CIESC Journal ›› 2022, Vol. 73 ›› Issue (8): 3326-3337.DOI: 10.11949/0438-1157.20220699

• Reviews and monographs • Previous Articles Next Articles

Shuangqiao YANG( ), Baojie WEI, Dawei XU, Li LI, Qi WANG(

), Baojie WEI, Dawei XU, Li LI, Qi WANG( )

)

Received:2022-05-16

Revised:2022-07-28

Online:2022-09-06

Published:2022-08-05

Contact:

Qi WANG

通讯作者:

王琪

作者简介:杨双桥(1990—),男,博士,副研究员,yangshuangqiao@scu.edu.cn

基金资助:CLC Number:

Shuangqiao YANG, Baojie WEI, Dawei XU, Li LI, Qi WANG. Application of aluminum-plastic packaging and new recycling technology of the waste[J]. CIESC Journal, 2022, 73(8): 3326-3337.

杨双桥, 韦宝杰, 徐大伟, 李莉, 王琪. 铝塑复合包装的应用及废弃物回收利用新技术[J]. 化工学报, 2022, 73(8): 3326-3337.

Add to citation manager EndNote|Ris|BibTeX

| Materials | Thickness/μm | Oxygen permeability/(cm3/(m2·d·(0.1 mPa))) | Water vapor permeability/ (g/(m2·d)) |

|---|---|---|---|

| PE | 50 | 2187.7 | 7.8 |

| BOPP | 50 | 582.5 | 3.0 |

| PET | 50 | 25.2 | 7.0 |

| PA | 15 | 41.2 | 290.6 |

| PET/PE | 50 | 88.7 | 5.6 |

| PET/CPP | 50 | 75.4 | 5.8 |

| PET/Al/PE | 60 | 0.13 | 0.48 |

| BOPA/Al/CPP | 60 | 0.07 | 0.51 |

| PET/Al/CPP | 60 | 0.12 | 0.45 |

Table 1 Oxygen and moisture permeability of common plastic packaging[5]

| Materials | Thickness/μm | Oxygen permeability/(cm3/(m2·d·(0.1 mPa))) | Water vapor permeability/ (g/(m2·d)) |

|---|---|---|---|

| PE | 50 | 2187.7 | 7.8 |

| BOPP | 50 | 582.5 | 3.0 |

| PET | 50 | 25.2 | 7.0 |

| PA | 15 | 41.2 | 290.6 |

| PET/PE | 50 | 88.7 | 5.6 |

| PET/CPP | 50 | 75.4 | 5.8 |

| PET/Al/PE | 60 | 0.13 | 0.48 |

| BOPA/Al/CPP | 60 | 0.07 | 0.51 |

| PET/Al/CPP | 60 | 0.12 | 0.45 |

| Polymer type | Particle size |

|---|---|

| PA6 | ~80 nm |

| PP, PS | 0.3—2 µm |

| PC, PPS | 10—50 µm |

| PES, PEEK | 1—10 µm |

| HDPE, waste rubber, SBS | micro-scale |

Table 2 Particle size of micro/nano polymer powder prepared by solid-state shear milling [21, 28-31]

| Polymer type | Particle size |

|---|---|

| PA6 | ~80 nm |

| PP, PS | 0.3—2 µm |

| PC, PPS | 10—50 µm |

| PES, PEEK | 1—10 µm |

| HDPE, waste rubber, SBS | micro-scale |

Fig.4 Photos of pre-crushed aluminum plastic packaging waste (APPW) (a), powders prepared by solid-state shear milling technology (b), SEM morphology of APPW powders [(c),(d)] and the distribution of aluminum after 1 (e) and 10 (f) milling cycles

