CIESC Journal ›› 2023, Vol. 74 ›› Issue (4): 1433-1445.DOI: 10.11949/0438-1157.20221678

• Reviews and monographs • Previous Articles Next Articles

Rong WANG1( ), Yonghong WANG1,2(

), Yonghong WANG1,2( ), Xinru ZHANG1,2, Jinping LI1,2

), Xinru ZHANG1,2, Jinping LI1,2

Received:2022-12-30

Revised:2023-03-15

Online:2023-06-02

Published:2023-04-05

Contact:

Yonghong WANG

王荣1( ), 王永洪1,2(

), 王永洪1,2( ), 张新儒1,2, 李晋平1,2

), 张新儒1,2, 李晋平1,2

通讯作者:

王永洪

作者简介:王荣(1997—),女,硕士研究生,wr2215706965@163.com

基金资助:CLC Number:

Rong WANG, Yonghong WANG, Xinru ZHANG, Jinping LI. Construction of 6FDA-based polyimide carbon molecular sieve membranes for gas separation and its application[J]. CIESC Journal, 2023, 74(4): 1433-1445.

王荣, 王永洪, 张新儒, 李晋平. 6FDA型聚酰亚胺炭分子筛气体分离膜的构筑及其应用[J]. 化工学报, 2023, 74(4): 1433-1445.

Add to citation manager EndNote|Ris|BibTeX

| 聚酰亚胺 | 密度/(g/cm3) | Tg/℃ | 链间距/nm | 自由体积/(cm3/g) | 文献 |

|---|---|---|---|---|---|

| 6FDA-ODA | 1.432 | 304 | 0.56 | 0.1142 | [ |

| 6FDA-MDA | 1.400 | 304 | 0.56 | 0.1143 | [ |

| 6FDA-m-PD | 1.474 | 298 | — | 0.160 | [ |

| 6FDA-p-PD | 1.473 | 351 | — | 0.161 | [ |

| 6FDA-DABA | 1.590 | 327 | 0.53 | 0.153 | [ |

Table 1 Physicochemical properties of 6FDA-based polyimides with different diamine

