CIESC Journal ›› 2024, Vol. 75 ›› Issue (12): 4780-4792.DOI: 10.11949/0438-1157.20240617

• Energy and environmental engineering • Previous Articles Next Articles

Zhongliang XIAO1( ), Yubo XIA1, Liubin SONG1(

), Yubo XIA1, Liubin SONG1( ), Youtao XIANG1, Tingting ZHAO1, Jing LUO1, Yuanjia LIU1, Penghui DENG1, Qunxuan YAN2(

), Youtao XIANG1, Tingting ZHAO1, Jing LUO1, Yuanjia LIU1, Penghui DENG1, Qunxuan YAN2( )

)

Received:2024-06-04

Revised:2024-08-16

Online:2025-01-03

Published:2024-12-25

Contact:

Liubin SONG, Qunxuan YAN

肖忠良1( ), 夏宇博1, 宋刘斌1(

), 夏宇博1, 宋刘斌1( ), 向优涛1, 赵亭亭1, 罗静1, 刘远佳1, 邓鹏辉1, 颜群轩2(

), 向优涛1, 赵亭亭1, 罗静1, 刘远佳1, 邓鹏辉1, 颜群轩2( )

)

通讯作者:

宋刘斌,颜群轩

作者简介:肖忠良(1964—),男,博士,教授,xiaozhongliang@163.com

基金资助:CLC Number:

Zhongliang XIAO, Yubo XIA, Liubin SONG, Youtao XIANG, Tingting ZHAO, Jing LUO, Yuanjia LIU, Penghui DENG, Qunxuan YAN. Synergistic leaching process of waste LiFePO4 with phosphoric acid-tartaric acid system[J]. CIESC Journal, 2024, 75(12): 4780-4792.

肖忠良, 夏宇博, 宋刘斌, 向优涛, 赵亭亭, 罗静, 刘远佳, 邓鹏辉, 颜群轩. 磷酸-酒石酸体系协同浸出废旧磷酸铁锂工艺[J]. 化工学报, 2024, 75(12): 4780-4792.

Add to citation manager EndNote|Ris|BibTeX

| 药品名称 | 分子式 | 规格 | 厂家 |

|---|---|---|---|

| 磷酸 | H3PO4 | AR | 国药集团有限公司 |

| 酒石酸 | C4H6O6 | AR | 国药集团有限公司 |

| 碳酸锂 | Li2CO3 | 电池级 | 上海麦克林生化科技股份有限公司 |

| 氧化铁 | Fe2O3 | AR | 上海麦克林生化科技股份有限公司 |

Table 1 Experimental reagents

| 药品名称 | 分子式 | 规格 | 厂家 |

|---|---|---|---|

| 磷酸 | H3PO4 | AR | 国药集团有限公司 |

| 酒石酸 | C4H6O6 | AR | 国药集团有限公司 |

| 碳酸锂 | Li2CO3 | 电池级 | 上海麦克林生化科技股份有限公司 |

| 氧化铁 | Fe2O3 | AR | 上海麦克林生化科技股份有限公司 |

| 仪器名称 | 型号 | 生产厂家 |

|---|---|---|

| 恒速电动搅拌器 | JJ-1B | 西城新瑞仪器厂 |

| 集热式恒温加热磁力 搅拌器 | DF-101S | 上海力辰邦西仪器科技公司 |

| 管式炉 | HLG-X-16 | 洛阳恒立窑炉有限公司 |

| X射线衍射分析仪 | D8 Advance | 德国Bruker公司 |

| 电感耦合等离子体发生光谱仪 | ARCOS | 德国SPECTRO公司 |

Table 2 Experimental equipments

| 仪器名称 | 型号 | 生产厂家 |

|---|---|---|

| 恒速电动搅拌器 | JJ-1B | 西城新瑞仪器厂 |

| 集热式恒温加热磁力 搅拌器 | DF-101S | 上海力辰邦西仪器科技公司 |

| 管式炉 | HLG-X-16 | 洛阳恒立窑炉有限公司 |

| X射线衍射分析仪 | D8 Advance | 德国Bruker公司 |

| 电感耦合等离子体发生光谱仪 | ARCOS | 德国SPECTRO公司 |

| Element | Composition/% |

|---|---|

| Li | 3.62 |

| Fe | 28.06 |

| Al | 0.72 |

| P | 16.28 |

Table 3 Chemical element composition of iron-lithium powder

| Element | Composition/% |

|---|---|

| Li | 3.62 |

| Fe | 28.06 |

| Al | 0.72 |

| P | 16.28 |

实验 序号 | 搅拌速度/(r/min) | 磷酸浓度/(mol/L) | 酒石酸浓度/(mol/L) | 液固比/(ml/g) | 温度/℃ | 时间/h | Li 浸出率/% | Fe 浸出率/% |

|---|---|---|---|---|---|---|---|---|

| 1 | 200 | 2.90 | 1.33 | 5∶1 | 70 | 5 | 89.60 | 88.78 |

| 2 | 300 | 2.90 | 1.33 | 5∶1 | 70 | 5 | 92.58 | 95.33 |

| 3 | 400 | 2.90 | 1.33 | 5∶1 | 70 | 5 | 92.59 | 96.34 |

| 4 | 500 | 2.90 | 1.33 | 5∶1 | 70 | 5 | 94.83 | 96.67 |

| 5 | 600 | 2.90 | 1.33 | 5∶1 | 70 | 5 | 93.14 | 97.34 |

| 6 | 700 | 2.90 | 1.33 | 5∶1 | 70 | 5 | 91.27 | 93.00 |

Table 4 Effect of stirring speed on leaching rate of Li and Fe

实验 序号 | 搅拌速度/(r/min) | 磷酸浓度/(mol/L) | 酒石酸浓度/(mol/L) | 液固比/(ml/g) | 温度/℃ | 时间/h | Li 浸出率/% | Fe 浸出率/% |

