CIESC Journal ›› 2023, Vol. 74 ›› Issue (10): 4201-4207.DOI: 10.11949/0438-1157.20230895

• Separation engineering • Previous Articles Next Articles

Received:2023-08-29

Revised:2023-09-27

Online:2023-12-22

Published:2023-10-25

Contact:

Qiao ZHANG

通讯作者:

张桥

作者简介:麻蓉(2001—),女,硕士研究生,marong0604@stu.xjtu.edu.cn

基金资助:CLC Number:

Rong MA, Qiao ZHANG. Establishment and simulation of hydrogen separation system coupled with PSA, rectisol and membrane separation[J]. CIESC Journal, 2023, 74(10): 4201-4207.

麻蓉, 张桥. PSA-低温甲醇洗-膜分离耦合的氢气分离系统建立与模拟[J]. 化工学报, 2023, 74(10): 4201-4207.

Add to citation manager EndNote|Ris|BibTeX

| 摩尔流率/(kmol/h) | 压力/MPa | 温度/K | 摩尔分数/% | |||

|---|---|---|---|---|---|---|

| CH4 | H2 | CO2 | CO | |||

| 3430.93 | 2.2 | 313.15 | 7.524 | 73.94 | 18.35 | 0.1870 |

Table 1 Data of feed gas

| 摩尔流率/(kmol/h) | 压力/MPa | 温度/K | 摩尔分数/% | |||

|---|---|---|---|---|---|---|

| CH4 | H2 | CO2 | CO | |||

| 3430.93 | 2.2 | 313.15 | 7.524 | 73.94 | 18.35 | 0.1870 |

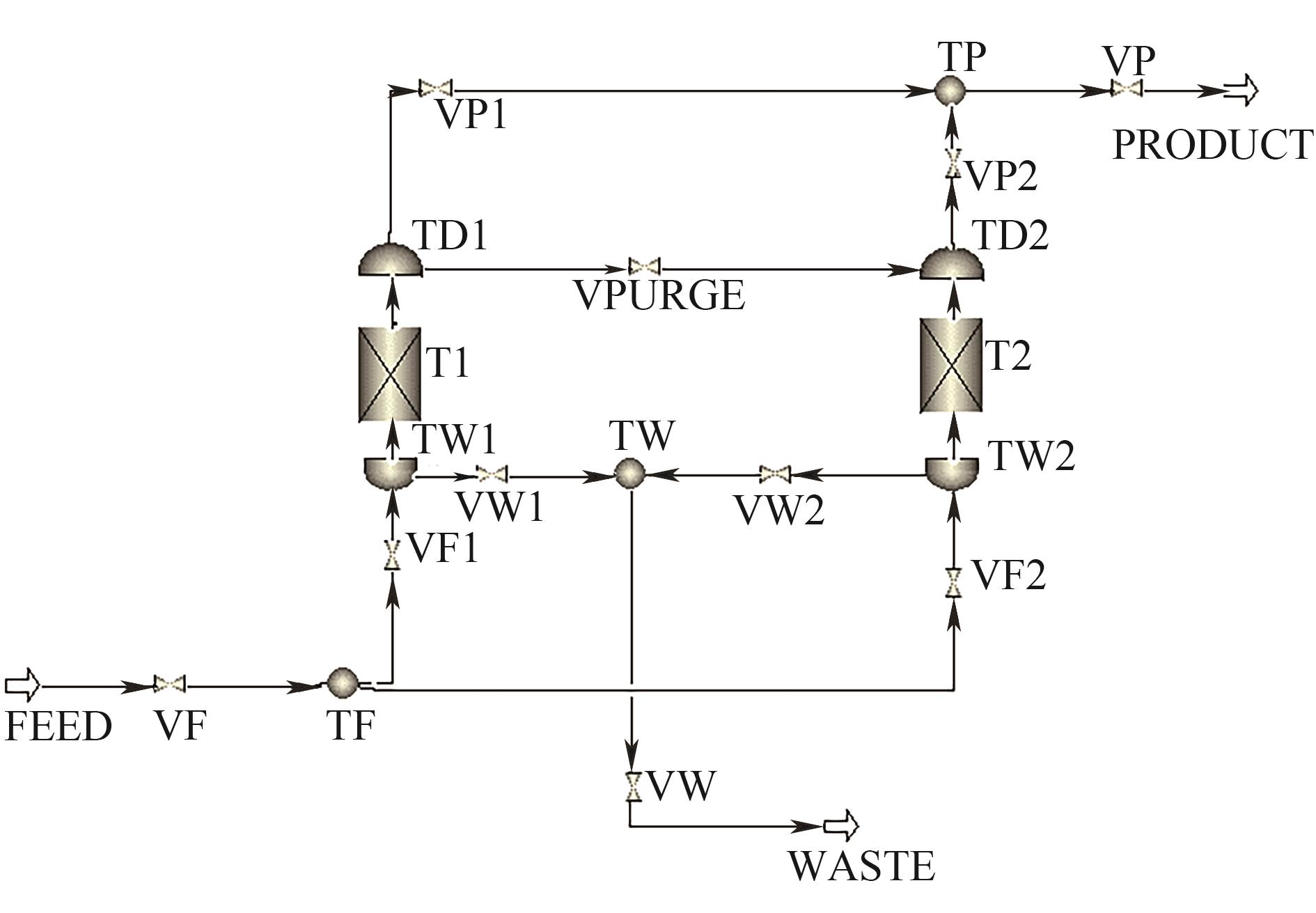

Fig.2 Simulation diagram of dual tower PSA processT1, T2—adsorption tower; TF, TD1, TD2, TW1, TW2, TP, TW—gas tank; VF, VF1, VF2, VP, VP1, VP2, VPURGE, VW—gas valve

