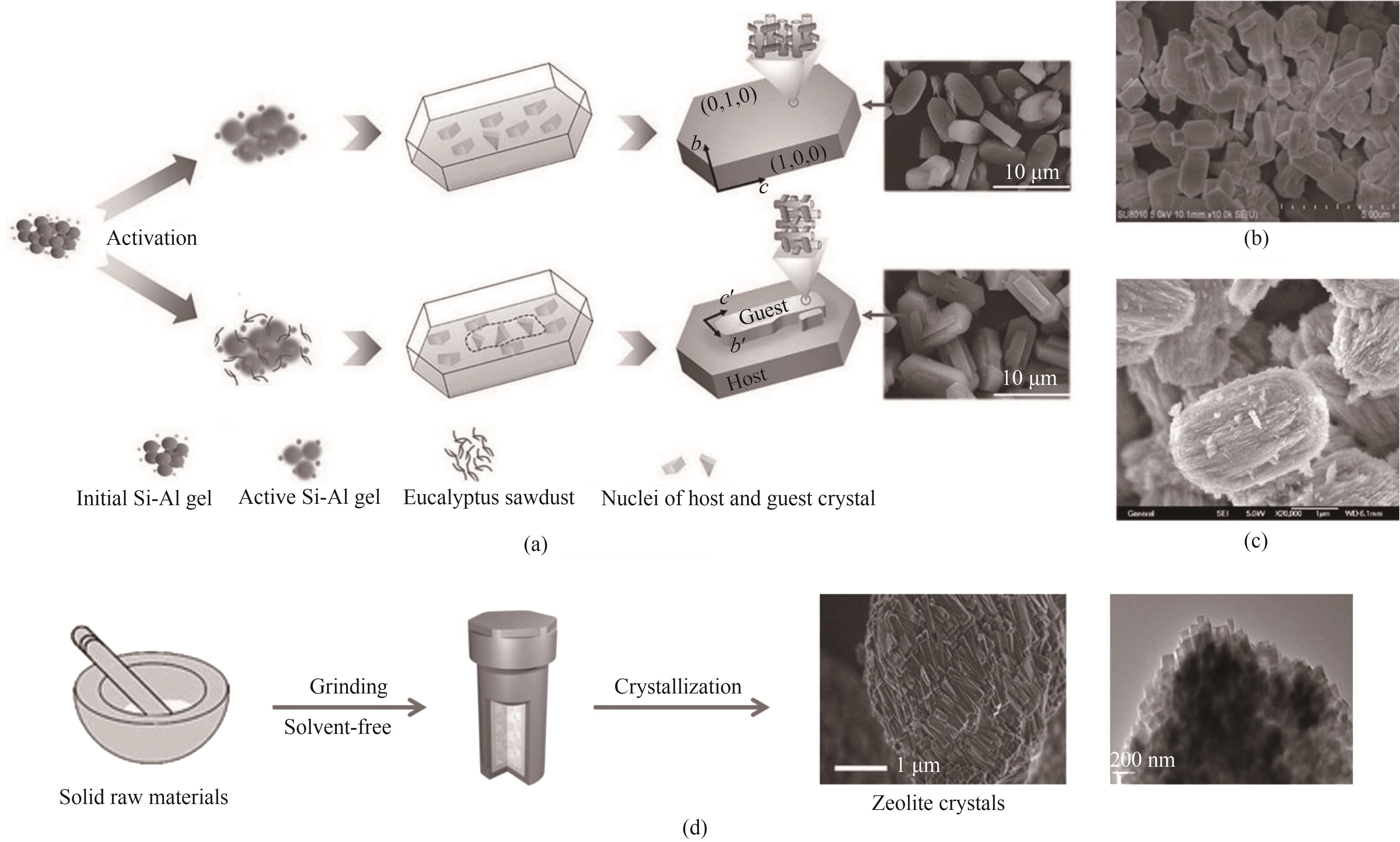

Fig.3 Schematic for synthesizing zeolites in different systems and theirs morphology images: (a)—(c) organic-free synthesis system[68,71,74]; (d) solvent-free synthesis system[75,77]