|---|---|---|---|---|---|---|---|---|

| 1 | 200 | 2.90 | 1.33 | 5∶1 | 70 | 5 | 89.60 | 88.78 |

| 2 | 300 | 2.90 | 1.33 | 5∶1 | 70 | 5 | 92.58 | 95.33 |

| 3 | 400 | 2.90 | 1.33 | 5∶1 | 70 | 5 | 92.59 | 96.34 |

| 4 | 500 | 2.90 | 1.33 | 5∶1 | 70 | 5 | 94.83 | 96.67 |

| 5 | 600 | 2.90 | 1.33 | 5∶1 | 70 | 5 | 93.14 | 97.34 |

| 6 | 700 | 2.90 | 1.33 | 5∶1 | 70 | 5 | 91.27 | 93.00 |

实验 序号 | 磷酸 浓度/(mol/L) | 搅拌 速度/(r/min) | 酒石酸 浓度/(mol/L) | 液固比/(ml/g) | 温度/℃ | 时间/h | Li 浸出率/% | Fe 浸出率/% |

|---|---|---|---|---|---|---|---|---|

| 1 | 1.74 | 500 | 1.33 | 5∶1 | 70 | 5 | 88.93 | 85.38 |

| 2 | 2.32 | 500 | 1.33 | 5∶1 | 70 | 5 | 94.55 | 94.32 |

| 3 | 2.90 | 500 | 1.33 | 5∶1 | 70 | 5 | 96.34 | 96.48 |

| 4 | 3.48 | 500 | 1.33 | 5∶1 | 70 | 5 | 95.97 | 94.44 |

| 5 | 4.06 | 500 | 1.33 | 5∶1 | 70 | 5 | 95.12 | 94.35 |

| 6 | 4.64 | 500 | 1.33 | 5∶1 | 70 | 5 | 95.61 | 74.15 |

Table 5 Effect of H3PO4 concentration on leaching rate of Li and Fe

实验 序号 | 磷酸 浓度/(mol/L) | 搅拌 速度/(r/min) | 酒石酸 浓度/(mol/L) | 液固比/(ml/g) | 温度/℃ | 时间/h | Li 浸出率/% | Fe 浸出率/% |

|---|---|---|---|---|---|---|---|---|

| 1 | 1.74 | 500 | 1.33 | 5∶1 | 70 | 5 | 88.93 | 85.38 |

| 2 | 2.32 | 500 | 1.33 | 5∶1 | 70 | 5 | 94.55 | 94.32 |

| 3 | 2.90 | 500 | 1.33 | 5∶1 | 70 | 5 | 96.34 | 96.48 |

| 4 | 3.48 | 500 | 1.33 | 5∶1 | 70 | 5 | 95.97 | 94.44 |

| 5 | 4.06 | 500 | 1.33 | 5∶1 | 70 | 5 | 95.12 | 94.35 |

| 6 | 4.64 | 500 | 1.33 | 5∶1 | 70 | 5 | 95.61 | 74.15 |

实验 序号 | 酒石酸 浓度/(mol/L) | 搅拌 速度/(r/min) | 磷酸 浓度/(mol/L) | 液固比/(ml/g) | 温度/℃ | 时间/h | Li 浸出率/% | Fe 浸出率/% |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.53 | 500 | 2.90 | 5∶1 | 70 | 5 | 93.21 | 24.94 |

| 2 | 0.80 | 500 | 2.90 | 5∶1 | 70 | 5 | 93.45 | 52.04 |

| 3 | 1.06 | 500 | 2.90 | 5∶1 | 70 | 5 | 94.03 | 81.83 |

| 4 | 1.33 | 500 | 2.90 | 5∶1 | 70 | 5 | 95.11 | 97.08 |

| 5 | 1.60 | 500 | 2.90 | 5∶1 | 70 | 5 | 95.11 | 94.44 |

| 6 | 1.86 | 500 | 2.90 | 5∶1 | 70 | 5 | 94.53 | 93.79 |

Table 6 Effect of tartaric acid concentration on leaching rate of Li and Fe

实验 序号 | 酒石酸 浓度/(mol/L) | 搅拌 速度/(r/min) | 磷酸 浓度/(mol/L) | 液固比/(ml/g) | 温度/℃ | 时间/h | Li 浸出率/% | Fe 浸出率/% |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.53 | 500 | 2.90 | 5∶1 | 70 | 5 | 93.21 | 24.94 |

| 2 | 0.80 | 500 | 2.90 | 5∶1 | 70 | 5 | 93.45 | 52.04 |

| 3 | 1.06 | 500 | 2.90 | 5∶1 | 70 | 5 | 94.03 | 81.83 |

| 4 | 1.33 | 500 | 2.90 | 5∶1 | 70 | 5 | 95.11 | 97.08 |

| 5 | 1.60 | 500 | 2.90 | 5∶1 | 70 | 5 | 95.11 | 94.44 |

| 6 | 1.86 | 500 | 2.90 | 5∶1 | 70 | 5 | 94.53 | 93.79 |

实验 序号 | 温度/℃ | 搅拌 速度/(r/min) | 磷酸 浓度/(mol/L) | 酒石酸 浓度/(mol/L) | 液固比/(ml/g) | 时间/h | Li 浸出率/% | Fe 浸出率/% |

|---|---|---|---|---|---|---|---|---|

| 1 | 40 | 500 | 2.90 | 1.33 | 5∶1 | 5 | 88.91 | 84.26 |

| 2 | 50 | 500 | 2.90 | 1.33 | 5∶1 | 5 | 93.71 | 90.03 |

| 3 | 60 | 500 | 2.90 | 1.33 | 5∶1 | 5 | 94.45 | 97.99 |

| 4 | 70 | 500 | 2.90 | 1.33 | 5∶1 | 5 | 95.76 | 99.20 |

| 5 | 80 | 500 | 2.90 | 1.33 | 5∶1 | 5 | 95.15 | 94.49 |

| 6 | 90 | 500 | 2.90 | 1.33 | 5∶1 | 5 | 94.43 | 92.78 |

Table 7 Effect of reaction temperature on leaching rate of Li and Fe

实验 序号 | 温度/℃ | 搅拌 速度/(r/min) | 磷酸 浓度/(mol/L) | 酒石酸 浓度/(mol/L) | 液固比/(ml/g) | 时间/h | Li 浸出率/% | Fe 浸出率/% |

