CIESC Journal ›› 2025, Vol. 76 ›› Issue (2): 654-666.DOI: 10.11949/0438-1157.20240266

• Catalysis, kinetics and reactors • Previous Articles

Chuanchao HE( ), Jinghong ZHOU(

), Jinghong ZHOU( ), Yueqiang CAO, Yao SHI, Xinggui ZHOU

), Yueqiang CAO, Yao SHI, Xinggui ZHOU

Received:2024-05-05

Revised:2024-06-11

Online:2025-03-10

Published:2025-03-25

Contact:

Jinghong ZHOU

通讯作者:

周静红

作者简介:何传超(1995—),男,硕士研究生,1982950218@qq.com

基金资助:CLC Number:

Chuanchao HE, Jinghong ZHOU, Yueqiang CAO, Yao SHI, Xinggui ZHOU. Bed-particle dual scale coupled simulation on Ag/SiO2 catalyzed hydrogenation of oxalate to methyl glycolate[J]. CIESC Journal, 2025, 76(2): 654-666.

何传超, 周静红, 曹约强, 施尧, 周兴贵. Ag/SiO2催化草酸酯加氢制乙醇酸甲酯的床层-颗粒双尺度耦合模拟研究[J]. 化工学报, 2025, 76(2): 654-666.

Add to citation manager EndNote|Ris|BibTeX

| ζ | 浓度边界条件 | 温度边界条件 |

|---|---|---|

| 0 | ||

| 1 |

Table 1 Boundary conditions applied to the particle model

| ζ | 浓度边界条件 | 温度边界条件 |

|---|---|---|

| 0 | ||

| 1 |

| 参数 | 浓度边界条件 | 温度边界条件 | 速度边界条件 |

|---|---|---|---|

| z=0,∀r | cf,i =cf,i0 | T=T0 | u=u0 |

| z=Ht,∀r | P=P0 | ||

| r=0,∀z | |||

| r=R,∀z | T=Tw | u=0 |

Table 2 Boundary conditions applied to the bed model

| 参数 | 浓度边界条件 | 温度边界条件 | 速度边界条件 |

|---|---|---|---|

| z=0,∀r | cf,i =cf,i0 | T=T0 | u=u0 |

| z=Ht,∀r | P=P0 | ||

| r=0,∀z | |||

| r=R,∀z | T=Tw | u=0 |

| 参数 | 数值 |

|---|---|

| 颗粒直径(dpe)/mm | 2 |

| 孔径(dpore)/nm | 6 |

| 孔隙率(εpe) | 0.6 |

| 曲折因子(τ) | 1.6667 |

