CIESC Journal ›› 2025, Vol. 76 ›› Issue (2): 825-834.DOI: 10.11949/0438-1157.20240962

• Energy and environmental engineering • Previous Articles

Mengfan YIN1( ), Qian WANG1, Tao ZHENG1, Kui JI1,2, Shaogui WANG2, Hui GUO2, Zhiqiang LIN2, Rui ZHANG1, Hui SUN1, Haiyan LIU1, Zhichang LIU1, Chunming XU1, Xianghai MENG1(

), Qian WANG1, Tao ZHENG1, Kui JI1,2, Shaogui WANG2, Hui GUO2, Zhiqiang LIN2, Rui ZHANG1, Hui SUN1, Haiyan LIU1, Zhichang LIU1, Chunming XU1, Xianghai MENG1( ), Yueping WANG2(

), Yueping WANG2( )

)

Received:2024-08-27

Revised:2024-12-06

Online:2025-03-10

Published:2025-03-25

Contact:

Xianghai MENG, Yueping WANG

殷梦凡1( ), 王倩1, 郑涛1, 姬奎1,2, 王绍贵2, 郭辉2, 林志强2, 张睿1, 孙晖1, 刘海燕1, 刘植昌1, 徐春明1, 孟祥海1(

), 王倩1, 郑涛1, 姬奎1,2, 王绍贵2, 郭辉2, 林志强2, 张睿1, 孙晖1, 刘海燕1, 刘植昌1, 徐春明1, 孟祥海1( ), 王月平2(

), 王月平2( )

)

通讯作者:

孟祥海,王月平

作者简介:殷梦凡(1997—),女,博士研究生,920045433@qq.com

基金资助:CLC Number:

Mengfan YIN, Qian WANG, Tao ZHENG, Kui JI, Shaogui WANG, Hui GUO, Zhiqiang LIN, Rui ZHANG, Hui SUN, Haiyan LIU, Zhichang LIU, Chunming XU, Xianghai MENG, Yueping WANG. Process design of 10000 t industrial demonstration of hydrogen production from renewable energy electrolytic water - low temperature and low pressure ammonia synthesis[J]. CIESC Journal, 2025, 76(2): 825-834.

殷梦凡, 王倩, 郑涛, 姬奎, 王绍贵, 郭辉, 林志强, 张睿, 孙晖, 刘海燕, 刘植昌, 徐春明, 孟祥海, 王月平. 可再生能源电解水制氢-低温低压合成氨万吨级工业示范流程设计[J]. 化工学报, 2025, 76(2): 825-834.

Add to citation manager EndNote|Ris|BibTeX

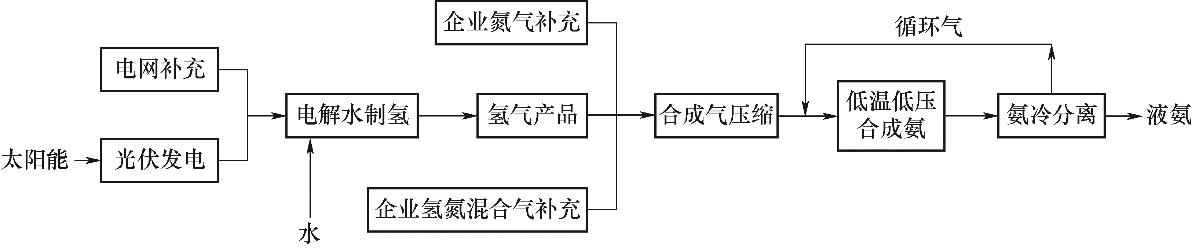

Fig.1 Process design of photovoltaic power generation - hydrogen production from electrolytic water-low temperature and low pressure ammonia synthesis

| 气体 | 进料产品气/(kmol/h) | 流股2组分流率/(kmol/h) | |||||

|---|---|---|---|---|---|---|---|

| 企业实际 | NRTL | UNIFAC | RKS-BM | PR | PR-BM | ||

| 氮气 | 103.03 | 0.06 | 1.96 | 4.52 | 0.05 | 0.06 | 0.05 |

| 氢气 | 309.17 | 0.15 | 0.29 | 0.00 | 0.14 | 0.15 | 0.24 |

| 氨 | 95.05 | 73.37 | 79.00 | 74.36 | 73.36 | 73.37 | 71.29 |

Table 1 Ammonia condensation separation section enterprise and calculation results

