CIESC Journal ›› 2024, Vol. 75 ›› Issue (4): 1594-1606.DOI: 10.11949/0438-1157.20231388

• Catalysis, kinetics and reactors • Previous Articles Next Articles

Ang LI1( ), Zhenyu ZHAO1(

), Zhenyu ZHAO1( ), Hong LI1, Xin GAO1,2(

), Hong LI1, Xin GAO1,2( )

)

Received:2023-12-28

Revised:2024-02-01

Online:2024-06-06

Published:2024-04-25

Contact:

Zhenyu ZHAO, Xin GAO

通讯作者:

赵振宇,高鑫

作者简介:李昂(1998—),男,硕士研究生,2021207419@tju.edu.cn

基金资助:CLC Number:

Ang LI, Zhenyu ZHAO, Hong LI, Xin GAO. Microwave induced construction of highly dispersed Pd/FeP catalysts and their electrocatalytic performance[J]. CIESC Journal, 2024, 75(4): 1594-1606.

李昂, 赵振宇, 李洪, 高鑫. 微波诱导高分散Pd/FeP催化剂构筑及其电催化性能研究[J]. 化工学报, 2024, 75(4): 1594-1606.

Add to citation manager EndNote|Ris|BibTeX

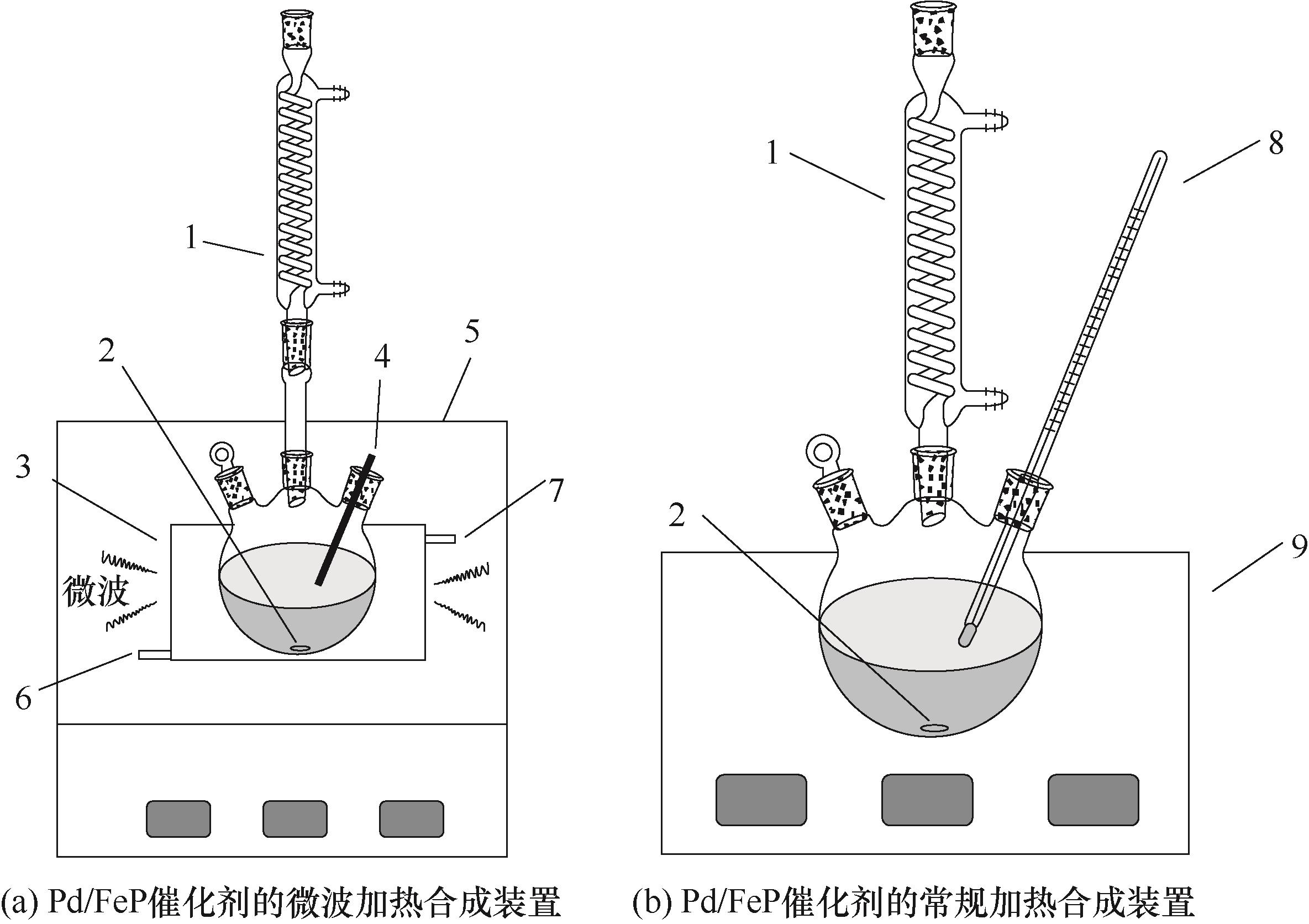

Fig.1 Schematic diagram of experimental apparatuses for the synthesis of Pd/FeP catalyst under microwave irradiation and conventional heating, respectively

| 1 | Yang C Z, Wang T Y, Li C C, et al. PdMo bimetallene coupled with MXene nanosheets as efficient bifunctional electrocatalysts for formic acid and methanol oxidation reactions[J]. ACS Applied Materials & Interfaces, 2023, 15(42): 49195-49203. |

| 2 | Hu S Z, Gao Z Q, Gao S J, et al. Atomic ordering effect of intermetallic PdCoNi/rGO catalysts on formic acid electro-oxidation[J]. ACS Applied Energy Materials, 2023, 6(21): 11051-11060. |

| 3 | Shatla A S, Hassan K M, Abd-El-Latif A A, et al. Poly 1,5-diaminonaphthalene supported Pt, Pd, Pt/Pd and Pd/Pt nanoparticles for direct formic acid oxidation[J]. Journal of Electroanalytical Chemistry, 2019, 833: 231-241. |

| 4 | Zhang L, Wan L, Ma Y R, et al. Crystalline palladium-cobalt alloy nanoassemblies with enhanced activity and stability for the formic acid oxidation reaction[J]. Applied Catalysis B: Environmental, 2013, 138/139: 229-235. |