| 密度(ρpe)/(kg/m3) | 880 |

| 热导率(λpe)/(W/(m∙K)) | 0.574 |

| 比热容(Cp,pe)/(J/(kg∙K)) | 1000 |

Table 3 Properties of the catalyst pellets

| 参数 | 数值 |

|---|---|

| 颗粒直径(dpe)/mm | 2 |

| 孔径(dpore)/nm | 6 |

| 孔隙率(εpe) | 0.6 |

| 曲折因子(τ) | 1.6667 |

| 密度(ρpe)/(kg/m3) | 880 |

| 热导率(λpe)/(W/(m∙K)) | 0.574 |

| 比热容(Cp,pe)/(J/(kg∙K)) | 1000 |

| 参数 | 数值 |

|---|---|

| 反应器内径(dbed)/mm | 32 |

| 床层高度(Ht)/m | 1 |

| 床层空隙率(εbed) | 0.45 |

| 进口温度(T0)/K | 493.15 |

| 反应器壁温(Tw)/K | 493.15 |

| 进口压力(P0)/MPa | 2 |

| DMO进口摩尔分数(yDMO) | 7.4532×10-3 |

| H2进口摩尔分数( | 7.4532×10-1 |

| 甲醇(ME)进口摩尔分数(yME) | 2.4723×10-1 |

| 质量空速(WHSV)/h-1 | 0.5 |

Table 4 The bed properties and operating parameters

| 参数 | 数值 |

|---|---|

| 反应器内径(dbed)/mm | 32 |

| 床层高度(Ht)/m | 1 |

| 床层空隙率(εbed) | 0.45 |

| 进口温度(T0)/K | 493.15 |

| 反应器壁温(Tw)/K | 493.15 |

| 进口压力(P0)/MPa | 2 |

| DMO进口摩尔分数(yDMO) | 7.4532×10-3 |

| H2进口摩尔分数( | 7.4532×10-1 |

| 甲醇(ME)进口摩尔分数(yME) | 2.4723×10-1 |

| 质量空速(WHSV)/h-1 | 0.5 |

| 分子 | 扩散体积/(cm3/mol) |

|---|---|

| DMO | 101.9 |

| H2 | 6.12 |

| MG | 79.89 |

| 乙二醇(EG) | 57.88 |

| 甲醇(ME) | 31.15 |

Table 5 Diffusion volume of each substance

| 分子 | 扩散体积/(cm3/mol) |

|---|---|

| DMO | 101.9 |

| H2 | 6.12 |

| MG | 79.89 |

| 乙二醇(EG) | 57.88 |

| 甲醇(ME) | 31.15 |

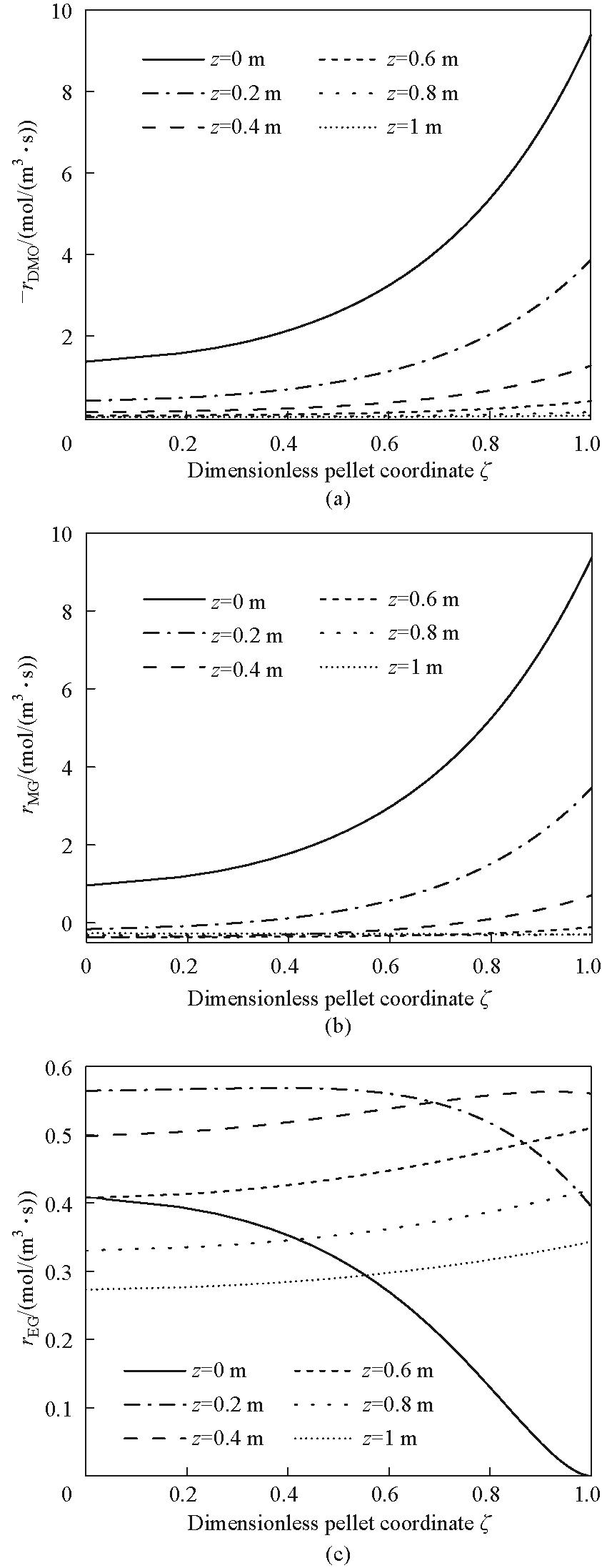

Fig.5 The internal DMO consumption rate, MG generation rate, and EG generation rate of the tube-centered particles at different axial positions along the bed height