| 气体 | 进料产品气/(kmol/h) | 流股2组分流率/(kmol/h) | |||||

|---|---|---|---|---|---|---|---|

| 企业实际 | NRTL | UNIFAC | RKS-BM | PR | PR-BM | ||

| 氮气 | 103.03 | 0.06 | 1.96 | 4.52 | 0.05 | 0.06 | 0.05 |

| 氢气 | 309.17 | 0.15 | 0.29 | 0.00 | 0.14 | 0.15 | 0.24 |

| 氨 | 95.05 | 73.37 | 79.00 | 74.36 | 73.36 | 73.37 | 71.29 |

| 温度/℃ | 压力/MPa | 电流密度/(A/m2) | 小室电压/V | 小室数量 | 有效活性直径/m | 有效电极面积/m2 | 电解槽功率/MW | 产氢量/(m3/h,标准工况) |

|---|---|---|---|---|---|---|---|---|

| 85 | 1.6 | 4000 | 1.99 | 200 | 2 | 3.14 | 5 | 1000 |

Table 2 Parameters of alkaline water electrolytic cell

| 温度/℃ | 压力/MPa | 电流密度/(A/m2) | 小室电压/V | 小室数量 | 有效活性直径/m | 有效电极面积/m2 | 电解槽功率/MW | 产氢量/(m3/h,标准工况) |