| 材料 | 吸附层高度/m | 吸附床内径/m | 颗粒间隙率 |

|---|---|---|---|

| 活性炭 | 9.530 | 3.2 | 0.36 |

| 5A分子筛 | 4.765 | 3.2 | 0.36 |

Table 2 Physical parameters of adsorption bed and adsorbents

| 材料 | 吸附层高度/m | 吸附床内径/m | 颗粒间隙率 |

|---|---|---|---|

| 活性炭 | 9.530 | 3.2 | 0.36 |

| 5A分子筛 | 4.765 | 3.2 | 0.36 |

| 项目 | 摩尔流率/(kmol/h) | 压力/MPa | 温度/K | 摩尔分数/% | |||

|---|---|---|---|---|---|---|---|

| CH4 | CO | CO2 | H2 | ||||

| PRODUCT | 2061.23 | 2.2 | 295.25 | 0.0018 | 0.0008 | 0.0322 | 99.96 |

| WASTE | 1377.56 | 0.1 | 296.35 | 18.79 | 0.5354 | 46.09 | 34.59 |

Table 3 Data of PSA product gas and disorbed gas

| 项目 | 摩尔流率/(kmol/h) | 压力/MPa | 温度/K | 摩尔分数/% | |||

|---|---|---|---|---|---|---|---|

| CH4 | CO | CO2 | H2 | ||||

| PRODUCT | 2061.23 | 2.2 | 295.25 | 0.0018 | 0.0008 | 0.0322 | 99.96 |

| WASTE | 1377.56 | 0.1 | 296.35 | 18.79 | 0.5354 | 46.09 | 34.59 |

Fig.3 Simulation diagram of rectisol processT3—absorption tower; Y1, Y2, Y3—compressor; C1, C2, C3—cooler; H1, H2—heater; V1—valve; F1—flash tank; PUMP—pump; MIX—mixer