| 聚酰亚胺 | 密度/(g/cm3) | Tg/℃ | 链间距/nm | 自由体积/(cm3/g) | 文献 |

|---|---|---|---|---|---|

| 6FDA-ODA | 1.432 | 304 | 0.56 | 0.1142 | [ |

| 6FDA-MDA | 1.400 | 304 | 0.56 | 0.1143 | [ |

| 6FDA-m-PD | 1.474 | 298 | — | 0.160 | [ |

| 6FDA-p-PD | 1.473 | 351 | — | 0.161 | [ |

| 6FDA-DABA | 1.590 | 327 | 0.53 | 0.153 | [ |

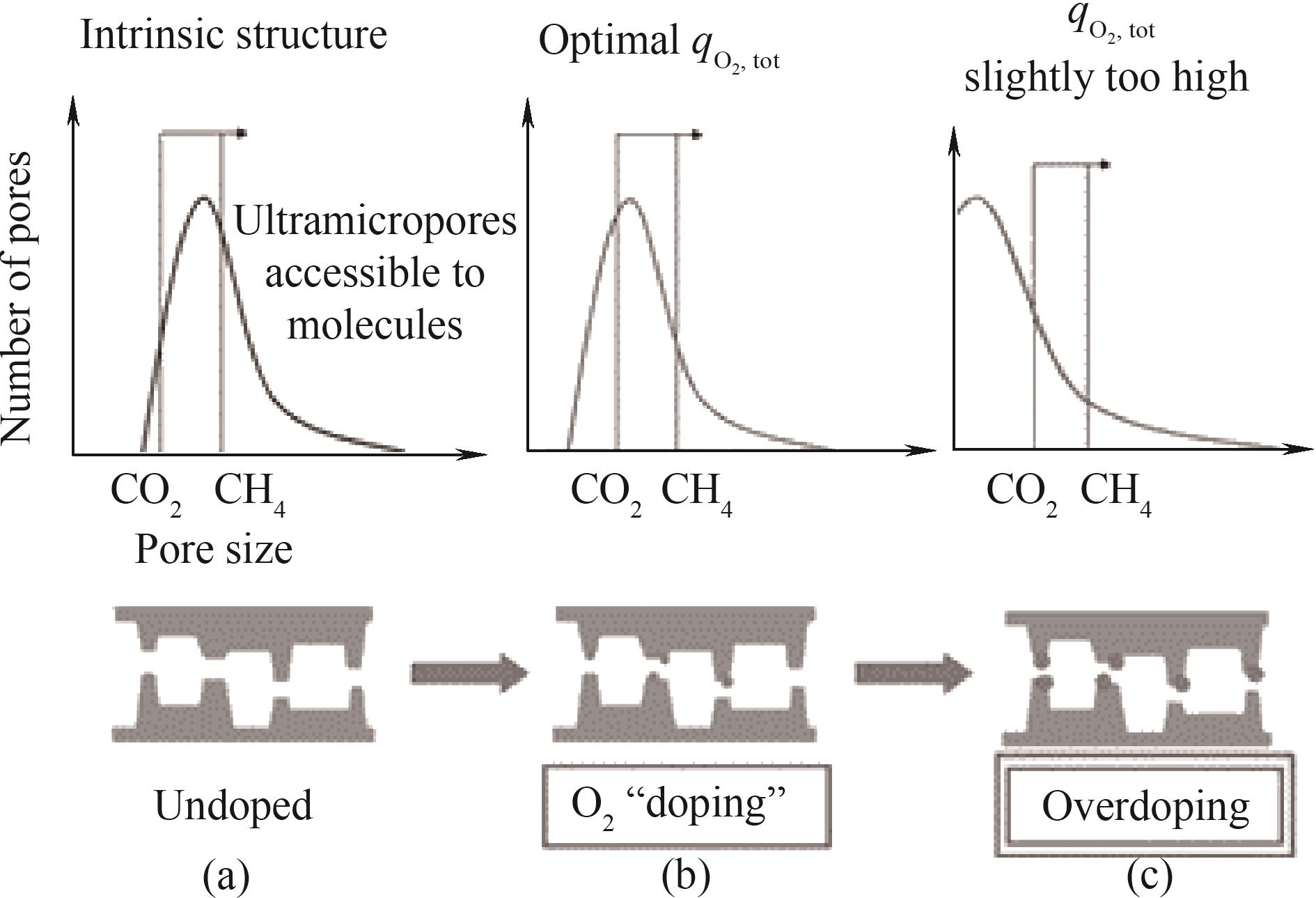

Fig.7 (a) Undoped structure when pyrolyzed without oxygen; (b) Optimal selective structure with adequate amount of oxygen doped; (c) Overdoped structure when slightly higher oxygen was introduced during pyrolysis[39]