|---|---|---|---|---|---|---|---|---|

| 85 | 1.6 | 4000 | 1.99 | 200 | 2 | 3.14 | 5 | 1000 |

| 项目 | 组分流率/(kmol/h) | ||||

|---|---|---|---|---|---|

| 水 | 氢气 | 氧气 | K+ | OH⁻ | |

| 新鲜水进料 | 44.69 | 0.00 | 0.00 | 0.00 | 0.00 |

| 电解槽进料 | 55.81 | 0.00 | 0.01 | 7.70 | 7.70 |

| 电解槽氢气侧出料 | 5.58 | 44.65 | 0.00 | 3.85 | 3.85 |

| 电解槽氧气侧出料 | 5.58 | 0.00 | 22.33 | 3.85 | 3.85 |

| 氢气产品 | 0.00 | 44.65 | 0.00 | 0.00 | 0.00 |

| 氧气产品 | 0.00 | 0.00 | 22.32 | 0.00 | 0.00 |

Table 3 Main flow rate of hydrogen production from alkaline electrolytic water

| 项目 | 组分流率/(kmol/h) | ||||

|---|---|---|---|---|---|

| 水 | 氢气 | 氧气 | K+ | OH⁻ | |

| 新鲜水进料 | 44.69 | 0.00 | 0.00 | 0.00 | 0.00 |

| 电解槽进料 | 55.81 | 0.00 | 0.01 | 7.70 | 7.70 |

| 电解槽氢气侧出料 | 5.58 | 44.65 | 0.00 | 3.85 | 3.85 |

| 电解槽氧气侧出料 | 5.58 | 0.00 | 22.33 | 3.85 | 3.85 |

| 氢气产品 | 0.00 | 44.65 | 0.00 | 0.00 | 0.00 |

| 氧气产品 | 0.00 | 0.00 | 22.32 | 0.00 | 0.00 |

| 项目 | 换热器E202 | 换热器E203 | 换热器E204 | 换热器E205 |

|---|---|---|---|---|

| 热负荷/kW | 891 | 519 | 239 | 82 |

| 总负荷/kW | 1731 | |||

Table 4 Heat load of four heat exchange equipment

| 项目 | 换热器E202 | 换热器E203 | 换热器E204 | 换热器E205 |

|---|---|---|---|---|

| 热负荷/kW | 891 | 519 | 239 | 82 |

| 总负荷/kW | 1731 | |||

| 项目 | 组分流率/(kmol/h) | ||

|---|---|---|---|

| 氮气 | 氢气 | 氨 | |

| 新鲜氮气进料 | 14.88 | 0.00 | 0.00 |

| 新鲜氢气进料 | 0.00 | 44.65 | 0.00 |

| 新鲜氢氮混合气进料 | 21.88 | 65.65 | 0.00 |

| 循环气 | 102.79 | 309.63 | 6.36 |

| 氨合成塔出口气 | 102.80 | 309.65 | 79.87 |

| 氨分离罐S201气相出料 | 102.78 | 309.62 | 70.47 |

| 氨分离罐S201液相出料 | 0.01 | 0.03 | 9.41 |

| 氨冷凝分离器S202气相出料 | 102.75 | 309.54 | 6.35 |

| 氨冷凝分离器S202液相出料 | 0.03 | 0.08 | 64.12 |

| 减压缓冲罐S203气相出料 | 0.03 | 0.09 | 0.01 |

| 减压缓冲罐S203液相出料 | 0.01 | 0.02 | 73.51 |

| 液氨产品 | 0.01 | 0.02 | 73.51 |

Table 5 Main flow rate of low temperature and low pressure ammonia synthesis process

| 项目 | 组分流率/(kmol/h) | ||

|---|---|---|---|

| 氮气 | 氢气 | 氨 | |

| 新鲜氮气进料 | 14.88 | 0.00 | 0.00 |

| 新鲜氢气进料 | 0.00 | 44.65 | 0.00 |

| 新鲜氢氮混合气进料 | 21.88 | 65.65 | 0.00 |

| 循环气 | 102.79 | 309.63 | 6.36 |

| 氨合成塔出口气 | 102.80 | 309.65 | 79.87 |

| 氨分离罐S201气相出料 | 102.78 | 309.62 | 70.47 |

| 氨分离罐S201液相出料 | 0.01 | 0.03 | 9.41 |

| 氨冷凝分离器S202气相出料 | 102.75 | 309.54 | 6.35 |

| 氨冷凝分离器S202液相出料 | 0.03 | 0.08 | 64.12 |

| 减压缓冲罐S203气相出料 | 0.03 | 0.09 | 0.01 |

| 减压缓冲罐S203液相出料 | 0.01 | 0.02 | 73.51 |

| 液氨产品 | 0.01 | 0.02 | 73.51 |

| 名称 | 年消耗量/产量 | 单价 | 金额/(104 CNY) | |

|---|---|---|---|---|

| 原料 | 水(脱盐水) | 6440 t/a | 2.5 CNY/t | 1.61 |

| 氮气 | 2666854 m3/a(标准工况) | 0.57 CNY/m3(标准工况) | 152.01 | |

| 氢氮混合气 | 15685376 m3/a(标准工况) | 0.74 CNY/m3(标准工况) | 1160.72 | |

| 锅炉水 | 10400 t/a | 2.5 CNY/t | 2.60 | |

| 原料总计 | 1316.94 | |||

| 产品 | 氧气 | 5715 t/a | 0.04×104 CNY/t | 228.60 |

| 饱和蒸汽 | 10400 t/a | 0.02×104 CNY/t | 208.00 | |

| 液氨 | 10019 t/a | 0.30×104 CNY/t | 3005.70 | |

| 产品总计 | 3442.30 | |||

| 产品经济潜力 | 2125.36 | |||

Table 6 Product economic potential

| 名称 | 年消耗量/产量 | 单价 | 金额/(104 CNY) | |

|---|---|---|---|---|

| 原料 | 水(脱盐水) | 6440 t/a | 2.5 CNY/t | 1.61 |

| 氮气 | 2666854 m3/a(标准工况) | 0.57 CNY/m3(标准工况) | 152.01 | |

| 氢氮混合气 | 15685376 m3/a(标准工况) | 0.74 CNY/m3(标准工况) | 1160.72 | |

| 锅炉水 | 10400 t/a | 2.5 CNY/t | 2.60 | |

| 原料总计 | 1316.94 | |||

| 产品 | 氧气 | 5715 t/a | 0.04×104 CNY/t | 228.60 |

| 饱和蒸汽 | 10400 t/a | 0.02×104 CNY/t | 208.00 | |

| 液氨 | 10019 t/a | 0.30×104 CNY/t | 3005.70 | |

| 产品总计 | 3442.30 | |||

| 产品经济潜力 | 2125.36 | |||

| 1 | Phan T S, Pham Minh D, Espitalier F, et al. Hydrogen production from biogas: process optimization using ASPEN Plus® [J]. International Journal of Hydrogen Energy, 2022, 47(100): 42027-42039. |

| 2 | Yan X, Wang K, Xiao F X. Electron tunneling fosters solar-to-hydrogen energy conversion[J]. Inorganic Chemistry, 2023, 62(42): 17454-17463. |