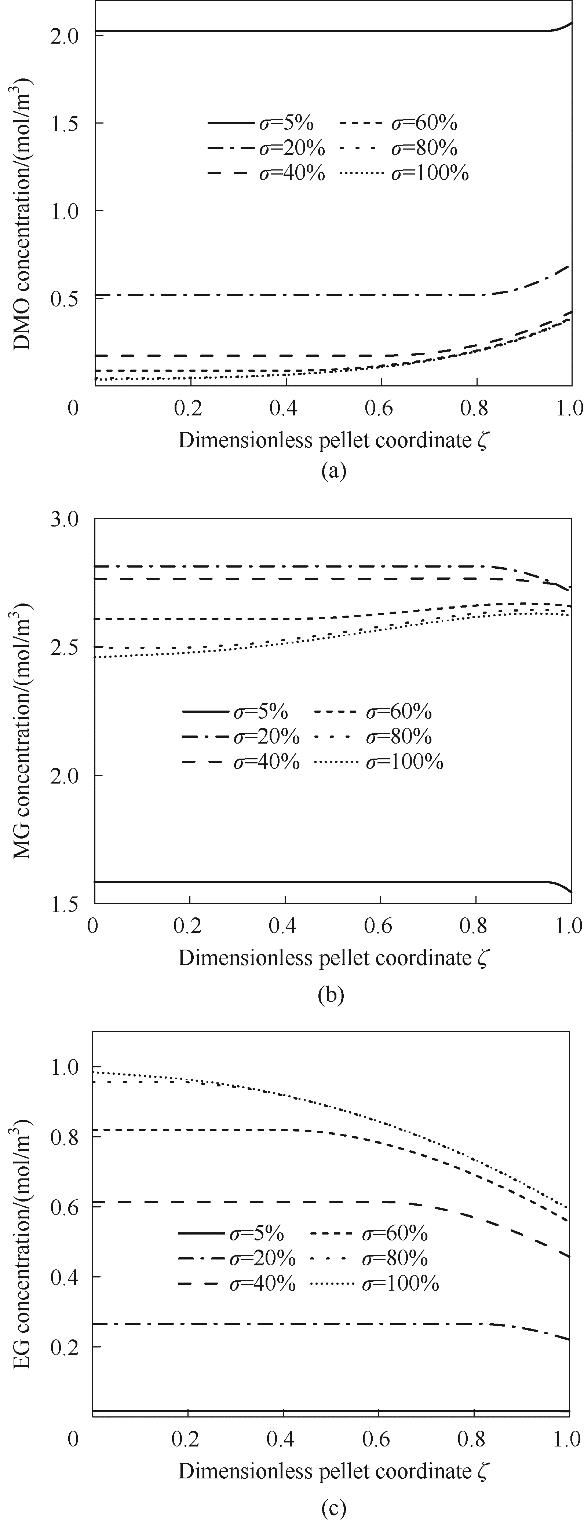

Fig.8 The concentration distribution of DMO, MG, and EG inside catalyst pellets with different relative eggshell thicknesses at z=0.4m along the catalyst bed height