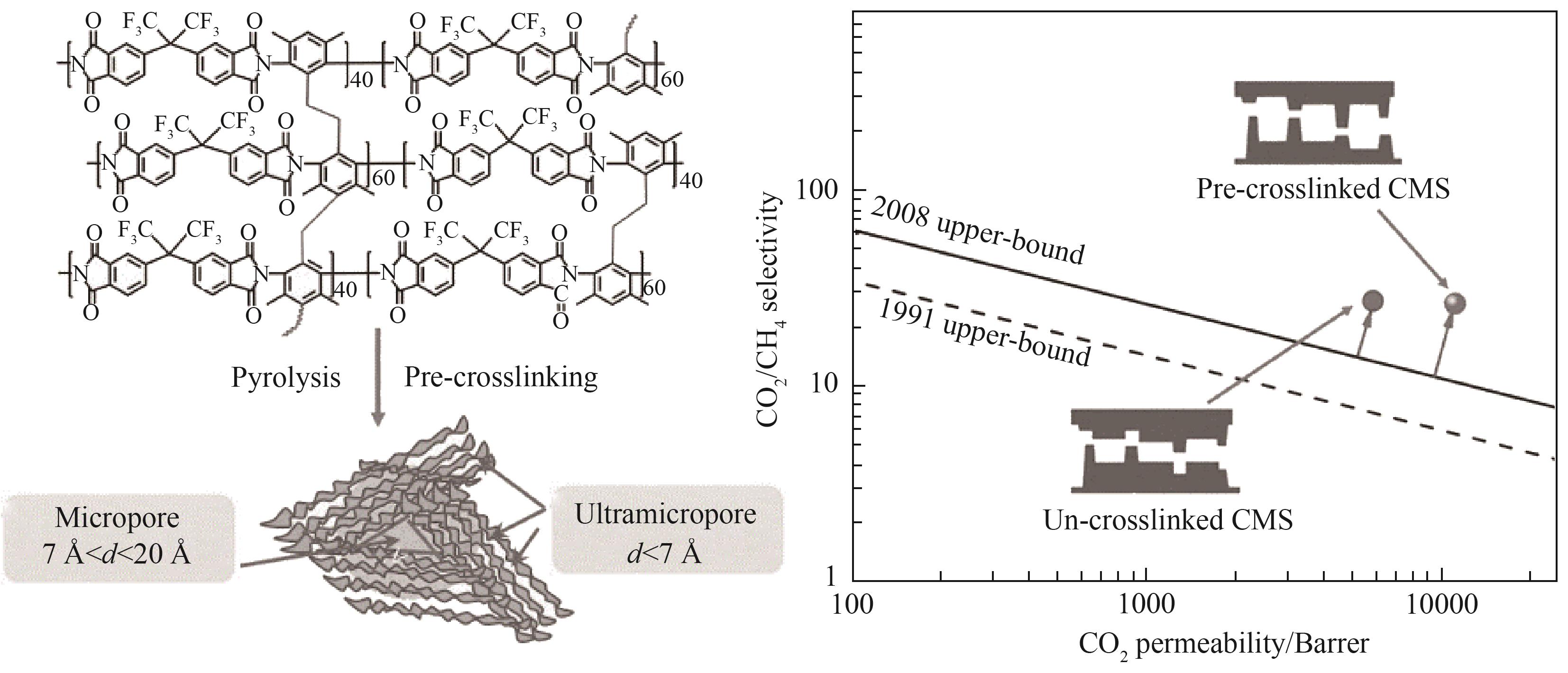

Fig.10 Structure of thermally crosslinkable brominated 6FDA-based polyimide (BMPI) and carbon molecular sieve membranes performance for CO2/CH4 separation[62]