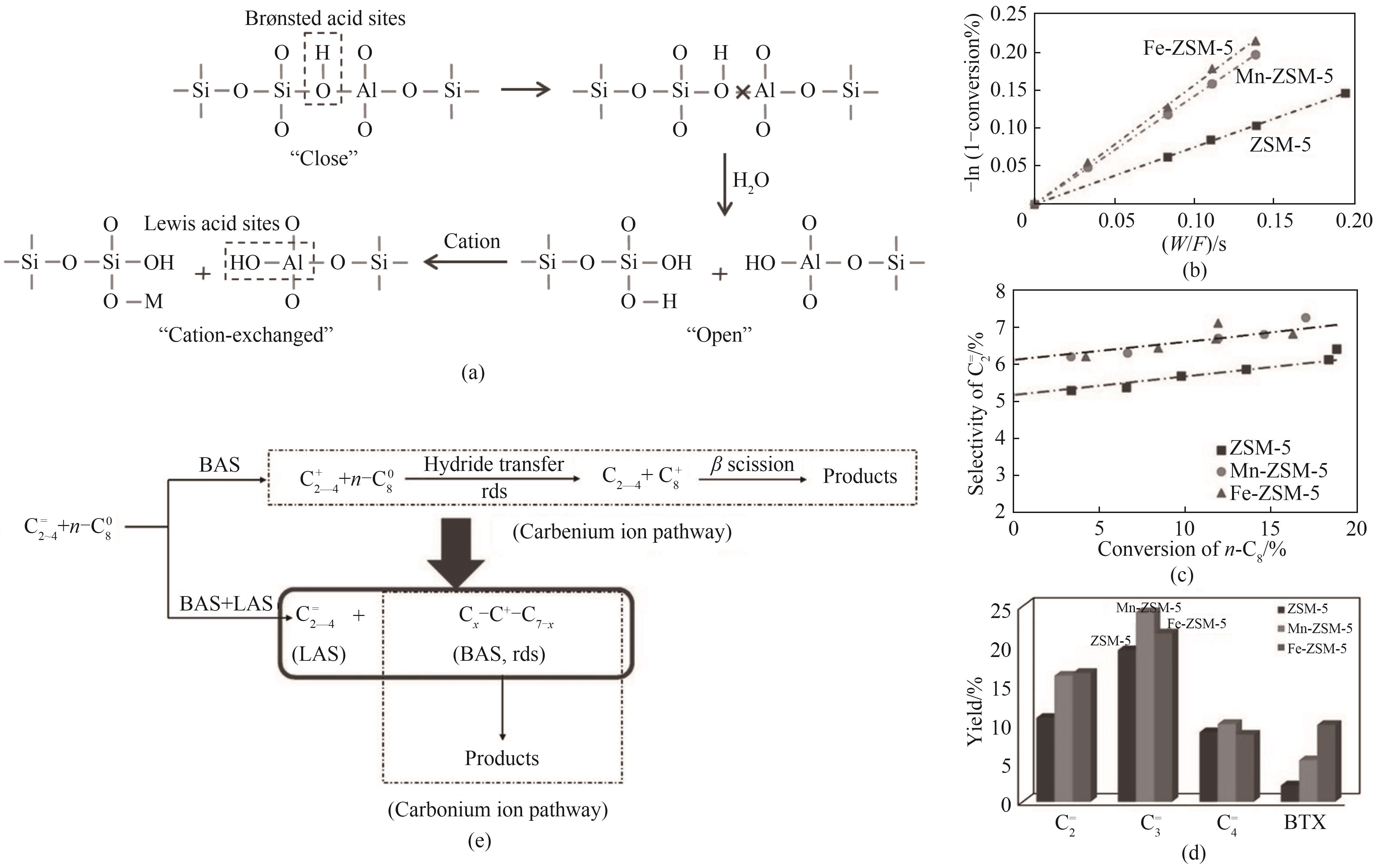

Fig.4 (a) Schematic of possible mechanism for ZSM-5 modified by metal cations[83]; (b)—(e) Catalytic performance of Fe and Mn modified ZSM-5 and reaction network for cracking n-octane[90]

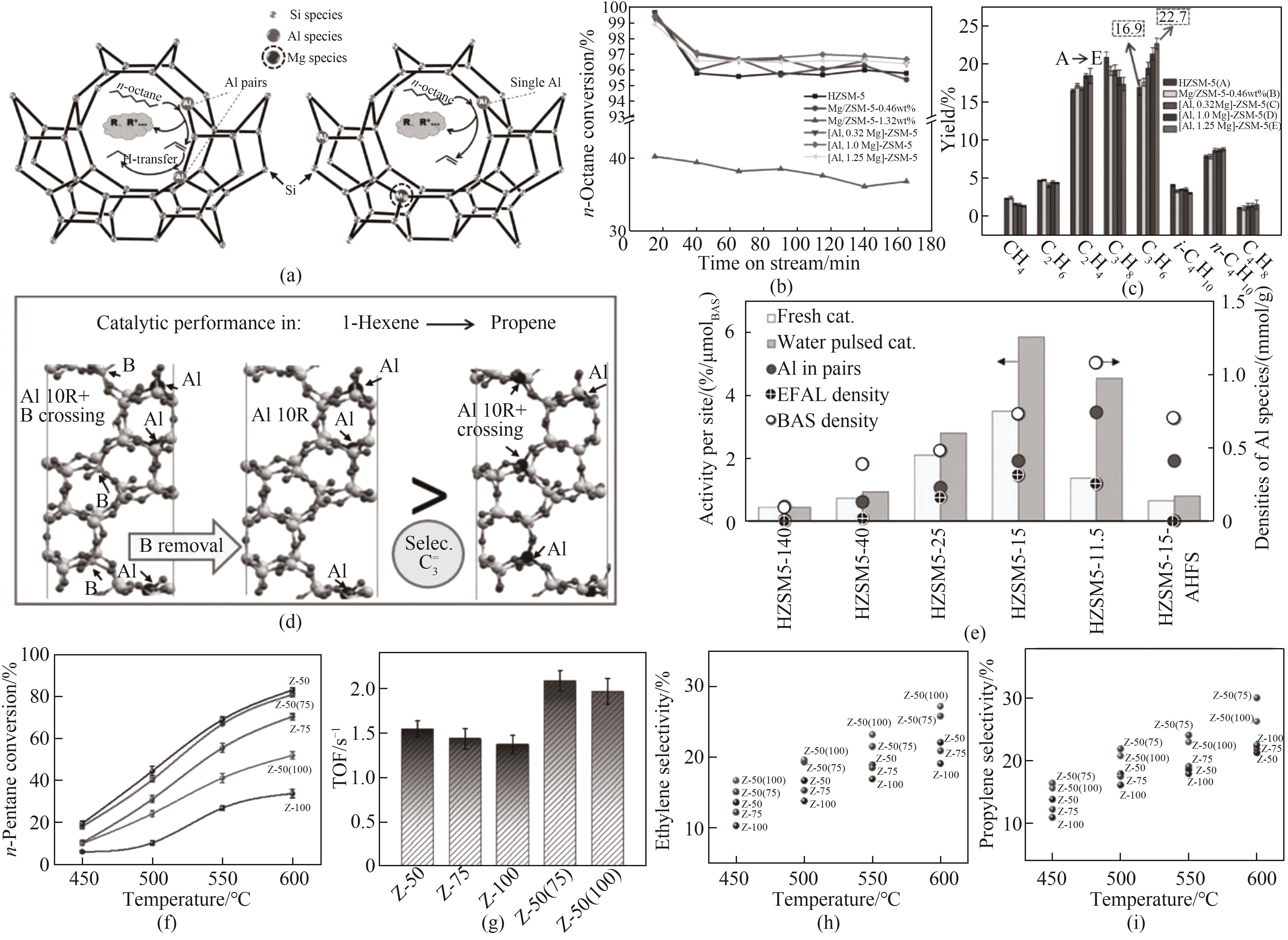

Fig.5 (a)—(d) Schematic of the effect of introducing metals on the Al distribution of zeolites by in-situ synthesis and their catalytic performance[95-96]; (e) EFAL and BAS densities as a function of rate per site of the hexane cracking reaction[97]; (f)—(i) The effect of changes in Al species of ZSM-5 zeolites for catalytic cracking reaction[98]

| 催化剂 | 改性金属 及含量(质量分数) | ΔS比表面积/ (m2/g) | ΔS微孔表面积/ (m2/g) | ΔS外表面积/ (m2/g) | ΔV孔体积/ (cm3/g) | ΔV微孔体积/ (cm3/g) | ΔV介孔体积/ (cm3/g) | 文献 |

|---|---|---|---|---|---|---|---|---|

| 1K/HZ-280 | K, 1% | -97.0 | — | — | -0.03 | — | — | [ |

| Ca-ZSM-5 | Ca, — | -78.0 | — | — | — | — | — | [ |

| ZSM-5-Cs | Cs, — | -50.0 | — | — | 0.00 | -0.02 | — | [ |

| 0.5Fe/H-ZSM-5 | Fe, 0.5% | -32.5 | -13.5 | -19.0 | -0.02 | -0.02 | 0.00 | [ |

| 0.5Cu/H-ZSM-5 | Cu, 0.5% | -13.3 | -7.7 | -5.6 | -0.01 | -0.01 | +0.01 | [ |

| 0.5Ni/H-ZSM-5 | Ni, 0.5% | -34.9 | -24.7 | -10.2 | -0.01 | -0.02 | 0.00 | [ |

| Au/ZSM-5-8.5 | Au, 0.5% | -47.0 | +10.0 | — | -0.03 | +0.01 | — | [ |

| 0.5%Au/ZSM-5 | Au, 0.5% | -14.8 | +6.1 | — | -0.01 | 0.00 | — | [ |

| 0.5%Au/2.0%La-ZSM-5 | Au, 0.5%; La, 2.0% | -32.9 | -4.6 | — | -0.02 | 0.00 | — | [ |