| 3 | Qu L, Gou Q Z, Deng J B, et al. A perspective of bioinspired interfaces applied in renewable energy storage and conversion devices[J]. Langmuir, 2024, 40(13): 6601-6611. |

| 4 | Nguyen N N. Prospect and challenges of hydrate-based hydrogen storage in the low-carbon future[J]. Energy & Fuels, 2023, 37(14): 9771-9789. |

| 5 | 廖龙飞, 李明雨, 尹永利, 等. 碱性水电解制氢催化剂研究进展[J]. 工业催化, 2023, 31(2): 7-17. |

| Liao L F, Li M Y, Yin Y L, et al. Research progress on catalysts of alkaline water electrolysis for hydrogen production[J]. Industrial Catalysis, 2023, 31(2): 7-17. | |

| 6 | Nikolic V M, Tasic G S, Maksic A D, et al. Raising efficiency of hydrogen generation from alkaline water electrolysis— energy saving[J]. International Journal of Hydrogen Energy, 2010, 35(22): 12369-12373. |

| 7 | Peng L Q, Guo Y, Liu S W, et al. Subsidizing grid-based electrolytic hydrogen will increase greenhouse gas emissions in coal dominated power systems[J]. Environmental Science & Technology, 2024, 58(12): 5187-5195. |

| 8 | 曾悦, 王月, 张学瑞, 等. 可再生能源合成绿氨研究进展及氢-氨储运经济性分析[J]. 化工进展, 2024, 43(1): 376-389. |

| Zeng Y, Wang Y, Zhang X R, et al. Research progress of green ammonia synthesis from renewable energy and economic analysis of hydrogen-ammonia storage and transportation[J]. Chemical Industry and Engineering Progress, 2024, 43(1): 376-389. | |

| 9 | 刘洪茹, 林文胜. 基于液氢和氨的氢运输链能效和碳排放分析[J]. 化工进展, 2023, 42(3): 1291-1298. |

| Liu H R, Lin W S. Energy efficiency and carbon emission analysis of hydrogen transport chains based on liquid hydrogen and ammonia[J]. Chemical Industry and Engineering Progress, 2023, 42(3): 1291-1298. | |

| 10 | Zhu X B, Liu J, Hu X L, et al. Plasma-catalytic synthesis of ammonia over Ru-based catalysts: insights into the support effect[J]. Journal of the Energy Institute, 2022, 102: 240-246. |

| 11 | Ma S C, Yu L Z, Jiang H X, et al. Coal-fired power plants using ammonia for flexibility enhancement under carbon control strategies: status, development, and perspectives[J]. Energy & Fuels, 2024, 38(6): 4946-4965. |

| 12 | Wang Y Y, Wang Q Y, Sun S H, et al. Highly efficient ammonia synthesis by gas-liquid interface pulsed discharge plasma: a synthesis method without hydrogen[J]. ACS Sustainable Chemistry & Engineering, 2023, 11(35): 13070-13080. |

| 13 | 李卫东, 李逸龙, 滕霖, 等. “双碳”目标下的氨能技术与经济性研究进展[J]. 化工进展, 2023, 42(12): 6226-6238. |

| Li W D, Li Y L, Teng L, et al. Research progress on ammonia energy technology and economy under “carbon emission peak” and “carbon neutrality” targets[J]. Chemical Industry and Engineering Progress, 2023, 42(12): 6226-6238. | |

| 14 | 孙晖, 孟祥海, 魏景海, 等. 绿电制氢生产氨的新场景与实践[J]. 化工进展, 2023, 42(2): 1098-1102. |

| Sun H, Meng X H, Wei J H, et al. New scene for ammonia synthesis by green hydrogen[J]. Chemical Industry and Engineering Progress, 2023, 42(2): 1098-1102. | |

| 15 | Cheng G S, Yang Y H, Xiu T C, et al. Analysis of hydrogen production potential from water electrolysis in China[J]. Energy & Fuels, 2023, 37(13): 9220-9232. |

| 16 | Sánchez M, Amores E, Abad D, et al. Aspen Plus model of an alkaline electrolysis system for hydrogen production[J]. International Journal of Hydrogen Energy, 2020, 45(7): 3916-3929. |

| 17 | Bystron T, Vesely M, Paidar M, et al. Enhancing PEM water electrolysis efficiency by reducing the extent of Ti gas diffusion layer passivation[J]. Journal of Applied Electrochemistry, 2018, 48(6): 713-723. |