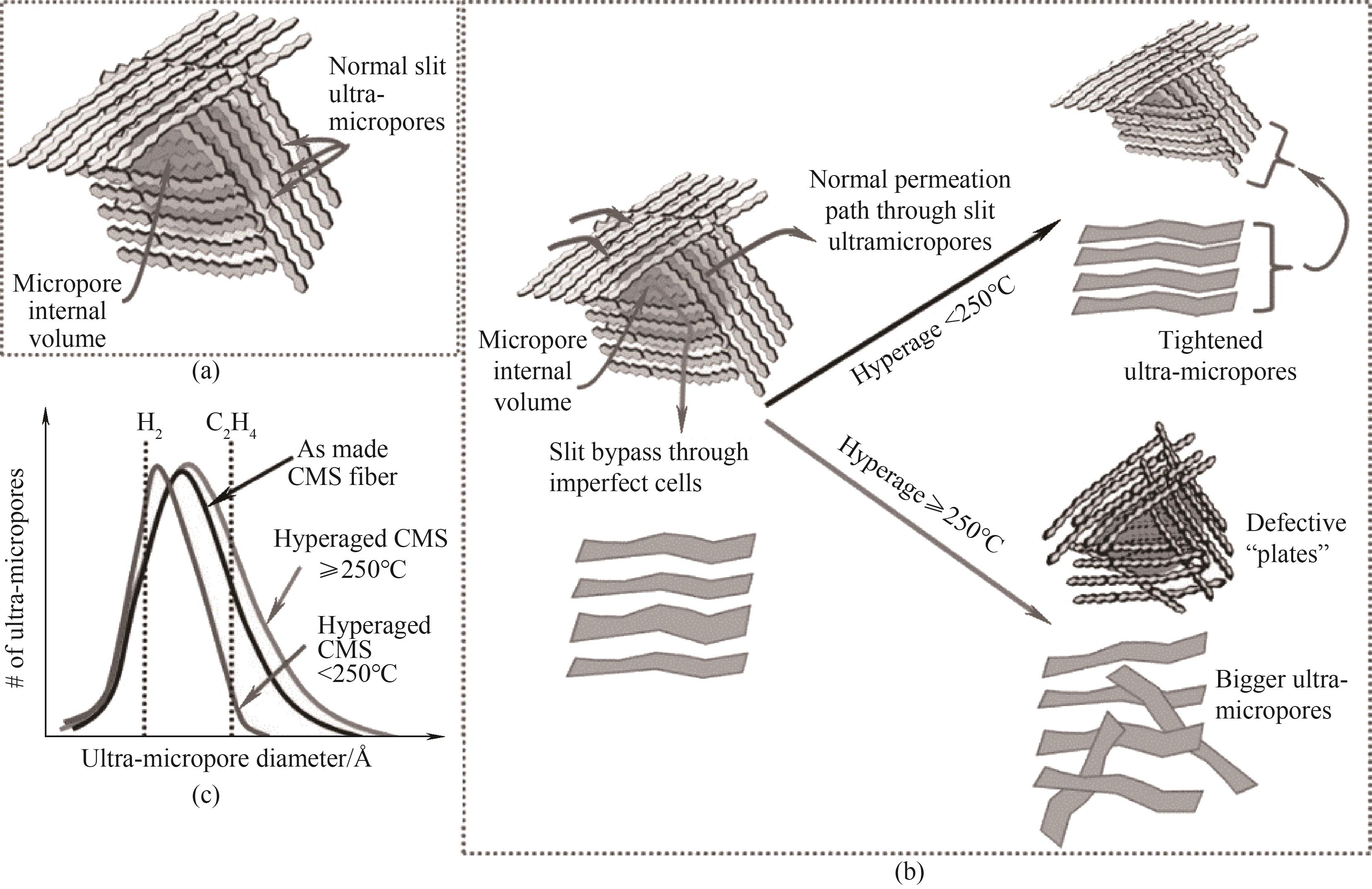

Fig.11 (a) The structure of the carbon molecular sieve membranes; (b) Structural changes in carbon molecular sieve membranes after being hyperaged below and above 250 °C; (c) Distribution of ultramicropores in carbon molecular sieve membranes[66]

| 1 | Sholl D S, Lively R P. Seven chemical separations to change the world[J]. Nature, 2016, 532(7600): 435-437. |

| 2 | Robinson S, Jubin R, Choate B. Materials for separation technologies. Energy and emission reduction opportunities[R]. Oak Ridge National Lab, 2005. |

| 3 | Brunetti A, Scura F, Barbieri G, et al. Membrane technologies for CO2 separation[J]. Journal of Membrane Science, 2010, 359(1/2): 115-125. |

| 4 | Wang Y H, Jin Z, Zhang X R, et al. Enhancing CO2 separation performance of mixed matrix membranes by incorporation of L-cysteine-functionalized MoS2 [J]. Separation and Purification Technology, 2022, 297: 121560. |

| 5 | Dai Z D, Deng J, He X Z, et al. Helium separation using membrane technology: recent advances and perspectives[J]. Separation and Purification Technology, 2021, 274: 119044. |

| 6 | Cong H L, Radosz M, Towler B F, et al. Polymer-inorganic nanocomposite membranes for gas separation[J]. Separation and Purification Technology, 2007, 55(3): 281-291. |

| 7 | Hazazi K, Ma X H, Wang Y G, et al. Ultra-selective carbon molecular sieve membranes for natural gas separations based on a carbon-rich intrinsically microporous polyimide precursor[J]. Journal of Membrane Science, 2019, 585: 1-9. |

| 8 | Koresh J, Soffer A. A molecular sieve carbon membrane for continuous process gas separation[J]. Carbon, 1984, 22(2): 225. |

| 9 | Richter H, Voss H, Kaltenborn N, et al. High-flux carbon molecular sieve membranes for gas separation[J]. Angewandte Chemie International Edition, 2017, 56(27): 7760-7763. |

| 10 | Lively R. Carbon molecular sieve membranes aim to cut energy use in hydrocarbon separations[J]. Membrane Technology, 2017, 2017(1): 9-10. |

| 11 | Yoshimune M, Fujiwara I, Haraya K. Carbon molecular sieve membranes derived from trimethylsilyl substituted poly(phenylene oxide) for gas separation[J]. Carbon, 2007, 45(3): 553-560. |

| 12 | Fu S L, Sanders E S, Kulkarni S S, et al. Carbon molecular sieve membrane structure-property relationships for four novel 6FDA based polyimide precursors[J]. Journal of Membrane Science, 2015, 487: 60-73. |

| 13 | Deng G X, Luo J Z, Liu S, et al. Molecular design and characterization of new polyimides based on binaphthyl-ether diamines for gas separation[J]. Separation and Purification Technology, 2020, 235: 116218. |

| 14 | Lively R P, Dose M E, Xu L R, et al. A high-flux polyimide hollow fiber membrane to minimize footprint and energy penalty for CO2 recovery from flue gas[J]. Journal of Membrane Science, 2012, 423/424: 302-313. |

| 15 | Sazali N, Wan Salleh W N, Ismail A F, et al. A brief review on carbon selective membranes from polymer blends for gas separation performance[J]. Reviews in Chemical Engineering, 2021, 37(3): 339-362. |

| 16 | Lei L F, Bai L, Lindbråthen A, et al. Carbon membranes for CO2 removal: status and perspectives from materials to processes[J]. Chemical Engineering Journal, 2020, 401: 126084. |

| 17 | Saufi S M, Ismail A F. Fabrication of carbon membranes for gas separation—a review[J]. Carbon, 2004, 42(2): 241-259. |

| 18 | Liu Z Y, Qiu W L, Quan W Y, et al. Fine-tuned thermally cross-linkable 6FDA-based polyimide membranes for aggressive natural gas separation[J]. Journal of Membrane Science, 2021, 635: 119474. |

