化工学报 ›› 2020, Vol. 71 ›› Issue (12): 5470-5478.DOI: 10.11949/0438-1157.20200315

刘作华1,3( ),杨林荣1,3,熊黠1,3,陶长元1,3,王运东2,程芳琴4

),杨林荣1,3,熊黠1,3,陶长元1,3,王运东2,程芳琴4

收稿日期:2020-03-25

修回日期:2020-05-18

出版日期:2020-12-05

发布日期:2020-12-05

通讯作者:

刘作华

作者简介:刘作华(1973—),男,博士,教授,基金资助:

LIU Zuohua1,3( ),YANG Linrong1,3,XIONG Xia1,3,TAO Changyuan1,3,WANG Yundong2,CHENG Fangqin4

),YANG Linrong1,3,XIONG Xia1,3,TAO Changyuan1,3,WANG Yundong2,CHENG Fangqin4

Received:2020-03-25

Revised:2020-05-18

Online:2020-12-05

Published:2020-12-05

Contact:

LIU Zuohua

摘要:

传统多层刚性桨用于假塑性非牛顿流体混合搅拌死区较大,流场界面稳定,混合效率低。提出多层刚柔组合桨诱发流场界面失稳强化非牛顿流体混沌混合的方法。实验以羧甲基纤维素钠为非牛顿流体体系,通过扭矩传感器测量功率特性,酸碱中和脱色法测定混合时间,并利用Matlab 软件编程计算最大Lyapunov 指数,分析了非牛顿流体混合过程中的混沌特性及其混合性能。结果表明,组合方式为RF-(PBTD+PBTD+DT)、桨叶排列方式θ=60°、柔性片长度安装比例r=0.8、1.2时,混沌程度较高,混合性能较好。多层刚柔组合桨可以产生多股螺旋流,并在层间柔性片扰动频率差下实现流场界面失稳,搅拌死区减小,在较低转速下使体系进入混沌状态(多层刚柔组合桨体系N>88 r/min时LLE>0,多层刚性桨体系N>125 r/min时LLE>0);在相同转速下,多层刚柔组合桨混合速率、单位体积功率高于多层刚性桨,而单位体积混合能大致相同。

中图分类号:

刘作华,杨林荣,熊黠,陶长元,王运东,程芳琴. 多层刚柔组合桨诱发流场界面失稳强化非牛顿流体混沌混合行为[J]. 化工学报, 2020, 71(12): 5470-5478.

LIU Zuohua,YANG Linrong,XIONG Xia,TAO Changyuan,WANG Yundong,CHENG Fangqin. Chaotic mixing behavior of non-Newtonian fluid intensified by multilayer rigid-flexible impeller induced flow field interface instability[J]. CIESC Journal, 2020, 71(12): 5470-5478.

