CIESC Journal ›› 2023, Vol. 74 ›› Issue (6): 2308-2321.DOI: 10.11949/0438-1157.20230366

• Reviews and monographs • Previous Articles Next Articles

Bin CAI( ), Xiaolin ZHANG(

), Xiaolin ZHANG( ), Qian LUO, Jiangtao DANG, Liyuan ZUO, Xinmei LIU

), Qian LUO, Jiangtao DANG, Liyuan ZUO, Xinmei LIU

Received:2023-04-12

Revised:2023-06-11

Online:2023-07-27

Published:2023-06-05

Contact:

Xiaolin ZHANG

蔡斌( ), 张效林(

), 张效林( ), 罗倩, 党江涛, 左栗源, 刘欣梅

), 罗倩, 党江涛, 左栗源, 刘欣梅

通讯作者:

张效林

作者简介:蔡斌(1999—),男,硕士研究生,1162292480@qq.com

基金资助:CLC Number:

Bin CAI, Xiaolin ZHANG, Qian LUO, Jiangtao DANG, Liyuan ZUO, Xinmei LIU. Research progress of conductive thin film materials[J]. CIESC Journal, 2023, 74(6): 2308-2321.

蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321.

Add to citation manager EndNote|Ris|BibTeX

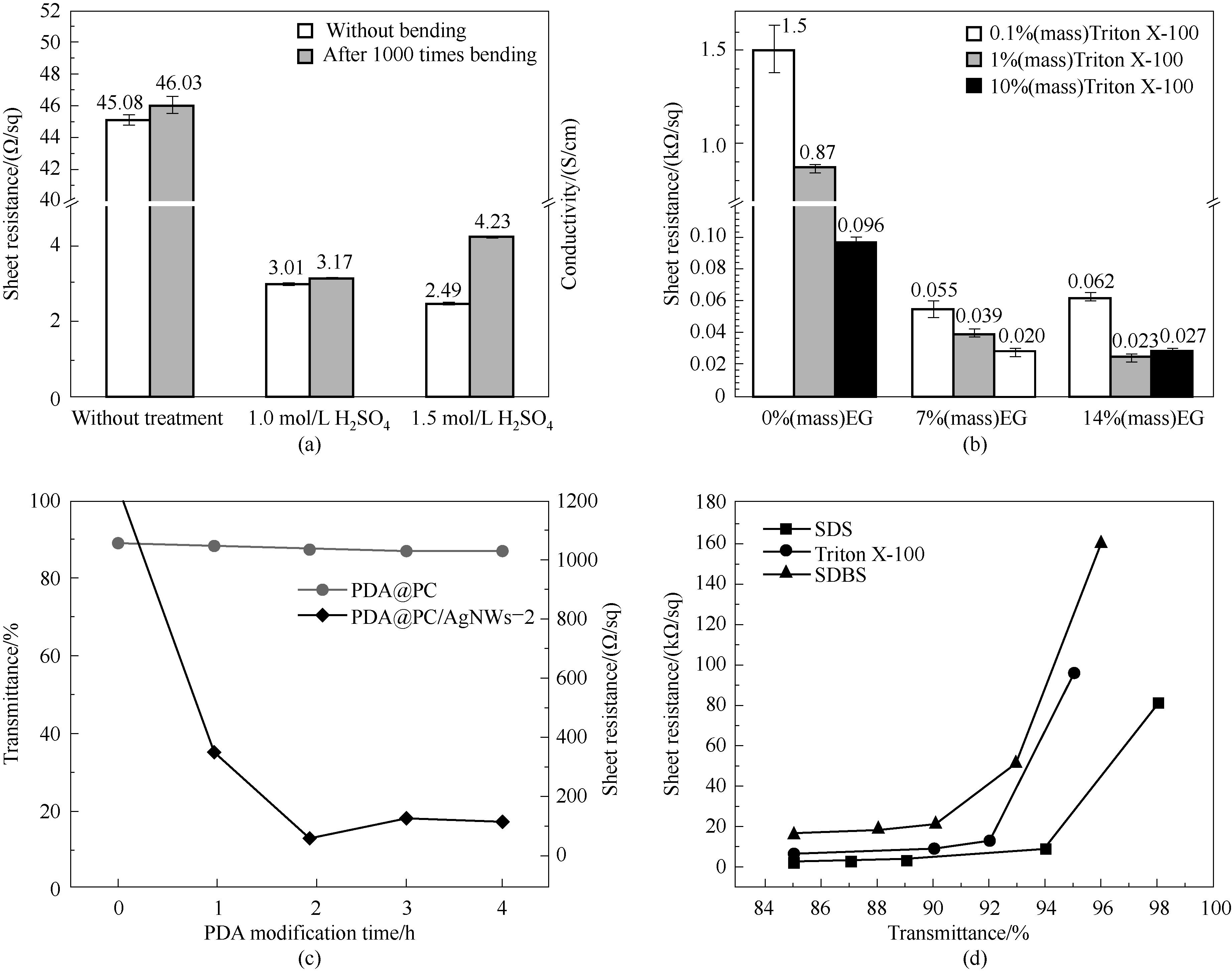

Fig.5 (a) Electrical properties of PEDOT∶PSS/ANFs composite films[56]; (b) Sheet resistance of conductive polymer films as a function of the content of EG and Triton X-100[54]; (c) Transmittance and conductivity of PDA@PC films coated with 2 cycles of AgNWs[18]; (d) Sheet resistance as a function of optical transmittance for the TCFs (SWCNT-H) prepared with different surfactants and spray coating method[42]