| 19 | Qiu W L, Leisen J E, Liu Z Y, et al. Key features of polyimide-derived carbon molecular sieves[J]. Angewandte Chemie International Edition, 2021, 60(41): 22322-22331. |

| 20 | 王睦铿. 含氟聚酰亚胺的制备及应用[J]. 有机氟工业, 1994(2): 15-25. |

| Wang M K. Preparation and application of fluorine-containing polyimide[J]. Organo-Flnorine Industry, 1994(2): 15-25. | |

| 21 | Qiu W L, Xu L R, Chen C C, et al. Gas separation performance of 6FDA-based polyimides with different chemical structures[J]. Polymer, 2013, 54(22): 6226-6235. |

| 22 | Fu S L, Sanders E S, Kulkarni S S, et al. Temperature dependence of gas transport and sorption in carbon molecular sieve membranes derived from four 6FDA based polyimides: entropic selectivity evaluation[J]. Carbon, 2015, 95: 995-1006. |

| 23 | Dasgupta B, Sen S K, Banerjee S. Gas transport properties of fluorinated poly(ether imide) membranes containing indan moiety in the main chain[J]. Journal of Membrane Science, 2009, 345(1/2): 249-256. |

| 24 | Coleman M R, Koros W J. Isomeric polyimides based on fluorinated dianhydrides and diamines for gas separation applications[J]. Journal of Membrane Science, 1990, 50(3): 285-297. |

| 25 | Tanaka K, Okano M, Toshino H, et al. Effect of methyl substituents on permeability and permselectivity of gases in polyimides prepared from methyl-substituted phenylenediamines[J]. Journal of Polymer Science Part B: Polymer Physics, 1992, 30(8): 907-914. |

| 26 | Karunaweera C, Musselman I H, Balkus K J, et al. Fabrication and characterization of aging resistant carbon molecular sieve membranes for C3 separation using high molecular weight crosslinkable polyimide, 6FDA-DABA[J]. Journal of Membrane Science, 2019, 581: 430-438. |

| 27 | Thür R, Lemmens V, Van Havere D, et al. Tuning 6FDA-DABA membrane performance for CO2 removal by physical densification and decarboxylation cross-linking during simple thermal treatment[J]. Journal of Membrane Science, 2020, 610: 118195. |

| 28 | Weidman J R, Luo S J, Zhang Q N, et al. Structure manipulation in triptycene-based polyimides through main chain geometry variation and its effect on gas transport properties[J]. Industrial & Engineering Chemistry Research, 2017, 56(7): 1868-1879. |

| 29 | Liang J C, Wang Z G, Huang M H, et al. Effects on carbon molecular sieve membrane properties for a precursor polyimide with simultaneous flatness and contortion in the repeat unit[J]. ChemSusChem, 2020, 13(20): 5531-5538. |

| 30 | Kaneda T, Katsura T, Nakagawa K, et al. High-strength-high-modulus polyimide fibers (Ⅰ): One-step synthesis of spinnable polyimides[J]. Journal of Applied Polymer Science, 1986, 32(1): 3133-3149. |

| 31 | Mehdipour-Ataei S, Bahri-Laleh N, Amirshaghaghi A. Comparison of one-step and two-step methods of polyimidization and substitution effect in the synthesis of new poly(ester-imide)s with bulky pendent group[J]. Polymer Degradation and Stability, 2006, 91(11): 2622-2631. |

| 32 | Xiao S D, Huang R Y M, Feng X S. Synthetic 6FDA-ODA copolyimide membranes for gas separation and pervaporation: functional groups and separation properties[J]. Polymer, 2007, 48(18): 5355-5368. |

| 33 | Aristizábal S L, Habboub O S, Pulido B A, et al. One-step, room temperature synthesis of well-defined, organo-soluble multifunctional aromatic polyimides[J]. Macromolecules, 2021, 54(23): 10870-10882. |

| 34 | Huo G L, Xu S, Wu L, et al. Structural engineering on copolyimide membranes for improved gas separation performance[J]. Journal of Membrane Science, 2022, 643: 119989. |

| 35 | 汪英, 青双桂, 冯婷婷, 等. 催化剂对部分化学亚胺化法制备聚酰亚胺薄膜的影响[J]. 绝缘材料, 2020, 53(1): 30-34. |

| Wang Y, Qing S G, Feng T T, et al. Effect of catalyst on preparation of polyimide films via partly chemical imidization method[J]. Insulating Materials, 2020, 53(1): 30-34. | |