Table 2 The pore properties of different metal modified ZSM-5 zeolites

| 催化剂 | 改性金属 及含量(质量分数) | ΔS比表面积/ (m2/g) | ΔS微孔表面积/ (m2/g) | ΔS外表面积/ (m2/g) | ΔV孔体积/ (cm3/g) | ΔV微孔体积/ (cm3/g) | ΔV介孔体积/ (cm3/g) | 文献 |

|---|---|---|---|---|---|---|---|---|

| 1K/HZ-280 | K, 1% | -97.0 | — | — | -0.03 | — | — | [ |

| Ca-ZSM-5 | Ca, — | -78.0 | — | — | — | — | — | [ |

| ZSM-5-Cs | Cs, — | -50.0 | — | — | 0.00 | -0.02 | — | [ |

| 0.5Fe/H-ZSM-5 | Fe, 0.5% | -32.5 | -13.5 | -19.0 | -0.02 | -0.02 | 0.00 | [ |

| 0.5Cu/H-ZSM-5 | Cu, 0.5% | -13.3 | -7.7 | -5.6 | -0.01 | -0.01 | +0.01 | [ |

| 0.5Ni/H-ZSM-5 | Ni, 0.5% | -34.9 | -24.7 | -10.2 | -0.01 | -0.02 | 0.00 | [ |

| Au/ZSM-5-8.5 | Au, 0.5% | -47.0 | +10.0 | — | -0.03 | +0.01 | — | [ |

| 0.5%Au/ZSM-5 | Au, 0.5% | -14.8 | +6.1 | — | -0.01 | 0.00 | — | [ |

| 0.5%Au/2.0%La-ZSM-5 | Au, 0.5%; La, 2.0% | -32.9 | -4.6 | — | -0.02 | 0.00 | — | [ |

| 催化剂 | 改性金属及含量 (质量分数) | Δ总酸量/(mmol/g) | Δ弱酸量/(mmol/g) | Δ中强酸量/(mmol/g) | Δ强酸量/(mmol/g) | ΔB酸量/(mmol/g) | ΔL酸量/(mmol/g) | 文献 |

|---|---|---|---|---|---|---|---|---|

| 1K/HZ-280 | K, 1% | — | -0.02 | — | — | — | — | [ |

| ZSM-5-Cs | Cs, — | -0.86 | — | — | — | — | — | [ |

| Gd/HZSM-5 | Gd, 7.54% | 0.00 | -0.01 | — | +0.01 | -0.17 | -0.01 | [ |

| 0.5Fe/H-ZSM-5 | Fe, 0.5% | -0.22 | -0.07 | -0.03 | -0.11 | — | — | [ |

| 0.5Cu/H-ZSM-5 | Cu, 0.5% | -0.16 | -0.04 | -0.04 | -0.07 | — | — | [ |

| 0.5Ni/H-ZSM-5 | Ni, 0.5% | -0.17 | -0.06 | +0.04 | -0.14 | — | — | [ |

| Zr-Z5 | Zr, — | -0.12 | -0.06 | — | -0.06 | -0.19 | +0.07 | [ |

| Ag-Z5 | Ag, — | -0.30 | -0.38 | — | +0.08 | -1.56 | +1.26 | [ |

| Au/ZSM-5-8.5 | Au, 0.5% | -0.02 | +0.01 | -0.02 | -0.01 | — | — | [ |

| 0.5%Au/ZSM-5 | Au, 0.5% | -0.02 | -0.01 | 0.00 | -0.01 | — | — | [ |

| 0.5%Au/2.0%La-ZSM-5 | Au, 0.5%; La, 2.0% | -0.05 | -0.01 | -0.02 | -0.02 | — | — | [ |

Table 3 The acid properties of different metal modified ZSM-5 zeolites

| 催化剂 | 改性金属及含量 (质量分数) | Δ总酸量/(mmol/g) | Δ弱酸量/(mmol/g) | Δ中强酸量/(mmol/g) | Δ强酸量/(mmol/g) | ΔB酸量/(mmol/g) | ΔL酸量/(mmol/g) | 文献 |

|---|---|---|---|---|---|---|---|---|

| 1K/HZ-280 | K, 1% | — | -0.02 | — | — | — | — | [ |

| ZSM-5-Cs | Cs, — | -0.86 | — | — | — | — | — | [ |

| Gd/HZSM-5 | Gd, 7.54% | 0.00 | -0.01 | — | +0.01 | -0.17 | -0.01 | [ |

| 0.5Fe/H-ZSM-5 | Fe, 0.5% | -0.22 | -0.07 | -0.03 | -0.11 | — | — | [ |

| 0.5Cu/H-ZSM-5 | Cu, 0.5% | -0.16 | -0.04 | -0.04 | -0.07 | — | — | [ |

| 0.5Ni/H-ZSM-5 | Ni, 0.5% | -0.17 | -0.06 | +0.04 | -0.14 | — | — | [ |

| Zr-Z5 | Zr, — | -0.12 | -0.06 | — | -0.06 | -0.19 | +0.07 | [ |

| Ag-Z5 | Ag, — | -0.30 | -0.38 | — | +0.08 | -1.56 | +1.26 | [ |

| Au/ZSM-5-8.5 | Au, 0.5% | -0.02 | +0.01 | -0.02 | -0.01 | — | — | [ |

| 0.5%Au/ZSM-5 | Au, 0.5% | -0.02 | -0.01 | 0.00 | -0.01 | — | — | [ |

| 0.5%Au/2.0%La-ZSM-5 | Au, 0.5%; La, 2.0% | -0.05 | -0.01 | -0.02 | -0.02 | — | — | [ |