| 5 | Zhao L, Sui X L, Li J Z, et al. Supramolecular assembly promoted synthesis of three-dimensional nitrogen doped graphene frameworks as efficient electrocatalyst for oxygen reduction reaction and methanol electrooxidation[J]. Applied Catalysis B: Environmental, 2018, 231: 224-233. |

| 6 | Qiu B C, Cai L J, Wang Y, et al. Fabrication of nickel-cobalt bimetal phosphide nanocages for enhanced oxygen evolution catalysis[J]. Advanced Functional Materials, 2018, 28(17): 1706008. |

| 7 | Yang J, Zhang Y, Sun C C, et al. Graphene and cobalt phosphide nanowire composite as an anode material for high performance lithium-ion batteries[J]. Nano Research, 2016, 9(3): 612-621. |

| 8 | Hong W T, Jian C Y, Wang G X, et al. Self-supported nanoporous cobalt phosphosulfate electrodes for efficient hydrogen evolution reaction[J]. Applied Catalysis B: Environmental, 2019, 251: 213-219. |

| 9 | Chang J F, Feng L G, Liu C P, et al. An effective Pd-Ni2P/C anode catalyst for direct formic acid fuel cells[J]. Angewandte Chemie (International Ed. in English), 2014, 53(1): 122-126. |

| 10 | Chang J F, Feng L G, Liu C P, et al. Ni2P enhances the activity and durability of the Pt anode catalyst in direct methanol fuel cells[J]. Energy & Environmental Science, 2014, 7(5): 1628-1632. |

| 11 | Wang F L, Xue H G, Tian Z Q, et al. Fe2P as a novel efficient catalyst promoter in Pd/C system for formic acid electro-oxidation in fuel cells reaction[J]. Journal of Power Sources, 2018, 375: 37-42. |

| 12 | Leng Y, Zhang C J, Liu B, et al. Synergistic activation of palladium nanoparticles by polyoxometalate-attached melem for boosting formic acid dehydrogenation efficiency[J]. ChemSusChem, 2018, 11(19): 3396-3401. |

| 13 | Bao Y F, Wang F L, Gu X C, et al. Core-shell structured PtRu nanoparticles@FeP promoter with an efficient nanointerface for alcohol fuel electrooxidation[J]. Nanoscale, 2019, 11(40): 18866-18873. |