| 36 | 张兵. 分子筛炭膜的制备、微结构及气体分离性能[D]. 大连: 大连理工大学, 2007. |

| Zhang B. Preparation, microstructure and gas separation performance of molecular sieving carbon membranes[D]. Dalian: Dalian University of Technology, 2007. | |

| 37 | 李琳. 聚酰亚胺基炭膜的制备、热解机理及结构调控[D]. 大连: 大连理工大学, 2013. |

| Li L. Preparation, pyrolysis mechanism and structure modification of polyimide based carbon membrane[D]. Dalian: Dalian University of Technology, 2013. | |

| 38 | Steel K M. Carbon membranes for challenging gas separations[D]. Austin: The University of Texas at Austin, 2000. |

| 39 | Kiyono M, Williams P J, Koros W J. Effect of pyrolysis atmosphere on separation performance of carbon molecular sieve membranes[J]. Journal of Membrane Science, 2010, 359(1/2): 2-10. |

| 40 | Adams J S, Itta A K, Zhang C, et al. New insights into structural evolution in carbon molecular sieve membranes during pyrolysis[J]. Carbon, 2019, 141: 238-246. |

| 41 | Rungta M, Wenz G B, Zhang C, et al. Carbon molecular sieve structure development and membrane performance relationships[J]. Carbon, 2017, 115: 237-248. |

| 42 | 李琳, 祁文博, 王虹, 等. 聚酰亚胺的化学结构在炭膜制备过程中的变化规律及热解机理[J]. 新型炭材料, 2015, 30(5): 459-465. |

| Li L, Qi W B, Wang H, et al. Pyrolysis of polyimide membranes from the same dianhydride monomer and different diamines to form carbon membranes[J]. New Carbon Materials, 2015, 30(5): 459-465. | |

| 43 | Fu S L, Wenz G B, Sanders E S, et al. Effects of pyrolysis conditions on gas separation properties of 6FDA/DETDA∶DABA(3∶2) derived carbon molecular sieve membranes[J]. Journal of Membrane Science, 2016, 520: 699-711. |

| 44 | Qiu W L, Zhang K, Li F S, et al. Gas separation performance of carbon molecular sieve membranes based on 6FDA-mPDA/DABA (3∶2) polyimide[J]. ChemSusChem, 2014, 7(4): 1186-1194. |

| 45 | Kiyono M, Williams P J, Koros W J. Generalization of effect of oxygen exposure on formation and performance of carbon molecular sieve membranes[J]. Carbon, 2010, 48(15): 4442-4449. |

| 46 | Vu D Q, Koros W J, Miller S J. High pressure CO2/CH4 separation using carbon molecular sieve hollow fiber membranes[J]. Industrial & Engineering Chemistry Research, 2002, 41(3): 367-380. |

| 47 | Petersen J, Matsuda M, Haraya K. Capillary carbon molecular sieve membranes derived from Kapton for high temperature gas separation[J]. Journal of Membrane Science, 1997, 131(1/2): 85-94. |

| 48 | Sazali N, Salleh W N W, Ismail A F, et al. Effect of heating rates on the microstructure and gas permeation properties of carbon membranes[J]. Malaysian Journal of Fundamental and Applied Sciences, 2018, 14(3): 378-381. |

| 49 | Pal N, Agarwal M. Advances in materials process and separation mechanism of the membrane towards hydrogen separation[J]. International Journal of Hydrogen Energy, 2021, 46(53): 27062-27087. |

| 50 | Nurwahdah F, Sazali N, Othman M. A mini review on carbon molecular sieve membrane for oxygen separation[J]. Journal of Modern Manufacturing Systems and Technology, 2020, 4(1): 23-35. |

| 51 | Gilron J, Soffer A. Knudsen diffusion in microporous carbon membranes with molecular sieving character[J]. Journal of Membrane Science, 2002, 209(2): 339-352. |

| 52 | 曾炜炜, 吴赟炎, 李毅, 等. 二维石墨相氮化碳纳米片的制备方法研究进展[J]. 化工新型材料, 2018, 46(6): 9-11, 14. |

| Zeng W W, Wu Y Y, Li Y, et al. Research process on preparation of two dimensional graphitic carbon nitride nanosheets[J]. New Chemical Materials, 2018, 46(6): 9-11, 14. | |

| 53 | Briceño K, Montané D, Garcia-Valls R, et al. Fabrication variables affecting the structure and properties of supported carbon molecular sieve membranes for hydrogen separation[J]. Journal of Membrane Science, 2012, 415/416: 288-297. |

| 54 | Fuertes A B. Adsorption-selective carbon membrane for gas separation[J]. Journal of Membrane Science, 2000, 177(1/2): 9-16. |