| 序号 | T/K | WHSV/h-1 | H/D | XDMO/% | SMG/% | SEG/% |

|---|---|---|---|---|---|---|

| 1 | 493.45 | 0.5 | 100 | 99.96 | 58.76 | 41.24 |

| 2 | 493.45 | 0.75 | 100 | 99.85 | 71.55 | 28.45 |

| 3 | 493.25 | 1 | 40 | 98.18 | 76.12 | 23.88 |

| 4 | 493.25 | 1 | 80 | 99.02 | 75.69 | 24.31 |

| 5 | 493.25 | 1 | 100 | 98.99 | 77.29 | 22.71 |

| 6 | 493.25 | 1 | 120 | 99.32 | 75.77 | 24.23 |

| 7 | 493.15 | 1.25 | 100 | 97.86 | 84.07 | 15.93 |

| 8 | 493.15 | 1.5 | 100 | 96.59 | 86.26 | 13.74 |

| 9 | 487.85 | 0.5 | 100 | 99.95 | 61.19 | 38.81 |

| 10 | 488.25 | 0.75 | 100 | 99.30 | 79.11 | 20.89 |

| 11 | 488.45 | 1 | 40 | 96.01 | 86.55 | 13.45 |

| 12 | 488.25 | 1 | 80 | 97.90 | 84.75 | 15.25 |

| 13 | 488.25 | 1 | 100 | 98.20 | 84.53 | 15.47 |

| 14 | 488.25 | 1 | 120 | 98.43 | 84.34 | 15.66 |

| 15 | 488.15 | 1.25 | 100 | 94.76 | 89.78 | 10.22 |

| 16 | 488.25 | 1.5 | 100 | 92.43 | 91.29 | 8.71 |

| 17 | 483.05 | 0.5 | 100 | 99.83 | 73.17 | 26.83 |

| 18 | 483.25 | 0.75 | 100 | 97.22 | 86.76 | 13.24 |

| 19 | 482.55 | 1 | 40 | 84.12 | 92.76 | 7.24 |

| 20 | 482.85 | 1 | 80 | 93.16 | 90.67 | 9.33 |

| 21 | 483.15 | 1 | 100 | 94.90 | 89.97 | 10.03 |

| 22 | 482.95 | 1 | 120 | 95.69 | 89.69 | 10.31 |

| 23 | 483.05 | 1.25 | 100 | 88.97 | 93.30 | 6.70 |

| 24 | 483.15 | 1.5 | 100 | 84.31 | 94.59 | 5.41 |

| 25 | 477.85 | 0.5 | 100 | 99.03 | 81.27 | 18.73 |

| 26 | 478.05 | 0.75 | 100 | 92.74 | 91.20 | 8.80 |

| 27 | 478.15 | 1 | 40 | 69.59 | 95.05 | 4.95 |

| 28 | 478.05 | 1 | 80 | 84.68 | 94.10 | 5.90 |

| 29 | 478.05 | 1 | 100 | 87.53 | 93.67 | 6.33 |

| 30 | 477.95 | 1 | 120 | 90.42 | 93.36 | 6.64 |

| 31 | 477.95 | 1.25 | 100 | 76.65 | 95.92 | 4.08 |

| 32 | 477.95 | 1.5 | 100 | 72.81 | 96.55 | 3.45 |

| 33 | 473.05 | 0.5 | 100 | 95.26 | 88.39 | 11.61 |

| 34 | 473.25 | 0.75 | 100 | 81.91 | 95.03 | 4.97 |

| 35 | 473.15 | 1 | 40 | 59.68 | 96.70 | 3.30 |

| 36 | 473.15 | 1 | 80 | 71.13 | 96.46 | 3.54 |

| 37 | 473.25 | 1 | 100 | 74.83 | 96.31 | 3.69 |

| 38 | 473.15 | 1 | 120 | 79.64 | 96.07 | 3.93 |

| 39 | 473.35 | 1.25 | 100 | 60.44 | 97.68 | 2.32 |

| 40 | 473.35 | 1.5 | 100 | 53.17 | 97.97 | 2.03 |

Table A1 Results of kinetic experiments

| 序号 | T/K | WHSV/h-1 | H/D | XDMO/% | SMG/% | SEG/% |

|---|---|---|---|---|---|---|

| 1 | 493.45 | 0.5 | 100 | 99.96 | 58.76 | 41.24 |

| 2 | 493.45 | 0.75 | 100 | 99.85 | 71.55 | 28.45 |

| 3 | 493.25 | 1 | 40 | 98.18 | 76.12 | 23.88 |

| 4 | 493.25 | 1 | 80 | 99.02 | 75.69 | 24.31 |

| 5 | 493.25 | 1 | 100 | 98.99 | 77.29 | 22.71 |

| 6 | 493.25 | 1 | 120 | 99.32 | 75.77 | 24.23 |

| 7 | 493.15 | 1.25 | 100 | 97.86 | 84.07 | 15.93 |