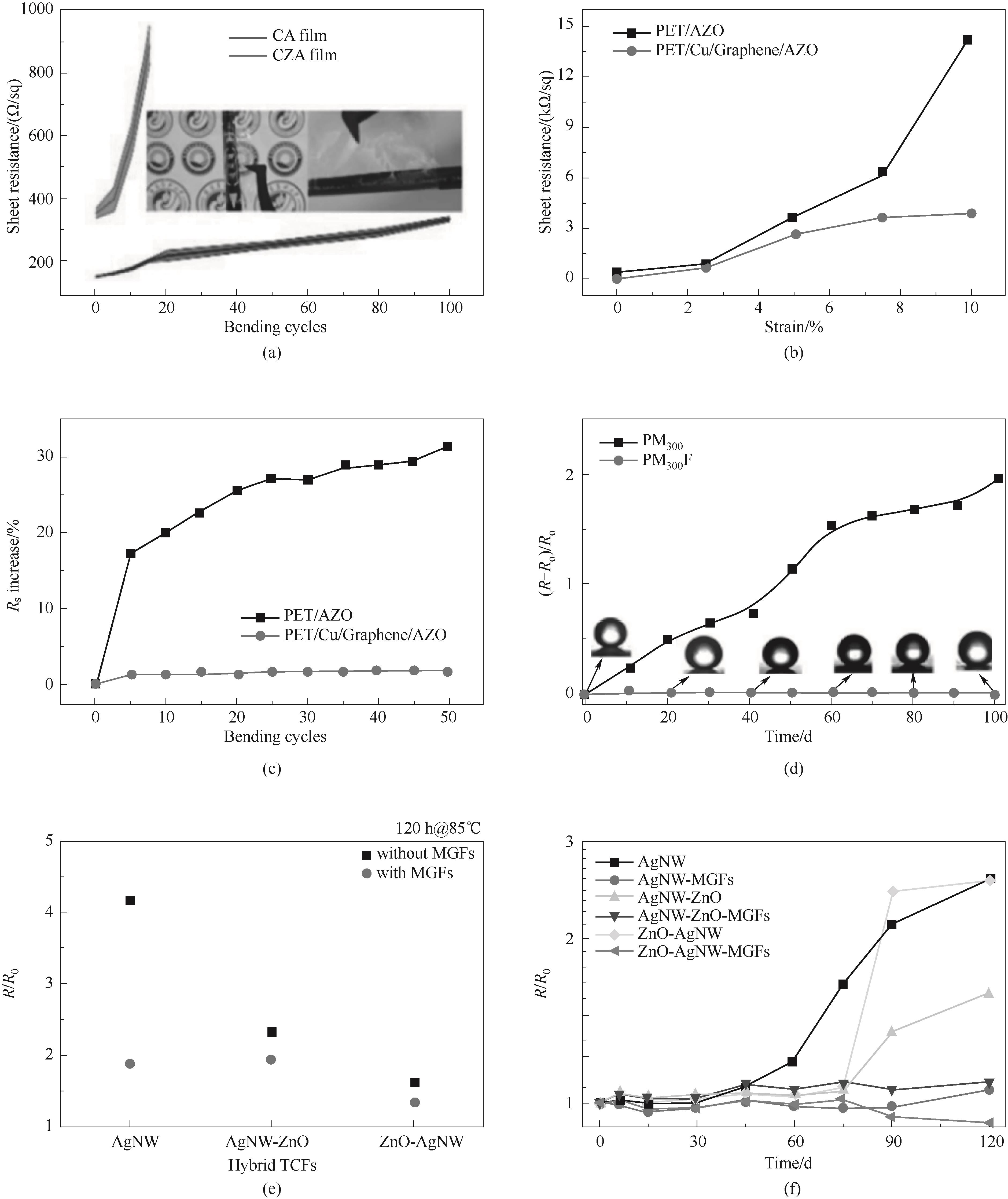

Fig.7 (a) The sheet resistance as a function of bending treatment[33]; (b) The sheet resistance of AZO and the Cu/Graphene/AZO multilayer versus strain[68]; (c) The resistance increase of AZO and the Cu/Graphene/AZO multilayer versus bending cycles[68]; (d) Relative resistance variation of PM300 film and PM300F film versus aging time[61]; (e) Sheet resistance changes of pristine AgNW, AgNW-ZnO and ZnO-AgNW with and without MGFs coating after thermal annealing at 85℃ for 120 h[70]; (f) Sheet resistance changes of the samples exposed to ambient condition at room temperature for 120 d[70]

| 种类 | 表面电阻/(Ω/sq) | 优点 | 缺点 |

|---|---|---|---|

| 金属及其化合物 | |||

| 氧化铟锡 | 101 | 导电性好、透射率高 | 毒性、资源稀缺、脆性大 |

| 纳米银 | 10-2~101 | 导电性、透射率、柔韧性好 | 与基体结合弱、成本高 |

| 纳米铜 | 100~101 | 导电性、柔韧性好,成本较低 | 室外暴露、氧化腐蚀下易被损坏 |

| 氧化锌 | 102 | 易于掺杂其他元素提高光电性能、成本较低 | 弯曲、折叠容易损坏导电网络 |

| 碳基材料 | |||

| 碳纳米管 | 102 | 导电性好、密度低、性能稳定 | 不易分散均匀 |

| 石墨烯 | 102~103 | 导电性好、密度低、性能稳定 | 存在表面缺陷、不易分散均匀 |