| 项目 | 摩尔流率/(kmol/h) | 压力/MPa | 温度/K | 摩尔分数/% | |||

|---|---|---|---|---|---|---|---|

| CH4 | CO | CO2 | H2 | ||||

| 产品气(S8) | 475.21 | 0.1 | 298.15 | 0.2915 | 0.7194 | 0.5861 | 98.40 |

| 尾气(S14) | 905.48 | 2.6 | 333.15 | 28.53 | 0.4385 | 70.05 | 0.9794 |

Table 4 Data of outlet gas of the absorption tower

| 项目 | 摩尔流率/(kmol/h) | 压力/MPa | 温度/K | 摩尔分数/% | |||

|---|---|---|---|---|---|---|---|

| CH4 | CO | CO2 | H2 | ||||

| 产品气(S8) | 475.21 | 0.1 | 298.15 | 0.2915 | 0.7194 | 0.5861 | 98.40 |

| 尾气(S14) | 905.48 | 2.6 | 333.15 | 28.53 | 0.4385 | 70.05 | 0.9794 |

| 项目 | 原料侧压力/MPa | 渗透侧压力/MPa | 操作 温度/K | 渗透速率/GPU | |||

|---|---|---|---|---|---|---|---|

| CH4 | CO | CO2 | H2 | ||||

| 一级 膜分离 | 2.6 | 0.1 | 298.15 | 0.25 | 10.7 | 10.7 | 28.1 |

| 二级 膜分离 | 2.5 | 0.1 | 298.15 | 0.25 | 10.7 | 10.7 | 28.1 |

Table 5 Separation membrane parameters and operating conditions

| 项目 | 原料侧压力/MPa | 渗透侧压力/MPa | 操作 温度/K | 渗透速率/GPU | |||

|---|---|---|---|---|---|---|---|

| CH4 | CO | CO2 | H2 | ||||

| 一级 膜分离 | 2.6 | 0.1 | 298.15 | 0.25 | 10.7 | 10.7 | 28.1 |

| 二级 膜分离 | 2.5 | 0.1 | 298.15 | 0.25 | 10.7 | 10.7 | 28.1 |

| 项目 | 摩尔流率/(kmol/h) | 压力/MPa | 温度/K | 摩尔分数/% | |||

|---|---|---|---|---|---|---|---|

| CH4 | CO | CO2 | H2 | ||||

| 一级 渗透气(P1) | 591.52 | 0.1 | 298.15 | 2.456 | 0.5975 | 95.46 | 1.484 |

| 二级 截留气(R2) | 221.79 | 2.5 | 298.15 | 98.12 | 0.0117 | 1.863 | 0.0003 |

| 二级 渗透气(P2) | 89.05 | 0.1 | 298.15 | 28.39 | 0.4450 | 71.10 | 0.0625 |

Tab1e 6 Simulation results of two-stage membrane separation

| 项目 | 摩尔流率/(kmol/h) | 压力/MPa | 温度/K | 摩尔分数/% | |||

|---|---|---|---|---|---|---|---|

| CH4 | CO | CO2 | H2 | ||||

| 一级 渗透气(P1) | 591.52 | 0.1 | 298.15 | 2.456 | 0.5975 | 95.46 | 1.484 |

| 二级 截留气(R2) | 221.79 | 2.5 | 298.15 | 98.12 | 0.0117 | 1.863 | 0.0003 |

| 二级 渗透气(P2) | 89.05 | 0.1 | 298.15 | 28.39 | 0.4450 | 71.10 | 0.0625 |

| 摩尔流率/(kmol/h) | 压力/MPa | 温度/K | 摩尔分数/% | |||

|---|---|---|---|---|---|---|

| CH4 | CO | CO2 | H2 | |||

| 2536.43 | 2.0 | 298.15 | 0.0561 | 0.1355 | 0.1359 | 99.67 |

Table 7 Data of hydrogen product

| 摩尔流率/(kmol/h) | 压力/MPa | 温度/K | 摩尔分数/% | |||

|---|---|---|---|---|---|---|

| CH4 | CO | CO2 | H2 | |||

| 2536.43 | 2.0 | 298.15 | 0.0561 | 0.1355 | 0.1359 | 99.67 |

| 项目 | 氢气 回收率/% | 回收氢气 纯度/% | 设备投资(相对)/% | 单位产氢 成本/(CNY/m3) |

|---|---|---|---|---|

| 一段PSA | ≥88.0 | ≥99.9 | 70 | 1.055 |

| 两段PSA耦合 | ≥96.3 | ≥99.9 | 110 | 1.012 |

| PSA-膜分离耦合 | ≥96.5 | ≥99.9 | 100 | 1.009 |

| PSA-低温 甲醇洗-膜分离 | ≥99.6 | ≥99.7 | 125 | 1.005 |

Table 8 Comparison of comprehensive indicators of different hydrogen separation processes

| 项目 | 氢气 回收率/% | 回收氢气 纯度/% | 设备投资(相对)/% | 单位产氢 成本/(CNY/m3) |

|---|---|---|---|---|

| 一段PSA | ≥88.0 | ≥99.9 | 70 | 1.055 |

| 两段PSA耦合 | ≥96.3 | ≥99.9 | 110 | 1.012 |

| PSA-膜分离耦合 | ≥96.5 | ≥99.9 | 100 | 1.009 |

| PSA-低温 甲醇洗-膜分离 | ≥99.6 | ≥99.7 | 125 | 1.005 |

| 1 | DeLuchi M A. Hydrogen vehicles: an evaluation of fuel storage, performance, safety, environmental impacts, and cost[J]. International Journal of Hydrogen Energy, 1989, 14(2): 81-130. |