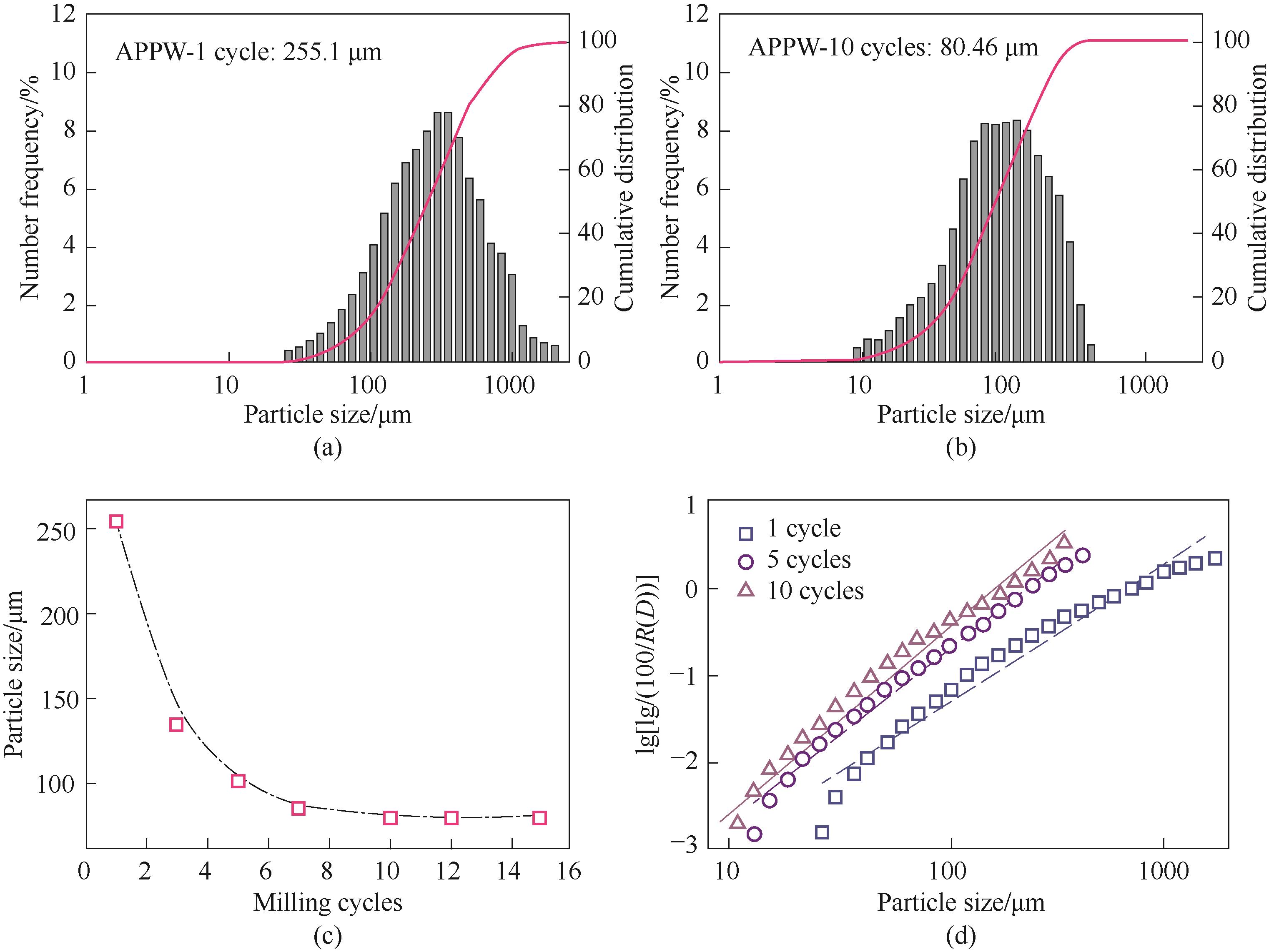

Fig.5 Particle size distribution of APPW after 1(a) and 10 (b) milling cycles, mean particle size (c) and Rosin-Rammler Bannet fitting curve of particle size (d)

| Parameter | 1 cycle | 5 cycles | 10 cycles |

|---|---|---|---|

| De/μm | 321 | 152 | 106 |

| b | 1.03×10-4 | 5.03×10-5 | 5.09×10-5 |

| n | 1.59 | 1.97 | 2.12 |

Table 3 Development of Rosin-Rammler Bennet coefficient during the solid-state shear milling

| Parameter | 1 cycle | 5 cycles | 10 cycles |

|---|---|---|---|

| De/μm | 321 | 152 | 106 |

| b | 1.03×10-4 | 5.03×10-5 | 5.09×10-5 |

| n | 1.59 | 1.97 | 2.12 |

Fig.6 Photos of APPW powders after 0 (a), 1 (b) and 10 (c) milling cycles during the mixing processing, torque curve (d), balance torque time (e) and melt index (f)