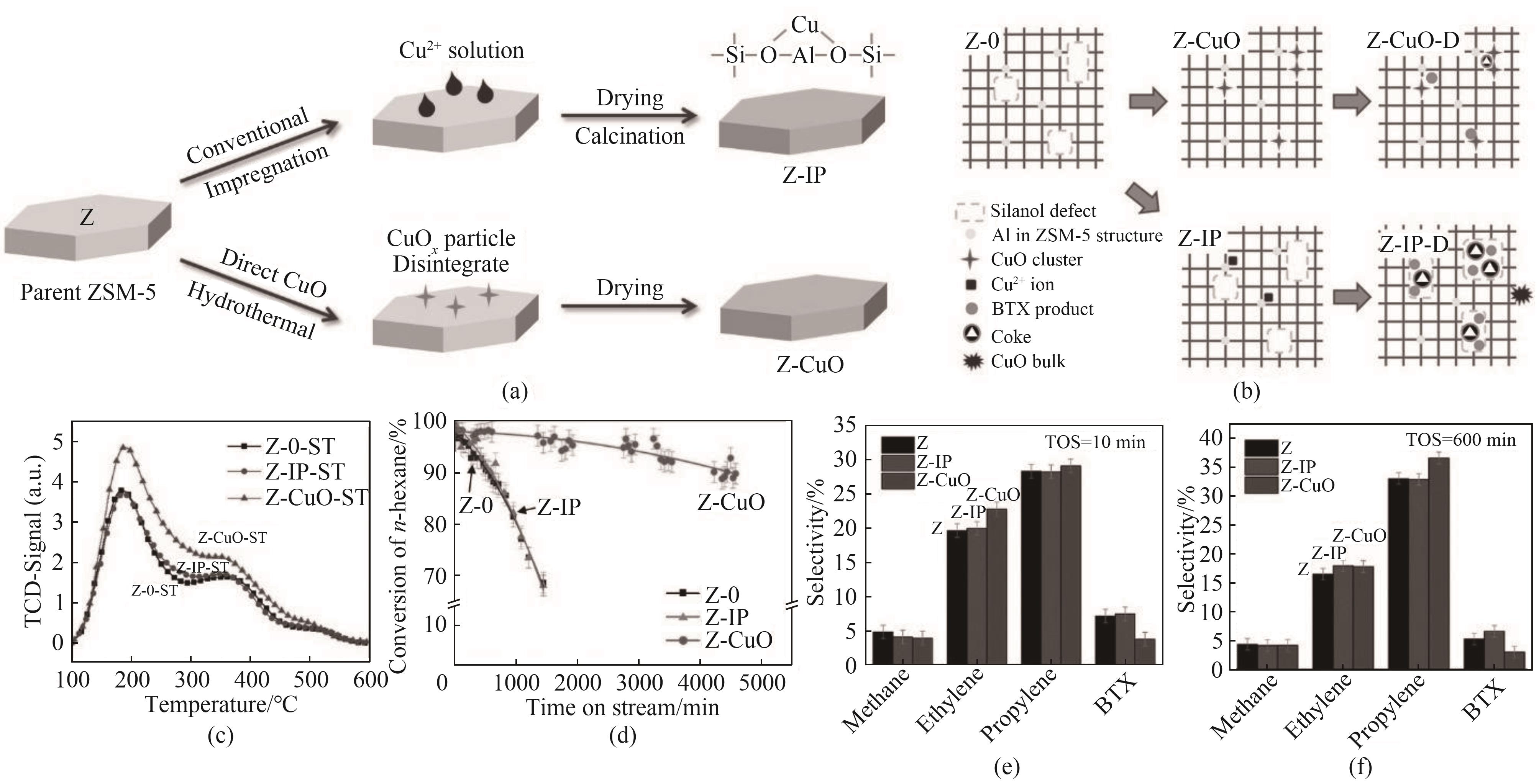

Fig.7 (a) Schematic of the preparation process of the CuO x /ZSM-5 catalyst; (b) The microstructure and deactivation behavior of different samples; (c) The NH3-TPD profiles of different samples; (d)—(f) The catalytic performance of different samples[108]

| 1 | Meng X H, Gao J S, Li L, et al. Advances in catalytic pyrolysis of hydrocarbons[J]. Petroleum Science and Technology, 2004, 22(9/10): 1327-1341. |

| 2 | Sadrameli S M. Thermal/catalytic cracking of liquid hydrocarbons for the production of olefins: a state-of-the-art review (Ⅱ): Catalytic cracking review[J]. Fuel, 2016, 173: 285-297. |

| 3 | 王洪华, 孙丽媛, 邢隆飞, 等. ZSM-5分子筛上轻烃裂解性能: 晶粒尺寸的影响[J]. 化工学报, 2015, 66(10): 3940-3949. |

| Wang H H, Sun L Y, Xing L F, et al. Transformation of light hydrocarbons to olefins: effect of ZSM-5 zeolites crystal size[J]. CIESC Journal, 2015, 66(10): 3940-3949. | |

| 4 | 唐勖尧, 王拴紧, 肖敏, 等. 重质油催化裂解制轻烯烃技术及催化剂研究进展[J]. 当代化工, 2020, 49(4): 620-625. |

| Tang X Y, Wang S J, Xiao M, et al. Research progress in heavy oil catalytic pyrolysis technology for light olefins and its catalysts[J]. Contemporary Chemical Industry, 2020, 49(4): 620-625. | |

| 5 | Auepattana-Aumrung C, Suriye K, Jongsomjit B, et al. Inhibition effect of Na+ form in ZSM-5 zeolite on hydrogen transfer reaction via 1-butene cracking[J]. Catalysis Today, 2020, 358: 237-245. |

| 6 | Peng P, Gao X H, Yan Z F, et al. Diffusion and catalyst efficiency in hierarchical zeolite catalysts[J]. National Science Review, 2020, 7(11): 1726-1742. |

| 7 | Xie Z K, Liu Z C, Wang Y D, et al. Applied catalysis for sustainable development of chemical industry in China[J]. National Science Review, 2015, 2(2): 167-182. |

| 8 | Cnudde P, de Wispelaere K, van der Mynsbrugge J, et al. Effect of temperature and branching on the nature and stability of alkene cracking intermediates in H-ZSM-5[J]. Journal of Catalysis, 2017, 345: 53-69. |

| 9 | 张燕, 沈凯旭, 滕加伟. 烯烃催化裂解技术研究进展[J]. 化学反应工程与工艺, 2021, 37(2): 181-192. |

| Zhang Y, Shen K X, Teng J W. Review of the olefin catalytic cracking technology[J]. Chemical Reaction Engineering and Technology, 2021, 37(2): 181-192. | |

| 10 | Liu X L, Shi J, Yang G, et al. A diffusion anisotropy descriptor links morphology effects of H-ZSM-5 zeolites to their catalytic cracking performance[J]. Communications Chemistry, 2021, 4: 107. |

| 11 | Liu Y H, Zhang Q, Li J Y, et al. Protozeolite-seeded synthesis of single-crystalline hierarchical zeolites with facet-shaped mesopores and their catalytic application in methanol-to-propylene conversion[J]. Angewandte Chemie International Edition, 2022, 61(34): e202205716. |

| 12 | Zhao D, Tian X X, Doronkin D E, et al. In situ formation of ZnO x species for efficient propane dehydrogenation[J]. Nature, 2021, 599: 234-238. |

| 13 | Shi J, Wang Y D, Yang W M, et al. Recent advances of pore system construction in zeolite-catalyzed chemical industry processes[J]. Chemical Society Reviews, 2015, 44(24): 8877-8903. |

| 14 | Bai Y E, Zhang G H, Liu D Y, et al. The advance in catalytic pyrolysis of naphtha technology using ZSM-5 as catalyst[J]. Applied Catalysis A: General, 2021, 628: 118399. |

| 15 | Rahimi N, Karimzadeh R. Catalytic cracking of hydrocarbons over modified ZSM-5 zeolites to produce light olefins: a review[J]. Applied Catalysis A: General, 2011, 398(1/2): 1-17. |

| 16 | Inagaki S, Takechi K, Kubota Y. Selective formation of propylene by hexane cracking over MCM-68 zeolite catalyst[J]. Chemical Communications, 2010, 46(15): 2662-2664. |

| 17 | Corma A, Planelles J, Sánchez-Marín J, et al. The role of different types of acid site in the cracking of alkanes on zeolite catalysts[J]. Journal of Catalysis, 1985, 93(1): 30-37. |