| 14 | Zhang L L, Ding L X, Luo Y R, et al. PdO/Pd-CeO2 hollow spheres with fresh Pd surface for enhancing formic acid oxidation[J]. Chemical Engineering Journal, 2018, 347: 193-201. |

| 15 | Wang H W, Gu X K, Zheng X S, et al. Disentangling the size-dependent geometric and electronic effects of palladium nanocatalysts beyond selectivity[J]. Science Advances, 2019, 5(1): eaat6413. |

| 16 | Zhou W J, Li M, Ding O L, et al. Pd particle size effects on oxygen electrochemical reduction[J]. International Journal of Hydrogen Energy, 2014, 39(12): 6433-6442. |

| 17 | Wei M, Zhao L, Jiang L W, et al. Development of high-throughput rapid heat-treatment and characterization process[J]. Acta Materialia, 2023, 261: 119365. |

| 18 | Kappe C O. Controlled microwave heating in modern organic synthesis[J]. Angewandte Chemie (International Ed. in English), 2004, 43(46): 6250-6284. |

| 19 | Varma R S. Journey on greener pathways: from the use of alternate energy inputs and benign reaction media to sustainable applications of nano-catalysts in synthesis and environmental remediation[J]. Green Chemistry, 2014, 16(4): 2027-2041. |

| 20 | Breeden S W, Clark J H, Farmer T J, et al. Microwave heating for rapid conversion of sugars and polysaccharides to 5-chloromethyl furfural[J]. Green Chemistry, 2013, 15(1): 72-75. |

| 21 | Demirskyi D, Agrawal D, Ragulya A. Neck growth kinetics during microwave sintering of copper[J]. Scripta Materialia, 2010, 62(8): 552-555. |

| 22 | Upadhyaya A, Tiwari S K, Mishra P. Microwave sintering of W-Ni-Fe alloy[J]. Scripta Materialia, 2007, 56(1): 5-8. |

| 23 | Ebadzadeh T, Sarrafi M H, Salahi E. Microwave-assisted synthesis and sintering of mullite[J]. Ceramics International, 2009, 35(8): 3175-3179. |

| 24 | Fidalgo B, Fernández Y, Zubizarreta L, et al. Growth of nanofilaments on carbon-based materials from microwave-assisted decomposition of CH4 [J]. Applied Surface Science, 2008, 254(11): 3553-3557. |

| 25 | Schwenke A M, Hoeppener S, Schubert U S. Synthesis and modification of carbon nanomaterials utilizing microwave heating[J]. Advanced Materials, 2015, 27(28): 4113-4141. |

| 26 | 陈婷, 胡泽浩, 秦喆, 等. 有机相微波合成AgInS2量子点及其白光发光二极管应用研究[J]. 化工学报, 2022,73(11): 5167-5176. |

| Chen T, Hu Z H, QIN Z, et al. Microwave synthesis of AgInS2 quantum dots in organic solvent and application for white light-emitting diodes[J]. CIESC Journal, 2022, 73(11): 5167-5176. | |

| 27 | Xu W T, Zhou J C, Su Z M, et al. Microwave catalytic effect: a new exact reason for microwave-driven heterogeneous gas-phase catalytic reactions[J]. Catalysis Science & Technology, 2016, 6(3): 698-702. |

| 28 | Luo M D, Zhou J C, Xu W T, et al. Development of composite microwave catalysts (ABS x /CNTs, A = Co, B = Ni, Mo) for the highly effective direct decomposition of H2S into H2 and S[J]. Fuel, 2020, 281: 118729. |

| 29 | Rodríguez A M, Prieto P, de la Hoz A, et al. Influence of polarity and activation energy in microwave-assisted organic synthesis (MAOS)[J]. ChemistryOpen, 2015, 4(3): 308-317. |

| 30 | Dudley G B, Richert R, Stiegman A E. On the existence of and mechanism for microwave-specific reaction rate enhancement[J]. Chemical Science, 2015, 6(4): 2144-2152. |

| 31 | Horikoshi S, Serpone N. Role of microwaves in heterogeneous catalytic systems[J]. Catalysis Science & Technology, 2014, 4(5): 1197-1210. |

| 32 | Horikoshi S, Osawa A, Abe M, et al. On the generation of hot-spots by microwave electric and magnetic fields and their impact on a microwave-assisted heterogeneous reaction in the presence of metallic Pd nanoparticles on an activated carbon support[J]. The Journal of Physical Chemistry C, 2011, 115(46): 23030-23035. |