| 8 | 493.15 | 1.5 | 100 | 96.59 | 86.26 | 13.74 |

| 9 | 487.85 | 0.5 | 100 | 99.95 | 61.19 | 38.81 |

| 10 | 488.25 | 0.75 | 100 | 99.30 | 79.11 | 20.89 |

| 11 | 488.45 | 1 | 40 | 96.01 | 86.55 | 13.45 |

| 12 | 488.25 | 1 | 80 | 97.90 | 84.75 | 15.25 |

| 13 | 488.25 | 1 | 100 | 98.20 | 84.53 | 15.47 |

| 14 | 488.25 | 1 | 120 | 98.43 | 84.34 | 15.66 |

| 15 | 488.15 | 1.25 | 100 | 94.76 | 89.78 | 10.22 |

| 16 | 488.25 | 1.5 | 100 | 92.43 | 91.29 | 8.71 |

| 17 | 483.05 | 0.5 | 100 | 99.83 | 73.17 | 26.83 |

| 18 | 483.25 | 0.75 | 100 | 97.22 | 86.76 | 13.24 |

| 19 | 482.55 | 1 | 40 | 84.12 | 92.76 | 7.24 |

| 20 | 482.85 | 1 | 80 | 93.16 | 90.67 | 9.33 |

| 21 | 483.15 | 1 | 100 | 94.90 | 89.97 | 10.03 |

| 22 | 482.95 | 1 | 120 | 95.69 | 89.69 | 10.31 |

| 23 | 483.05 | 1.25 | 100 | 88.97 | 93.30 | 6.70 |

| 24 | 483.15 | 1.5 | 100 | 84.31 | 94.59 | 5.41 |

| 25 | 477.85 | 0.5 | 100 | 99.03 | 81.27 | 18.73 |

| 26 | 478.05 | 0.75 | 100 | 92.74 | 91.20 | 8.80 |

| 27 | 478.15 | 1 | 40 | 69.59 | 95.05 | 4.95 |

| 28 | 478.05 | 1 | 80 | 84.68 | 94.10 | 5.90 |

| 29 | 478.05 | 1 | 100 | 87.53 | 93.67 | 6.33 |

| 30 | 477.95 | 1 | 120 | 90.42 | 93.36 | 6.64 |

| 31 | 477.95 | 1.25 | 100 | 76.65 | 95.92 | 4.08 |

| 32 | 477.95 | 1.5 | 100 | 72.81 | 96.55 | 3.45 |

| 33 | 473.05 | 0.5 | 100 | 95.26 | 88.39 | 11.61 |

| 34 | 473.25 | 0.75 | 100 | 81.91 | 95.03 | 4.97 |

| 35 | 473.15 | 1 | 40 | 59.68 | 96.70 | 3.30 |

| 36 | 473.15 | 1 | 80 | 71.13 | 96.46 | 3.54 |

| 37 | 473.25 | 1 | 100 | 74.83 | 96.31 | 3.69 |

| 38 | 473.15 | 1 | 120 | 79.64 | 96.07 | 3.93 |

| 39 | 473.35 | 1.25 | 100 | 60.44 | 97.68 | 2.32 |

| 40 | 473.35 | 1.5 | 100 | 53.17 | 97.97 | 2.03 |

| 1 | Zhou R J, Yan W Q, Cao Y Q, et al. Probing the structure sensitivity of dimethyl oxalate partial hydrogenation over Ag nanoparticles: a combined experimental and microkinetic study[J]. Chemical Engineering Science, 2022, 259: 117830. |

| 2 | Yang Q C, Fan Y J, Liu C L, et al. A promising alternative potential solution for sustainable and economical development of coal to ethylene glycol industry: dimethyl oxalate to methyl glycolate process[J]. Energy, 2023, 277: 127668. |

| 3 | Xie T H, Ai S, Huang Y C, et al. Synthesis and purification of glycolic acid from the mixture of methyl levulinate and methyl glycolate via acid-mediated hydrolysis reactions and extraction[J]. Separation and Purification Technology, 2021, 268: 118718. |

| 4 | Sun Y, Wang H, Shen J H, et al. Highly effective synthesis of methyl glycolate with heteropolyacids as catalysts[J]. Catalysis Communications, 2009, 10(5): 678-681. |