| 18 | Wielers A F H, Vaarkamp M, Post M F M. Relation between properties and performance of zeolites in paraffin cracking[J]. Journal of Catalysis, 1991, 127(1): 51-66. |

| 19 | Yamaguchi A, Jin D F, Ikeda T, et al. Deactivation of ZSM-5 zeolite during catalytic steam cracking of n-hexane[J]. Fuel Processing Technology, 2014, 126: 343-349. |

| 20 | Hou X, Zhao L, Diao Z H. Roles of alkenes and coke formation in the deactivation of ZSM-5 zeolites during n-pentane catalytic cracking[J]. Catalysis Letters, 2020, 150(9): 2716-2725. |

| 21 | Javaid R, Urata K, Furukawa S, et al. Factors affecting coke formation on H-ZSM-5 in naphtha cracking[J]. Applied Catalysis A: General, 2015, 491: 100-105. |

| 22 | Urata K, Furukawa S, Komatsu T. Location of coke on H-ZSM-5 zeolite formed in the cracking of n-hexane[J]. Applied Catalysis A: General, 2014, 475: 335-340. |

| 23 | Nakasaka Y, Nishimura J I, Tago T, et al. Deactivation mechanism of MFI-type zeolites by coke formation during n-hexane cracking[J]. Chemical Engineering Journal, 2015, 278: 159-165. |

| 24 | 胡思, 张卿, 巩雁军, 等. HZSM-5分子筛在甲醇制丙烯反应中的失活与再生[J]. 物理化学学报, 2016, 32(7): 1785-1794. |

| Hu S, Zhang Q, Gong Y J, et al. Deactivation and regeneration of HZSM-5 zeolite in methanol-to-propylene reaction[J]. Acta Physico-Chimica Sinica, 2016, 32(7): 1785-1794. | |

| 25 | Zabihpour A, Ahmadpour J, Yaripour F. Strategies to control reversible and irreversible deactivation of ZSM-5 zeolite during the conversion of methanol to propylene (MTP): a review[J]. Chemical Engineering Science, 2023, 273: 118639. |

| 26 | Guan L J, Liu M Y, Liu H H, et al. Regionally spatial framework Al distribution in MFI channels and its impact on the n-butane cracking reaction pathways[J]. Fuel, 2023, 353: 129230. |

| 27 | Song J H, Chen P L, Kim S H, et al. Catalytic cracking of n-hexane over MoO2 [J]. Journal of Molecular Catalysis A: Chemical, 2002, 184(1/2): 197-202. |

| 28 | Xu Q H, Gong Y J, Xu W J, et al. Synthesis of high-silica EU-1 zeolite in the presence of hexamethonium ions: a seeded approach for inhibiting ZSM-48[J]. Journal of Colloid and Interface Science, 2011, 358(1): 252-260. |

| 29 | Kosinov N, Wijpkema A S G, Uslamin E, et al. Confined carbon mediating dehydroaromatization of methane over Mo/ZSM-5[J]. Angewandte Chemie International Edition, 2018, 57(4): 1016-1020. |

| 30 | Jin Z, Wang L, Zuidema E, et al. Hydrophobic zeolite modification for in situ peroxide formation in methane oxidation to methanol[J]. Science, 2020, 367(6474): 193-197. |

| 31 | Pop G, Ivanus G, Boteanu S, et al. Catalytic process for preparing olefins by hydrocarbon pyrolysis: US4172816[P]. 1979-10-30. |

| 32 | Wang S, Li Z K, Qin Z F, et al. Catalytic roles of the acid sites in different pore channels of H-ZSM-5 zeolite for methanol-to-olefins conversion[J]. Chinese Journal of Catalysis, 2021, 42(7): 1126-1136. |

| 33 | Xiao X, Zhang Y Y, Jiang G Y, et al. Simultaneous realization of high catalytic activity and stability for catalytic cracking of n-heptane on highly exposed (010) crystal planes of nanosheet ZSM-5 zeolite[J]. Chemical Communications, 2016, 52(65): 10068-10071. |

| 34 | 孙宇. ZSM-5分子筛微-介结构与酸性质调变及其反应性能[D]. 北京: 中国石油大学(北京), 2023. |

| Sun Y. Regulating ZSM-5 zeolite structural morphology and acid properties and its reactivity[D].Beijing: China University of Petroleum, 2023. | |

| 35 | Cui W H, Zhu D L, Tan J, et al. Synthesis of mesoporous high-silica zeolite Y and their catalytic cracking performance[J]. Chinese Journal of Catalysis, 2022, 43(7): 1945-1954. |

| 36 | 赵长斌, 周翔, 许昀, 等. 高丙烯低生焦催化裂解催化剂的工业应用[J]. 石油炼制与化工, 2022, 53(3): 37-40. |

| Zhao C B, Zhou X, Xu Y, et al. Commercial application of deep catalytic cracking catalyst for high propylene and low coke[J]. Petroleum Processing and Petrochemicals, 2022, 53(3): 37-40. | |

| 37 | Mavrovouniotis G M, Cheng W C, Peters A W. Role of hydrogen transfer in isobutene-isobutane selectivities[J]. ACS Symposium Series, 1994, 571: 16-23. |

| 38 | Al-Shafei E N, Albahar M Z, Aljishi M F, et al. Effect of zeolite structure and addition of steam on naphtha catalytic cracking to improve olefin production[J]. Fuel, 2022, 321: 124089. |

| 39 | Wang X Y, Ma Y, Wu Q M, et al. Zeolite nanosheets for catalysis[J]. Chemical Society Reviews, 2022, 51(7): 2431-2443. |

| 40 | Corma A, Martı́nez-Triguero J. The use of MCM-22 as a cracking zeolitic additive for FCC[J]. Journal of Catalysis, 1997, 165(1): 102-120. |

| 41 | Xu G L, Zhu X X, Niu X L, et al. One-pot synthesis of high silica MCM-22 zeolites and their performances in catalytic cracking of 1-butene to propene[J]. Microporous and Mesoporous Materials, 2009, 118(1/2/3): 44-51. |

| 42 | Meloni D, Martin D, Guisnet M. Acidic and catalytic properties of H-MCM-22 zeolites[J]. Applied Catalysis A: General, 2001, 215(1/2): 67-79. |

| 43 | Song Y, Liu S L, Wang Q X, et al. Coke burning behavior of a catalyst of ZSM-5/ZSM-11 co-crystallized zeolite in the alkylation of benzene with FCC off-gas to ethylbenzene[J]. Fuel Processing Technology, 2006, 87(4): 297-302. |

| 44 | Chen H L, Shen B J, Pan H F. In situ formation of ZSM-5 in NaY gel and characterization of ZSM-5/Y composite zeolite[J]. Chemistry Letters, 2003, 32(8): 726-727. |

| 45 | 巩雁军, 张亚飞, 孙丽媛, 等. 一种EU-1/ZSM-48共生分子筛及其制备和应用: 105000571A[P]. 2015-10-28. |

| Gong Y J, Zhang Y F, Sun L Y, et al. An EU-1/ZSM-48 intergrowth zeolite and its preparation and application: 105000571A[P]. 2015-10-28. | |