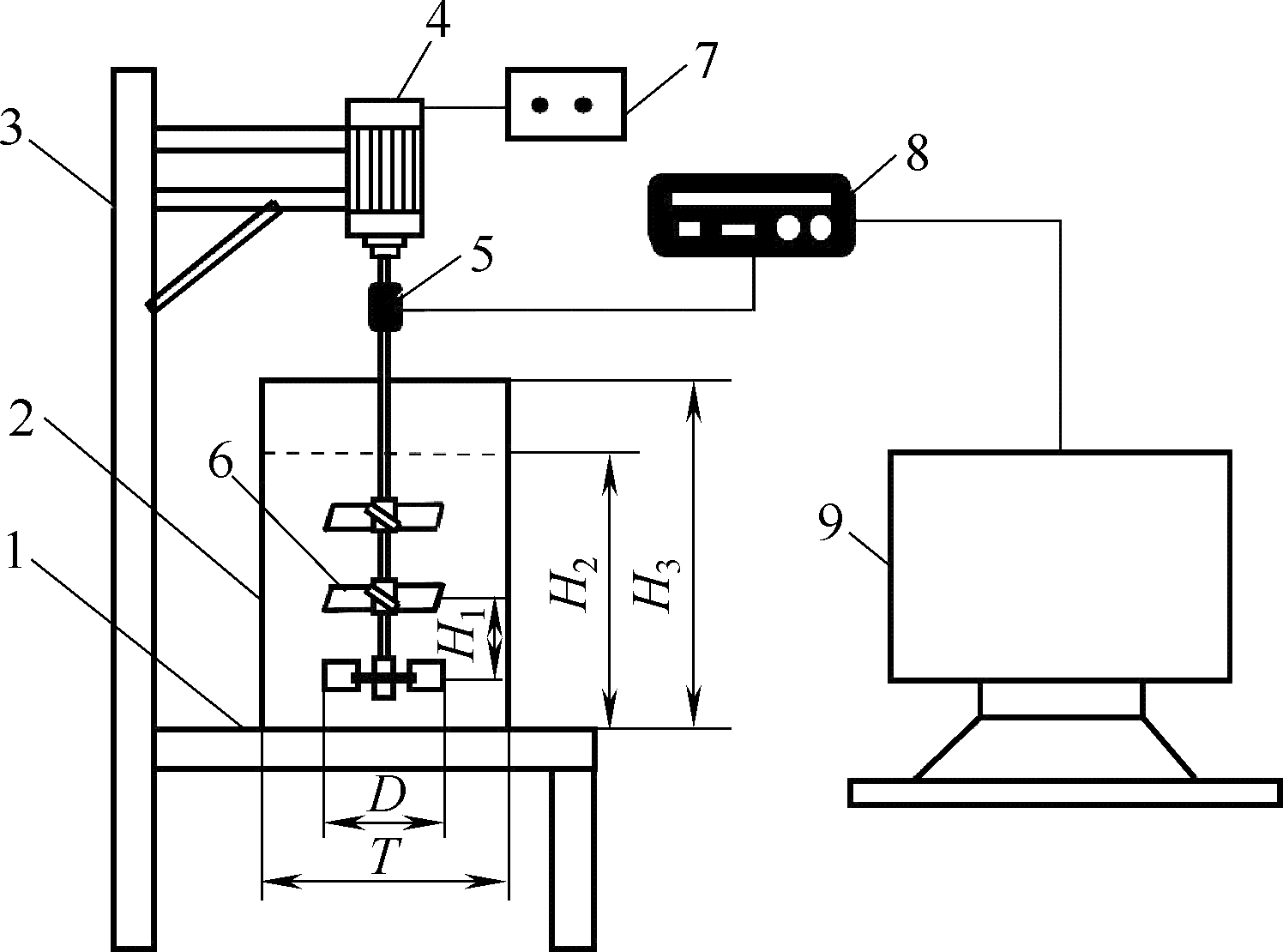

图1 实验装置1—mixing tank base;2—mixing tank;3—motor bracket;4—motor; 5—torque sensor;6—rigid impeller;7—frequency modulator;8—signal converter;9—computer

Fig.1 Experimental device

| 1 | 朱克勤. 非牛顿流体力学研究的若干进展[J]. 力学与实践, 2006, (4): 1-8. |

| Zhu K Q. Some advances in non-Newtonian fluid mechanics[J]. Mechanics in Engineering, 2006, (4): 1-8. | |

| 2 | 施庆珊, 王计伟, 欧阳友生, 等. 非牛顿流体黏度测定方法研究进展[J]. 发酵科技通讯, 2011, 40(2): 42-45. |

| Shi Q S, Wang J W, Ouyang Y S, et al . Advances in viscosity determination of non-Newtonian fluids[J]. Bulletin of Fermentation Science and Technology, 2011, 40(2): 42-45. | |

| 3 | 张敏革, 张吕鸿, 姜斌, 等. 非牛顿流体搅拌流场的数值模拟研究进展[J]. 化工进展, 2009, 28(8): 1296-1301. |

| Zhang M G, Zhang L H, Jiang B, et al. Progress in the numerical simulation for agitated flow field of non-Newtonian fluid[J]. Chemical Industry and Engineering Progress, 2009, 28(8): 1296-1301. | |

| 4 | Mehdi Y, Nariman A. Rotational and axial flow of pseudoplastic fluids [J]. Mechanics of Time-Dependent Materials, 2019, 23(2): 173-192. |

| 5 | Reviol T, Kluck S, Etringer G, et al. Investigation of propeller mixer for agitation of non-Newtonian fluid flow to predict the characteristics within the design process[J]. Chemical Engineering Science, 2018, 191: 420-435. |

| 6 | Wang P, Reviol T, Kluck S, et al. Mixing of non-Newtonian fluids in a cylindrical stirred vessel equipped with a novel side-entry propeller[J]. Chemical Engineering Science, 2018, 190: 384-395. |

| 7 | 栾德玉, 周慎杰, 陈颂英. 搅拌槽内假塑性流体洞穴研究进展[J]. 化工进展, 2012, 31(3): 502-507. |

| Luan D Y, Zhou S J, Chen S Y. Recent development on the cavern in pseudoplastic fluid in stirred tank[J]. Chemical Industry and Engineering Progress, 2012, 31(3): 502-507. | |

| 8 | 刘海龙, 曹宇, 丁学翀, 等. 搅拌槽内液相层流荧光可视化及高效混合技术[J]. 化工学报, 2018, 69(12): 5042-5048. |

| Liu H L, Cao Y, Ding X C, et al. Mixing enhancement technique for laminar flow in stirred tank[J]. CIESC Journal, 2018, 69(12): 5042-5048. | |