| 5 | Xu Y, Dou W J, Zhao Y J, et al. Kinetics study for ion-exchange-resin catalyzed hydrolysis of methyl glycolate[J]. Industrial & Engineering Chemistry Research, 2012, 51(36): 11653-11658. |

| 6 | 袁彩彩. 乙醇酸及聚乙醇酸的合成研究[D]. 郑州: 郑州大学, 2019. |

| Yuan C C. Synthesis of glycolic acid and polyglycolic acid[D]. Zhengzhou: Zhengzhou University, 2019. | |

| 7 | 张军伟, 陈建军, 贾彩敬. 一种多柱连续色谱除盐以纯化羟基乙酸的方法: 111635302B[P]. 2021-06-15. |

| Zhang J W, Chen J J, Jia C J. Method of purifying glycolic acid through multi-column continuous chromatographic desalination: 111635302B[P]. 2021-06-15. | |

| 8 | 石磊, 陈飞, 姚杰. 一种制备乙醇酸甲酯并副产甲氧基乙酸甲酯的方法: 107337602A[P]. 2017-11-10. |

| Shi L, Chen F, Yao J. Method for preparing methyl glycolate and by-producing methyl methoxyacetate: 107337602A[P]. 2017-11-10. | |

| 9 | 李锦春. 乙醇酸甲酯的合成及其开发前景[J]. 四川化工与腐蚀控制, 1998, 1(6): 24-27. |

| Li J C. Synthesis and development prospect of methyl glycolate[J]. Sichuan Chemical Industry and Corrosion Control, 1998, 1(6): 24-27. | |

| 10 | Dong G L, Luo Z W, Cao Y Q, et al. Understanding size-dependent hydrogenation of dimethyl oxalate to methyl glycolate over Ag catalysts[J]. Journal of Catalysis, 2021, 401: 252-261. |

| 11 | Chen H M, Tan J J, Zhu Y L, et al. An effective and stable Ni2P/TiO2 catalyst for the hydrogenation of dimethyl oxalate to methyl glycolate[J]. Catalysis Communications, 2016, 73: 46-49. |

| 12 | Niu J C, Ai P P, Guo Q W, et al. The effect of nitrogen doping on hydrogenation capability and stability of Cu-based catalyst in ester hydrogenation to methyl glycolate[J]. Fuel, 2023, 351: 128866. |

| 13 | Xue J, Wu M M, Song Y W, et al. Study on performance of Ag-modified layered copper silicate catalyst for hydrogenation of dimethyl oxalate to methyl glycolate[J]. Journal of Fuel Chemistry and Technology, 2022, 50(8): 1014-1022. |

| 14 | Dong G L, Cao Y Q, Zheng S N, et al. Catalyst consisting of Ag nanoparticles anchored on amine-derivatized mesoporous silica nanospheres for the selective hydrogenation of dimethyl oxalate to methyl glycolate[J]. Journal of Catalysis, 2020, 391: 155-162. |

| 15 | Hu M L, Yan Y, Duan X P, et al. Effective anchoring of silver nanoparticles onto N-doped carbon with enhanced catalytic performance for the hydrogenation of dimethyl oxalate to methyl glycolate[J]. Catalysis Communications, 2017, 100: 148-152. |

| 16 | Jurtz N, Wehinger G D, Srivastava U, et al. Validation of pressure drop prediction and bed generation of fixed‐beds with complex particle shapes using discrete element method and computational fluid dynamics[J]. AIChE Journal, 2020, 66(6): 16967. |

| 17 | 胡鑫. 草酸二甲酯加氢制乙醇酸甲酯 Ag/SiO2蛋壳型催化剂的制备及性能[D]. 上海: 华东理工大学, 2022. |

| Hu X. Preparation and properties of Ag/SiO2 eggshell catalyst for hydrogenation of dimethyl oxalate to methyl glycolate[D]. Shanghai: East China University of Science and Technology, 2022. | |

| 18 | Froment G F, Bischoff K B, Wilde J D. Chemical Reactor Analysis and Design[M]. 3rd ed. New York: Wiley, 1990: 462-474. |