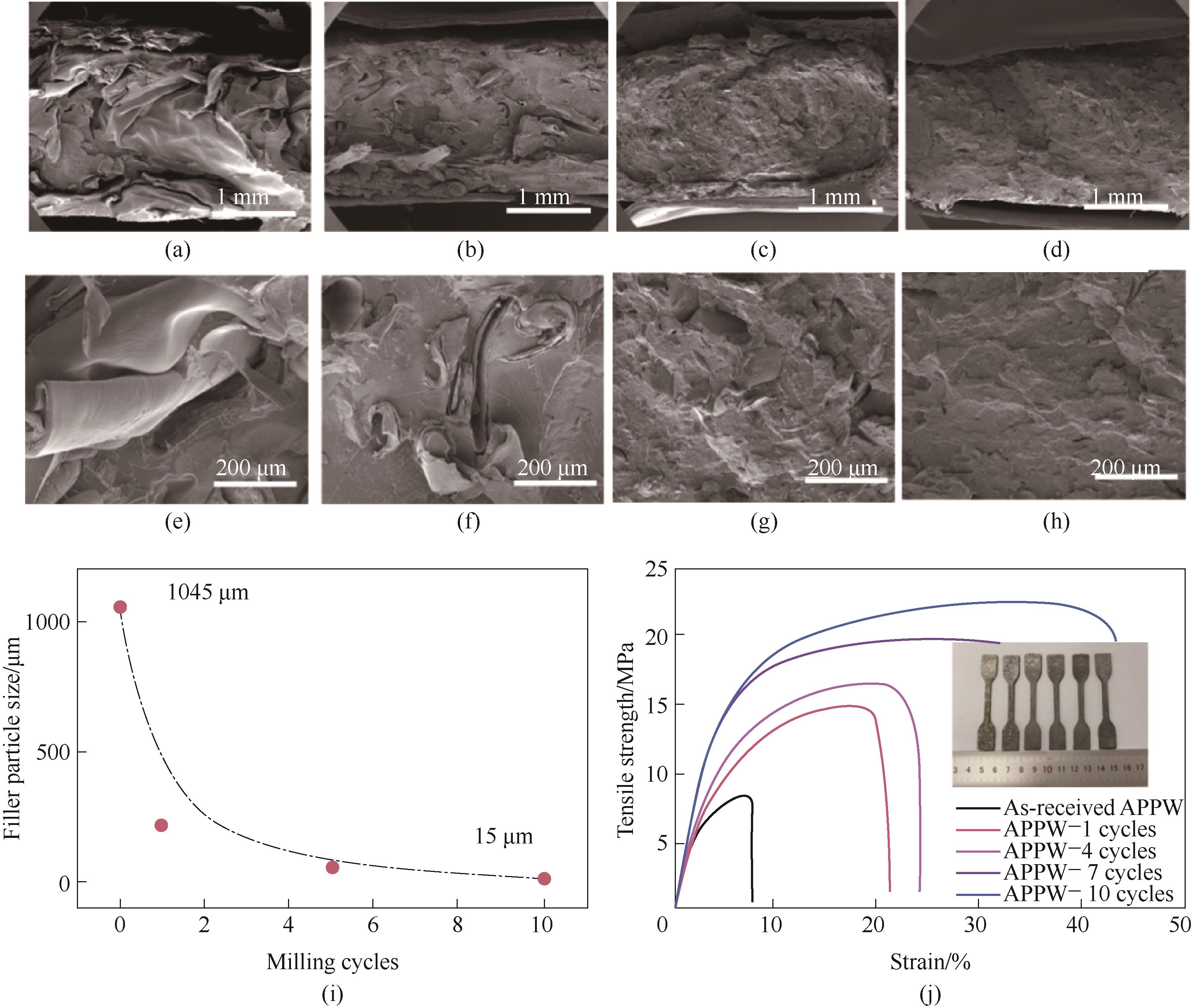

Fig.7 SEM images of reused APPW composites with 0 cycle [(a),(e)], 1 cycle [(b),(f)], 4 cycles[(c),(g)], and 10 cycles [(d),(h)], relation between filler size and milling cycle (i) and tensile strength (j)

| Samples | Tensile strength /MPa | Elongation at break/% | Electrical conductivity/ (S/cm) | Thermal conductivity/ (W/(m∙K)) |

|---|---|---|---|---|

| after milling | 22.1 | 47.1 | 10-12 | 0.6 |

| without milling | 8.5 | 7.9 | 10-14 | — |

Table 4 Properties of recycled APPW composites

| Samples | Tensile strength /MPa | Elongation at break/% | Electrical conductivity/ (S/cm) | Thermal conductivity/ (W/(m∙K)) |