|---|---|---|---|---|---|---|---|---|

| 1 | 40 | 500 | 2.90 | 1.33 | 5∶1 | 5 | 88.91 | 84.26 |

| 2 | 50 | 500 | 2.90 | 1.33 | 5∶1 | 5 | 93.71 | 90.03 |

| 3 | 60 | 500 | 2.90 | 1.33 | 5∶1 | 5 | 94.45 | 97.99 |

| 4 | 70 | 500 | 2.90 | 1.33 | 5∶1 | 5 | 95.76 | 99.20 |

| 5 | 80 | 500 | 2.90 | 1.33 | 5∶1 | 5 | 95.15 | 94.49 |

| 6 | 90 | 500 | 2.90 | 1.33 | 5∶1 | 5 | 94.43 | 92.78 |

实验 序号 | 液固比/(ml/g) | 搅拌 速度/(r/min) | 磷酸 浓度/(mol/L) | 酒石酸 浓度/(mol/L) | 温度/℃ | 时间/h | Li 浸出率/% | Fe 浸出率/% |

|---|---|---|---|---|---|---|---|---|

| 1 | 3∶1 | 500 | 2.90 | 1.33 | 70 | 5 | 83.92 | 77.84 |

| 2 | 4∶1 | 500 | 2.90 | 1.33 | 70 | 5 | 92.01 | 90.71 |

| 3 | 5∶1 | 500 | 2.90 | 1.33 | 70 | 5 | 94.00 | 97.39 |

| 4 | 6∶1 | 500 | 2.90 | 1.33 | 70 | 5 | 97.52 | 98.87 |

| 5 | 8∶1 | 500 | 2.90 | 1.33 | 70 | 5 | 96.53 | 97.71 |

| 6 | 10∶1 | 500 | 2.90 | 1.33 | 70 | 5 | 92.23 | 86.51 |

Table 8 Effect of liquid-solid ratio on leaching rate of Li and Fe

实验 序号 | 液固比/(ml/g) | 搅拌 速度/(r/min) | 磷酸 浓度/(mol/L) | 酒石酸 浓度/(mol/L) | 温度/℃ | 时间/h | Li 浸出率/% | Fe 浸出率/% |

|---|---|---|---|---|---|---|---|---|

| 1 | 3∶1 | 500 | 2.90 | 1.33 | 70 | 5 | 83.92 | 77.84 |

| 2 | 4∶1 | 500 | 2.90 | 1.33 | 70 | 5 | 92.01 | 90.71 |

| 3 | 5∶1 | 500 | 2.90 | 1.33 | 70 | 5 | 94.00 | 97.39 |

| 4 | 6∶1 | 500 | 2.90 | 1.33 | 70 | 5 | 97.52 | 98.87 |

| 5 | 8∶1 | 500 | 2.90 | 1.33 | 70 | 5 | 96.53 | 97.71 |

| 6 | 10∶1 | 500 | 2.90 | 1.33 | 70 | 5 | 92.23 | 86.51 |

实验 序号 | 时间/h | 搅拌 速度/(r/min) | 磷酸 浓度/(mol/L) | 酒石酸 浓度/(mol/L) | 温度/℃ | 液固比/(ml/g) | Li 浸出率/% | Fe 浸出率/% |

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 500 | 2.90 | 1.33 | 70 | 6∶1 | 86.65 | 86.69 |

| 2 | 3 | 500 | 2.90 | 1.33 | 70 | 6∶1 | 91.03 | 91.39 |

| 3 | 4 | 500 | 2.90 | 1.33 | 70 | 6∶1 | 94.92 | 96.83 |

| 4 | 5 | 500 | 2.90 | 1.33 | 70 | 6∶1 | 97.88 | 98.47 |

| 5 | 6 | 500 | 2.90 | 1.33 | 70 | 6∶1 | 98.08 | 97.43 |

| 6 | 7 | 500 | 2.90 | 1.33 | 70 | 6∶1 | 97.69 | 97.29 |

Table 9 Effect of reaction time on leaching rate of Li and Fe

实验 序号 | 时间/h | 搅拌 速度/(r/min) | 磷酸 浓度/(mol/L) | 酒石酸 浓度/(mol/L) | 温度/℃ | 液固比/(ml/g) | Li 浸出率/% | Fe 浸出率/% |

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 500 | 2.90 | 1.33 | 70 | 6∶1 | 86.65 | 86.69 |

| 2 | 3 | 500 | 2.90 | 1.33 | 70 | 6∶1 | 91.03 | 91.39 |

| 3 | 4 | 500 | 2.90 | 1.33 | 70 | 6∶1 | 94.92 | 96.83 |

| 4 | 5 | 500 | 2.90 | 1.33 | 70 | 6∶1 | 97.88 | 98.47 |

| 5 | 6 | 500 | 2.90 | 1.33 | 70 | 6∶1 | 98.08 | 97.43 |

| 6 | 7 | 500 | 2.90 | 1.33 | 70 | 6∶1 | 97.69 | 97.29 |

| Factors | Code value | ||

|---|---|---|---|

| -1 | 0 | 1 | |

| A: H3PO4/(mol/L) | 2 | 3 | 4 |

| B: Tartaric acid/(mol/L) | 0.8 | 1.3 | 1.8 |

| C: L/S/(ml/g) | 4∶1 | 7∶1 | 10∶1 |

| D: Temperature/℃ | 40 | 65 | 90 |

Table 10 Box-Behnken experimental factor level

| Factors | Code value | ||

|---|---|---|---|

| -1 | 0 | 1 | |

| A: H3PO4/(mol/L) | 2 | 3 | 4 |

| B: Tartaric acid/(mol/L) | 0.8 | 1.3 | 1.8 |

| C: L/S/(ml/g) | 4∶1 | 7∶1 | 10∶1 |

| D: Temperature/℃ | 40 | 65 | 90 |

| Run | H3PO4 concentration/(mol/L) | Tartaric acid concentration /(mol/L) | Liquid/Solid ratios/(ml/g) | Leaching temperature /℃ | Leaching rate of Li/% | Leaching rate of Fe/% |