| 55 | Sabil K M, Partoon B. Recent advances on carbon dioxide capture through a hydrate-based gas separation process[J]. Current Opinion in Green and Sustainable Chemistry, 2018, 11: 22-26. |

| 56 | Baker R W, Lokhandwala K. Natural gas processing with membranes: an overview[J]. Industrial & Engineering Chemistry Research, 2008, 47(7): 2109-2121. |

| 57 | Parry M L, Canziani O F, Hanson C E. Climate change 2007: impacts, adaptation and vulnerability[R]. Cambridge, UK, 2007: 173-210. |

| 58 | Arnell N W, Liu C, Compagnucci R, et al. Hydrology and water resources: impacts, adaptation, and vulnerability[R]. Cambridge, UK, 2001: 191-233. |

| 59 | Sreedhar I, Vaidhiswaran R, Kamani B M, et al. Process and engineering trends in membrane based carbon capture[J]. Renewable and Sustainable Energy Reviews, 2017, 68: 659-684. |

| 60 | Joglekar M, Itta A K, Kumar R, et al. Carbon molecular sieve membranes for CO2/N2 separations: evaluating subambient temperature performance[J]. Journal of Membrane Science, 2019, 569: 1-6. |

| 61 | Wang Y H, Sheng L C, Zhang X R, et al. Hybrid carbon molecular sieve membranes having ordered Fe3O4@ZIF-8-derived microporous structure for gas separation[J]. Journal of Membrane Science, 2023, 666: 121127. |

| 62 | Xu S, Zhao N, Wu L, et al. Carbon molecular sieve gas separation membranes from crosslinkable bromomethylated 6FDA-DAM polyimide[J]. Journal of Membrane Science, 2022, 659: 120781. |

| 63 | Jiao Y, Du A J, Smith S C, et al. H2 purification by functionalized graphdiyne—role of nitrogen doping[J]. Journal of Materials Chemistry A, 2015, 3(13): 6767-6771. |

| 64 | Chen W H, Chen C Y. Water gas shift reaction for hydrogen production and carbon dioxide capture: a review[J]. Applied Energy, 2020, 258: 114078. |

| 65 | Lei L F, Lindbråthen A, Hillestad M, et al. Carbon molecular sieve membranes for hydrogen purification from a steam methane reforming process[J]. Journal of Membrane Science, 2021, 627: 119241. |

| 66 | Qiu W L, Vaughn J, Liu G P, et al. Hyperaging tuning of a carbon molecular-sieve hollow fiber membrane with extraordinary gas-separation performance and stability[J]. Angewandte Chemie International Edition, 2019, 58(34): 11700-11703. |

| 67 | Gao T, Lin W S, Gu A Z, et al. Coalbed methane liquefaction adopting a nitrogen expansion process with propane pre-cooling[J]. Applied Energy, 2010, 87(7): 2142-2147. |

| 68 | Xu M, Deng S G. Efficient screening of novel adsorbents for coalbed methane recovery[J]. Journal of Colloid and Interface Science, 2020, 565: 131-141. |

| 69 | Ning X, Koros W J. Carbon molecular sieve membranes derived from Matrimid® polyimide for nitrogen/methane separation[J]. Carbon, 2014, 66: 511-522. |

| 70 | Low B T, Chung T S. Carbon molecular sieve membranes derived from pseudo-interpenetrating polymer networks for gas separation and carbon capture[J]. Carbon, 2011, 49(6): 2104-2112. |

| 71 | Yu H J, Shin J H, Lee A S, et al. Tailoring selective pores of carbon molecular sieve membranes towards enhanced N2/CH4 separation efficiency[J]. Journal of Membrane Science, 2021, 620: 118814. |

| 72 | Fu S L, Sanders E S, Kulkarni S, et al. The significance of entropic selectivity in carbon molecular sieve membranes derived from 6FDA/DETDA∶DABA(3∶2) polyimide[J]. Journal of Membrane Science, 2017, 539: 329-343. |

| 73 | Shao L, Chung T S, Wensley G, et al. Casting solvent effects on morphologies, gas transport properties of a novel 6FDA/PMDA-TMMDA copolyimide membrane and its derived carbon membranes[J]. Journal of Membrane Science, 2004, 244(1/2): 77-87. |

| 74 | Orhan I B, Daglar H, Keskin S, et al. Prediction of O2/N2 selectivity in metal-organic frameworks via high-throughput computational screening and machine learning[J]. ACS Applied Materials & Interfaces, 2022, 14(1): 736-749. |