| 2 | Momirlan M, Veziroglu T N. The properties of hydrogen as fuel tomorrow in sustainable energy system for a cleaner planet[J]. International Journal of Hydrogen Energy, 2005, 30(7): 795-802. |

| 3 | 李非凡, 薛贺来, 李黎明, 等. 传统制氢工艺的发展与展望[J]. 化学工程与装备, 2022(4): 210-212. |

| Li F F, Xue H L, Li L M, et al. Development and prospect of traditional hydrogen production process[J]. Chemical Engineering & Equipment, 2022(4): 210-212. | |

| 4 | 邹才能, 李建明, 张茜, 等. 氢能工业现状、技术进展、挑战及前景[J]. 天然气工业, 2022, 42(4): 1-20. |

| Zou C N, Li J M, Zhang X, et al. Industrial status, technological progress, challenges and prospects of hydrogen energy[J]. Natural Gas Industry, 2022, 42(4): 1-20. | |

| 5 | Bhandari R, Trudewind C A, Zapp P. Life cycle assessment of hydrogen production via electrolysis—a review[J]. Journal of Cleaner Production, 2014, 85: 151-163. |

| 6 | Barrett S. Road map to a US hydrogen economy[J]. Fuel Cells Bulletin, 2020, 2020(11): 12. |

| 7 | 黄格省, 李锦山, 魏寿祥, 等. 化石原料制氢技术发展现状与经济性分析[J]. 化工进展, 2019, 38(12): 5217-5224. |

| Huang G S, Li J S, Wei S X, et al. Status and economic analysis of hydrogen production technology from fossil raw materials[J]. Chemical Industry and Engineering Progress, 2019, 38(12): 5217-5224. | |

| 8 | 杨铮, 田桂丽. 我国氢气市场分析及发展前景研判[J]. 化学工业, 2022, 40(4): 51-57. |

| Yang Z, Tian G L. Market analysis and development outlook of hydrogen in China[J]. Chemical Industry, 2022, 40(4): 51-57. | |

| 9 | 杨颖, 曲冬蕾, 李平, 等. 低浓度煤层气吸附浓缩技术研究与发展[J]. 化工学报, 2018, 69(11): 4518-4529. |

| Yang Y, Qu D L, Li P, et al. Research and development on enrichment of low concentration coal mine methane by adsorption technology[J]. CIESC Journal, 2018, 69(11): 4518-4529. | |

| 10 | Xue C L, Cheng W P, Hao W M, et al. CH4/N2 adsorptive separation on zeolite X/AC composites[J]. Journal of Chemistry, 2019, 2019: 1-9. |

| 11 | 范鹏鹏, 刘晓, 陈贞龙, 等. 中美煤层气勘探开发现状对比及启示[J]. 现代化工, 2023, 43(8): 22-25, 30. |

| Fan P P, Liu X, Chen Z L, et al. Comparison and enlightenment of current situation of coalbed methane exploration and development between China and the United States[J]. Modern Chemical Industry, 2023, 43(8): 22-25, 30. | |

| 12 | 钮朝阳, 江南, 沈圆辉, 等. 快速变压吸附制氢工艺的模拟与分析[J]. 化工学报, 2021, 72(2): 1036-1046. |

| Niu Z Y, Jiang N, Shen Y H, et al. Simulation and analysis of rapid pressure swing adsorption for hydrogen production[J]. CIESC Journal, 2021, 72(2): 1036-1046. | |

| 13 | Carta M. Gas separation[M]//Encyclopedia of Membranes. Berlin Heidelberg: Springer-Verlag, 2016. |

| 14 | Li H R, Liao Z W, Sun J Y, et al. Modelling and simulation of two-bed PSA process for separating H2 from methane steam reforming[J]. Chinese Journal of Chemical Engineering, 2019, 27(8): 1870-1878. |