|---|---|---|---|---|---|---|

| 1 | 0 | 1 | 0 | 1 | 83.38 | 85.78 |

| 2 | 0 | 0 | 0 | 0 | 97.08 | 98.03 |

| 3 | -1 | -1 | 0 | 0 | 75.33 | 63.17 |

| 4 | -1 | 0 | 1 | 0 | 63.06 | 62.65 |

| 5 | -1 | 0 | 0 | 1 | 72.45 | 70.76 |

| 6 | 0 | 0 | 0 | 0 | 97.41 | 97.48 |

| 7 | 1 | 0 | 0 | 1 | 80.24 | 80.87 |

| 8 | 1 | -1 | 0 | 0 | 76.08 | 71.25 |

| 9 | 0 | 1 | 0 | -1 | 84.37 | 75.74 |

| 10 | 1 | 0 | 1 | 0 | 64.95 | 70.24 |

| 11 | 0 | -1 | 0 | -1 | 80.78 | 65.75 |

| 12 | 0 | 0 | 0 | 0 | 97.63 | 98.21 |

| 13 | -1 | 0 | -1 | 0 | 68.94 | 74.24 |

| 14 | 0 | 1 | -1 | 0 | 77.45 | 85.15 |

| 15 | 0 | -1 | 0 | 1 | 84.98 | 69.54 |

| 16 | 0 | 0 | 1 | 1 | 75.45 | 68.25 |

| 17 | 1 | 0 | -1 | 0 | 75.3 | 81.53 |

| 18 | -1 | 1 | 0 | 0 | 72.45 | 77.47 |

| 19 | 0 | 0 | 1 | -1 | 67.26 | 69.36 |

| 20 | 1 | 1 | 0 | 0 | 78.9 | 83.18 |

| 21 | 0 | 0 | -1 | 1 | 78.93 | 87.32 |

| 22 | 0 | 1 | 1 | 0 | 72.78 | 71.3 |

| 23 | -1 | 0 | 0 | -1 | 72.75 | 67.56 |

| 24 | 0 | 0 | -1 | -1 | 82.38 | 73.69 |

| 25 | 1 | 0 | 0 | -1 | 72.88 | 71.24 |

| 26 | 0 | -1 | 1 | 0 | 70.28 | 64.27 |

| 27 | 0 | -1 | -1 | 0 | 81.05 | 72.53 |

Table 11 BBD experimental design for Li and Fe leaching rate

| Run | H3PO4 concentration/(mol/L) | Tartaric acid concentration /(mol/L) | Liquid/Solid ratios/(ml/g) | Leaching temperature /℃ | Leaching rate of Li/% | Leaching rate of Fe/% |

|---|---|---|---|---|---|---|

| 1 | 0 | 1 | 0 | 1 | 83.38 | 85.78 |

| 2 | 0 | 0 | 0 | 0 | 97.08 | 98.03 |

| 3 | -1 | -1 | 0 | 0 | 75.33 | 63.17 |

| 4 | -1 | 0 | 1 | 0 | 63.06 | 62.65 |

| 5 | -1 | 0 | 0 | 1 | 72.45 | 70.76 |

| 6 | 0 | 0 | 0 | 0 | 97.41 | 97.48 |

| 7 | 1 | 0 | 0 | 1 | 80.24 | 80.87 |

| 8 | 1 | -1 | 0 | 0 | 76.08 | 71.25 |

| 9 | 0 | 1 | 0 | -1 | 84.37 | 75.74 |

| 10 | 1 | 0 | 1 | 0 | 64.95 | 70.24 |

| 11 | 0 | -1 | 0 | -1 | 80.78 | 65.75 |

| 12 | 0 | 0 | 0 | 0 | 97.63 | 98.21 |

| 13 | -1 | 0 | -1 | 0 | 68.94 | 74.24 |

| 14 | 0 | 1 | -1 | 0 | 77.45 | 85.15 |

| 15 | 0 | -1 | 0 | 1 | 84.98 | 69.54 |

| 16 | 0 | 0 | 1 | 1 | 75.45 | 68.25 |

| 17 | 1 | 0 | -1 | 0 | 75.3 | 81.53 |

| 18 | -1 | 1 | 0 | 0 | 72.45 | 77.47 |

| 19 | 0 | 0 | 1 | -1 | 67.26 | 69.36 |

| 20 | 1 | 1 | 0 | 0 | 78.9 | 83.18 |

| 21 | 0 | 0 | -1 | 1 | 78.93 | 87.32 |

| 22 | 0 | 1 | 1 | 0 | 72.78 | 71.3 |

| 23 | -1 | 0 | 0 | -1 | 72.75 | 67.56 |

| 24 | 0 | 0 | -1 | -1 | 82.38 | 73.69 |

| 25 | 1 | 0 | 0 | -1 | 72.88 | 71.24 |

| 26 | 0 | -1 | 1 | 0 | 70.28 | 64.27 |

| 27 | 0 | -1 | -1 | 0 | 81.05 | 72.53 |

| Source | Sum of Squares | Degree of freedom(df) | Mean Square | F | P-value Prob>F | |

|---|---|---|---|---|---|---|

| Model | 2097.05 | 14 | 149.79 | 156.62 | <0.0001 | Significant |

| A-H3PO4 | 45.51 | 1 | 45.51 | 118.05 | <0.0001 | |

| B-Tartaric acid | 0.0574 | 1 | 0.0574 | 340.48 | 0.7773 | |

| C-L/S ratios | 210.59 | 1 | 210.59 | 306.26 | <0.0001 | |

| D-Temperature | 18.78 | 1 | 18.78 | 100.51 | 0.0002 | |

| AB | 8.12 | 1 | 8.12 | 1.10 | 0.0049 | |

| AC | 5.00 | 1 | 5.00 | 0.0177 | 0.0194 | |

| AD | 14.67 | 1 | 14.67 | 8.12 | 0.0006 | |

| BC | 9.30 | 1 | 9.30 | 6.14 | 0.0031 | |

| BD | 6.73 | 1 | 6.73 | 7.67 | 0.0086 | |

| CD | 33.87 | 1 | 33.87 | 42.68 | <0.0001 | |

| A2 | 1206.07 | 1 | 1206.07 | 723.00 | <0.0001 | |

| B2 | 259.24 | 1 | 259.50 | 579.92 | <0.0001 | |

| C2 | 1117.53 | 1 | 1117.53 | 638.00 | <0.0001 | |

| D2 | 278.24 | 1 | 278.24 | 570.96 | <0.0001 | |

| Residual | 8.23 | 12 | 0.6860 | |||

| Lack of Fit | 8.08 | 10 | 0.8079 | 10.54 | 0.0897 | Not significant |

| Pure error | 0.1533 | 2 | 0.0766 | |||

| Cor total | 2105.28 | 26 | ||||

| Adeq precision | 55.9368 | |||||

| R2 | 0.9961 | |||||

| Adjusted R2 | 0.9915 | |||||

| Predicted R2 | 0.9777 | |||||

| C.V./% | 1.06 |

Table 12 Variance analysis of BBD model for Li leaching rate

| Source | Sum of Squares | Degree of freedom(df) | Mean Square | F | P-value Prob>F | |