|---|---|---|---|---|

| after milling | 22.1 | 47.1 | 10-12 | 0.6 |

| without milling | 8.5 | 7.9 | 10-14 | — |

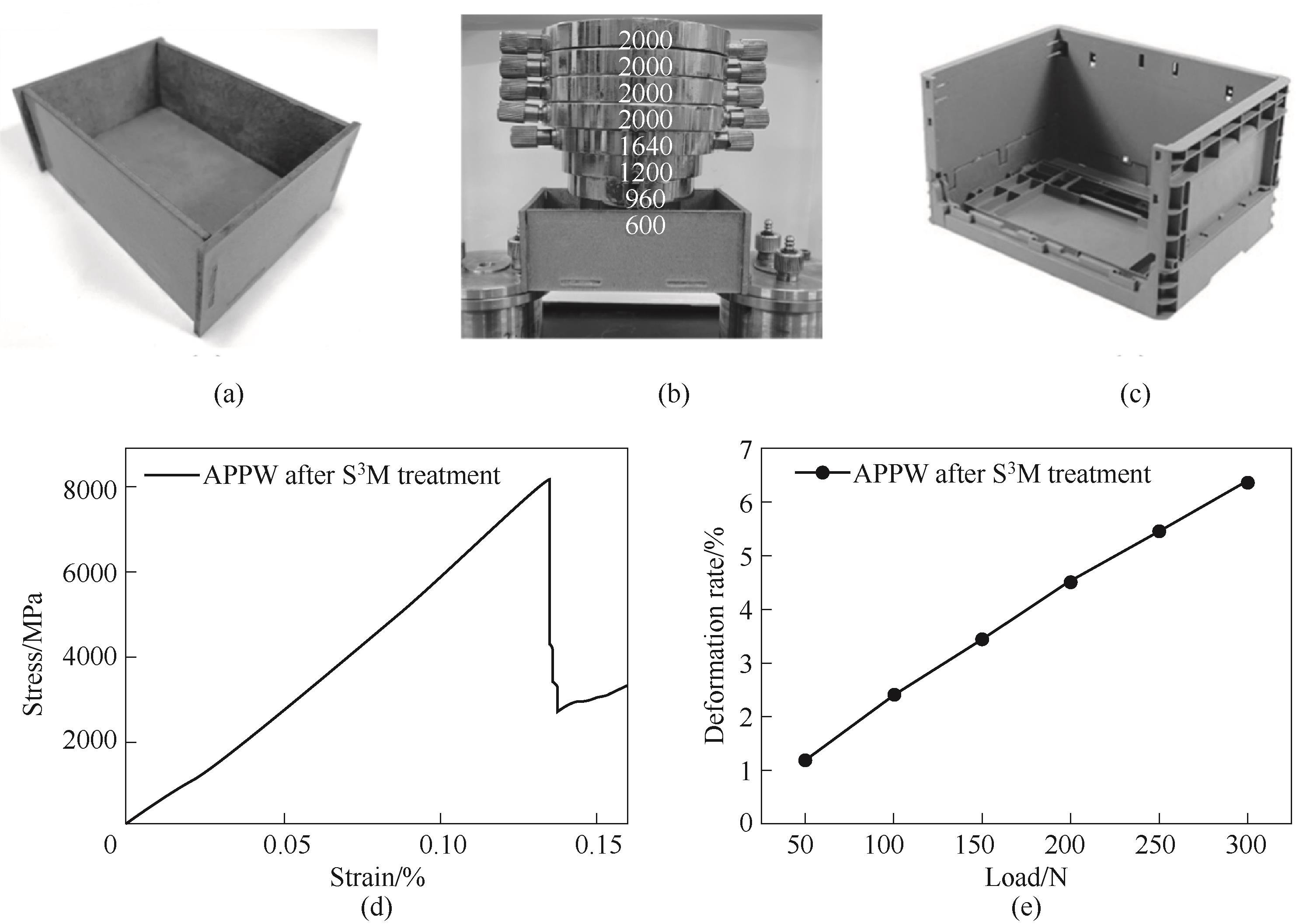

Fig.8 Molded APPW part (a), load test (b), industrial detachable logistics packer prepared by injection molding (c), stress-strain cure (d) and relation between deformation rate and load (e)