| 18 | Noor Azam A M I, Ragunathan T, Zulkefli N N, et al. Investigation of performance of anion exchange membrane (AEM) electrolysis with different operating conditions[J]. Polymers, 2023, 15(5): 1301. |

| 19 | Mastropasqua L, Pecenati I, Giostri A, et al. Solar hydrogen production: techno-economic analysis of a parabolic dish-supported high-temperature electrolysis system[J]. Applied Energy, 2020, 261: 114392. |

| 20 | 曾少娟, 尚大伟, 余敏, 等. 离子液体在氨气分离回收中的应用及展望[J]. 化工学报, 2019, 70(3): 791-800. |

| Zeng S J, Shang D W, Yu M, et al. Applications and perspectives of NH3 separation and recovery with ionic liquids[J]. CIESC Journal, 2019, 70(3): 791-800. | |

| 21 | 林承顺. 合成氨工艺技术现状及发展趋势[J]. 能源化工, 2024, 45(1): 12-15. |

| Lin C S. Current status and development trends of synthetic ammonia process technology[J]. Energy Chemical Industry, 2024, 45(1): 12-15. | |

| 22 | 杨晨. 合成氨工艺增效改善与节能降耗策略研究[J]. 山西化工, 2024, 44(6): 216-218. |

| Yang C. Research on efficiency improvement and energy conservation and consumption reduction strategies for synthetic ammonia process[J]. Shanxi Chemical Industry, 2024, 44(6): 216-218. | |

| 23 | 刘福建, 郑勇, 曹彦宁, 等. 高炉煤气/转炉煤气低碳高效合成氨工艺流程[J]. 过程工程学报, 2023, 23(3): 350-358. |

| Liu F J, Zheng Y, Cao Y N, et al. Low-carbon and high-efficiency ammonia synthesis process from blast furnace gas/converter gas[J]. The Chinese Journal of Process Engineering, 2023, 23(3): 350-358. | |

| 24 | 麻蓉, 张桥. PSA-低温甲醇洗-膜分离耦合的氢气分离系统建立与模拟[J]. 化工学报, 2023, 74(10): 4201-4207. |

| Ma R, Zhang Q. Establishment and simulation of hydrogen separation system coupled with PSA, rectisol and membrane separation[J]. CIESC Journal, 2023, 74(10): 4201-4207. | |

| 25 | 张生安, 刘桂莲. 高效太阳能电解水制氢系统及其性能的多目标优化[J]. 化工学报, 2023, 74(3): 1260-1274. |

| Zhang S A, Liu G L. Multi-objective optimization of high-efficiency solar water electrolysis hydrogen production system and its performance[J]. CIESC Journal, 2023, 74(3): 1260-1274. | |

| 26 | 李木金, 胡松, 施德磐, 等. 环氧丁烷尾气溶剂吸收及精制工艺[J]. 化工学报, 2023, 74(4): 1607-1618. |

| Li M J, Hu S, Shi D P, et al. A process for offgas absorption and purification of 1,2-butylene oxide[J]. CIESC Journal, 2023, 74(4): 1607-1618. | |

| 27 | 张晨佳. 高温固体氧化物电解水制氢性能分析与模拟研究[D]. 北京: 华北电力大学, 2021. |

| Zhang C J. Performance analysis and simulation research on hydrogen production by high temperature solid oxide electrolysis[D]. Beijing: North China Electric Power University, 2021. | |

| 28 | Ishaq H, Dincer I. Design and simulation of a new cascaded ammonia synthesis system driven by renewables[J]. Sustainable Energy Technologies and Assessments, 2020, 40: 100725. |

| 29 | 王定标, 张荣, 向飒, 等. 氨合成工段过程模拟与优化[J]. 郑州大学学报(工学版), 2009, 30(4): 48-52. |

| Wang D B, Zhang R, Xiang S, et al. Simulation and optimization of ammonia synthesis process[J]. Journal of Zhengzhou University (Engineering Science), 2009, 30(4): 48-52. | |

| 30 | Sánchez M, Amores E, Rodríguez L, et al. Semi-empirical model and experimental validation for the performance evaluation of a 15 kW alkaline water electrolyzer[J]. International Journal of Hydrogen Energy, 2018, 43(45): 20332-20345. |