| 15 | Burgers I, Dehdari L, Xiao P, et al. Techno-economic analysis of PSA separation for hydrogen/natural gas mixtures at hydrogen refuelling stations[J]. International Journal of Hydrogen Energy, 2022, 47(85): 36163-36174. |

| 16 | Luberti M, Ahn H. Review of polybed pressure swing adsorption for hydrogen purification[J]. International Journal of Hydrogen Energy, 2022, 47(20): 10911-10933. |

| 17 | Da Conceicao M, Nemetz L, Rivero J, et al. Gas separation membrane module modeling: a comprehensive review[J]. Membranes, 2023, 13(7): 639. |

| 18 | Mao D L, Griffin J M, Dawson R, et al. Metal organic frameworks for hydrogen purification[J]. International Journal of Hydrogen Energy, 2021, 46(45): 23380-23405. |

| 19 | Gu Z L, Shi Z P, Lin G J, et al. Highly efficient and selective H2/CH4 separation by graphene membranes with embedded crown ethers[J]. International Journal of Hydrogen Energy, 2022, 47(59): 24835-24842. |

| 20 | 张习文, 吕超, 金理健, 等. 低温甲醇洗碳捕集工艺的优化与(㶲)分析[J]. 东南大学学报(自然科学版), 2023, 53(2): 356-362. |

| Zhang X W, Lyu C, Jin L J, et al. Optimization and exergy analysis of low temperature methanol washing carbon capture process[J]. Journal of Southeast University (Natural Science Edition), 2023, 53(2): 356-362. | |

| 21 | 杨声, 梁嘉能, 杨思宇, 等. 煤制气中甲烷化余热利用集成串级吸收式制冷新工艺[J]. 化工学报, 2016, 67(3): 779-787. |

| Yang S, Liang J N, Yang S Y, et al. A novel integrated cascade absorption refrigeration technology by using waste heat in CTG’s methanation process[J]. CIESC Journal, 2016, 67(3): 779-787. | |

| 22 | Wang J, Shen Y H, Zhang D H, et al. Integrated vacuum pressure swing adsorption and rectisol process for CO2 capture from underground coal gasification syngas[J]. Chinese Journal of Chemical Engineering, 2023, 57: 265-279. |

| 23 | Ohs B, Falkenberg M, Wessling M. Optimizing hybrid membrane-pressure swing adsorption processes for biogenic hydrogen recovery[J]. Chemical Engineering Journal, 2019, 364: 452-461. |

| 24 | Li B J, He G H, Jiang X B, et al. Pressure swing adsorption/membrane hybrid processes for hydrogen purification with a high recovery[J]. Frontiers of Chemical Science and Engineering, 2016, 10(2): 255-264. |

| 25 | 党凯, 艾力江, 孙镭, 等. 氢气提纯耦合工艺及其应用[J]. 天然气化工—C1化学与化工, 2021, 46(6): 86-90. |

| Dang K, Ai L J, Sun L, et al. Hydrogen purification coupling process and its application[J]. Natural Gas Chemical Industry, 2021, 46(6): 86-90. | |

| 26 | Park J H, Kim J N, Cho S H, et al. Adsorber dynamics and optimal design of layered beds for multicomponent gas adsorption[J]. Chemical Engineering Science, 1998, 53(23): 3951-3963. |

| 27 | Ramírez-Santos Á A, Bozorg M, Addis B, et al. Optimization of multistage membrane gas separation processes. Example of application to CO2 capture from blast furnace gas[J]. Journal of Membrane Science, 2018, 566: 346-366. |

| 28 | 乔义书. 油田伴生气多级膜分离工艺模拟及实验研究[D]. 青岛: 青岛科技大学, 2022. |

| Qiao Y S. Simulation and experimental study on multistage membrane separation process of oilfield associated gas[D]. Qingdao: Qingdao University of Science and Technology, 2022. | |

| 29 | 许家友. CO2膜分离过程的模拟及优化[D]. 天津: 天津大学, 2019. |

| Xu J Y. Simulation and optimization of CO2 membrane separation process[D]. Tianjin: Tianjin University, 2019. | |

| 30 | 陶宇鹏. 不同氢气净化提纯技术在煤制氢中的经济性分析[J]. 四川化工, 2021, 24(4): 13-16. |

| Tao Y P. Economic analysis of different hydrogen purification technologies in hydrogen production from coal[J]. Sichuan Chemical Industry, 2021, 24(4): 13-16. |