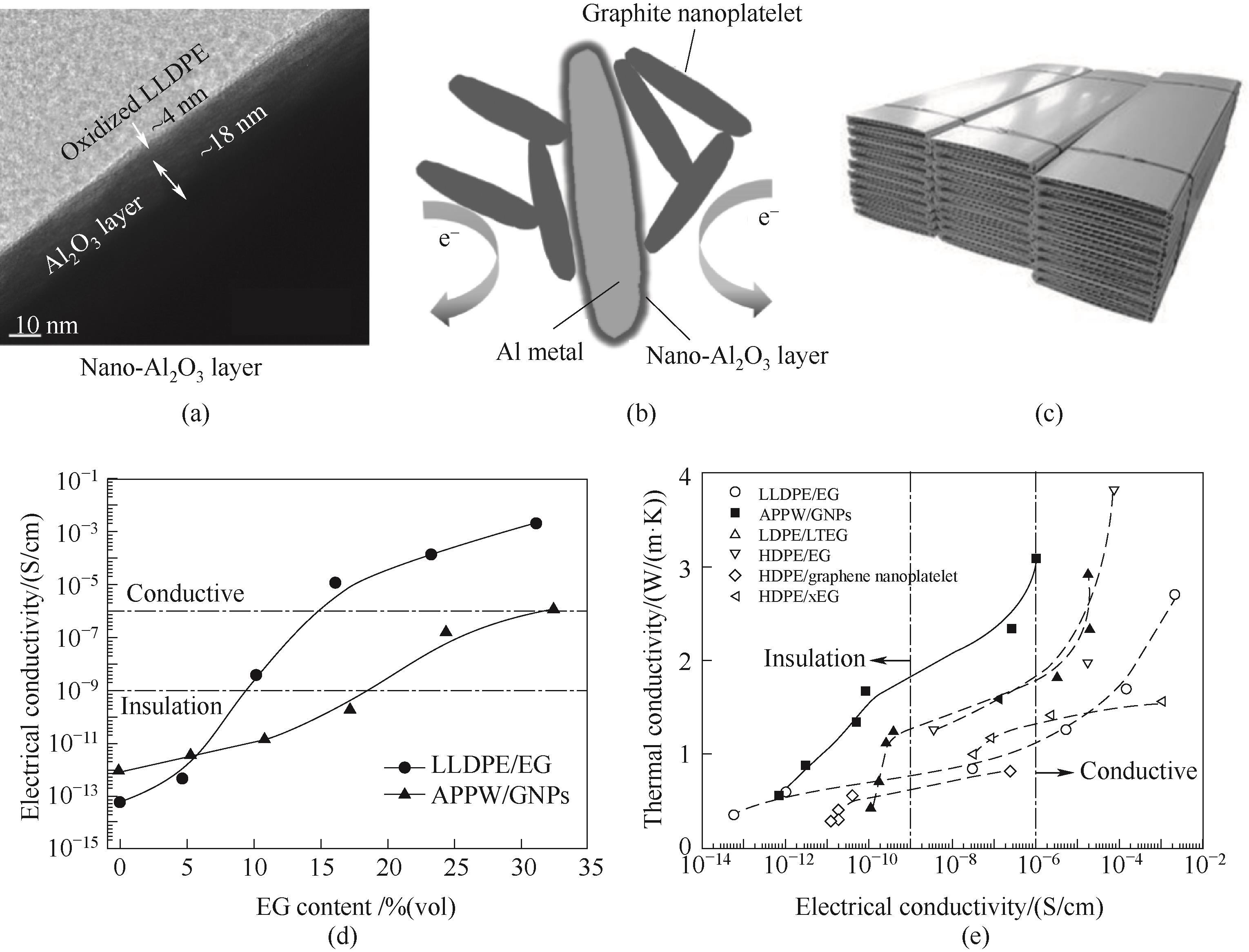

Fig.9 TEM of Al in APPW thermal conductive material (a), mechanism of thermal conductivity (b), prepared industrial cooling plates (c), relation between conductivity and expandable graphite loading (d) and relation between thermal conductivity and conductivity (e) [40]

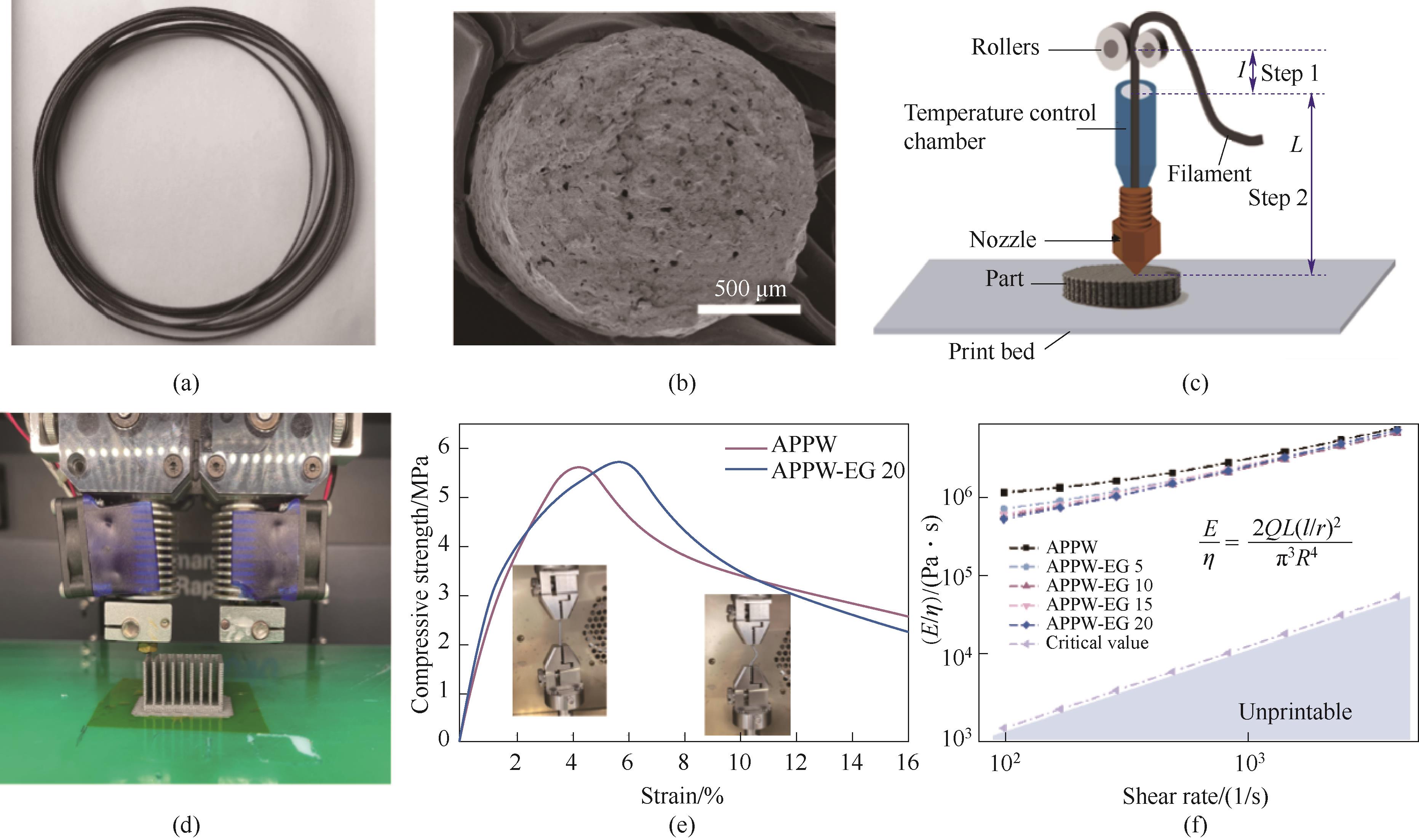

Fig.10 Photos of APPW filaments for 3D printing (a), SEM image of APPW filaments (b), schematic diagram of 3D printing process (c), photos of 3D printing process (d), relation between compressive strength and strain (e) and relation between E/η and shear rate (f) [41]