| 75 | Deng G X, Wang Y L, Zong X P, et al. Structure evolution in carbon molecular sieve membranes derived from binaphthol-6FDA polyimide and their gas separation performance[J]. Journal of Industrial and Engineering Chemistry, 2021, 94: 489-497. |

| [1] | Zhiguo WANG, Meng XUE, Yushuang DONG, Tianzhen ZHANG, Xiaokai QIN, Qiang HAN. Numerical simulation and analysis of geothermal rock mass heat flow coupling based on fracture roughness characterization method [J]. CIESC Journal, 2023, 74(S1): 223-234. |

| [2] | He JIANG, Junfei YUAN, Lin WANG, Guyu XING. Experimental study on the effect of flow sharing cavity structure on phase change flow characteristics in microchannels [J]. CIESC Journal, 2023, 74(S1): 235-244. |

| [3] | Weiqi JIN, Yuerong WU, Xia WANG, Li LI, Su QIU, Pan YUAN, Minghe WANG. Progress in infrared imaging detection technology and domestic equipment for industrial gas leakage in chemical industry parks [J]. CIESC Journal, 2023, 74(S1): 32-44. |

| [4] | Meisi CHEN, Weida CHEN, Xinyao LI, Shangyu LI, Youting WU, Feng ZHANG, Zhibing ZHANG. Advances in silicon-based ionic liquid microparticle enhanced gas capture and conversion [J]. CIESC Journal, 2023, 74(9): 3628-3639. |

| [5] | Song HE, Qiaomai LIU, Guangshuo XIE, Simin WANG, Juan XIAO. Two-phase flow simulation and surrogate-assisted optimization of gas film drag reduction in high-concentration coal-water slurry pipeline [J]. CIESC Journal, 2023, 74(9): 3766-3774. |

| [6] | Zhewen CHEN, Junjie WEI, Yuming ZHANG. System integration and energy conversion mechanism of the power technology with integrated supercritical water gasification of coal and SOFC [J]. CIESC Journal, 2023, 74(9): 3888-3902. |

| [7] | Jiaqi YUAN, Zheng LIU, Rui HUANG, Lefu ZHANG, Denghui HE. Investigation on energy conversion characteristics of vortex pump under bubble inflow [J]. CIESC Journal, 2023, 74(9): 3807-3820. |

| [8] | Yaxin ZHAO, Xueqin ZHANG, Rongzhu WANG, Guo SUN, Shanjing YAO, Dongqiang LIN. Removal of monoclonal antibody aggregates with ion exchange chromatography by flow-through mode [J]. CIESC Journal, 2023, 74(9): 3879-3887. |

| [9] | Yan GAO, Peng WU, Chao SHANG, Zejun HU, Xiaodong CHEN. Preparation of magnetic agarose microspheres based on a two-fluid nozzle and their protein adsorption properties [J]. CIESC Journal, 2023, 74(8): 3457-3471. |

| [10] | Shuang LIU, Linzhou ZHANG, Zhiming XU, Suoqi ZHAO. Study on molecular level composition correlation of viscosity of residual oil and its components [J]. CIESC Journal, 2023, 74(8): 3226-3241. |

| [11] | Chen HAN, Youmin SITU, Bin ZHU, Jianliang XU, Xiaolei GUO, Haifeng LIU. Study of reaction and flow characteristics in multi-nozzle pulverized coal gasifier with co-processing of wastewater [J]. CIESC Journal, 2023, 74(8): 3266-3278. |

| [12] | Lei XING, Chunyu MIAO, Minghu JIANG, Lixin ZHAO, Xinya LI. Optimal design and performance analysis of downhole micro gas-liquid hydrocyclone [J]. CIESC Journal, 2023, 74(8): 3394-3406. |

| [13] | Jiayi ZHANG, Jiali HE, Jiangpeng XIE, Jian WANG, Yu ZHAO, Dongqiang ZHANG. Research progress of pervaporation technology for N-methylpyrrolidone recovery in lithium battery production [J]. CIESC Journal, 2023, 74(8): 3203-3215. |

| [14] | Ruihang ZHANG, Pan CAO, Feng YANG, Kun LI, Peng XIAO, Chun DENG, Bei LIU, Changyu SUN, Guangjin CHEN. Analysis of key parameters affecting product purity of natural gas ethane recovery process via ZIF-8 nanofluid [J]. CIESC Journal, 2023, 74(8): 3386-3393. |

| [15] | Wenxiang NI, Jing ZHAO, Bo LI, Xiaolin WEI, Dongyin WU, Di LIU, Qiang WANG. Study on waste heat boiler ash deposition characteristics in sensible heat recovery process of converter gas [J]. CIESC Journal, 2023, 74(8): 3485-3493. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||