| 46 | Ryoo R, Park I S, Jun S, et al. Synthesis of ordered and disordered silicas with uniform pores on the border between micropore and mesopore regions using short double-chain surfactants[J]. Journal of the American Chemical Society, 2001, 123(8): 1650-1657. |

| 47 | Sun M H, Gao S S, Hu Z Y, et al. Boosting molecular diffusion following the generalized Murray's Law by constructing hierarchical zeolites for maximized catalytic activity[J]. National Science Review, 2022, 9(12): nwac236. |

| 48 | Li W L, Ma T, Zhang Y F, et al. Facile control of inter-crystalline porosity in the synthesis of size-controlled mesoporous MFI zeolites via in situ conversion of silica gel into zeolite nanocrystals for catalytic cracking[J]. CrystEngComm, 2015, 17(30): 5680-5689. |

| 49 | 王务刚, 张少龙, 张兰兰, 等. 系列硅铝比纳米薄层ZSM-5分子筛的合成和表征[J]. 物理化学学报, 2013, 29(9): 2035-2040. |

| Wang W G, Zhang S L, Zhang L L, et al. Synthesis and characterization of nanosheet ZSM-5 zeolites with different SiO2/Al2O3 molar ratios[J]. Acta Physico-Chimica Sinica, 2013, 29(9): 2035-2040. | |

| 50 | Wang J, Shan J W, Tian Y J, et al. Catalytic cracking of n-heptane over Fe modified HZSM-5 nanosheet to produce light olefins[J]. Fuel, 2021, 306: 121725. |

| 51 | Lin L F, Qiu C F, Zhuo Z X, et al. Acid strength controlled reaction pathways for the catalytic cracking of 1-butene to propene over ZSM-5[J]. Journal of Catalysis, 2014, 309: 136-145. |

| 52 | Zhou J, Teng J W, Ren L P, et al. Full-crystalline hierarchical monolithic ZSM-5 zeolites as superiorly active and long-lived practical catalysts in methanol-to-hydrocarbons reaction[J]. Journal of Catalysis, 2016, 340: 166-176. |

| 53 | Xu H, Wu P. New progress in zeolite synthesis and catalysis[J]. National Science Review, 2022, 9(9): nwac045. |

| 54 | Ma T, Zhang L M, Song Y, et al. A comparative synthesis of ZSM-5 with ethanol or TPABr template: distinction of Brønsted/Lewis acidity ratio and its impact on n-hexane cracking[J]. Catalysis Science & Technology, 2018, 8(7): 1923-1935. |

| 55 | Zhu J L, Yan S Y, Qian Y, et al. Fabrication of fluffy-ball like ZSM-5 zeolite and its application in hexane catalytic cracking[J]. Microporous and Mesoporous Materials, 2023, 351: 112465. |

| 56 | Pérez-Ramírez J, Christensen C H, Egeblad K, et al. Hierarchical zeolites: enhanced utilisation of microporous crystals in catalysis by advances in materials design[J]. Chemical Society Reviews, 2008, 37(11): 2530-2542. |

| 57 | Choi M, Na K, Kim J, et al. Stable single-unit-cell nanosheets of zeolite MFI as active and long-lived catalysts[J]. Nature, 2009, 461: 246-249. |

| 58 | Zhang X Y, Liu D X, Xu D D, et al. Synthesis of self-pillared zeolite nanosheets by repetitive branching[J]. Science, 2012, 336(6089): 1684-1687. |

| 59 | Zhang L L, Song Y, Li G D, et al. F-Assisted synthesis of a hierarchical ZSM-5 zeolite for methanol to propylene reaction: a b-oriented thinner dimensional morphology[J]. RSC Advances, 2015, 5(75): 61354-61363. |

| 60 | Hao J, Cheng D G, Chen F Q, et al. n-Heptane catalytic cracking on ZSM-5 zeolite nanosheets: effect of nanosheet thickness[J]. Microporous and Mesoporous Materials, 2021, 310: 110647. |

| 61 | Seo Y, Cho K, Jung Y, et al. Characterization of the surface acidity of MFI zeolite nanosheets by 31P NMR of adsorbed phosphine oxides and catalytic cracking of decalin[J]. ACS Catalysis, 2013, 3(4): 713-720. |

| 62 | Tian Y J, Qiu Y, Hou X, et al. Catalytic cracking of JP-10 over HZSM-5 nanosheets[J]. Energy & Fuels, 2017, 31(11): 11987-11994. |

| 63 | Zhang J X, Ren L M, Zhou A J, et al. Tailored synthesis of ZSM-5 nanosheets with controllable b-axis thickness and aspect ratio: strategy and growth mechanism[J]. Chemistry of Materials, 2022, 34(7): 3217-3226. |

| 64 | Zhu J L, Yan S Y, Xu G H, et al. Fabrication of sheet-like HZSM-5 zeolites with various SiO2/Al2O3 and process optimization in hexane catalytic cracking[J]. Journal of Solid State Chemistry, 2023, 318: 123772. |

| 65 | Tian Y J, Zhang B F, Liang H R, et al. Synthesis and performance of pillared HZSM-5 nanosheet zeolites for n-decane catalytic cracking to produce light olefins[J]. Applied Catalysis A: General, 2019, 572: 24-33. |

| 66 | Hao J, Xu S M, Cheng D G, et al. Synthesis of nanosheet epitaxial growth ZSM-5 zeolite with increased diffusivity and its catalytic cracking performance[J]. Catalysis Science & Technology, 2022, 12(12): 3912-3920. |

| 67 | Nakhaei Pour A, Mohammadi A. Kinetic study of the crystallization of ZSM-5 under organic template-free conditions[J]. Inorganic and Nano-Metal Chemistry, 2023, 53(1): 33-38. |

| 68 | Li F W, Wang X F, Gu H S, et al. Catalytic co-cracking of biomass and waste plastics with sawdust mediated ZSM-5 synthesized via activating gel process[J]. Fuel, 2023, 332: 126141. |

| 69 | Meng X J, Xiao F S. Green routes for synthesis of zeolites[J]. Chemical Reviews, 2014, 114(2): 1521-1543. |

| 70 | Shestakova D O, Babina K A, Sladkovskiy D A, et al. Seed-assisted synthesis of hierarchical zeolite ZSM-5 in the absence of organic templates[J]. Materials Chemistry and Physics, 2022, 288: 126432. |

| 71 | 唐贺. 晶种辅助合成ZSM-5分子筛及其应用性能[D]. 北京: 中国石油大学(北京), 2022. |

| Tang H. Seed-assisted synthesis of ZSM-5 zeolite and its application performance[D].Beijing: China University of Petroleum, 2022. | |

| 72 | Pan H H, Pan Q X, Zhao Y S, et al. A green and efficient synthesis of ZSM-5 using NaY as seed with mother liquid recycling and in the absence of organic template[J]. Industrial & Engineering Chemistry Research, 2010, 49(16): 7294-7302. |

| 73 | Pour A N, Mohammadi A. Effect of ZSM-5 zeolite porosity on catalytic cracking of n-heptane[J]. New Journal of Chemistry, 2022, 46(32): 15585-15595. |