Fig.11 3D printed radiators from APPW (a), relation between thermal conductivity and filler loading [(b),(c)], schematic diagram of thermal conductive mechanism (d) and comparison of heat dissipation effect of composites (e) [41]

| 1 | 中国包装联合会. 2021年全国包装行业运行概况[EB/OL]. [2022-02-22]. . |

| China Packaging Federation. 2021 operation overview of national packaging industry[EB/OL]. [2022-02-22]. . | |

| 2 | 蓝敏怡, 李会茹, 胡立新, 等. 塑料食品包装材料的环境污染综述[J]. 生态毒理学报, 2021, 16(5): 186-210. |

| Lan M Y, Li H R, Hu L X, et al. A review of the environmental pollution of food plastic packaging materials[J]. Asian Journal of Ecotoxicology, 2021, 16(5): 186-210. | |

| 3 | Creton C. Molecular stitches for enhanced recycling of packaging[J]. Science, 2017, 355(6327): 797-798. |

| 4 | 马占峰, 姜宛君, 杨森. 中国塑料加工工业(2019)[J]. 中国塑料, 2020, 34(5): 102-106. |

| Ma Z F, Jiang W J, Yang S. China plastics industry (2019)[J]. China Plastics, 2020, 34(5): 102-106. | |

| 5 | 祝爱萍, 麦伟明, 林锡康. 几种食品包装用塑料膜阻透性能比较[J]. 包装工程, 2018, 39(1): 74-78. |

| Zhu A P, Mai W M, Lin X K. Comparison on the barrier properties of several plastic films for food packaging[J]. Packaging Engineering, 2018, 39(1): 74-78. | |

| 6 | Garcia J M, Robertson M L. The future of plastics recycling[J]. Science, 2017, 358(6365): 870-872. |

| 7 | 叶聪贤, 钱庆荣, 曹长林, 等. 碳中和目标下利乐包的高值化回收利用[J]. 再生资源与循环经济, 2022, 15(2): 34-38. |

| Ye C X, Qian Q R, Cao C L, et al. High-value recycling of Tetra Pak with the goal of carbon neutrality[J]. Recyclable Resources and Circular Economy, 2022, 15(2): 34-38. | |

| 8 | 余绍火, 邵双喜, 段景宽, 等. 废塑料基复合材料粉体分离及回收技术(续)[J]. 资源再生, 2010(8): 42-43. |

| Yu S H, Shao S X, Duan J K, et al. Separating and recycling technology of scraps of plastic-base composite[J]. Resource Recycling, 2010(8): 42-43. | |

| 9 | Xie M H, Bai W N, Bai L, et al. Life cycle assessment of the recycling of Al-PE (a laminated foil made from polyethylene and aluminum foil) composite packaging waste[J]. Journal of Cleaner Production, 2016, 112: 4430-4434. |

| 10 | Samorì C, Cespi D, Blair P, et al. Application of switchable hydrophilicity solvents for recycling multilayer packaging materials[J]. Green Chemistry, 2017, 19(7): 1714-1720. |

| 11 | 张冀飞, 闫大海, 李丽, 等. 分离剂甲酸溶液浓度和温度对于铝塑湿法分离的影响研究[J]. 环境工程学报, 2010, 4(3): 665-670. |

| Zhang J F, Yan D H, Li L, et al. Research on the effect of separation reagent concentration and reaction temperature on Al-PE wet separation technics[J]. Chinese Journal of Environmental Engineering, 2010, 4(3): 665-670. | |

| 12 | 张海舰, 吴韬, 冯嘉宁, 等. 废弃铝塑包装材料高效回收方法的研究[J]. 塑料工业, 2014, 42(7): 114-117. |

| Zhang H J, Wu T, Feng J N, et al. Recovery methods of waste aluminum-plastic packaging materials[J]. China Plastics Industry, 2014, 42(7): 114-117. | |

| 13 | 张志红, 刘玉婷, 魏守端, 等. 药用铝塑包装材料分离回收研究[J]. 昌吉学院学报, 2011(2): 95-98. |

| Zhang Z H, Liu Y T, Wei S D, et al. Study on separation and recovery of aluminum-plastic packaging materials for medicine [J]. Journal of Changji University, 2011(2): 95-98. | |

| 14 | Yousef S, Eimontas J, Striūgas N, et al. Pyrolysis kinetic behavior and TG-FTIR-GC-MS analysis of metallised food packaging plastics[J]. Fuel, 2020, 282: 118737. |

| 15 | 宋薇, 岳东北, 刘建国, 等. 铝塑包装废物热解过程能量平衡分析[J]. 环境工程学报, 2012, 6(1): 307-310. |

| Song W, Yue D B, Liu J G, et al. Energy balance analysis on the pyrolysis process of aluminum-plastic package waste[J]. Chinese Journal of Environmental Engineering, 2012, 6(1): 307-310. | |

| 16 | Chu M Y, Tu W L, Yang S Q, et al. Sustainable chemical upcycling of waste polyolefins by heterogeneous catalysis[J]. SusMat, 2022, 2(2): 161-185. |

| 17 | 余绍火, 邵双喜, 段景宽, 等. 废塑料基复合材料粉体分离及回收技术[J]. 宁波工程学院学报, 2010, 22(2): 40-45. |

| Yu S H, Shao S X, Duan J K, et al. Separating and recycling technology of scraps of plastic-base composite[J]. Journal of Ningbo University of Technology, 2010, 22(2): 40-45. | |