| 碳纤维 | >103 | 成本低、柔韧性好、性能稳定 | 不易分散均匀、导电性和透射率较低 |

| 导电聚合物 | 100~101 | 导电性好、密度低、柔韧性好 | 成本较高、较易被氧化 |

| MXene纳米片 | 101 | 高导电性、亲水性 | 力学性能较差 |

| 金属/碳基复合材料 | 100~101 | 导电性好、力学性能好、稳定性好 | 成本较高,容易团聚 |

Table 1 Conductivity, advantages and disadvantages of different conductive materials

| 种类 | 表面电阻/(Ω/sq) | 优点 | 缺点 |

|---|---|---|---|

| 金属及其化合物 | |||

| 氧化铟锡 | 101 | 导电性好、透射率高 | 毒性、资源稀缺、脆性大 |

| 纳米银 | 10-2~101 | 导电性、透射率、柔韧性好 | 与基体结合弱、成本高 |

| 纳米铜 | 100~101 | 导电性、柔韧性好,成本较低 | 室外暴露、氧化腐蚀下易被损坏 |

| 氧化锌 | 102 | 易于掺杂其他元素提高光电性能、成本较低 | 弯曲、折叠容易损坏导电网络 |

| 碳基材料 | |||

| 碳纳米管 | 102 | 导电性好、密度低、性能稳定 | 不易分散均匀 |

| 石墨烯 | 102~103 | 导电性好、密度低、性能稳定 | 存在表面缺陷、不易分散均匀 |

| 碳纤维 | >103 | 成本低、柔韧性好、性能稳定 | 不易分散均匀、导电性和透射率较低 |

| 导电聚合物 | 100~101 | 导电性好、密度低、柔韧性好 | 成本较高、较易被氧化 |

| MXene纳米片 | 101 | 高导电性、亲水性 | 力学性能较差 |

| 金属/碳基复合材料 | 100~101 | 导电性好、力学性能好、稳定性好 | 成本较高,容易团聚 |

| 1 | Yu S H, Song L J, Wu C, et al. Enhanced conductivity and stability of Cu-embedded zinc tin oxide flexible transparent conductive thin films[J]. Ceramics International, 2022, 48(11): 15925-15931. |