|---|---|---|---|---|---|---|

| Model | 2097.05 | 14 | 149.79 | 156.62 | <0.0001 | Significant |

| A-H3PO4 | 45.51 | 1 | 45.51 | 118.05 | <0.0001 | |

| B-Tartaric acid | 0.0574 | 1 | 0.0574 | 340.48 | 0.7773 | |

| C-L/S ratios | 210.59 | 1 | 210.59 | 306.26 | <0.0001 | |

| D-Temperature | 18.78 | 1 | 18.78 | 100.51 | 0.0002 | |

| AB | 8.12 | 1 | 8.12 | 1.10 | 0.0049 | |

| AC | 5.00 | 1 | 5.00 | 0.0177 | 0.0194 | |

| AD | 14.67 | 1 | 14.67 | 8.12 | 0.0006 | |

| BC | 9.30 | 1 | 9.30 | 6.14 | 0.0031 | |

| BD | 6.73 | 1 | 6.73 | 7.67 | 0.0086 | |

| CD | 33.87 | 1 | 33.87 | 42.68 | <0.0001 | |

| A2 | 1206.07 | 1 | 1206.07 | 723.00 | <0.0001 | |

| B2 | 259.24 | 1 | 259.50 | 579.92 | <0.0001 | |

| C2 | 1117.53 | 1 | 1117.53 | 638.00 | <0.0001 | |

| D2 | 278.24 | 1 | 278.24 | 570.96 | <0.0001 | |

| Residual | 8.23 | 12 | 0.6860 | |||

| Lack of Fit | 8.08 | 10 | 0.8079 | 10.54 | 0.0897 | Not significant |

| Pure error | 0.1533 | 2 | 0.0766 | |||

| Cor total | 2105.28 | 26 | ||||

| Adeq precision | 55.9368 | |||||

| R2 | 0.9961 | |||||

| Adjusted R2 | 0.9915 | |||||

| Predicted R2 | 0.9777 | |||||

| C.V./% | 1.06 |

| Source | Sum of Squares | Degee of freedom(df) | Mean Square | F | P-value Prob>F | |

|---|---|---|---|---|---|---|

| Model | 2790.57 | 14 | 199.33 | 156.62 | <0.0001 | Significant |

| A-H3PO4 | 150.24 | 1 | 150.24 | 118.05 | <0.0001 | |

| B-Tartaric acid | 433.32 | 1 | 433.32 | 340.48 | <0.0001 | |

| C-L/S ratios | 389.77 | 1 | 389.77 | 306.26 | <0.0001 | |

| D-Temperature | 127.92 | 1 | 127.92 | 100.51 | <0.0001 | |

| AB | 1.40 | 1 | 1.40 | 1.10 | 0.3142 | |

| AC | 0.0225 | 1 | 0.0225 | 0.0177 | 0.8964 | |

| AD | 10.34 | 1 | 10.34 | 8.12 | 0.0146 | |

| BC | 7.81 | 1 | 7.81 | 6.14 | 0.0291 | |

| BD | 9.77 | 1 | 9.77 | 7.67 | 0.0170 | |

| CD | 54.32 | 1 | 54.32 | 42.68 | <0.0001 | |

| A2 | 920.15 | 1 | 920.15 | 723.00 | <0.0001 | |

| B2 | 738.06 | 1 | 738.06 | 579.92 | <0.0001 | |

| C2 | 811.97 | 1 | 811.97 | 638.00 | <0.0001 | |

| D2 | 726.65 | 1 | 726.65 | 570.96 | <0.0001 | |

| Residual | 15.27 | 12 | 1.27 | |||

| Lack of Fit | 14.98 | 10 | 1.50 | 10.36 | 0.0912 | Not significant |

| Pure error | 0.2893 | 2 | 0.1446 | |||

| Cor total | 2805.84 | 26 | ||||

| Adeq precision | 41.6701 | |||||

| R2 | 0.9946 | |||||

| Adjusted R2 | 0.9882 | |||||

| Predicted R2 | 0.9690 | |||||

| C.V./% | 1.48 |

Table 13 Variance analysis of BBD model for Fe leaching rate

| Source | Sum of Squares | Degee of freedom(df) | Mean Square | F | P-value Prob>F | |