| 9 | 毛在砂, 杨超. 化学反应器宏观混合研究展望[J]. 化工学报, 2015, 66(8): 2795-2804. |

| Mao Z S, Yang C. Perspective to study on macro-mixing in chemical reactors[J]. CIESC Journal, 2015, 66(8): 2795-2804. | |

| 10 | 顾培韵, 孙建中, 潘勤敏, 等. 间歇搅拌反应器的微观混合特性[J]. 化工学报, 1994, 45(1): 106-111. |

| Gu P Y, Sun J Z, Pan Q M, et al. Characteristics of micromixing in batch stirred tank reactor[J]. Journal of Chemical Industry and Engineering(China), 1994, 45(1): 106-111. | |

| 11 | 丛海峰, 高正明, Atibeni R A, 等. 搅拌槽内非牛顿流体的微观混合特性[J]. 合成橡胶工业, 2006, (1): 14-17. |

| Cong H F, Gao Z M, Atibeni R A, et al. Micromixing characteristics of non-Newtonian fluid in a stirred tank[J]. China Synthetic Rubber Industry, 2006, (1): 14-17. | |

| 12 | Alvarez-Hernández M M, Shinbrot T, Zalc J, et al. Practical chaotic mixing[J]. Chemical Engineering Science, 2002, 57(17): 3749-3753. |

| 13 | Vassilicos J C. Mixing in vortical, chaotic and turbulent flows[J]. Philosophical Transactions. Series A, Mathematical, Physical, and Engineering Sciences, 2002, 360 (1801): 2819-37. |

| 14 | 栾德玉, 周慎杰, 陈颂英, 等. 错位六弯叶桨在假塑性流体中的混沌搅拌特性[J]. 化学工程, 2011, 39(9): 41-46. |

| Luan D Y, Zhou S J, Chen S Y, et al. Chaotic agitation characteristics of shifted 6-bent-blade impeller in pseudoplastic fluid[J]. Chemical Engineering(China), 2011, 39(9): 41-46. | |

| 15 | Luan D, Zhang S, Lu J, et al. Chaotic characteristics enhanced by impeller of perturbed six-bent-bladed turbine in stirred tank[J]. Results in Physics, 2017, 7: 1524-1530. |

| 16 | 栾德玉, 周慎杰, 陈颂英. 错位六弯叶桨搅拌假塑性流体的洞穴变化[J]. 机械工程学报, 2012, 48(16): 152-157. |

| Luan D Y, Zhou S J, Chen S Y. Cavern development of pseudoplastic fluids stirred by impeller of perturbed six-bent-bladed turbine[J]. Journal of Mechanical Engineering, 2012, 48(16): 152-157. | |

| 17 | Yang J, Zhang Q H, Mao Z S, et al. Enhanced micromixing of non-Newtonian fluids by a novel zigzag punched impeller [J]. Industrial & Engineering Chemistry Research, 2019, 58(16): 6822-6829. |

| 18 | 朱俊, 刘作华, 郑雄攀, 等. 双层刚柔组合搅拌桨调控流体宏观不稳定性行为[J]. 化工学报, 2015, 66(3): 896-904. |

| Zhu J, Liu Z H, Zheng X P. et al. Macro-instability regulated by double rigid-flexible combination impeller[J]. CIESC Journal, 2015, 66(3): 896-904. | |

| 19 | 刘作华, 陈超, 刘仁龙, 等. 刚柔组合搅拌桨强化搅拌槽中流体混沌混合[J]. 化工学报, 2014, 65(1): 61-70. |

| Liu Z H, Chen C, Liu R L, et al. Chaotic mixing enhanced by rigid-flexible impeller in stirred vessel[J]. CIESC Journal, 2014, 65(1): 61-70. | |

| 20 | 刘作华, 唐巧, 王运东, 等. 刚柔组合搅拌桨增强混合澄清槽内流体宏观不稳定性[J]. 化工学报, 2014, 65(1): 78-86. |

| Liu Z H, Tang Q, Wang Y D, et al. Enhancement of macro-instability in mixer-settler with rigid-flexible impeller[J]. CIESC Journal, 2014, 65(1): 78-86. | |

| 21 | Gu D Y, Cheng C, Liu Z H, et al. Numerical simulation of solid-liquid mixing characteristics in a stirred tank with fractal impellers[J]. Advanced Powder Technology, 2019, 30(10): 2126-2138. |

| 22 | Başbuğ S, Papadakis G, Vassilicos J C. Reduced power consumption in stirred vessels by means of fractal impellers [J]. AIChE Journal, 2018, 64(4): 1485-99. |

| 23 | 胡凡金. 多层桨在假塑性流体中的混合特性研究[D]. 济南: 山东大学, 2012. |

| Hu F J. Study on the mixing performance of multi-stage impeller in the mixing of pseudoplastic fluid[D]. Jinan: Shandong University, 2012. | |