| 2 | Cai Y G, Piao X Q, Yao X J, et al. A facile method to prepare silver nanowire transparent conductive film for heaters[J]. Materials Letters, 2019, 249: 66-69. |

| 3 | Jiao C Y, Deng Z M, Min P, et al. Photothermal healable, stretchable, and conductive MXene composite films for efficient electromagnetic interference shielding[J]. Carbon, 2022, 198: 179-187. |

| 4 | Wang P C, Jian M L, Wu M J Q, et al. Highly sandwich-structured silver nanowire hybrid transparent conductive films for flexible transparent heater applications[J]. Composites Part A: Applied Science and Manufacturing, 2022, 159: 106998. |

| 5 | Yokoyama S, Kimura H, Oikawa H, et al. Surface treatment of Cu nanowires using hydroxy acids to form oxide-free Cu junctions for high-performance transparent conductive films[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2019, 583: 123939. |

| 6 | Liu R Y, Chen Y, Ding S Y, et al. Preparation of highly transparent conductive aluminum-doped zinc oxide thin films using a low-temperature aqueous solution process for thin-film solar cells applications[J]. Solar Energy Materials and Solar Cells, 2019, 203: 110161. |

| 7 | 孙磊, 晏菲, 周璘, 等. 氧化铟锡薄膜电极的表面修饰[J]. 分析测试学报, 2018, 37(10): 1182-1191. |

| Sun L, Yan F, Zhou L, et al. Surface modification of indium tin oxide film electrodes[J]. Journal of Instrumental Analysis, 2018, 37(10): 1182-1191. | |

| 8 | Ruan C, Sun Q, Xiao D J, et al. Lightwave irradiation-assisted low-temperature solution synthesis of indium-tin-oxide transparent conductive films[J]. Ceramics International, 2022, 48(9): 12317-12323. |

| 9 | Liu T, Dong H L, Wang H Y, et al. Nano cone ITO thin films prepared by pulsed laser deposition for surface measurement of high-temperature components[J]. Journal of Alloys and Compounds, 2023, 959: 170538. |

| 10 | Liu W S, Cheng H M, Hu H C, et al. Indium tin oxide with titanium doping for transparent conductive film application on CIGS solar cells[J]. Applied Surface Science, 2015, 354: 31-35. |

| 11 | Klein E, Huber K, Paul O, et al. Low-temperature plasma annealing of sputtered indium tin oxide for transparent and conductive thin-films on glass and polymer substrates[J]. Thin Solid Films, 2020, 693: 137715. |

| 12 | Wang K Z, Jiao P W, Cheng Y Y, et al. ITO films with different preferred orientations prepared by DC magnetron sputtering[J]. Optical Materials, 2022, 134: 113040. |

| 13 | 雷沛, 束小文, 刘培元, 等. 氧化铟锡(ITO)薄膜溅射生长及光电性能调控[J]. 表面技术, 2022, 51(8): 100-106. |

| Lei P, Shu X W, Liu P Y, et al. Growth and the tunable optical and electrical of sputtered ITO films[J]. Surface Technology, 2022, 51(8): 100-106. | |

| 14 | Yu S H, Tang B M, Wu C, et al. Ultraflexible transparent conductive films based on Ag nanowires for use in quick thermal response transparent heater[J]. Optical Materials, 2022, 125: 112083. |

| 15 | Mou Y, Wang H, Peng Y, et al. Low temperature enhanced flexible conductive film by Ag flake/ion composite ink[J]. Materials & Design, 2020, 186: 108339. |

| 16 | Yang H, Bai S C, Guo X Z, et al. Robust and smooth UV-curable layer overcoated AgNW flexible transparent conductor for EMI shielding and film heater[J]. Applied Surface Science, 2019, 483: 888-894. |

| 17 | Li G, Zhao J, Wang Z, et al. Ultrathin, flexible, conductive silver nanowires@polyvinyl alcohol composite film fabricated via the combination of air plasma treatment and thermal sintering for electromagnetic interference shielding[J]. Materials Letters, 2022, 325: 132814. |

| 18 | Li D Y, Li T, Zhang J L, et al. Highly stable and transparent conductive film realized by semi-embedded polydopamine/silver nanowire network[J]. Materials Today Communications, 2020, 25: 101551. |

| 19 | Dong H L, Yu S H, Song L J, et al. Fabrication of high-quality flexible transparent conductive thin films with a Nb2O5/AgNWs/Nb2O5 sandwich structure[J]. Ceramics International, 2022, 48(11): 15348-15354. |