| 74 | Zhang H Y, Wang L, Zhang D L, et al. Mesoporous and Al-rich MFI crystals assembled with aligned nanorods in the absence of organic templates[J]. Microporous and Mesoporous Materials, 2016, 233: 133-139. |

| 75 | Wu Q M, Meng X J, Gao X H, et al. Solvent-free synthesis of zeolites: mechanism and utility[J]. Accounts of Chemical Research, 2018, 51(6): 1396-1403. |

| 76 | Luo W, Yang X Y, Wang Z R, et al. Synthesis of ZSM-5 aggregates made of zeolite nanocrystals through a simple solvent-free method[J]. Microporous and Mesoporous Materials, 2017, 243: 112-118. |

| 77 | Gu Y, Wang X H, Qin Z X, et al. Intra-crystalline mesoporous ZSM-5 zeolite by grinding synthesis method[J]. Microporous and Mesoporous Materials, 2020, 306: 110437. |

| 78 | Qian M, Lei H W, Zhao Y F, et al. Lignin-mediated preparation of hierarchical ZSM-5 catalysts and their effects in the catalytic co-pyrolysis of softwood biomass and low-density polyethylene mixtures[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(37): 12602-12613. |

| 79 | Zhu T T, Liang H R, Zhang B F, et al. Controllably tailoring external surface sites of nanosheet HZSM-5 for maximizing light olefins in catalytic cracking of n-decane[J]. Chinese Journal of Chemical Engineering, 2021, 38: 276-285. |

| 80 | Zhang X X, Cheng D G, Chen F Q, et al. The role of external acidity of hierarchical ZSM-5 zeolites in n-heptane catalytic cracking[J]. ChemCatChem, 2018, 10(12): 2655-2663. |

| 81 | Epelde E, Gayubo A G, Olazar M, et al. Modified HZSM-5 zeolites for intensifying propylene production in the transformation of 1-butene[J]. Chemical Engineering Journal, 2014, 251: 80-91. |

| 82 | Wakui K, Satoh K, Sawada G, et al. Cracking of n-butane over alkaline earth-containing HZSM-5 catalysts[J]. Catalysis Letters, 2002, 84(3): 259-264. |

| 83 | Ji Y J, Yang H H, Yan W. Effect of alkali metal cations modification on the acid/basic properties and catalytic activity of ZSM-5 in cracking of supercritical n-dodecane[J]. Fuel, 2019, 243: 155-161. |

| 84 | Wang X N, Zhao Z, Xu C M, et al. Effects of light rare earth on acidity and catalytic performance of HZSM-5 zeolite for catalytic cracking of butane to light olefins[J]. Journal of Rare Earths, 2007, 25(3): 321-328. |

| 85 | Tynjälä P, Pakkanen T T. Acidic properties of ZSM-5 zeolite modified with Ba2+, Al3+ and La3+ ion-exchange[J]. Journal of Molecular Catalysis A: Chemical, 1996, 110(2): 153-161. |

| 86 | 李延锋. 镧改性ZSM-5分子筛的结构、水热稳定性及其催化性能的理论研究[D]. 北京: 北京化工大学, 2011. |

| Li Y F. Theoretical study on the structure, hydrothermal stability and catalytic performance of La-modified ZSM-5 zeolite[D].Beijing: Beijing University of Chemical Technology, 2011. | |

| 87 | Auepattana-aumrung C, Praserthdam S, Wannakao S, et al. Observation of reduction on alkane products in butene cracking over ZSM-5 modified with Fe, Cu, and Ni catalysts[J]. Fuel, 2021, 291: 120265. |

| 88 | Li X F, Shen B J, Xu C M. Interaction of titanium and iron oxide with ZSM-5 to tune the catalytic cracking of hydrocarbons[J]. Applied Catalysis A: General, 2010, 375(2): 222-229. |

| 89 | Hou X, Qiu Y, Yuan E X, et al. Promotion on light olefins production through modulating the reaction pathways for n-pentane catalytic cracking over ZSM-5 based catalysts[J]. Applied Catalysis A: General, 2017, 543: 51-60. |

| 90 | Wang L X, Peng B, Zheng A G, et al. Mechanistic origin of transition metal modification on ZSM-5 zeolite for the ethylene yield enhancement from the primary products of n-octane cracking[J]. Journal of Catalysis, 2022, 416: 387-397. |

| 91 | Fu X P, Guo L W, Wang W W, et al. Direct identification of active surface species for the water-gas shift reaction on a gold-ceria catalyst[J]. Journal of the American Chemical Society, 2019, 141(11): 4613-4623. |

| 92 | Qi C X, Wang Y X, Ding X T, et al. Catalytic cracking of light diesel over Au/ZSM-5 catalyst for increasing propylene production[J]. Chinese Journal of Catalysis, 2016, 37(10): 1747-1754. |

| 93 | Zhang M, Liu Q, Long H A, et al. Insights into Au nanoparticle size and chemical state of Au/ZSM-5 catalyst for catalytic cracking of n-octane to increase propylene production[J]. The Journal of Physical Chemistry C, 2021, 125(29): 16013-16023. |

| 94 | Liu Q, Zhang M, Sun L B, et al. The performance of catalytic conversion of ZSM-5 comodified with gold and lanthanum for increasing propylene production[J]. Industrial & Engineering Chemistry Research, 2019, 58(32): 14695-14704. |

| 95 | Chen K, Wu X Q, Zhao J Y, et al. Organic-free modulation of the framework Al distribution in ZSM-5 zeolite by magnesium participated synthesis and its impact on the catalytic cracking reaction of alkanes[J]. Journal of Catalysis, 2022, 413: 735-750. |

| 96 | Li C G, Vidal-Moya A, Miguel P J, et al. Selective introduction of acid sites in different confined positions in ZSM-5 and its catalytic implications[J]. ACS Catalysis, 2018, 8(8): 7688-7697. |

| 97 | Pham T N, Nguyen V, Nguyen-Phu H, et al. Influence of Brønsted acid site proximity on alkane cracking in MFI zeolites[J]. ACS Catalysis, 2023, 13(2): 1359-1370. |

| 98 | He X Y, Tian Y J, Guo L H, et al. Fabrication of extra-framework Al in ZSM-5 to enhance light olefins production in catalytic cracking of n-pentane[J]. Journal of Analytical and Applied Pyrolysis, 2022, 165: 105550. |

| 99 | Blasco T, Corma A, Martínez-Triguero J. Hydrothermal stabilization of ZSM-5 catalytic-cracking additives by phosphorus addition[J]. Journal of Catalysis, 2006, 237(2): 267-277. |

| 100 | Lv J, Hua Z L, Ge T G, et al. Phosphorus modified hierarchically structured ZSM-5 zeolites for enhanced hydrothermal stability and intensified propylene production from 1-butene cracking[J]. Microporous and Mesoporous Materials, 2017, 247: 31-37. |