|---|---|---|---|---|---|---|

| Model | 2790.57 | 14 | 199.33 | 156.62 | <0.0001 | Significant |

| A-H3PO4 | 150.24 | 1 | 150.24 | 118.05 | <0.0001 | |

| B-Tartaric acid | 433.32 | 1 | 433.32 | 340.48 | <0.0001 | |

| C-L/S ratios | 389.77 | 1 | 389.77 | 306.26 | <0.0001 | |

| D-Temperature | 127.92 | 1 | 127.92 | 100.51 | <0.0001 | |

| AB | 1.40 | 1 | 1.40 | 1.10 | 0.3142 | |

| AC | 0.0225 | 1 | 0.0225 | 0.0177 | 0.8964 | |

| AD | 10.34 | 1 | 10.34 | 8.12 | 0.0146 | |

| BC | 7.81 | 1 | 7.81 | 6.14 | 0.0291 | |

| BD | 9.77 | 1 | 9.77 | 7.67 | 0.0170 | |

| CD | 54.32 | 1 | 54.32 | 42.68 | <0.0001 | |

| A2 | 920.15 | 1 | 920.15 | 723.00 | <0.0001 | |

| B2 | 738.06 | 1 | 738.06 | 579.92 | <0.0001 | |

| C2 | 811.97 | 1 | 811.97 | 638.00 | <0.0001 | |

| D2 | 726.65 | 1 | 726.65 | 570.96 | <0.0001 | |

| Residual | 15.27 | 12 | 1.27 | |||

| Lack of Fit | 14.98 | 10 | 1.50 | 10.36 | 0.0912 | Not significant |

| Pure error | 0.2893 | 2 | 0.1446 | |||

| Cor total | 2805.84 | 26 | ||||

| Adeq precision | 41.6701 | |||||

| R2 | 0.9946 | |||||

| Adjusted R2 | 0.9882 | |||||

| Predicted R2 | 0.9690 | |||||

| C.V./% | 1.48 |

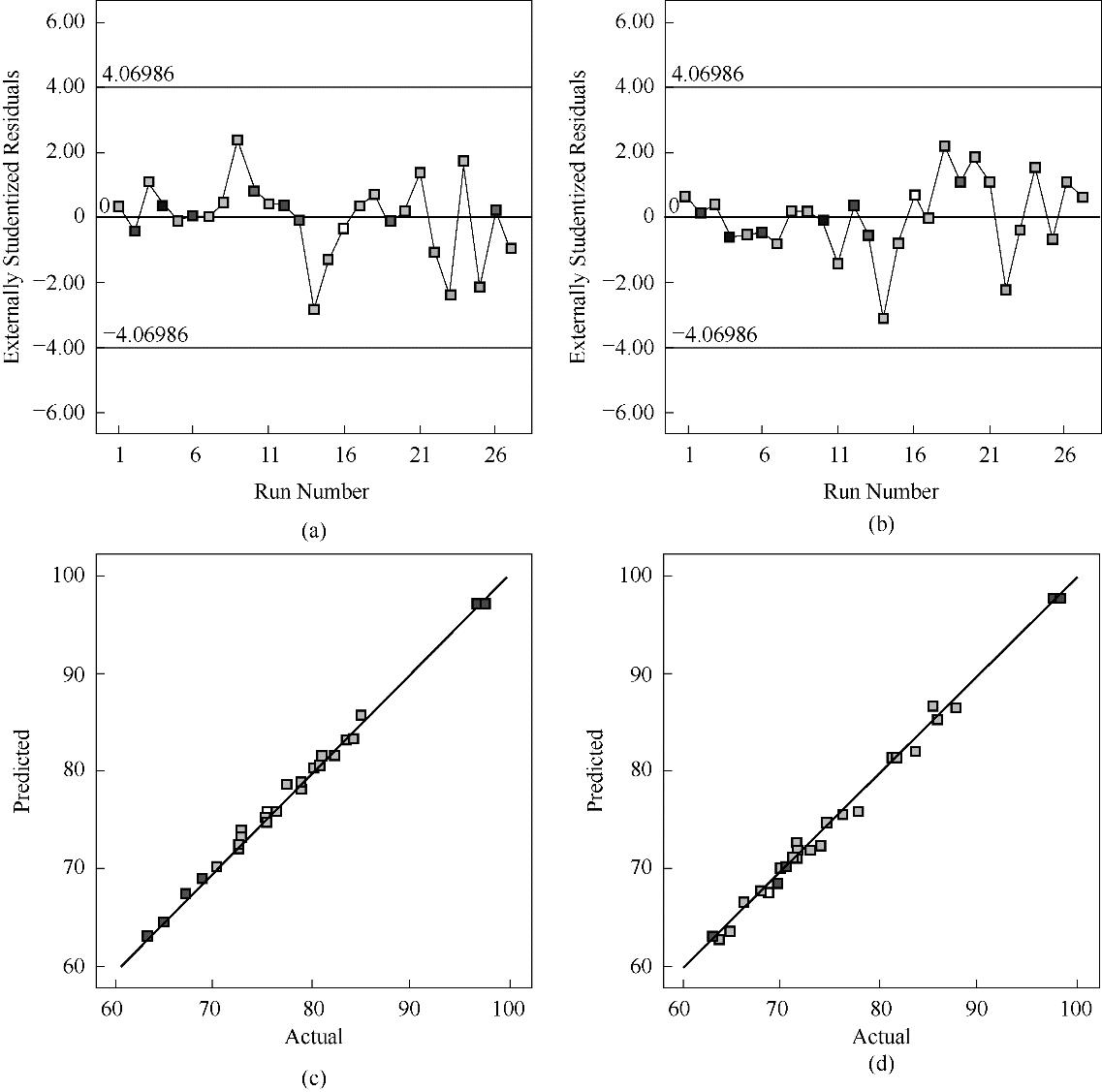

Fig.4 (a) Residual diagram of Li response surface model; (b) Residual diagram of Fe response surface model; (c) Distribution diagram of experimental value and predicted value of Li leaching rate; (d) Distribution diagram of experimental value and predicted value of Fe leaching

Fig.5 (a) Three-dimensional response surface diagram of Li leaching rate; (b) Three-dimensional response surface diagram of Fe leaching rate; (c) Two-dimensional contour map of Li leaching rate; (d) Two-dimensional contour map of Fe leaching rate

| 1 | Liu Z H, Zhou T, Yang H R, et al. A review of the resourceful utilization status for decommissioned power batteries[J]. Energies, 2023, 16(23): 7869. |

| 2 | Xu J J, Cai X Y, Cai S M, et al. High-energy lithium-ion batteries: recent progress and a promising future in applications [J]. Energy & Environmental Materials, 2023, 6(5): 12450. |

| 3 | 李峻, 田阳, 杨斌, 等. 废旧锂离子电池正极材料有价金属回收研究现状[J]. 中国有色金属学报, 2024, 36(6): 1789-1808. |

| Li J, Tian Y, Yang B, et al. Research status of valuable metal recovery of cathode materials of spent lithium-ion batteries[J]. The Chinese Journal of Nonferrous Metals, 2024, 36(6): 1789-1808. | |