| 20 | Zhu B L, Yi C H, Zhao X, et al. Improvement of transparent conductive properties of Cu films by introducing H2 into deposition atmosphere during RF magnetron sputtering[J]. Superlattices and Microstructures, 2020, 145: 106628. |

| 21 | Sarwar N, Choi S H, Dastgeer G, et al. Synthesis of citrate-capped copper nanoparticles: a low temperature sintering approach for the fabrication of oxidation stable flexible conductive film[J]. Applied Surface Science, 2021, 542: 148609. |

| 22 | Yu S H, Liu Z W, Zhao L, et al. Degradable, ultra-flexible, transparent and conductive film made of assembling CuNWs on chitosan[J]. Optical Materials, 2022, 123: 111752. |

| 23 | Zhang H, Wang S, Tian Y H, et al. Electrodeposition fabrication of Cu@Ni core shell nanowire network for highly stable transparent conductive films[J]. Chemical Engineering Journal, 2020, 390: 124495. |

| 24 | Song L J, Wu C, Yu S H, et al. Flexible transparent conductive ZnSnO/Cu/ZnSnO multilayer films for flexible transparent heaters[J]. Materials Letters, 2022, 312: 131683. |

| 25 | Yuan Y H, Liu M J, Chen Y Z, et al. Submicron Cu@glass core-shell powders for the preparation of conductive thick films on ceramic substrates[J]. Advanced Powder Technology, 2022, 33(9): 103718. |

| 26 | Li Y K, Feng J C, Wang Y, et al. Highly conductive and flexible electrodes based on ultrathin aluminum-doped zinc oxide epitaxial films[J]. Applied Surface Science, 2021, 568: 150925. |

| 27 | Tiwari A, Sahay P P. Modification in the physical properties of nanocrystalline ZnO thin films by Sn/Ni co-doping for transparent conductive oxide applications[J]. Physica B: Condensed Matter, 2022, 629: 413638. |

| 28 | Li Z Y, Li J W, Xiong M, et al. Effects of Mo single-doping and Mo-Al co-doping on ZnO transparent conductive films[J]. Applied Surface Science, 2022, 584: 152588. |

| 29 | Smaali A, Abdelli-Messaci S, Lafane S, et al. Pulsed laser deposited transparent and conductive V-doped ZnO thin films[J]. Thin Solid Films, 2020, 700: 137892. |

| 30 | Duan L B, Zhao X R, Zhang Y Y, et al. Fabrication of flexible Al-doped ZnO films via sol-gel method[J]. Materials Letters, 2016, 162: 199-202. |

| 31 | Wang Y F, Song J M, Guo Y J, et al. Optimization of physical properties of transparent conductive F and Ga co-doped ZnO films for optoelectronic applications[J]. Materials Letters, 2020, 269: 127591. |

| 32 | Liu Y, Zeng Q D, Nie C J, et al. F, Mg and Ga co-doped ZnO transparent conductive thin films by dual-target magnetron sputtering: fabrication, structure, and characteristics[J]. Journal of Alloys and Compounds, 2022, 907: 164480. |

| 33 | Liu X, Xiao W, Tao T, et al. Transparent, smooth, and sustainable cellulose-derived conductive film applied for the flexible electronic device[J]. Carbohydrate Polymers, 2021, 260: 117820. |

| 34 | Gu T, Sun D X, Xie X, et al. Highly thermally conductive, electrically insulated and flexible cellulose nanofiber-based composite films achieved via stereo complex crystallites cross-linked graphene nanoplatelets[J]. Composites Science and Technology, 2022, 230: 109757. |

| 35 | Goak J C, Lee S H, Lee N. Effect of purification on the electrical properties of transparent conductive films fabricated from single-walled carbon nanotubes[J]. Diamond and Related Materials, 2020, 106: 107815. |

| 36 | Zhang L J, Liu X, Zhong M J, et al. Micro-nano hybrid-structured conductive film with ultrawide range pressure-sensitivity and bioelectrical acquirability for ubiquitous wearable applications[J]. Applied Materials Today, 2020, 20: 100651. |

| 37 | Jiang S, Hou P X, Liu C, et al. High-performance single-wall carbon nanotube transparent conductive films[J]. Journal of Materials Science & Technology, 2019, 35(11): 2447-2462. |

| 38 | Wang Y T, Xin Z Y, Wang B J, et al. Fabrication of highly conductive natural rubber-based composite films via Pickering emulsion interfacial assembly[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 651: 129774. |