| 18 | Favaro S L, Pereira A G B, Fernandes J R, et al. Outstanding impact resistance of post-consumer HDPE/multilayer packaging composites[J]. Materials Sciences and Applications, 2017, 8(1): 15-25. |

| 19 | Ragaert K, Delva L, Geem K V. Mechanical and chemical recycling of solid plastic waste[J]. Waste Management, 2017, 69: 24-58. |

| 20 | Schyns Z O G, Shaver M P. Mechanical recycling of packaging plastics: a review[J]. Macromolecular Rapid Communications, 2021, 42(3): e2000415. |

| 21 | 王琪, 卢灿辉, 夏和生. 高分子力化学研究进展[J]. 高分子通报, 2013(9): 35-49. |

| Wang Q, Lu C H, Xia H S. Research progress in polymer mechanochemistry[J]. Polymer Bulletin, 2013(9): 35-49. | |

| 22 | Yang S Q, Zhong F, Wang M, et al. Recycling of automotive shredder residue by solid state shear milling technology[J]. Journal of Industrial and Engineering Chemistry, 2018, 57: 143-153. |

| 23 | 张新星, 张伟, 卢灿辉. 力化学技术在聚合物加工中的应用进展[J]. 高分子材料科学与工程, 2013, 29(7): 183-186. |

| Zhang X X, Zhang W, Lu C H. Application advances of mechanochemical technology in polymer processing[J]. Polymer Materials Science & Engineering, 2013, 29(7): 183-186. | |

| 24 | 卢灿辉, 王琪. 聚合物固体粉碎过程中力化学效应的应用[J]. 高分子材料科学与工程, 2001, 17(5): 11-15. |

| Lu C H, Wang Q. Application of mechanochemical effects of polymer solids during pulverization[J]. Polymeric Materials Science & Cngineering, 2001, 17(5): 11-15. | |

| 25 | Wang Q, Xu X. A pan-milling type of equipment and its application in developing polymer materials[J]. Chemical Research in Chinese Universities, 1997(7): 1197-1201. |

| 26 | Xu X, Wang Q, Kong X, et al. Pan mill type equipment designed for polymer stress reactions: theoretical analysis of structure and milling process of equipment[J]. Plastics, Rubber and Composites Processing and Applications, 1996, 25: 152-158. |

| 27 | Liu P J, Chen W H, Bai S B. Influence of solid-state shear milling on structure and mechanical properties of polypropylene/polyethylene blends[J]. Polymer-Plastics Technology and Engineering, 2018, 57(7): 682-689. |

| 28 | Liu Y, Li J, Wang Q. Pan-milling to prepare ultrafine high-density polyethylene powder with sodium chloride serving as grinding aid[J]. Journal of Applied Polymer Science, 2007, 105(6): 3426-3431. |

| 29 | Lu C H, Wang Q. Preparation of ultrafine polypropylene/iron composite powders through pan-milling[J]. Journal of Materials Processing Technology, 2004, 145(3): 336-344. |

| 30 | Chen Z, Liu C S, Wang Q. Solid-phase preparation of ultra-fine PA6 powder through pan-milling[J]. Polymer Engineering & Science, 2001, 41(7): 1187-1195. |

| 31 | Zhang X X, Lu C H, Liang M. Preparation of rubber composites from ground tire rubber reinforced with waste-tire fiber through mechanical milling[J]. Journal of Applied Polymer Science, 2007, 103(6): 4087-4094. |

| 32 | Liu Q, He P, Yang S Q, et al. Recycling and reuse of waste artificial turf via solid-state shear milling technology[J]. RSC Advances, 2017, 7(85): 54117-54127. |

| 33 | Yang S Q, Jiang J, Duan W F, et al. Production of sustainable wood-plastic composites from the nonmetals in waste printed circuit boards: excellent physical performance achieved by solid-state shear milling[J]. Composites Science and Technology, 2020, 200: 108411. |

| 34 | Yang S Q, Bai S B, Wang Q. Preparation of fine fiberglass-resin powders from waste printed circuit boards by different milling methods for reinforcing polypropylene composites[J]. Journal of Applied Polymer Science, 2015, 132(35): 42494. |

| 35 | Yang S Q, Jiang J, Wang Q. The novel application of nonmetals from waste printed circuit board in high-performance thermal management materials[J]. Composites Part A: Applied Science and Manufacturing, 2020, 139: 106096. |

| 36 | 郭杰. 破碎-分选废弃电路板中非金属粉的资源化利用研究[D]. 上海: 上海交通大学, 2011. |

| Guo J. Study on reutilization of nonmetals reclamed from crushing-separating waste printed circuit boards[D]. Shanghai: Shanghai Jiao Tong University, 2011. | |

| 37 | Wu H J, Liang M, Lu C H. Morphological and structural development of recycled crosslinked polyethylene during solid-state mechanochemical milling[J]. Journal of Applied Polymer Science, 2011, 122(1): 257-264. |

| 38 | Sun F S, Guo J, Li Y J, et al. Preparation of high-performance polyethylene tubes under the coexistence of silicone cross-linked polyethylene and rotation extrusion[J]. Royal Society Open Science, 2019, 6(5): 182095. |