| [1] | Xiaohang ZHONG, Wei XU, Wen ZHANG, Li XU, Yuxin WANG. A critical review on the effects of Fe impurity on H2 production via alkaline water electrolysis [J]. CIESC Journal, 2025, 76(2): 519-531. |

| [2] | Jinhao BAI, Xiaoping GUAN, Ning YANG. Analysis and optimization of flow characteristics in a filter-press water electrolyzer mastoid plate [J]. CIESC Journal, 2025, 76(2): 584-595. |

| [3] | Ke ZHANG, Weijie REN, Mengna WANG, Kaifeng FAN, Liping CHANG, Jiabin LI, Tao MA, Jinping TIAN. Liquid-liquid mixing characteristics of Bunsen reaction products in microchannels [J]. CIESC Journal, 2025, 76(2): 623-636. |

| [4] | Ping LIU, Yusheng QIU, Shijing LI, Ruiqi SUN, Chen SHEN. Heat transfer and flow characteristics of nanofluids in microchannels [J]. CIESC Journal, 2025, 76(1): 184-197. |

| [5] | Ye YANG, Jiangang LU. Mooney viscosity prediction modeling based on fusion Transformer [J]. CIESC Journal, 2025, 76(1): 266-282. |

| [6] | Qiwo HAN, Yongfeng LIU, Pucheng PEI, Lu ZHANG, Shengzhuo YAO. Analysis of influence of operating temperature on water distribution, proton transport and performance of PEMFC [J]. CIESC Journal, 2025, 76(1): 374-384. |

| [7] | Yushi LI, Yuan CHEN, Yuntang LI, Xudong PENG, Bingqing WANG, Xiaolu LI. Intelligent optimization and deformation analysis of novel flexible dam foil face gas seal [J]. CIESC Journal, 2025, 76(1): 324-334. |

| [8] | Haidong LI, Qiqi ZHANG, Lu YANG, Naeem AKRAM, Chenglin CHANG, Wenlong MO, Weifeng SHEN. Detailed design of shell-and-tube heat exchanger using intelligent evolutionary algorithms [J]. CIESC Journal, 2025, 76(1): 241-255. |

| [9] | Jian HU, Jinghua JIANG, Shengjun FAN, Jianhao LIU, Haijiang ZOU, Wanlong CAI, Fenghao WANG. Research on heat extraction performance of deep U-type borehole heat exchanger [J]. CIESC Journal, 2024, 75(S1): 76-84. |

| [10] | Junfeng WANG, Junjie ZHANG, Wei ZHANG, Jiale WANG, Shuyan SHUANG, Yadong ZHANG. Liquid-phase discharge plasma decomposition of methanol for hydrogen production: optimization of electrode configuration [J]. CIESC Journal, 2024, 75(9): 3277-3286. |

| [11] | Xinyi LUO, Qiang XU, Yonglu SHE, Tengfei NIE, Liejin GUO. Study on bubble dynamic characteristics and mass transfer mechanism in photoelectrochemical water splitting for hydrogen production [J]. CIESC Journal, 2024, 75(9): 3083-3093. |

| [12] | Yanxi LI, Yechun WANG, Xiangdong XIE, Jinzhi WANG, Jiang WANG, Yu ZHOU, Yingxiu PAN, Wentao DING, Liejin GUO. Study on separation characteristics and structure optimization of a volute type multi-channel gas-liquid cyclone separator [J]. CIESC Journal, 2024, 75(8): 2875-2885. |

| [13] | Jiaqi DING, Haitao LIU, Pu ZHAO, Xiangning ZHU, Xiaofang WANG, Rong XIE. Study on intelligent rolling prediction of the multiphase flows in coal-supercritical water fluidized bed reactor for hydrogen production [J]. CIESC Journal, 2024, 75(8): 2886-2896. |

| [14] | Zhihong HUANG, Li ZHOU, Shiyang CHAI, Xu JI. Integrating optimization of hydrogenation units in multi-period hydrogen network [J]. CIESC Journal, 2024, 75(5): 1951-1965. |

| [15] | Xiaoqing YAN, Ying ZHAO, Yuzhe ZHANG, Honghui OU, Qizhong HUANG, Huagui HU, Guidong YANG. Preparation of five-fold twinned copper nanowires@polypyrrole and their electrocatalytic conversion of nitrate to ammonia [J]. CIESC Journal, 2024, 75(4): 1519-1532. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||