| 39 | Wang Y Q, Fugetsu B. Mono-dispersed ultra-long single-walled carbon nanotubes as enabling components in transparent and electrically conductive thin films[J]. Carbon, 2015, 82: 152-160. |

| 40 | Ding Z Q, Zhu Y P, Branford-White C, et al. Self-assembled transparent conductive composite films of carboxylated multi-walled carbon nanotubes/poly(vinyl alcohol) electrospun nanofiber mats[J]. Materials Letters, 2014, 128: 310-313. |

| 41 | Xie R B, Sugime H, Noda S. Dispersing and doping carbon nanotubes by poly(p-styrene-sulfonic acid) for high-performance and stable transparent conductive films[J]. Carbon, 2020, 164: 150-156. |

| 42 | Paul S, Kang Y S, Yim J H, et al. Effect of surfactant and coating method on the electrical and optical properties of thin conductive films prepared with single-walled carbon nanotubes[J]. Current Applied Physics, 2010, 10(4): e101-e104. |

| 43 | Aimon A H, Hidayat R, Rahmawati D, et al. Facile deposition of reduced graphene oxide-based transparent conductive film with microwave assisted method[J]. Thin Solid Films, 2019, 692: 137618. |

| 44 | Zhang L K, Chen Y, Liu Q, et al. Ultrathin flexible electrospun carbon nanofibers reinforced graphene microgasbags films with three-dimensional conductive network toward synergetic enhanced electromagnetic interference shielding[J]. Journal of Materials Science & Technology, 2022, 111: 57-65. |

| 45 | Wang Z, Li P, Song R G, et al. High conductive graphene assembled films with porous micro-structure for freestanding and ultra-low power strain sensors[J]. Science Bulletin, 2020, 65(16): 1363-1370. |

| 46 | Liu L Y, Cheng Y, Zhang X L, et al. Graphene-based transparent conductive films with enhanced transmittance and conductivity by introducing antireflection nanostructure[J]. Surface and Coatings Technology, 2017, 325: 611-616. |

| 47 | Liu Z W, Xie Y F, Zhao J, et al. Rapid preparation of conductive transparent films via solution printing of graphene precursor[J]. Thin Solid Films, 2018, 657: 24-31. |

| 48 | Karthick R, Brindha M, Selvaraj M, et al. Stable colloidal dispersion of functionalized reduced graphene oxide in aqueous medium for transparent conductive film[J]. Journal of Colloid and Interface Science, 2013, 406: 69-74. |

| 49 | Wang B T, Thio T H G, Chong H S. Transparent conductive far-infrared radiative film based on cotton pulp (CP) with carbon fiber (CF) in agriculture greenhouse[J]. Journal of Materials Research and Technology, 2022, 19: 1049-1058. |

| 50 | Xu H G, Qu M C, Schubert D W. Conductivity of poly(methyl methacrylate) composite films filled with ultra-high aspect ratio carbon fibers[J]. Composites Science and Technology, 2019, 181: 107690. |

| 51 | 李益华. PVDF/碳纤维催化阴极膜耦合MBR/MFC体系的性能提升及应用[D]. 大连: 大连理工大学, 2017. |

| Li Y H. Application and improvement of PVDF/carbon fiber cloth composite catalytic cathode membrane in integrated MBR/MFC system[D]. Dalian: Dalian University of Technology, 2017. | |

| 52 | Taunk M. Charge transport studies in flexible and rollable polypyrrole-PVDF composite films[J/OL]. Materials Today: Proceedings, 2023, . |

| 53 | Wang Y T, Peng H K, Li T T, et al. Lightweight, flexible and superhydrophobic conductive composite films based on layer-by-layer self-assembly for high-performance electromagnetic interference shielding[J]. Composites Part A: Applied Science and Manufacturing, 2021, 141: 106199. |

| 54 | Luo R B, Li H B, Du B, et al. A simple strategy for high stretchable, flexible and conductive polymer films based on PEDOT: PSS-PDMS blends[J]. Organic Electronics, 2020, 76: 105451. |

| 55 | Dias O A T, Konar S, Leão A L, et al. Flexible electrically conductive films based on nanofibrillated cellulose and polythiophene prepared via oxidative polymerization[J]. Carbohydrate Polymers, 2019, 220: 79-85. |