| 39 | Murthy K. Grinding studies of mango ginger: mathematical modelling of particle size distribution and energy consumption[J]. American Journal of Food Science & Technology, 2013, 4: 70-76. |

| 40 | Yang S Q, Bai S B, Duan W F, et al. Production of value-added composites from aluminum–plastic package waste via solid-state shear milling process[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(3): 4282-4293. |

| 41 | Wei B J, Yang S Q, Wang Q. Green recycling of aluminum plastic packaging waste by solid-state shear milling and 3D printing for thermal conductive composites[J]. Polymers for Advanced Technologies, 2021, 32(6): 2576-2587. |

| [1] | Xingzhi HU, Haoyan ZHANG, Jingkun ZHUANG, Yuqing FAN, Kaiyin ZHANG, Jun XIANG. Preparation and microwave absorption properties of carbon nanofibers embedded with ultra-small CeO2 nanoparticles [J]. CIESC Journal, 2023, 74(8): 3584-3596. |

| [2] | Ao ZHANG, Yingwu LUO. Low modulus, high elasticity and high peel adhesion acrylate pressure sensitive adhesives [J]. CIESC Journal, 2023, 74(7): 3079-3092. |

| [3] | Bin CAI, Xiaolin ZHANG, Qian LUO, Jiangtao DANG, Liyuan ZUO, Xinmei LIU. Research progress of conductive thin film materials [J]. CIESC Journal, 2023, 74(6): 2308-2321. |

| [4] | Jialin DAI, Weidong BI, Yumei YONG, Wenqiang CHEN, Hanyang MO, Bing SUN, Chao YANG. Effect of thermophysical properties on the heat transfer characteristics of solid-liquid phase change for composite PCMs [J]. CIESC Journal, 2023, 74(5): 1914-1927. |

| [5] | Shaoyun CHEN, Dong XU, Long CHEN, Yu ZHANG, Yuanfang ZHANG, Qingliang YOU, Chenglong HU, Jian CHEN. Preparation and adsorption properties of monolayer polyaniline microsphere arrays [J]. CIESC Journal, 2023, 74(5): 2228-2238. |

| [6] | Ruiqi LIU, Xitong ZHOU, Yue ZHANG, Ying HE, Jing GAO, Li MA. The construction and application of biosensor based on gold nanoparticles loaded SiO2-nanoflowers [J]. CIESC Journal, 2023, 74(3): 1247-1259. |

| [7] | Dong XU, Du TIAN, Long CHEN, Yu ZHANG, Qingliang YOU, Chenglong HU, Shaoyun CHEN, Jian CHEN. Preparation and electrochemical energy storage of polyaniline/manganese dioxide/polypyrrole composite nanospheres [J]. CIESC Journal, 2023, 74(3): 1379-1389. |

| [8] | Ruizhe CHEN, Leilei CHENG, Jing GU, Haoran YUAN, Yong CHEN. Research progress in chemical recovery technology of fiber-reinforced polymer composites [J]. CIESC Journal, 2023, 74(3): 981-994. |

| [9] | Lei ZHONG, Xueqing QIU, Wenli ZHANG. Advances in lignin-derived carbon anodes for alkali metal ion batteries [J]. CIESC Journal, 2022, 73(8): 3369-3380. |

| [10] | Xin ZHANG, Rui XU, Xinyu LU, Yong'an NIU. Synthesis and photocatalysis of SiO2@BiOCl-Bi24O31Cl10 core-shell microspheres [J]. CIESC Journal, 2022, 73(8): 3636-3646. |

| [11] | Renjie GU, Jiawei ZHANG, Xueyang JIN, Lixiong WEN. Synthesis of nickel-cobalt hydroxide composites as supercapacitor materials by micro-impinging stream reactors and their performance study [J]. CIESC Journal, 2022, 73(8): 3749-3757. |

| [12] | Zhenhe XU, Hongjiang LI, Yu GAO, Zheng LI, Hanyan ZHANG, Baotong XU, Fu DING, Yaguang SUN. Preparation of In2O3/Ag:ZnIn2S4 “Type Ⅱ” heterogeneous structure materials for visible light catalysis [J]. CIESC Journal, 2022, 73(8): 3625-3635. |

| [13] | Duanhui GAO, Weiqiang XIAO, Feng GAO, Qian XIA, Manqiu WANG, Xinbo LU, Xiaoli ZHAN, Qinghua ZHANG. Preparation and application of polyimide-based aerogels [J]. CIESC Journal, 2022, 73(7): 2757-2773. |

| [14] | Shuyan WANG, Ruiyang ZHANG, Run LIU, Kai LIU, Ying ZHOU. Interfacial structure regulation of Mn(BO2)2/BNO to enhance catalytic ozone decomposition performance [J]. CIESC Journal, 2022, 73(7): 3193-3201. |

| [15] | Shiyuan HUANG, Jian DENG, Hanqin YUAN, Guohua WANG, Xingliang WU. Experimental study on activation of peroxymonosulfate by cobalt-enhanced ferromagnet [J]. CIESC Journal, 2022, 73(7): 3045-3056. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||