| [1] | Xin YANG, Wen WANG, Kai XU, Fanhua MA. Simulation analysis of temperature characteristics of the high-pressure hydrogen refueling process [J]. CIESC Journal, 2023, 74(S1): 280-286. |

| [2] | Congqi HUANG, Yimei WU, Jianye CHEN, Shuangquan SHAO. Simulation study of thermal management system of alkaline water electrolysis device for hydrogen production [J]. CIESC Journal, 2023, 74(S1): 320-328. |

| [3] | Zehao MI, Er HUA. DFT and COSMO-RS theoretical analysis of SO2 absorption by polyamines type ionic liquids [J]. CIESC Journal, 2023, 74(9): 3681-3696. |

| [4] | Ke LI, Jian WEN, Biping XIN. Study on influence mechanism of vacuum multi-layer insulation coupled with vapor-cooled shield on self-pressurization process of liquid hydrogen storage tank [J]. CIESC Journal, 2023, 74(9): 3786-3796. |

| [5] | Zhewen CHEN, Junjie WEI, Yuming ZHANG. System integration and energy conversion mechanism of the power technology with integrated supercritical water gasification of coal and SOFC [J]. CIESC Journal, 2023, 74(9): 3888-3902. |

| [6] | Yaxin ZHAO, Xueqin ZHANG, Rongzhu WANG, Guo SUN, Shanjing YAO, Dongqiang LIN. Removal of monoclonal antibody aggregates with ion exchange chromatography by flow-through mode [J]. CIESC Journal, 2023, 74(9): 3879-3887. |

| [7] | Yuanchao LIU, Bin GUAN, Jianbin ZHONG, Yifan XU, Xuhao JIANG, Duan LI. Investigation of thermoelectric transport properties of single-layer XSe2 (X=Zr/Hf) [J]. CIESC Journal, 2023, 74(9): 3968-3978. |

| [8] | Junfeng LU, Huaiyu SUN, Yanlei WANG, Hongyan HE. Molecular understanding of interfacial polarization and its effect on ionic liquid hydrogen bonds [J]. CIESC Journal, 2023, 74(9): 3665-3680. |

| [9] | Shuang LIU, Linzhou ZHANG, Zhiming XU, Suoqi ZHAO. Study on molecular level composition correlation of viscosity of residual oil and its components [J]. CIESC Journal, 2023, 74(8): 3226-3241. |

| [10] | Yali HU, Junyong HU, Suxia MA, Yukun SUN, Xueyi TAN, Jiaxin HUANG, Fengyuan YANG. Development of novel working fluid and study on electrochemical characteristics of reverse electrodialysis heat engine [J]. CIESC Journal, 2023, 74(8): 3513-3521. |

| [11] | Jiayi ZHANG, Jiali HE, Jiangpeng XIE, Jian WANG, Yu ZHAO, Dongqiang ZHANG. Research progress of pervaporation technology for N-methylpyrrolidone recovery in lithium battery production [J]. CIESC Journal, 2023, 74(8): 3203-3215. |

| [12] | Ruihang ZHANG, Pan CAO, Feng YANG, Kun LI, Peng XIAO, Chun DENG, Bei LIU, Changyu SUN, Guangjin CHEN. Analysis of key parameters affecting product purity of natural gas ethane recovery process via ZIF-8 nanofluid [J]. CIESC Journal, 2023, 74(8): 3386-3393. |

| [13] | Feifei YANG, Shixi ZHAO, Wei ZHOU, Zhonghai NI. Sn doped In2O3 catalyst for selective hydrogenation of CO2 to methanol [J]. CIESC Journal, 2023, 74(8): 3366-3374. |

| [14] | Lei XING, Chunyu MIAO, Minghu JIANG, Lixin ZHAO, Xinya LI. Optimal design and performance analysis of downhole micro gas-liquid hydrocyclone [J]. CIESC Journal, 2023, 74(8): 3394-3406. |

| [15] | Yuanliang ZHANG, Xinqi LUAN, Weige SU, Changhao LI, Zhongxing ZHAO, Liqin ZHOU, Jianmin CHEN, Yan HUANG, Zhenxia ZHAO. Study on selective extraction of nicotine by ionic liquids composite extractant and DFT calculation [J]. CIESC Journal, 2023, 74(7): 2947-2956. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||