| 101 | Degnan T F, Chitnis G K, Schipper P H. History of ZSM-5 fluid catalytic cracking additive development at Mobil[J]. Microporous and Mesoporous Materials, 2000, 35/36: 245-252. |

| 102 | Zhao Y, Liu J X, Xiong G, et al. Enhancing hydrothermal stability of nano-sized HZSM-5 zeolite by phosphorus modification for olefin catalytic cracking of full-range FCC gasoline[J]. Chinese Journal of Catalysis, 2017, 38(1): 138-145. |

| 103 | Xue N H, Chen X K, Nie L, et al. Understanding the enhancement of catalytic performance for olefin cracking: hydrothermally stable acids in P/HZSM-5[J]. Journal of Catalysis, 2007, 248(1): 20-28. |

| 104 | Li J W, Li T, Ma H F, et al. Effect of impregnating Fe into P-modified HZSM-5 in the coupling cracking of butene and pentene[J]. Industrial & Engineering Chemistry Research, 2015, 54(6): 1796-1805. |

| 105 | Li J W, Ma H F, Sun Q W, et al. Effect of iron and phosphorus on HZSM-5 in catalytic cracking of 1-butene[J]. Fuel Processing Technology, 2015, 134: 32-38. |

| 106 | Li J W, Li T, Ma H F, et al. Effect of nickel on phosphorus modified HZSM-5 in catalytic cracking of butene and pentene[J]. Fuel Processing Technology, 2017, 159: 31-37. |

| 107 | Ravandi R, Khoshbin R, Karimzadeh R. Synthesis of free template ZSM-5 catalyst from rice husk ash and co-modified with lanthanum and phosphorous for catalytic cracking of naphtha[J]. Journal of Porous Materials, 2018, 25(2): 451-461. |

| 108 | Zhang L M, Gong Y J, Zhai Y L, et al. Creation of CuO x /ZSM-5 zeolite complex: healing defect sites and boosting acidic stability and catalytic activity[J]. Catalysis Science & Technology, 2020, 10(15): 4981-4989. |

| 109 | 商世明. 金属改性调控ZSM-5分子筛酸性和微结构及其催化裂解性能[D]. 北京: 中国石油大学(北京), 2021. |

| Shang S M. Metal modification of ZSM-5 zeolite regulating its acidity and microstructure for hexane catalytic cracking[D].Beijing: China University of Petroleum, 2021. | |

| 110 | 杨正康. ZSM-5分子筛的金属改性及其对烃类裂解性能的影响[D]. 北京: 中国石油大学(北京), 2022. |

| Yang Z K. Metal modification of ZSM-5 zeolite and its effect on hydrocarbon cracking performance[D].Beijing: China University of Petroleum, 2022. |

| [1] | Xiangjun MENG, Yingxi HUA, Changjin ZHANG, Chi ZHANG, Linrui YANG, Ruoxi YANG, Jianyi LIU, Chunjian XU. Preparation and purification of 6N electronic-grade deuterium gas [J]. CIESC Journal, 2024, 75(1): 377-390. |

| [2] | Guoyi XIAN, Lifang CHEN, Zhiwen QI. DFT-based study of liquid-phase Beckmann rearrangement mechanism of cyclohexanone oxime [J]. CIESC Journal, 2024, 75(1): 302-311. |

| [3] | Yepin CHENG, Daqing HU, Yisha XU, Huayan LIU, Hanfeng LU, Guokai CUI. Application of ionic liquid-based deep eutectic solvents for CO2 conversion [J]. CIESC Journal, 2023, 74(9): 3640-3653. |

| [4] | Yaxin CHEN, Hang YUAN, Guanzhang LIU, Lei MAO, Chun YANG, Ruifang ZHANG, Guangya ZHANG. Advances in enzyme self-immobilization mediated by protein nanocages [J]. CIESC Journal, 2023, 74(7): 2773-2782. |

| [5] | Xiaoling TANG, Jiarui WANG, Xuanye ZHU, Renchao ZHENG. Biosynthesis of chiral epichlorohydrin by halohydrin dehalogenase based on Pickering emulsion system [J]. CIESC Journal, 2023, 74(7): 2926-2934. |

| [6] | Lei MAO, Guanzhang LIU, Hang YUAN, Guangya ZHANG. Efficient preparation of carbon anhydrase nanoparticles capable of capturing CO2 and their characteristics [J]. CIESC Journal, 2023, 74(6): 2589-2598. |

| [7] | Tan ZHANG, Guang LIU, Jinping LI, Yuhan SUN. Performance regulation strategies of Ru-based nitrogen reduction electrocatalysts [J]. CIESC Journal, 2023, 74(6): 2264-2280. |

| [8] | Hao GU, Fujian ZHANG, Zhen LIU, Wenxuan ZHOU, Peng ZHANG, Zhongqiang ZHANG. Desalination performance and mechanism of porous graphene membrane in temporal dimension under mechanical-electrical coupling [J]. CIESC Journal, 2023, 74(5): 2067-2074. |

| [9] | Zheng ZHANG, Yongping HE, Haidong SUN, Rongzi ZHANG, Zhengping SUN, Jinlan CHEN, Yixuan ZHENG, Xiao DU, Xiaogang HAO. Electrochemically switched ion exchange device with serpentine flow field for selective extraction of lithium [J]. CIESC Journal, 2023, 74(5): 2022-2033. |

| [10] | Tianhao BAI, Xiaowen WANG, Mengzi YANG, Xinwei DUAN, Jie MI, Mengmeng WU. Study on release and inhibition behavior of COS during high-temperature gas desulfurization process using Zn-based oxide derived from hydrotalcite [J]. CIESC Journal, 2023, 74(4): 1772-1780. |

| [11] | Zijian WANG, Ming KE, Jiahan LI, Shuting LI, Jinru SUN, Yanbing TONG, Zhiping ZHAO, Jiaying LIU, Lu REN. Progress in preparation and application of short b-axis ZSM-5 molecular sieve [J]. CIESC Journal, 2023, 74(4): 1457-1473. |

| [12] | Yin XU, Jie CAI, Lu CHEN, Yu PENG, Fuzhen LIU, Hui ZHANG. Advances in heterogeneous visible light photocatalysis coupled with persulfate activation for water pollution control [J]. CIESC Journal, 2023, 74(3): 995-1009. |

| [13] | Runzhu LIU, Tiantian CHU, Xiaoa ZHANG, Chengzhong WANG, Junying ZHANG. Synthesis and properties of phenylene-containing α,ω-hydroxy-terminated fluorosilicone polymers [J]. CIESC Journal, 2023, 74(3): 1360-1369. |

| [14] | Jieyuan ZHENG, Xianwei ZHANG, Jintao WAN, Hong FAN. Synthesis and curing kinetic analysis of eugenol-based siloxane epoxy resin [J]. CIESC Journal, 2023, 74(2): 924-932. |

| [15] | Yating CHAI, Jiawei LU, Ruixin WANG, Weizhou JIAO. Carbon paper self-supported N-doped carbon nanotubes with MoC/NiCo heterostructures for electrolytic water oxygen evolution reaction [J]. CIESC Journal, 2023, 74(12): 4904-4913. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||