| 19 | Stitt H, Marigo M, Wilkinson S, et al. How good is your model?[J]. Johnson Matthey Technology Review, 2015, 59(2): 74-89. |

| 20 | Dong Y, Keil F J, Korup O, et al. Effect of the catalyst pore structure on fixed-bed reactor performance of partial oxidation of n-butane: a simulation study[J]. Chemical Engineering Science, 2016, 142: 299-309. |

| 21 | Krammer A, Peham M, Lehner M. 2D heterogeneous model of a polytropic methanation reactor[J]. Journal of CO2 Utilization, 2022, 62: 102059. |

| 22 | Bac S, Avci A K. Ethylene oxide synthesis in a wall-coated microchannel reactor with integrated cooling[J]. Chemical Engineering Journal, 2019, 377: 120104. |

| 23 | Marín P, Díez F V, Ordóñez S. Fixed bed membrane reactors for WGSR-based hydrogen production: optimisation of modelling approaches and reactor performance[J]. International Journal of Hydrogen Energy, 2012, 37(6): 4997-5010. |

| 24 | Liu X L, Qin B, Zhang Q F, et al. Optimizing catalyst supports at single catalyst pellet and packed bed reactor levels: a comparison study[J]. AIChE Journal, 2021, 67(8): 1-13. |

| 25 | Solsvik J, Jakobsen H A. A survey of multicomponent mass diffusion flux closures for porous pellets: mass and molar forms[J]. Transport in Porous Media, 2012, 93(1): 99-126. |

| 26 | Solsvik J, Jakobsen H A. Impacts on the reactor performance of intra-particle multicomponent mass diffusion limitations: Knudsen diffusion[J]. Energy Procedia, 2012, 26: 116-124. |

| 27 | Fuller E N, Schettler P D, Giddings J C. New method for prediction of binary gas-phase diffusion coefficients[J]. Industrial & Engineering Chemistry, 2002, 58(5): 18-27. |

| 28 | Thompson C R, Marín P, Díez F V, et al. Evaluation of the use of ceramic foams as catalyst supports for reverse-flow combustors[J]. Chemical Engineering Journal, 2013, 221: 44-54. |

| 29 | Winterberg M, Tsotsas E, Krischke A, et al. A simple and coherent set of coefficients for modelling of heat and mass transport with and without chemical reaction in tubes filled with spheres[J]. Chemical Engineering Science, 2000, 55(5): 967-979. |

| 30 | Tsotsas E. Wärmeleitung und dispersion in durchströmten schüttungen[M]//Stephan P, Kabelac S, Kind M, et al, eds. Springer Reference Technik. Berlin, Heidelberg: Springer Berlin Heidelberg, 2019: 1753-1772. |

| 31 | 李绍芬.反应工程[M]. 3版. 北京: 化学工业出版社, 2013: 50. |

| Li S F. Reaction Engineering[M]. 3rd ed. Beijing: Chemical Industry Press, 2013: 50. | |

| 32 | Luo Z W, Xu X F, Dong G L, et al. Regulating mesopore structures of support toward enhanced selective hydrogenation of dimethyl oxalate to methyl glycolate on Ag catalysts[J]. Chemical Engineering Journal, 2022, 450: 138397. |

| 33 | 邬时海, 卢立义, 谢在库, 等. 非均匀分布催化剂的性能及制备[J]. 工业催化, 2002, 10(6): 48-52. |

| Wu S H, Lu L Y, Xie Z K, et al. Properties and preparation of non-uniform distributed catalysts[J]. Gongye Cuihua (Industrial Catalysis), 2002, 10(6): 48-52. | |

| 34 | Xu X F, Hu X, Luo Z W, et al. Engineering an egg-shell structure for the Ag/SiO2 pellet catalyst for selective hydrogenation of dimethyl oxalate to methyl glycolate[J]. New Journal of Chemistry, 2023, 47(13): 6045-6049. |

| [1] | Zilin PENG, Lei ZHOU, Qinghang DENG, Guanghua YE, Xinggui ZHOU. Kinetics of 3D NAND flash wet etching with phosphoric acid under the influence of H2SiO3 [J]. CIESC Journal, 2025, 76(2): 645-653. |