| 56 | Liu G D, Zheng L, Sun Y M, et al. Preparation of flexible conductive composite electrode film of PEDOT: PSS/aramid nanofibers via vacuum-assisted filtration and acid post-treatment for efficient solid-state supercapacitor[J]. International Journal of Hydrogen Energy, 2022, 47(53): 22454-22468. |

| 57 | Lapka T, Vilčáková J, Kopecký D, et al. Flexible, ultrathin and light films from one-dimensional nanostructures of polypyrrole and cellulose nanofibers for high performance electromagnetic interference shielding[J]. Carbohydrate Polymers, 2023, 309: 120662. |

| 58 | Han J W, Wibowo A F, Park J, et al. Highly stretchable, robust, and conductive lab-synthesized PEDOT: PSS conductive polymer/hydroxyethyl cellulose films for on-skin health-monitoring devices[J]. Organic Electronics, 2022, 105: 106499. |

| 59 | Wang Y T, Li T T, Shiu B C, et al. MXene-coated multi-response conductive film based on layer-by-layer assembly strategy for electromagnetic interference shielding[J]. Journal of Materials Research and Technology, 2021, 15: 6011-6024. |

| 60 | Shahzad F, Alhabeb M, Hatter C B, et al. Electromagnetic interference shielding with 2D transition metal carbides (MXenes)[J]. Science, 2016, 353(6304): 1137-1140. |

| 61 | Zhou B, Li Z Y, Li Y L, et al. Flexible hydrophobic 2D Ti3C2T x -based transparent conductive film with multifunctional self-cleaning, electromagnetic interference shielding and joule heating capacities[J]. Composites Science and Technology, 2021, 201: 108531. |

| 62 | Wang Y T, Peng H K, Li T T, et al. MXene-coated conductive composite film with ultrathin, flexible, self-cleaning for high-performance electromagnetic interference shielding[J]. Chemical Engineering Journal, 2021, 412: 128681. |

| 63 | Luo J Q, Zhao S, Zhang H B, et al. Flexible, stretchable and electrically conductive MXene/natural rubber nanocomposite films for efficient electromagnetic interference shielding[J]. Composites Science and Technology, 2019, 182: 107754. |

| 64 | Jiang M Y, Jiang D G, Wang J H, et al. Stretchable MXene based films towards achieving balanced electrical, mechanical and energy storage properties[J]. Chemical Engineering Journal, 2023, 459: 141527. |

| 65 | Chen D X, Zhou M Q, Hu J C, et al. Adhesive, reflective, and conductive films comprised of graphene nanosheets decorated with Ag nanoparticles for flexible electronics[J]. Applied Surface Science, 2021, 543: 148802. |

| 66 | Yin J L, Kim J Y, Lee H U, et al. Highly conductive and flexible thin film electrodes based on silver nanowires wrapped carbon fiber networks for supercapacitor applications[J]. Thin Solid Films, 2018, 660: 564-571. |

| 67 | Wang S Y, Liu H, Pan Y Q, et al. Demonstration of wide spectrum transparent conductive composite films based on silver nanowires and graphene[J]. Infrared Physics & Technology, 2022, 124: 104172. |

| 68 | Zhang L Q, Yang R, Chen K, et al. The fabrication of Cu nanowire/graphene/Al doped ZnO transparent conductive film on PET substrate with high flexibility and air stability[J]. Materials Letters, 2017, 207: 62-65. |

| 69 | Zhu P W, He Z C, Liu S Q, et al. A highly elastic conductive film prepared by bidirectional AS-LBL method[J]. European Polymer Journal, 2022, 162: 110868. |

| 70 | Arat R, Jia G B, Dellith J, et al. Solution processed transparent conductive hybrid thin films based on silver nanowires, zinc oxide and graphene[J]. Materials Today Communications, 2021, 26: 102162. |

| 71 | Gao S L, Zhao X H, Fu Q, et al. Highly transmitted silver nanowires-SWCNTs conductive flexible film by nested density structure and aluminum-doped zinc oxide capping layer for flexible amorphous silicon solar cells[J]. Journal of Materials Science & Technology, 2022, 126: 152-160. |

| 72 | Song C K, Meng X Y, Chen H, et al. Flexible, graphene-based films with three-dimensional conductive network via simple drop-casting toward electromagnetic interference shielding[J]. Composites Communications, 2021, 24: 100632. |

| 73 | Li M, Wang T, Liu X L, et al. Highly stable phosphotungstic acid/Au dual doped carbon nanotube transparent conductive films for transparent flexible heaters[J]. Carbon, 2023, 207: 219-229. |