| 33 | Zhao Z Y, Shen X, Li H, et al. Watching microwave-induced microscopic hot spots via the thermosensitive fluorescence of europium/terbium mixed-metal organic complexes[J]. Angewandte Chemie (International Ed. in English), 2022, 61(6): e202114340. |

| 34 | Mu S Y, Liu K, Li H, et al. Microwave-assisted synthesis of highly dispersed ZrO2 on CNTs as an efficient catalyst for producing 5-hydroxymethylfurfural (5-HMF)[J]. Fuel Processing Technology, 2022, 233: 107292. |

| 35 | Buinachev S, Mashkovtsev M A, Zhirenkina N, et al. A new approach for the synthesis of monodisperse zirconia powders with controlled particle size[J]. International Journal of Hydrogen Energy, 2021, 46(32): 16878-16887. |

| 36 | Xiao S N, Zhou C, Ye X Y, et al. Solid-phase microwave reduction of WO3 by GO for enhanced synergistic photo-Fenton catalytic degradation of bisphenol A[J]. ACS Applied Materials & Interfaces, 2020, 12(29): 32604-32614. |

| 37 | Huang H W, Zhou S, Yu C, et al. Rapid and energy-efficient microwave pyrolysis for high-yield production of highly-active bifunctional electrocatalysts for water splitting[J]. Energy & Environmental Science, 2020, 13(2): 545-553. |

| 38 | Zhao B, Shao G, Fan B B, et al. Synthesis of flower-like CuS hollow microspheres based on nanoflakes self-assembly and their microwave absorption properties[J]. Journal of Materials Chemistry A, 2015, 3(19): 10345-10352. |

| 39 | Wen C Y, Li X, Zhang R X, et al. High-density anisotropy magnetism enhanced microwave absorption performance in Ti3C2T x MXene@Ni microspheres[J]. ACS Nano, 2022, 16(1): 1150-1159. |

| 40 | Li B D, Zeng Z H, Qiao J, et al. Hollow ZnO/Fe3O4@C nanofibers for efficient electromagnetic wave absorption[J]. ACS Applied Nano Materials, 2022, 5(8): 11617-11626. |

| 41 | Elhassan A, Abdalla I, Yu J Y, et al. Microwave-assisted fabrication of sea cucumber-like hollow structured composite for high-performance electromagnetic wave absorption[J]. Chemical Engineering Journal, 2020, 392: 123646. |

| 42 | Zheng Q, Cao W Q, Zhai H Z, et al. Tailoring carbon-based nanofiber microstructures for electromagnetic absorption, shielding, and devices[J]. Materials Chemistry Frontiers, 2023, 7(9): 1737-1759. |

| 43 | Ji T, Tu R, Mu L W, et al. Structurally tuning microwave absorption of core/shell structured CNT/polyaniline catalysts for energy efficient saccharide-HMF conversion[J]. Applied Catalysis B: Environmental, 2018, 220: 581-588. |

| 44 | Wang F L, Yang X D, Dong B X, et al. A FeP powder electrocatalyst for the hydrogen evolution reaction[J]. Electrochemistry Communications, 2018, 92: 33-38 |

| 45 | Tian L H, Yan X D, Chen X B. Electrochemical activity of iron phosphide nanoparticles in hydrogen evolution reaction[J]. ACS Catalysis, 2016, 6(8): 5441-5448. |

| 46 | Wang B, Wu H B, Yu L, et al. Template-free formation of uniform urchin-like α-FeOOH hollow spheres with superior capability for water treatment[J]. Advanced Materials, 2012, 24(8): 1111-1116. |

| 47 | 王亭杰, 金涌, 汪展文, 等. 针状羟基氧化铁的成核与生长过程[J]. 化工学报, 1998, 49(2): 201-207. |

| Wang T J, Jin Y, Wang Z W, et al. Nucleation and growth process of the needle-like goethite crystals[J]. Journal of Chemical Industry and Engineering (China), 1998, 49(2): 201-207. |

| [1] | Tianyi LI, Yutai WU, Yongsheng WANG, Jiarui GU, Yiheng SONG, Fengcheng YANG, Guangping HAO. Advances in light isotopes separation and catalytic labeling [J]. CIESC Journal, 2024, 75(4): 1284-1301. |