| 4 | Zhang L G, Zhang Y, Xu Z M, et al. The foreseeable future of spent lithium-ion batteries: advanced upcycling for toxic electrolyte, cathode, and anode from environmental and technological perspectives[J]. Environmental Science & Technology, 2023, 57(36): 13270-13291. |

| 5 | Fan T, Liang W C, Guo W, et al. Life cycle assessment of electric v e h i c l e s ' lithium-ion batteries reused for energy storage[J]. Journal of Energy Storage, 2023, 71: 108126. |

| 6 | 肖忠良, 尹碧露, 宋刘斌, 等. 废旧锂离子电池回收工艺研究进展及其安全风险分析[J]. 化工学报, 2023, 74(4): 1446-1456. |

| Xiao Z L, Yin B L, Song L B, et al. Research progress of waste lithium-ion battery recycling process and its safety risk analysis[J]. CIESC Journal, 2023, 74(4): 1446-1456. | |

| 7 | 江洋, 彭长宏, 陈伟, 等. 废旧磷酸铁锂粉料综合回收中试研究[J]. 化工学报, 2024, 75(6): 2353-2361. |

| Jiang Y, Peng C H, Chen W, et al. Pilot study on comprehensive recycling of waste lithium iron phosphate powder[J]. CIESC Journal, 2024, 75(6): 2353-2361. | |

| 8 | Naseri T, Mousavi S M. Treatment of spent lithium iron phosphate (LFP) batteries[J]. Current Opinion in Green and Sustainable Chemistry, 2024, 47: 100906. |

| 9 | Saju D, Ebenezer J, Chandran N, et al. Recycling of lithium iron phosphate cathode materials from spent lithium-ion batteries: a mini-review[J]. Industrial & Engineering Chemistry Research, 2023, 62(30): 11768-11783. |

| 10 | Li Y J, Dong L P, Shi P, et al. Selective recovery of lithium from lithium iron phosphate[J]. Journal of Power Sources, 2024, 598: 234158. |

| 11 | Xu Y L, Zhang B C, Ge Z F, et al. Advances and perspectives towards spent LiFePO4 battery recycling[J]. Journal of Cleaner Production, 2024, 434: 140077. |

| 12 | Liang Q, Yue H F, Wang S F, et al. Recycling and crystal regeneration of commercial used LiFePO4 cathode materials[J]. Electrochimica Acta, 2020, 330: 135323. |

| 13 | Qiu X J, Wang C Y, Xie L L, et al. Challenges and perspectives towards direct regeneration of spent LiFePO4 cathode[J]. Journal of Power Sources, 2024, 602: 234365. |

| 14 | Zhang J F, Zou J T, He D, et al. Molten salt infiltration–oxidation synergistic controlled lithium extraction from spent lithium iron phosphate batteries: an efficient, acid free, and closed-loop strategy[J]. Green Chemistry, 2023, 25(15): 6057-6066. |

| 15 | 颜群轩, 罗碧云, 陈嘉鑫, 等. 废旧磷酸铁锂电池可持续回收技术研究进展[J]. 矿冶工程, 2023, 43(4): 174-177, 181. |

| Yan Q X, Luo B Y, Chen J X, et al. Progress in sustainable recycling of spent LiFePO4 batteries[J]. Mining and Metallurgical Engineering, 2023, 43(4): 174-177, 181. | |

| 16 | 张英杰, 许斌, 梁风, 等. 废旧磷酸铁锂电池正极材料的回收研究现状[J]. 人工晶体学报, 2019, 48(5):800-808. |

| Zhang Y J, Xu B, Liang F, et al. Review on recycling cathode materials of spent lithium iron phosphate batteries[J]. Journal of Synthetic Crystals, 2019, 48(5): 800-808. | |

| 17 | Lei S Y, Sun W, Yang Y. Comprehensive technology for recycling and regenerating materials from spent lithium iron phosphate battery[J]. Environmental Science & Technology, 2024, 58(8): 3609-3628. |

| 18 | 肖忠良, 向优涛, 宋刘斌, 等. 机械化学法回收废旧锂离子电池正极材料中有价金属的研究进展[J]. 化工学报, 2023, 74(11): 4419-4432. |

| Xiao Z L, Xiang Y T, Song L B, et al. Progress of mechanochemical recovery of valuable metals from used lithium-ion battery cathode materials[J]. CIESC Journal, 2023, 74(11): 4419-4432. | |

| 19 | Mahandra H, Ghahreman A. A sustainable process for selective recovery of lithium as lithium phosphate from spent LiFePO4 batteries[J]. Resources, Conservation and Recycling, 2021, 175: 105883. |

| 20 | Chen Z, Shen C, Liu F, et al. Selective separation and recovery of Li from spent LiFePO4 cathode materials by oxidation roasting followed by low-acid pressure leaching[J]. Metals, 2023, 13(11): 1884. |

| 21 | Yang Y X, Meng X Q, Cao H B, et al. Selective recovery of lithium from spent lithium iron phosphate batteries: a sustainable process[J]. Green Chemistry, 2018, 20(13): 3121-3133. |

| 22 | Du J W, Qing J L, Fang K Y, et al. The priority leaching of lithium from spent LiFePO4 cathode without the oxidization[J]. Resources, Conservation and Recycling, 2024, 202: 107374. |

| 23 | 鲁俊雀, 黄宁湘, 刘勇奇, 等. 磷酸铁锂正极粉选择性提锂[J]. 有色金属(冶炼部分), 2023, 12: 32-37. |

| Lu J Q, Huang N X, Liu Y Q, et al. Selective extraction of lithium from lithium iron phosphate positive powder[J]. Nonferrous Metals(Extractive Metallurgy), 2023, 12: 32-37. | |

| 24 | Li H, Xing S Z, Liu Y, et al. Recovery of lithium, iron, and phosphorus from spent LiFePO4 batteries using stoichiometric sulfuric acid leaching system[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(9): 8017-8024. |

| 25 | Wang Y H, Wu J J, Hu G C, et al. Recovery of Li and Fe from spent lithium iron phosphate using organic acid leaching system[J]. Transactions of Nonferrous Metals Society of China, 2024, 34(1): 336-346. |

| 26 | Chai X L, Yu X H, Shen Q F, et al. Study on green closed-loop regeneration of waste lithium iron phosphate based on oxalic acid system[J]. Waste Management, 2024, 181: 168-175. |