| 24 | Metzner A B, Otto R E. Agitation of non-Newtonian fluids[J]. AIChE Journal, 1957, 3(1): 3-10. |

| 25 | Deng K, Li J, Yu S. Dynamics analysis and synchronization of a new chaotic attractor[J]. Optik, 2014, 125(13): 3071-3075. |

| 26 | Hu H, Liu D. The judgment of chaotic detection systems state based on the Lyapunov exponent[J]. Procedia Engineering, 2012, 29: 2894-2898. |

| 27 | 严绍瑾, 彭永清, 王建中. 一维气候时间序列的李亚普诺夫指数所显示的动态系统的演化特征[J]. 热带气象, 1990, (3): 210-217. |

| Yan S J, Peng Y Q, Wang J Z. Evolutional features of a dynamic system displayed by Lyapunov exponents in a 1-dimensional climatglogical time series[J]. Journal of Tropical Meteorology, 1990, (3): 210-217. | |

| 28 | Wolf A, Swift J B, Swinney H L, et al. Determining Lyapunov exponents from a time series [J]. Physica D, 1985, 16(3): 285-317. |

| 29 | Zlokarnik M. Stirring Theory and Practice [M]. Weinheim: Wiley-VCH Verlag GmbH, 2001: 76-94. |

| 30 | Bao Y Y, Lu Y, Liang Q Q, et al. Power demand and mixing performance of coaxial mixers in a stirred tank with CMC solution[J]. Chinese Journal of Chemical Engineering, 2015, 23(4): 623-632. |

| 31 | 王凯, 冯连芳. 混合设备设计[M]. 北京: 机械工业出版社, 2000: 27-29. |

| Wang K, Feng L F. Mixing Equipment Design[M]. Beijing: China Machine Press, 2000: 27-29. | |

| 32 | 王凯. 非牛顿流体的流动、混合和传热[M]. 杭州: 浙江大学出版社, 1988: 161-183. |

| Wang K. Flow, Mixing, and Heat Transfer of Non-Newtonian Fluids[M]. Hangzhou: Zhejiang University Press, 1988: 161-183. |

| [1] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [2] | 谈莹莹, 刘晓庆, 王林, 黄鲤生, 李修真, 王占伟. R1150/R600a自复叠制冷循环开机动态特性实验研究[J]. 化工学报, 2023, 74(S1): 213-222. |

| [3] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [4] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [5] | 汪尔奇, 彭书舟, 杨震, 段远源. 含HFO混合体系气液相平衡的理论模型评价[J]. 化工学报, 2023, 74(8): 3216-3225. |

| [6] | 黄可欣, 李彤, 李桉琦, 林梅. 加装旋转叶轮T型通道流场的模态分解[J]. 化工学报, 2023, 74(7): 2848-2857. |

| [7] | 张艳梅, 袁涛, 李江, 刘亚洁, 孙占学. 高效SRB混合菌群构建及其在酸胁迫条件下的性能研究[J]. 化工学报, 2023, 74(6): 2599-2610. |

| [8] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| [9] | 姚晓宇, 沈俊, 李健, 李振兴, 康慧芳, 唐博, 董学强, 公茂琼. 流体气液临界参数测量方法研究进展[J]. 化工学报, 2023, 74(5): 1847-1861. |

| [10] | 党玉荣, 莫春兰, 史科锐, 方颖聪, 张子杨, 李作顺. 综合评价模型联合遗传算法的混合工质ORC系统性能研究[J]. 化工学报, 2023, 74(5): 1884-1895. |

| [11] | 项星宇, 王忠东, 董艳鹏, 李守川, 朱春英, 马友光, 付涛涛. 微通道内屈服应力型流体的流变特性及多相流研究进展[J]. 化工学报, 2023, 74(2): 546-558. |

| [12] | 唐茹意, 潘罕骞, 郑侠俊, 张广欣, 汪星平, 崔希利, 邢华斌. Z型全氟聚醚的结构表征[J]. 化工学报, 2023, 74(1): 479-486. |

| [13] | 席国君, 刘子涵, 雷广平. FeTPPs-CuBTC协同强化低浓度煤层气吸附分离[J]. 化工学报, 2022, 73(9): 3940-3949. |

| [14] | 杨克, 王辰升, 纪虹, 郑凯, 邢志祥, 毕海普, 蒋军成. 聚多巴胺包覆混合粉体抑制甲烷爆炸的实验研究[J]. 化工学报, 2022, 73(9): 4245-4254. |

| [15] | 裴仁花, 王永洪, 张新儒, 李晋平. 碳纳米管/环糊精金属有机骨架协同强化混合基质膜的CO2分离[J]. 化工学报, 2022, 73(9): 3904-3914. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号