| [2] | Mingze SUN, Helai HUANG, Zhiqiang NIU. Pt-based oxygen reduction reaction catalysts: from single crystal electrode to nanostructured extended surface [J]. CIESC Journal, 2024, 75(4): 1256-1269. |

| [3] | Yu HAN, Le ZHOU, Xin ZHANG, Yong LUO, Baochang SUN, Haikui ZOU, Jianfeng CHEN. Preparation of high adhesion Pd/SiO2/NF monolithic catalyst and its hydrogenation performance [J]. CIESC Journal, 2024, 75(4): 1533-1542. |

| [4] | Xiaokai CHENG, Wei LI, Jingdai WANG, Yongrong YANG. Advances in nickel catalyzed controlled/living radical polymerization reactions [J]. CIESC Journal, 2024, 75(4): 1105-1117. |

| [5] | Xi WU, Bo SUN, Yindong LIU, Chuanlei QI, Kaiyi CHEN, Luhai WANG, Chong XU, Yongfeng LI. Research progress in preparation technology of pitch-based carbon anode materials for sodium-ion batteries [J]. CIESC Journal, 2024, 75(4): 1270-1283. |

| [6] | Yunxuan LI, Xinyue LIU, Xi CHEN, Wen LIU, Mingyue ZHOU, Xingying LAN. Energy storage technologies based on solid-liquid redox-targeting reactions: materials, devices, and kinetics [J]. CIESC Journal, 2024, 75(4): 1222-1240. |

| [7] | Yiwei FAN, Wei LIU, Yingying LI, Peixia WANG, Jisong ZHANG. Research progress on catalytic dehydrogenation of dodecahydro-N-ethylcarbazole as liquid organic hydrogen carrier [J]. CIESC Journal, 2024, 75(4): 1198-1208. |

| [8] | Xudong JIA, Bolong YANG, Qian CHENG, Xueli LI, Zhonghua XIANG. Preparation of high-efficiency iron-cobalt bimetallic site oxygen reduction electrocatalysts by step-by-step metal loading method [J]. CIESC Journal, 2024, 75(4): 1578-1593. |

| [9] | Xiaoqing YAN, Ying ZHAO, Yuzhe ZHANG, Honghui OU, Qizhong HUANG, Huagui HU, Guidong YANG. Preparation of five-fold twinned copper nanowires@polypyrrole and their electrocatalytic conversion of nitrate to ammonia [J]. CIESC Journal, 2024, 75(4): 1519-1532. |

| [10] | Yuexing WEI, Ziyue HE, Kezhou YAN, Linyu LI, Yuhong QIN, Chong HE, Luchang JIAO. Catalytic degradation of bisphenol A by modified coal gasification slag [J]. CIESC Journal, 2024, 75(3): 877-889. |

| [11] | Zhiming CHEN, Zefeng WANG, Gaoqi MA, Liangbo WANG, Chengtao YU, Pengju PAN. Research progress on improving thermal stability of polylactic acid based on stannous inactivation and chain end-group modification [J]. CIESC Journal, 2024, 75(3): 760-767. |

| [12] | Na PAN, Chang TIAN, Lankun HUAI, Yuyu LIU, Fenfen ZHANG, Xiaomei GAO, Wei LIU, Liangguo YAN, Yanxia ZHAO. Synthesis and application of polymerized Al-Ti based flocculant [J]. CIESC Journal, 2024, 75(3): 1009-1018. |

| [13] | Xingyu GAI, Yuxue YUE, Chunhua YANG, Zilong ZHANG, Tianzi CAI, Haifeng ZHANG, Bolin WANG, Xiaonian LI. Carbon supported Cs- and Cu-based catalysts for gas-phase dehydrochlorination of 1,1,2-trichloroethane [J]. CIESC Journal, 2024, 75(2): 575-583. |

| [14] | Yuhua YIN, Can FANG, Qingfeng YI, Guang LI. Impact of different carbon conductive agents on performance of iron-air battery [J]. CIESC Journal, 2024, 75(2): 685-694. |

| [15] | Xuejie WANG, Guoqing CUI, Wenhan WANG, Yang YANG, Congkai WANG, Guiyuan JIANG, Chunming XU. Study on highly efficient methylcyclohexane dehydrogenation over Pt/NPC catalysts by internal electric heating [J]. CIESC Journal, 2024, 75(1): 292-301. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||