| [2] | Shuyue LI, Huan WANG, Shaoqiang ZHOU, Zhihong MAO, Yongmin ZHANG, Junwu WANG, Xiuhua WU. Current status and prospects of research on fluidization characteristics of high-density particles [J]. CIESC Journal, 2025, 76(2): 466-483. |

| [3] | Yifei LI, Yanfei SU, Tian YIN, Haoqiang JIANG, Zhiming XU, Linzhou ZHANG, Quan SHI, Chunming XU. Molecular composition and structure characterization of coal liquefaction product oil based on GC×GC-TOF MS [J]. CIESC Journal, 2025, 76(2): 543-553. |

| [4] | Ke ZHANG, Weijie REN, Mengna WANG, Kaifeng FAN, Liping CHANG, Jiabin LI, Tao MA, Jinping TIAN. Liquid-liquid mixing characteristics of Bunsen reaction products in microchannels [J]. CIESC Journal, 2025, 76(2): 623-636. |

| [5] | Shan GUO, Yu TIAN, Yongbin XU, Peng WANG, Zhiming LIU. Synthesis of a high-efficacy medium-entropy alloy catalyst via the recycling of spent batteries and its subsequent performance evaluation [J]. CIESC Journal, 2025, 76(1): 231-240. |

| [6] | Hanbin WANG, Shuai HU, Fenglei BI, Junsen LI, Laibin HE. Desorption performance analysis of a metal hydride reactor with novel corrugated fins based on finite element method [J]. CIESC Journal, 2025, 76(1): 221-230. |

| [7] | Xianming GAO, Wenxuan YANG, Shaohui LU, Xiaosong REN, Fangcai LU. Influence of droplet merging and jumping by dual-groove structures on superhydrophobic surfaces [J]. CIESC Journal, 2025, 76(1): 208-220. |

| [8] | Yanping JIA, Yanju MA, Wenxin GUAN, Bin YANG, Jian ZHANG, Lanhe ZHANG. Process conditions optimization and degradation mechanism of dye wastewater by Fe0/H2O2 system using response surface methodology [J]. CIESC Journal, 2025, 76(1): 348-362. |

| [9] | Ping LIU, Yusheng QIU, Shijing LI, Ruiqi SUN, Chen SHEN. Heat transfer and flow characteristics of nanofluids in microchannels [J]. CIESC Journal, 2025, 76(1): 184-197. |

| [10] | Zhimin HAN, Xiangyu ZHOU, Hongyu ZHANG, Zhiming XU. Local deposition characteristics of CaCO3 fouling under different roughness element structures [J]. CIESC Journal, 2025, 76(1): 151-160. |

| [11] | Qiwo HAN, Yongfeng LIU, Pucheng PEI, Lu ZHANG, Shengzhuo YAO. Analysis of influence of operating temperature on water distribution, proton transport and performance of PEMFC [J]. CIESC Journal, 2025, 76(1): 374-384. |

| [12] | Zhicheng DENG, Huan YANG, Simin WANG, Jiarui WANG. Microtube structure impacts on hydrogen-air mixing effect and combustion performance in micromix combustor [J]. CIESC Journal, 2025, 76(1): 335-347. |

| [13] | Guanyu REN, Yifei ZHANG, Xinze LI, Wenjing DU. Numerical study on flow and heat transfer characteristics of airfoil printed circuit heat exchangers [J]. CIESC Journal, 2024, 75(S1): 108-117. |

| [14] | Yong YANG, Zixuan ZU, Yukun LI, Dongliang WANG, Zongliang FAN, Huairong ZHOU. Numerical simulation of CO2 absorption by alkali liquor in T-junction cylindrical microchannels [J]. CIESC Journal, 2024, 75(S1): 135-142. |

| [15] | Junhao HUANG, Keliang PANG, Fangyuan SUN, Fujun LIU, Zhiyuan GU, Long HAN, Yanquan DUAN, Yanhui FENG. Influence of bell structure of coke dry quenching furnace on coke distribution [J]. CIESC Journal, 2024, 75(S1): 158-169. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||