| 27 | Zhao T Y, Mahandra H, Choi Y, et al. A clean and sustainable method for recycling of lithium from spent lithium iron phosphate battery powder by using formic acid and oxygen[J]. Science of the Total Environment, 2024, 920: 170930. |

| 28 | Jiang S Q, Li X G, Gao Q, et al. Review on full-component green recycling of spent lithium iron phosphate cathode materials: from the perspective of economy and efficiency[J]. Separation and Purification Technology, 2023, 324: 124630. |

| 29 | Wang T, Wang X L, Lyv W, et al. Regeneration behavior of FePO4·2H2O from spent LiFePO4 under extremely acidic condition (pH0.8): mechanism study and the properties of regenerated LiFePO4 [J]. Separation and Purification Technology, 2024, 330: 125508. |

| 30 | Zeng Y J, Wang Y, Cai S C, et al. All-component recycling and reuse process for spent LiFePO4 cathodes[J]. Industrial & Engineering Chemistry Research, 2024, 63(16): 6847-6856. |

| 31 | Zheng R J, Zhao L, Wang W H, et al. Optimized Li and Fe recovery from spent lithium-ion batteries via a solution-precipitation method[J]. RSC Advances, 2016, 6(49): 43613-43625. |

| 32 | 王猛, 张家靓, 陈永强, 等. 退役磷酸铁锂电池回收技术综述[J]. 有色金属(冶炼部分), 2023, 5: 100-110. |

| Wang M, Zhang J L, Chen Y Q, et al. Review on recycling technology of retired LiFePO4 batteries[J]. Nonferrous Metals(Extractive Metallurgy), 2023, 5: 100-110. | |

| 33 | Kulka A, Braun A, Huang T-W, et al. Evidence for Al doping in lithium sublattice of LiFePO4 [J]. Solid State Ionics, 2015, 270: 33-38. |

| [1] | Tianyong ZHANG, Jingyi ZHANG, Shuang JIANG, Bin LI, Dongjun LYU, Dumin CHEN, Xue CHEN. Preparation and utilization of carbon-based adsorbent from organic pollutants in waste salt during acidic blue AS dye production [J]. CIESC Journal, 2024, 75(3): 890-899. |

| [2] | Lingjie WANG, Hailong GAO, Jipeng JIN, Zhihao WANG, Jianbo LI. Influence of pollutants in seawater on performance of reverse electrodialysis stacks [J]. CIESC Journal, 2024, 75(2): 695-705. |

| [3] | Zhichao GONG, Shuangxi LI, Fangjun LI, Zesheng HUANG, Keying XIAO. Multi-objective optimization and performance analysis of structural parameters of open stern shaft lip seal [J]. CIESC Journal, 2024, 75(12): 4689-4701. |

| [4] | Enzhe BI, Shuangxi LI, Lianxiang SHA, Dengyu LIU, Kaifang CHEN. Multi-objective optimization analysis of high temperature dynamic pressure split ring seal parameters [J]. CIESC Journal, 2023, 74(6): 2565-2579. |

| [5] | ZHANG Qinyi, YANG Xiaohong, DENG Hongling, HU Junhu, TIAN Rui. Study on optimization of thermal-photovoltaic membrane distillation system based on response surface methodology [J]. CIESC Journal, 2021, 72(4): 2156-2166. |

| [6] | Lianyan ZHU, Yuming WANG, Xingfu ZHOU. Application of response surface methodology in optimizing electrocatalytic degradation of dye wastewater [J]. CIESC Journal, 2020, 71(3): 1335-1342. |

| [7] | Yuying LU, Liming YU, Jiake YANG, Wusong ZENG, Jiangyin LU. Preparation of LDHs-CRMA composite modified asphalt by response surface methodology and its characterization [J]. CIESC Journal, 2020, 71(3): 1362-1369. |

| [8] | Qian ZHANG, Xiangyang LIU, Wang CHEN, Heng WU, Pengying XIAO, Fangying JI, Chen LI, Haiming NIAN. Preparation of a novel phosphorus removal filler and optimization of phosphate removal adsorption bed process [J]. CIESC Journal, 2019, 70(3): 1099-1110. |

| [9] | Haisheng CHEN, Tengfei WANG, Kejin HUANG, Yang YUAN, Xing QIAN, Liang ZHANG. Decentralized control system designs for reactive distillation columns with external recycle [J]. CIESC Journal, 2019, 70(2): 440-449. |

| [10] | SONG Dihui, AN Luyang, ZHANG Litao, ZHANG Yafeng, XU Xinwei, WANG Yunan, WEI Huangzhao. Optimization of electrochemical coupling system process for coking waste water pretreatment by response surface method [J]. CIESC Journal, 2018, 69(9): 4001-4011. |

| [11] | WANG Anqi, WANG Yongliang, YE Liping, LU Yonggang, QIAN Peng, YE Shufeng. Optimization of recycling copper from copper oxide smelting slag by response surface methodology [J]. CIESC Journal, 2018, 69(7): 3018-3028. |

| [12] | TIAN Pengfei, SHENG Yiyi, SUN Yang, DING Doudou, XU Jing, HAN Yifan. Formation efficiency of hydroxyl radical from H2O2 decomposition over Cu/Al2O3 catalyst [J]. CIESC Journal, 2018, 69(11): 4713-4721. |

| [13] | LI Yuhua, LI Qinggang, ZHANG Guiqing, CAO Zuoying, GUAN Wenjuan, ZENG Li. Recycling utilization of scandium from hydrolyzed sulfuric acid of titanium dioxide production [J]. CIESC Journal, 2017, 68(7): 2818-2825. |

| [14] | JIANG Xinsheng, LÜ Kezong, WEI Shuwang, ZHU Liang. Optimal design of three phase fire-fighting foam formulation based on response surface methodology [J]. CIESC Journal, 2017, 68(7): 2886-2895. |

| [15] | LI Lei, ZHOU Feng, YAO Chaoqun, CHEN Guangwen. Synthesis process of 4-(6-hydroxyhexyloxy)phenol in microreactor [J]. CIESC Journal, 2017, 68(6): 2336-2343. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||