| [1] | He JIANG, Junfei YUAN, Lin WANG, Guyu XING. Experimental study on the effect of flow sharing cavity structure on phase change flow characteristics in microchannels [J]. CIESC Journal, 2023, 74(S1): 235-244. |

| [2] | Jianbo HU, Hongchao LIU, Qi HU, Meiying HUANG, Xianyu SONG, Shuangliang ZHAO. Molecular dynamics simulation insight into translocation behavior of organic cage across the cellular membrane [J]. CIESC Journal, 2023, 74(9): 3756-3765. |

| [3] | Cong QI, Zi DING, Jie YU, Maoqing TANG, Lin LIANG. Study on solar thermoelectric power generation characteristics based on selective absorption nanofilm [J]. CIESC Journal, 2023, 74(9): 3921-3930. |

| [4] | Song HE, Qiaomai LIU, Guangshuo XIE, Simin WANG, Juan XIAO. Two-phase flow simulation and surrogate-assisted optimization of gas film drag reduction in high-concentration coal-water slurry pipeline [J]. CIESC Journal, 2023, 74(9): 3766-3774. |

| [5] | Lingding MENG, Ruqing CHONG, Feixue SUN, Zihui MENG, Wenfang LIU. Immobilization of carbonic anhydrase on modified polyethylene membrane and silica [J]. CIESC Journal, 2023, 74(8): 3472-3484. |

| [6] | Yuyuan ZHENG, Zhiwei GE, Xiangyu HAN, Liang WANG, Haisheng CHEN. Progress and prospect of medium and high temperature thermochemical energy storage of calcium-based materials [J]. CIESC Journal, 2023, 74(8): 3171-3192. |

| [7] | Xingzhi HU, Haoyan ZHANG, Jingkun ZHUANG, Yuqing FAN, Kaiyin ZHANG, Jun XIANG. Preparation and microwave absorption properties of carbon nanofibers embedded with ultra-small CeO2 nanoparticles [J]. CIESC Journal, 2023, 74(8): 3584-3596. |

| [8] | Ben ZHANG, Songbai WANG, Ziya WEI, Tingting HAO, Xuehu MA, Rongfu WEN. Capillary liquid film condensation and heat transfer enhancement driven by superhydrophilic porous metal structure [J]. CIESC Journal, 2023, 74(7): 2824-2835. |

| [9] | Ao ZHANG, Yingwu LUO. Low modulus, high elasticity and high peel adhesion acrylate pressure sensitive adhesives [J]. CIESC Journal, 2023, 74(7): 3079-3092. |

| [10] | Lei MAO, Guanzhang LIU, Hang YUAN, Guangya ZHANG. Efficient preparation of carbon anhydrase nanoparticles capable of capturing CO2 and their characteristics [J]. CIESC Journal, 2023, 74(6): 2589-2598. |

| [11] | Wenchao XU, Zhigao SUN, Cuimin LI, Juan LI, Haifeng HUANG. Effect of surfactant E-1310 on the formation of HCFC-141b hydrate under static conditions [J]. CIESC Journal, 2023, 74(5): 2179-2185. |

| [12] | Jialin DAI, Weidong BI, Yumei YONG, Wenqiang CHEN, Hanyang MO, Bing SUN, Chao YANG. Effect of thermophysical properties on the heat transfer characteristics of solid-liquid phase change for composite PCMs [J]. CIESC Journal, 2023, 74(5): 1914-1927. |

| [13] | Zihan YUAN, Shuyan WANG, Baoli SHAO, Lei XIE, Xi CHEN, Yimei MA. Investigation on flow characteristics of wet particles with power-law liquid-solid drag models in fluidized bed [J]. CIESC Journal, 2023, 74(5): 2000-2012. |

| [14] | Jianhua ZHANG, Mengmeng CHEN, Yawen SUN, Yongzhen PENG. Efficient nitrogen and phosphorus removal from domestic wastewater via simultaneous partial nitritation and phosphorus removal combined Anammox [J]. CIESC Journal, 2023, 74(5): 2147-2156. |

| [15] | Shaoyun CHEN, Dong XU, Long CHEN, Yu ZHANG, Yuanfang ZHANG, Qingliang YOU, Chenglong HU, Jian CHEN. Preparation and adsorption properties of monolayer polyaniline microsphere arrays [J]. CIESC Journal, 2023, 74(5): 2228-2238. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||